Previously, when a stove served as a heating system, there were no problems how to get rid of soot. And such a profession as a chimney sweep was held in high esteem. Now many people use boilers as a heating system. But in order to ensure uninterrupted operation, you need to observe simple conditions and clean them in time, as well as carry out a preventive inspection of the equipment.

Causes and consequences of clogging

To answer this question, you need to know which boiler is in the house: volatile or mechanical.

Volatile are divided in turn into:

- processing gas;

- electrical installations;

- solid fuel and liquid fuel equipment;

- combined models.

Volatile boilers can be shut down for a number of reasons:

- power line surges and surges

- lack of electricity

- failure of factory settings.

Often used in homes: AOGV, Zhukovsky boiler, gas "Ochag", Lemax, Signal, Conord.

How to clean a chimney pipe in a private house: a detailed analysis of cleaning methods, tips, prices. Do-it-yourself furnace for working out: drawing, work diagram. Read here.

Connection to the city water supply network: documents, prices:

https://klimatlab.com/vodosnabzhenie/vodoprovod/podklyuchenie-k-gorodskoj-seti-v-chastnom-dome.html

Mechanical can work intermittently due to the ingress of wind flow into the chimney. In addition, the flame may go out due to insufficient oxygen. You should pay attention to the hood (it is not always present in cheaper models).

If the chimney is dirty, modern devices have an alert system that will notify you of problems and the need for cleaning.

The benefits of regular cleaning

It is quite simple to clean such a boiler with your own hands, especially with the help of special tools and substances. There are only a few ways to clean a solid fuel boiler with your own hands.

You can clean the boiler using:

- poker;

- a variety of special scrapers;

- blades of different parameters;

- metal brushes;

- ruff;

- specialized boiler cleaning agents, such as solid fuel boiler cleaning powder.

Follow the link and learn how to make a DIY chimney brush.

Cleaning methods

Cleaning is done in two ways: mechanical and chemical

Mechanical cleaning

The cleaning method is imperfect and involves mechanical action. The soot should be carefully removed so as not to damage the inner surface of the boiler and parts, which can lead to metal corrosion in the future. Often the tools come with the boiler - these are brushes, brushes and scrapers. It is also possible to use air cleaning when warm air is supplied under pressure.

Dry cleaning

It is recommended to apply means for cleaning parts in PPE (personal protective equipment), usually rubber-based gloves are used, so it will turn out to protect the skin from interaction with harmful substances. Chemicals clean not only the soot, but also the metal, which in the future can lead to its destruction. This method is best used on light dirt and small areas of pollution.

Hydrodynamic cleaning

Hydrodynamic cleaning or how to clean a diesel boiler from soot.

It is used in boilers with a small thickness of pollution, as well as when speed of execution is required.The equipment for such washing consists of:

- pump and

- containers with waterwhich is supplied under high pressure.

Thanks to such cleaning, soot and soot are removed quite quickly, but this method is applicable only to specialists, it is not recommended at home.

Booster cleaning

The procedure for flushing the heat exchanger with a booster (for example, cleaning the Zhukovsky boiler from soot):

- First you need to disconnect the pipes from the heating system.

- Then connect to one of them to the booster hose in order to supply the reagent.

- We connect the second pipe to the second end of the hose. The spent reagent will be discharged through it. Thus, the system is closed and the reagent will circulate through the pipes.

- After cleaning, the solution must be drained from the tube.

- Flush the heat exchanger itself with sufficient water.

Booster is an apparatus for chemical cleaning. Thanks to it, the reagents circulate autonomously.

During such cleaning, it is recommended to change the reagent several times, since the old one gradually decreases its properties. This method is most often carried out by specialists.

Combustion products and their cause

By-products that appear during the incineration process are:

- soot;

- resin;

- tar.

The reasons for the appearance of these substances are in the following important points:

- Reasons for the appearance of soot:

- there is not enough oxygen for the combustion process;

- the combustion temperature of the fuel is too low.

- Factors affecting the appearance of resin:

- low-quality fuel is used;

- the fuel material has a high degree of moisture;

- the boiler is operating at a low temperature;

- Too much fuel is being loaded into the firebox.

- Tar appears in the following cases:

- weak injection of air flow into the combustion chamber of the pyrolysis boiler;

- incorrect design of the unit;

- low height chimney.

