The last step in the distillation process is the accumulation of alcohol vapors. To make this stage proceed faster, a moonshine coil is used.

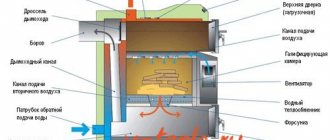

The purpose of the coil in the moonshine installation (Graham refrigerator) is to cool the vapors of the drink through the pipe walls.

The vapors of the moonshine in the coil come into contact with the surface of the walls. The vapors are cooled and condensed in the form of moonshine into a special container.

The coil has several features that affect the operation of the moonshine still.

What is a coil for?

A good and suitable coil for the moonshine is more important than the tank itself. The output of the drink, its quality and productivity depend on the spiral tube inside. If for the cube itself, in which the mash or other alcohol-containing solution is heated, it is possible to adapt a pressure cooker, a flask, a juice cooker, then it is very difficult to find a ready-made alternative to a coil.

The main task of the coil is to cool the alcohol vapors and condense them inside the tube. The correct name for this part is coil cooler.

Serpentine Doctor Degree

How this part of the device works:

- Braga or other liquid inside the cube heats up.

- Alcohol vapors enter the tube.

- When they come into contact with the cold coil walls, they turn into condensation.

- Moonshine (or another drink, depending on the base) flows through a tube into prepared dishes.

You can buy a coil for a moonshine still, even together with an outer tube, now this is not a problem, but more often it is made independently. The reasons are different: desire to save money, non-standard size, do not like the material that the stores offer.

The main task of the coil

The principle of operation of this device is quite simple. When the mash is heated, alcohol vapors enter the coil, the surfaces of which cool this mixture. The temperature decrease occurs due to the contact of the outer side of the element with the cooling medium, more often it is water. How well this process will take place depends on the diameter of the coil, the material and the common contact surfaces of the working agent and the cooler. Some call this part of the system - the heart of the moonshine still.

Moonshine coil material

Steel is considered a durable and reliable material. It has many advantages: it does not oxidize, does not rust, it serves for a long time. The only negative is that it is difficult to find food steel, technical materials are more common. Coils are often made of aluminum. But this material cannot boast of high strength and durability, moreover, it reacts with alcohol.

There was no steel and aluminum in the old days, so a copper coil was most often used for the moonshine still. And to this day it is the most demanded material. Brass is sometimes used. In this alloy, copper also occupies a large part.

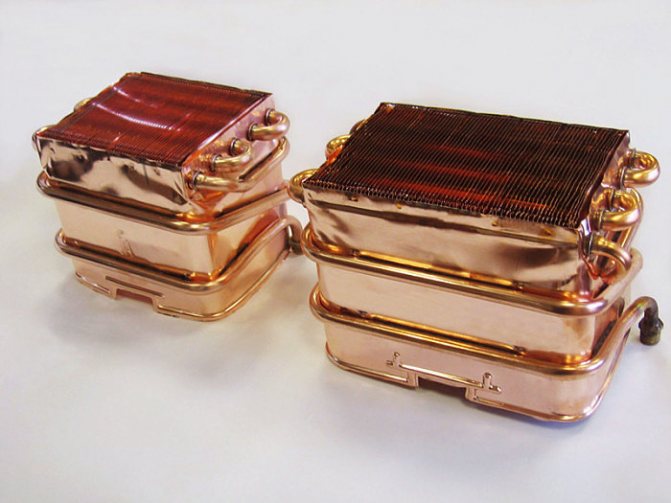

Stainless steel coil

Aluminum tube coil for moonshine still

Copper coil for moonshine still

Sometimes for moonshine stills, coils from gas columns are used. They are also made of copper, but this is not the best option.

Reverse Coolers and Graham Tubes

As for the return coils, they exist in several varieties. Ball air chambers can be referred to as reverse coils. They have a large heat exchange area, which ensures their high performance. Such refrigerants are applied to liquids with a low boiling point.

Liebig chambers can function as both reverse and direct-flow refrigerators. The Liebig chamber design is represented by a single copper or glass tube. In moonshine stills, Liebig's chambers look like tubes, fastened with self-tapping screws or by soldering.

All return coils differ from direct-flow ones in that the refrigerant is supplied to them from the bottom up. This feature is considered an advantage of this design, which allows additional substances to be introduced into the chamber with moonshine vapors.

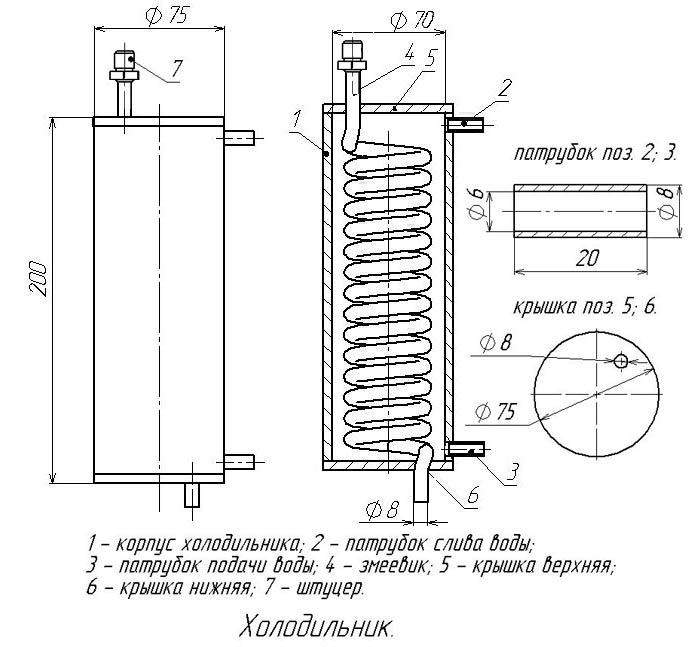

Most often, moonshine still contains coolers, which are a winding tube, and such refrigerators are called Graham tubes. Such elements are installed vertically, which allows the distillate to drain freely into the substituted container. Such coils differ from each other in the number of spirals. The larger the volume of the mash, the more such spirals should be on the Graham refrigerator.