As you can see, the main reasons for the appearance of harmful substances are poor fuel and technical aspects of the organization of the combustion process.

Experts advise: use only high quality fuel - otherwise, boiler wear will increase rapidly.

Information on boiler flushing can be found at this link:

Time to clean the heat exchanger

When it is necessary to flush the heat exchanger of a gas boiler is a frequent question. There are a number of signs by which you can be sure that the time has come.

Some of the main ones:

- permanently on gas burner;

- the circulation pump has become noisier, which means it is overloaded;

- heating radiators began to heat up longer in time;

- gas consumption increases;

- the water pressure has become weaker (the first sign for flushing a double-circuit boiler).

In addition to cleaning the chimney, the boiler is also cleaned from soot. If the work of the chimney is difficult, then in some cases it turns off, but when it is clogged with soot, this does not happen. Combustion products are released into the air, and the owners breathe them.

It is recommended to clean the boilers once a year, especially if there is a year-round operation.

Dry cleaning

A special cleaner for solid fuel units is used for dry cleaning.

There are two methods of dry cleaning:

- Cleaner spills onto fuel... During the operation of the device, the crystals will react with soot and resin, crush their particles and remove them along with the smoke.

- The special agent is applied to the surface of the fuel chamber, and acid-based reagents will react with combustion products remaining on the walls of the unit chamber.

Do not forget about safety measures when cleaning solid fuel boilers.

Dismantling and removal of soot from the inner surface of the boiler

In order to clean the entire system at home, you will need the following tools:

- screwdriver;

- metal brushes (soft and for metal);

- brush;

- open-end wrenches;

- rags or any cotton cloth.

Stages of work:

- Shut off the gas.

- Remove the boiler door and disconnect the wire leading to the piezoelectric element.

- Unscrew the thermocouple, ignition electrode and pilot tube one after the other.

- Replace with a new gasket under the pilot burner.

- Remove the nozzle, copper pipe, burner.

- Carefully take out the thermometer sleeve and then remove the boiler lid together with the insulating sheet.

- Disconnect the terminals from the traction sensor and take out the gas duct.

Before cleaning, turn off the gas supply, wait until the structures have completely cooled down and only then disassemble.

After removing all the parts, you need to:

- clean with a brush and metal brushes.

- The channels should be cleaned with a vacuum cleaner.

- Particular attention should be paid to the burner, as the inner channel can be easily damaged, it must be wiped carefully.

Wood-fired boilers are often used for heating in homes. And only a few people think about what kind of firewood should be chosen for kindling. Usually they use whatever they have. Resin firewood is especially harmful to chimneys. It settles on the walls of the boiler and the chimney pipe. Mechanical cleaning is required. In this case, the chimney must be cleaned of tar and soot residues from the roof, so it will be easier to remove the combustion residues from the inside. Observe safety measures!

How to clear tar from a solid fuel boiler

There are many methods for cleaning the boiler heating surfaces, it is better to use the one that is indicated as the main one by the boiler manufacturer. If the user does not have such information, it can be found on the Internet. In this matter, the frequency of cleaning is more important. There are 3 key methods for cleaning resin and soot from the boiler's internal heating surface: mechanical, chemical and steam.

Mechanical

This method is performed using specialized tools in the form of steel brushes, scrapers of various sizes. Prepare in advance for the cleaning procedure. Before you clean the boiler from the resin, heat it up. This will require half a bucket of anthracite or 15 kg of non-resinous dry firewood. They are burned in a furnace to create conditions for burning most of the resin, thereby simplifying further cleaning.

In the process of performing work, care must be taken so that the tool does not damage the inner surfaces of the device. Basic cleaning points:

- The aggregate is melted to soften the hardened resin.

- They turn off the boiler and wait for it to cool down to a temperature of 40-50 C.

- The flue damper must remain open.

- All impurities on the internal heating surfaces of the boiler are thoroughly removed.

- At the end of the cleaning, I ignite the boiler so that the remaining particles of deposits are completely burned out.

Chemical

It is based on the use of specialized cleaning products for heating surfaces. Today it is very popular because it does not require a significant investment of time and money.

There are 2 types of dry cleaning:

- Before cleaning the boiler from resin, the slagged boiler partitions are treated with a cleaning acid solution, which quickly destroys unwanted deposits, and then it will not be difficult to get rid of them mechanically.