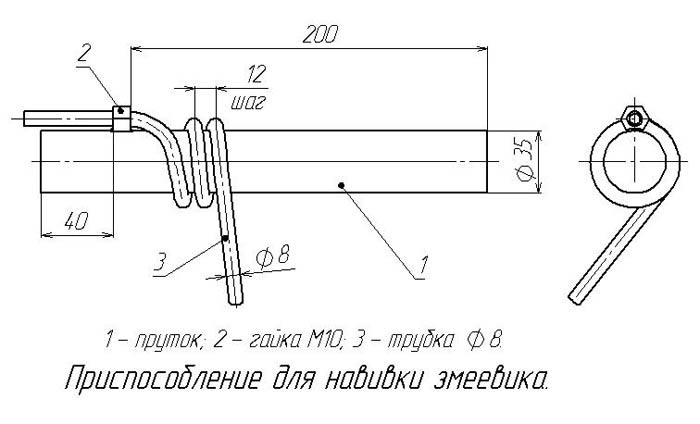

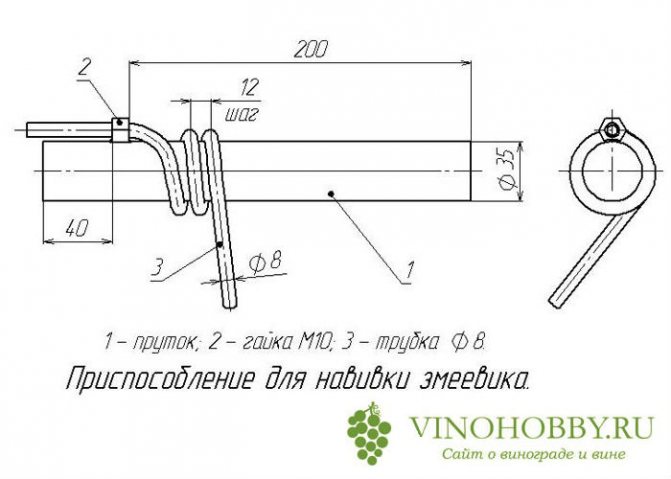

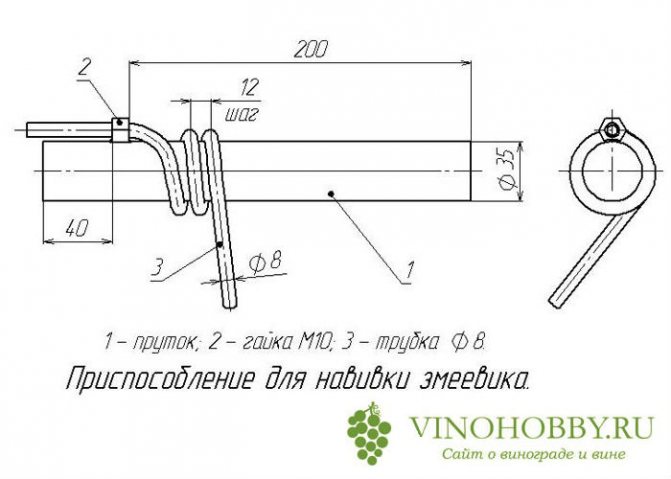

You can also make a refrigerator with spirals yourself, but before starting this task, using special calculations, you should make an accurate drawing of the coil structure. The thing is that the diameter of the spirals of such a device should be the same, regardless of their number. The implementation of the scheme of the future coil will allow you to accurately determine the parameters of the spirals and recreate them in the finished product.

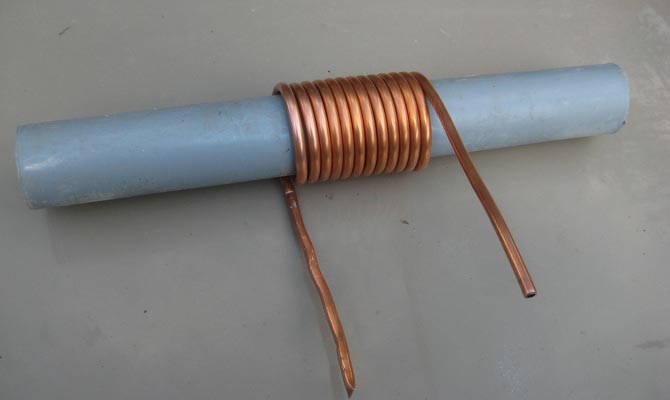

For making a coil tube with your own hands, you should prepare a copper (as an option - aluminum or brass) tube up to two meters long, with a cross section of 8 to 12 millimeters and a metal thickness of up to 1.1 millimeters. You should also prepare the body of the future refrigerator, because the parameters of the tube spirals will depend on its size. As a body, you can choose a plastic sewer pipe with a diameter of 80 millimeters.

How to make your own Graham refrigerator:

- First, the copper (brass, aluminum) tube should be well filled with fine sand, which will avoid deformation of the material when curling the structure.

- Wood pegs are attached to the ends of the tube. You can also clamp the ends tightly or solder them altogether.

- Next, you should take a smooth object with a circular cross-section of the required diameter and screw a tube onto it. When choosing a step between turns, you should pay attention to the diagram and the calculation performed.

- The ends of the almost finished coil should be opened and filler should be poured out of them. After that, the tube should be thoroughly rinsed.

- The coil body should be equipped with water outlet and water supply connections.

- The coil itself should be inserted into the body, plugs installed at both ends. All joints must have perfect tightness, and this can be achieved through the use of super glue.

Before use, it is also better to test such a refrigerator with a low pressure of water in the still.

All coils are cooled by ice, air or water. The latter option is considered the simplest and most convenient from the point of view of distillation. Chillers powered by water can be either open or closed. Opened refrigerators require running water, while closed refrigerators are filled with liquid manually.

Today, all ready-made moonshine stills offered for sale are equipped with refrigerators. Therefore, if there is no desire to make a cooler with your own hands, you can give preference to a ready-made distiller.

What will help to get moonshine from the mash? That's right, moonshine still. And its integral part is a coil, a thing without which such a unit cannot be imagined. The coil condenses the vapors released by the mash during boiling and, when cooled, turns them into moonshine. It can be made independently or purchased; the part can be different in length, diameter, location in space.It doesn't matter what the moonshine coil was made of, but it is clear that it is irreplaceable.