- The chemical cleaner is poured directly onto the burning fuel. It reacts with resinous deposits and destroys them, removing them from the boiler unit through the chimney.

In the role of a reagent, they are more used:

- A solution of adipic acid, calculated concentration. Interacting with furnace deposits, the acid dissolves them, converting them into salts, which are washed off with ordinary clean water.

- The sulfamic acid solution easily breaks down soot and tar and can also be easily washed off with tap water.

Steam

This cleaning method requires a steam generator to generate steam for cleaning.This can be a common household steam device, used for cleaning a house, for example, and capable of generating high pressure steam. It softens deposits and makes it easier to remove. Electric steam cleaning provides an option to simply get rid of not only soot and tar deposits, but also of mold and mildew. In some cases, a source of steam can be obtained from a nearby heating steam boiler.

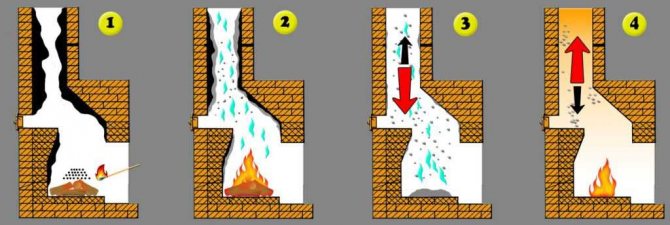

Why does combustion products accumulate?

The raw material for a heating boiler can be wood, coal, peat or pellets. Burning, any fuel leaves behind various deposits that negatively affect the operation of the device. Resin in a solid fuel boiler accumulates much faster in the following cases:

- use of low quality or wet fuel;

- too much fuel material in the combustion chamber;

- the use of a heating device for the disposal of household waste;

- insufficiently high operating temperature, due to which the fuel smolders, and does not burn;

- the use of firewood, emitting a large number of volatile resinous substances, which, when the temperature drops, settle on the walls of the boiler.

Oxygen deficiency and mistakes made during the assembly of the heating device, in particular, insufficiently high chimney height, can also increase the amount of unwanted deposits.

Types of pollution

Waste types are generated depending on what you throw into the boiler for combustion in order to generate heat. The consequences of combustion are the formation of ash and ash, and other products on the walls of the unit. If you do not clean the surface of them in time, then the efficiency of the boiler becomes much lower.

The main cause of soot is the lack of oxygen during combustion. If you use low-quality fuel, throw wet food into the boiler or, in order to save money, set the boiler to work continuously in low mode, be prepared to fight soot. An overflowing firebox also provokes malfunctions.

Tar is formed if there is a low air flow in the combustion chamber and an incorrectly adjusted unit. A low chimney also provokes the accumulation of tar.

Consequences of ignoring cleaning

If there are a lot of harmful substances in the boiler and the user does not take any action to eliminate them, the following negative processes occur:

- the boiler starts to heat worse;

- it becomes noticeably cool in the house, even when setting the usual indicators of the operating mode;

- there is a need to use more fuel;

- the service life of the boiler is rapidly decreasing.

The benefit of regular cleaning is to extend the life of the unit and to keep it in good working order.

How often should you clean?

To determine the regularity of cleaning, it is important to consider the quality of the fuel material used.

If you don't save money and prefer to buy proven fuel, then the boiler can be cleaned once a month. If you choose affordable options, then you will have to clean it every 15-20 days.

Frequency rates are approximate. The main criterion is the operation of the boiler. Not functioning as well as before? It is advisable to read out of turn.

Cleaning methods

As it has already become clear, cleaning is a mandatory process. It remains to figure out how to carry it out correctly. There are four options.

The first is a mechanical method, involving the elimination of contamination using a set of specific tools, consisting of the following elements:

- poker;

- scrapers;

- shoulder blades;

- metal brushes;

- brush for cleaning.

It is sold in specialty stores and consists of tools of different sizes, which allows you to easily get to even the most hidden places.Only start work after the boiler has completely cooled down. And open the damper fully.

When using wood as the main fuel for cleaning, follow these steps:

- Warm up the unit. This is done to make it easier to clean the walls of the boiler from tar and tar. When heated, this is much easier to do, since these types of contaminants have a solid structure;

- Take a spatula and thoroughly clean the walls of the unit;

- After thorough cleaning, let the boiler run for a while at a higher level than usual. Then the remnants of tar and tar will self-burn on the walls of the boiler.