In the old days, when in Russia they were just starting to drive moonshine, the most accessible and convenient metal to work with was copper. It is not surprising that the craftsmen chose it as the main material for making the coil. Hence the winged expression "green serpent" came from. Copper oxidizes over time, becomes covered with a green bloom. The shape of the device is spiral, twisted into rings like snake ones.

Moonshine coil

The distillation process is to separate alcohols, water and fusel oils from the mash. This is accomplished by raising the temperature of the fluid. Alcohol begins to evaporate at 78 °, water at 100 °, and harmful oils at 120 °. Then everything depends on the correct design of the refrigerator - coil. Inside the tube, alcohol vapors are cooled and flow down in the form of a liquid into a special container.

Manufacturing material

Different people may have different opinions about the coil material. It all depends on the goals and the individual approach. Here are the main criteria from which to build on when choosing what equipment to make:

- thermal conductivity;

- safety;

- availability;

- convenience;

- price.

These criteria are usually chosen:

- Copper. The oldest and most proven material over the years. It is convenient to work with, its thermal conductivity speeds up the distillation process. Some distillers are afraid to deal with it, as there is an opinion that copper is toxic. But the experience of large French, American, Scottish companies producing excellent whiskey and cognac suggests otherwise. Copper is a proven option for years and quality.

- Stainless steel. A great way to get quality alcohol is to use stainless steel equipment. It does not enter into a chemical reaction with active compounds, acids, alkalis, it has good thermal conductivity. It is worth noting that only food grade stainless steel is suitable. Such a coil will be more difficult to make than a copper coil. This material is less soft, so you need equipment or you have to put in more effort.

- Aluminum. Its thermal conductivity is worse than that of copper, but better than that of stainless steel. In addition, the price of aluminum is significantly lower, which makes it more affordable. There is also a minus. Over time, such a coil becomes unusable because its oxides react with alcohol. New substances accumulate in the body, while they are harmful to health. The taste of moonshine obtained through an aluminum coil is specific.

- Glass. Everyone knows that it is used to make laboratory equipment. This is because it is completely neutral to chemical interactions. The advantage is that you can follow the process. It is unlikely that you will be able to make a glass coil yourself. We'll have to look for a chemical equipment store or make a custom coil. Its downside is its excessive fragility.

- Metal-plastic. Such coils are popular lately. Such a tube is easy to buy at a hardware store, it bends easily. But the shape will not hold well, so you need to immediately place the coil in the refrigerator. The material is non-toxic, which is undoubtedly a plus.

Silver, brass, polyethylene, nylon are used much less often.

Tube dimensions

You should buy a tube 1.5-2 meters long: this is the best option. A longer length will increase the distillation time of the product, as the hydraulic resistance will increase. The larger the contact area of the coil with cold water, the easier it is to condense the steam into alcohol. This means that the speed of distillation depends on this. The diameter of the tube for the coil, in order to ensure optimal operation of the moonshine still, it is better to take 8-12 mm.

Too thin tube walls will not allow you to work freely with it. It will be fragile, there is a chance to break the workpiece. It is better that the walls are from 0.9 to 1.1 mm.This size will only improve thermal conductivity. It is better to set the dimensions of the refrigerator according to the ready-made coil, so that everything fits exactly.

Position in space

The coil has an oblong shape of spirals. The design of the moonshine still can be different, therefore, the cooling can be installed in different ways:

- vertically;

- horizontally;

- at an angle.

The best option would be a vertical arrangement. So the moonshine will drain without difficulty, without interfering with the vapors of alcohol. And the distillation will speed up a little. The location of the coil can be downward: steam goes from top to bottom - and upward. Minimum resistance is achieved when steam is lowered.

Coil cooling system

It is easiest to cool the coil tube with cold water. For this purpose, ordinary air and ice can be used, but the design of such an apparatus would be too complex. The container in which the coil is installed can be open or closed. In the second case, the water simply stands, which leads to its gradual heating. It is necessary to periodically change the liquid to a cold one, otherwise the quality of the product may decrease.

Open type means running water. Such a device will take up less space, it does not need a large reservoir. The moonshine will cool faster, which will speed up the process and improve the quality of the alcohol. Better if the water comes from below. This will cool the coil evenly.