Chemical variant

This is a thorough cleaning of the boiler from contamination using a special chemical cleaning agent. It assumes two ways to do it.

The first way is to pour the powder onto the hot fuel. Since it contains crystals that react with soot and resin, the pollution is destroyed under its action, and then evaporates along with the smoke.

The second option is the chemical treatment of the boiler walls. Apply to places of contamination, wait for the time specified in the instructions, clean the unit from the remnants of the used products.

Be careful when cleaning. Do not let your skin come into contact with active ingredients. Use gloves, wear glasses. Take care of purchasing special clothing.

The next cleaning option is "soft blasting"

To implement it, you need to purchase a special device that has a solution inside, made on the basis of chalk and baking soda. With this device, the boiler is completely processed.

Steam cleaning is a steam generator treatment followed by a disinfection process. That is, not only clean the walls of the boiler, but also rid the unit of bacteria. The steam generator generates steam under high pressure, which softens impurities and they stick off the boiler walls. It is used for wood burning and pyrolysis equipment.

Folk methods are no less popular among the population who do not want to spend money on the purchase of special devices and substances. Many users simply put salt on the burning wood, after which the soot comes out of the boiler along with the smoke. Many people also put pre-dried potato peelings on hot fuel. Starch is released during combustion, which significantly reduces the level of pollution.

Heat exchanger flushing methods

When choosing a flushing method, they are usually guided by their own capabilities and knowledge. Let's dwell on three generally accepted methods.

Method # 1 - manual cleaning

To perform it, it is necessary to carefully remove the heat exchanger from the boiler, otherwise there will be no free access to dirty surfaces. Next, we choose either mechanical cleaning or rinsing with solutions. Mechanical removal of deposits will require a scraper, brush and vacuum cleaner. For flushing, which is good for double-circuit boilers, is a salt dissolving liquid.

With a manual method of cleaning, all actions must be accurate and careful. When assembling the heat exchanger in place, you should carefully check the tightness of the connections.

After removing the heat exchanger from the boiler body, you will understand that the inner surface of its main part - the curved pipe needs cleaning, and it will be extremely problematic to perform a full cleaning manually

Method # 2 - chemical solution through a booster

It involves the use of special equipment - a booster, with the help of which an acidic washing solution is pumped into the heat exchanger. For a long time, it is driven through the pipes several times, as a result of which the plaque dissolves and is removed along with the flushing liquid. As a result, the indicators of throughput and thermal conductivity increase. Even the most persistent contaminants - salt deposits of carbonate and deposits of ferric iron - lend themselves to an acidic solution.Residual acid in the pipes is neutralized with a special solution, which is finally run into the heat exchanger.

Method # 3 - hydrodynamic flushing

Does not require equipment disassembly. It consists in pumping water (in some cases with an abrasive filler) and then building up pressure. The movement of fluid at an increased speed causes the destruction of deposits, which as a result are removed to the outside. There is a danger of exceeding the critical pressure values, as a result of which pipe rupture can occur.

It is not recommended to clean the heat exchanger on your own. The best solution is to turn to professionals who have permission to work with gas equipment. Knowing the methods and sequence of cleaning, you will be able to control the work of specialists.

The prevention and repair of gas equipment by specialists guarantees that high-quality equipment, proven materials, safe technologies will be used - and all this in compliance with the standards

The importance of timely cleaning of the gas boiler

The soot formed during the combustion of gas contains caustic poisonous substances that corrode the metal and gradually lead to corrosion of the elements. If you do not clean the gas units in time, then this is fraught with the following consequences:

- a decrease in traction;

- a decrease in the efficiency of a gas boiler;

- fire;

- the appearance of soot.

The frequency of cleaning a gas boiler is usually indicated in its technical documentation. The various components have excellent cleaning times. Also, different models of units require a certain frequency of cleaning. For example, devices with one circuit require less maintenance than two-circuit counterparts.

Note! The number of cleanings is also influenced by the quality of gas and water.

The clear signs that your gas boiler needs cleaning are:

- the device cannot reach the desired temperature;

- increased consumption of gas and electricity;

- there was a smell of carbon monoxide, soot;

- the flame burns unstably.

In order not to have to call specialists and pay them considerable sums for professional cleaning, it is better to take care of the gas boiler on time yourself. The instructions supplied with the unit will help you figure out how to properly remove the elements that need cleaning.