Coil size for moonshine still

Why does the coil spiral? This is done only in order to increase the cooling area of alcohol vapors. However, the length cannot be increased indefinitely. First, the curls should not touch each other. Secondly, in a large coil, the resistance is higher, therefore, the driving speed decreases, the process is delayed. Hardly anyone wants to squeeze a glass of distillate per hour.

The optimal tube length for the moonshine coil is from 1.5 to 2 meters. It will be much shorter when curved. Cross section from 8 to 1.2 mm. The optimum material thickness is around 1 cm.

Serpentine: Sample Drawing

The best materials

What to make a coil for a home moonshine still with your own hands? The material must be easy to process, not form harmful compounds during distillation and be sufficiently strong. The most popular materials for moonshiners are: copper, stainless steel, aluminum, glass. Much less often, coils are made of silver, brass and metal-plastic.

Copper

Copper coils are most common in moonshine stills. Copper lends itself well to processing, and the high thermal conductivity of copper allows for faster distillation. Copper is not completely chemically inert, that is, it can form new compounds when interacting with heated vapors.

Theoretically, they can turn into ready-made moonshine, and then have a negative effect on the body, but the experience of French winemakers does not confirm these assumptions. They traditionally use copper distillation stills in the production of whiskey and cognac, recognized throughout the world for their high quality.

Stainless steel

Stainless steel has good thermal conductivity and does not interact with most active chemical compounds. A coil for a home moonshine still made of food-grade stainless steel will allow you to get a high-quality alcohol product.

Aluminum

When making an aluminum refrigerator, it is necessary to take into account that with age, such a device ages and becomes hazardous to health. During distillation, aluminum oxides interact with alcohol compounds, and the resulting complex substances accumulate in the body. The alcohol obtained with the help of an aluminum apparatus has a slight specific taste.

Glass

Glass devices have excellent thermal conductivity and allow you to regulate the distillation process. The disadvantage of such a device is the difficulty of making it at home and high fragility. If you decide to stay with this option, then in most cases it is better to buy a sufficient number of ready-made glass refrigerators on the Internet.

DIY moonshine coil

Consider a copper option. In addition to the pipe, you will need construction sand or regular table salt. They are necessary to keep the hole inside and shape, to prevent kinking, flattening. If the tube is damaged and bent, it will be difficult for vapors to move, congestion will form, and the device may explode. Additionally, you will need a template pipe of a larger diameter, onto which a copper spiral will be wound. Diameter in the region of 3.5-4 cm.

Making a coil for a moonshine still

How to make a coil for a moonshine still

- Fill the hole with copper or any other pipe with sand (salt), put plugs on the ends, you can simply wrap it with tape, insulating tape, stick pegs inside or insert sticks.

- Gently spirally wind the prepared pipe with sand onto the template, observing a distance of 10-12 mm between the curls.

- Remove the resulting coil from the template, remove the plugs from the ends of the pipe, pour out the filler.

- Attach the coil to a tap with running water, rinse the inside to remove any remaining sand or salt.

Instead of salt and sand, the tube can be filled with water and frozen. This is convenient in winter, when the structure can be taken outside. The advantage of this method is that the coil does not have to be washed.

It is not difficult to make a coil for a moonshine still with your own hands, but it is important to install it correctly. Basically, it is placed vertically so that the dripping condensate does not disturb the incoming steam from moving. It is also important not to forget about sealing the joints. If done correctly, the capacity of the coil of the above dimensions will be from 2.5 to 4 liters of distillate per hour.

How to make a cooler with your own hands

First you need to decide on the material, since it will depend on how long and often the coil will be used. When preparing alcohol at home, it is important that there are no interactions between solution or steam. This must be taken into account, since high temperatures and an aggressive environment, in the presence of surfaces that are unstable to such factors, can ruin all the advantages of making drinks with your own hands.

The coil design technology practically does not differ in stages from the material used. By analogy, you can make a product from corrugated steel, copper or other surfaces. Since steel is one of the most practical materials, although a little more expensive than copper, we can use it as an example to consider the manufacturing process:

- Steel tube preparation. It is important that it is food grade, stainless, and has not been previously used in other chemical processes. You should focus on a diameter of 10 to 15 mm. As for the length, it is calculated in relation to the desired capacity of the cooler. On average, it can be about 1.8 meters. Thickness - 1.5mm;

- The choice of the cylinder, which will become the basis for winding the steel tube. The section of the cylinder can also vary, but it must be at least 6 cm;

- Preparation for winding. It is impossible to simply bend the material relative to the cylinder, since it can deform significantly. To prevent this from happening, you need to make a seal, namely, fill clean, or better calcined, sand along the entire length of the pipe. On the one hand, the pipe is sealed or you can simply insert a suitable stopper, the sand is filled up, on the other hand it is also clogged;

- Steel tube winding. Beforehand, the cylinder must be well fixed; this can be done with the help of a vice.The winding process itself must be carried out carefully and this will require certain physical efforts.

- Uncorking, pouring out sand.

What materials can a coil be made of?

To date, the official prohibitions on making home-brewed home brew at home have been canceled, and it is for this reason that everyone has the right to purchase a full-fledged device for making moonshine in its full configuration. This can be done in a special store. Also in the same stores you can buy coils of different models and many additional devices.

However, a less costly option would be to make a working version of the coil yourself. Moreover, there is nothing difficult or specific in this.

How does the work begin?

Since coils differ in different types and modifications, the first thing to do is to determine the materials from which the coil will be made. It is in this block that such important processes as condensation and a decrease in the temperature of alcohol vapors take place.

Distillation without coil

If you are a beginner moonshiner, then it is not always worthwhile to immediately equip the perfect wine-making corner. To get started, you can use the materials at hand. An old saucepan or can with a sealed lid is perfect as a distillation cube. As a coil, you can use materials at hand. Moonshine after distillation will not be of the highest quality, but the first exciting experience of home brewing will be obtained at almost no cost.

Grandma's design

This is the simplest moonshine still you can make. The role of the refrigerator in the design is played by a large bowl of cold water, in which you can put snow in winter. Alcohol vapors condense on the walls of the "refrigerator" and fall into the funnel, and then flow down the groove into the alcohol receiver.

Lazy serpentine

If the soul yearns for a homemade drink, but there is no time, then imagination will help out. In the presented model, the role of the coil is played by a small diameter silicone tube attached to the distillation cube. The free turns of the condenser are immersed in a container, which is placed in the sink and cooled by water. Silicone tubing of various lengths are available at the pharmacy. When buying, it is important to pay attention to the material - rubber products will not work.

Metal tube refrigerator

A do-it-yourself coil for a moonshine still will compete with store counterparts. Before starting the assembly of a moonshine design, you need to decide on its parameters:

- Dimensions.

To make the moonshine flow faster and tastier, you should find a longer copper or aluminum tube. Its length before twisting should be about 2 meters, and the cross-sectional diameter should be 8-12 mm. Such dimensions will provide a sufficiently large contact area with the cooling medium. The wall thickness of the tube should not be very thin, on the order of 1 mm, so as not to complicate processing. - Spatial location.

The orientation of the refrigerator can be any, but it is better to prefer vertical, and serve the steam from the top. In this case, the condensed moonshine flows down under the action of gravity, without creating obstacles to the steam. - Cooling

can be produced by air, snow or water. Water cooling systems are more efficient. The choice between a capacitive and a flow (open) refrigerator depends on the availability of water supply and sewerage.

How to bend a pipe?

You can get a beautifully curled coil in a variety of ways. An air conditioner store sells copper tubing of the right length, and there you can find “pipe benders” that create smooth bends without creases. If no special device was found, then the old-fashioned way of making neat turns with your own hands will help:

- one end of the tube is closed;

- the cavity is tightly packed with sand (salt, soda);

- the second end is closed;

- the structure is wound onto a pipe of a suitable diameter;

- the spiral is removed, its ends open, the filler is carefully poured out.

See which one is easy to make and produces a quality product. Also, the article describes in detail the process of making a coil from a copper tube.

Distillers, which can not only be used at home, but also made by hand, are necessary to improve the quality of the future alcoholic beverage. At the same time, distillers, regardless of the model, differ slightly from each other, but the main units with unique functions in the moonshine should be. One of the important elements is the coil.

What can be used to make such a component with your own hands and at home, what parameters and requirements should be followed in order for the quality of the drink to be the best for any person?

Navigation