Causes of resin build-up

The reason must be determined before cleaning to be effective.

The main reasons for the accumulation of resin in boilers include:

- the use of low-quality fuel;

- increased moisture level of the material used;

- boiler operation at reduced temperature conditions;

- loading an excessive amount of fuel.

Regularity of cleaning procedures

The interval between cleaning a wood-burning or pyrolysis boiler depends primarily on the quality of the fuel material:

- if high quality fuel is used, the boiler unit must be cleaned once a month;

- in the case of using fuel of poor quality and with a high degree of moisture, the cleaning should be carried out once every 15–20 days.

Despite the indicated terms, you must always monitor the operation of the solid fuel boiler, and in case of a violation of the working rhythm, you can perform an extraordinary cleaning.

Tools for cleaning the boiler from soot

First, consider which nodes periodically need to be cleaned of soot. These include:

- igniter;

- burner with nozzles;

- firebox;

- heat exchanger;

- chimney.

To perform a good cleaning, the following tools are required:

- long handle for cleaning the chimney;

- scrapers;

- steel rope;

- holders for brushes.

To thoroughly and safely clean all components of the burner from soot, you must perform the following steps:

- shut off the gas supply;

- dismantle the unit cover, nozzles, burner tubes;

- disconnect the chimney;

- choose metal brushes;

- gently clean the heat exchanger from soot;

- you can use a vacuum cleaner to clean the circuit pipes;

- cleaning the walls of the boiler with a rag, scraper and brush;

- chimney cleaning is performed with a brush with a long handle;

- after completion of work, all parts should be reassembled in reverse order.

Note! When disassembling a gas boiler, you need to carefully monitor which element, where it is, so that you can then properly assemble the device.

Cleaning methods

Probably, every boiler owner thinks about how to clean the unit and how to do it correctly. There are four main ways to clean the boiler from soot, tar and tar. Their features are in the following important points.

Mechanical cleaning. It is the purification of a solid fuel boiler from combustion products using a special set of tools, which includes the following elements:

- poker;

- scrapers of different sizes;

- blades of various widths;

- metal brushes;

- ruffs of various configurations, you can buy them at any store, for example, here: https://pelletshome.com.ua/.

It should be understood that cleaning the boiler from soot with the help of these tools is performed only when the unit has cooled down completely.

Thus, we see that cleaning a solid fuel boiler from soot, tar and tar can be done by hand.

Read an informative article on flushing the heating system of a private house here.

"Soft blasting". This method is considered an American technology for cleaning a pyrolysis or wood-burning boiler from combustion products.

Its essence lies in the fact that with the help of a special device a special solution is supplied to the contaminated surfaces of the boiler, which includes chalk and baking soda.

Steam cleaning of the boiler. The essence of the method lies in the fact that with the help of a steam generator, the walls of the boiler are processed, while the boiler is still being disinfected.

Cleaning a solid fuel boiler from soot, tar and tar can be carried out in a way that suits you in terms of financial capabilities and labor costs. And in conclusion, I would like to dwell on one more aspect of cleaning the boiler from combustion products. There are also several popular methods for cleaning the boiler from soot and tar.

So, for example, salt is poured onto burning firewood, which accompanies the removal of soot along with the smoke. Also, dried potato peelings are placed on the burning fuel, which, emitting starch, significantly soften the contaminated surfaces for subsequent cleaning. We hope our information will help you to keep your home always warm and cozy.

Why is the resin in the boiler dangerous?

Cleaning the solid fuel boiler from tar and other contaminants should be carried out regularly, and not from time to time. Otherwise, the negative consequences will not be long in coming. To begin with, the heat transfer rates will decrease - it will take much more time to properly warm up the house, and the heat will be unevenly distributed. Plaque just a few millimeters high reduces the boiler output by 30%, which entails an increase in the consumption of raw materials and the volume of financial costs for heating.

A solid fuel boiler, inside which a thick layer of soot, tar and tar has formed, will not be able to last long. First of all, its main elements, which are entrusted with the functions of heating, will fail. In addition, oily deposits accumulating in large quantities are corrosive, which also shortens the service life of the heater. The risk of smoke pollution in the boiler room also increases due to a decrease or complete absence of draft in a contaminated combustion chamber.