Coal heaters are designed for higher temperatures than wood-fired ones. Running on high-calorie fuels, they provide more heat and are able to maintain productivity for longer on one tab.

In order for all these advantages to manifest themselves in full force, you need to know how to properly heat the boiler with coal.

The principle of operation of a coal boiler

There are several types of coal-fired boilers:

- direct burning... The fuel simply burns in the firebox, bounded from below by a grate. There is an ash chamber under it. The generated heat is communicated to the heat carrier passing through the heat exchanger;

- pyrolysis... The action is based on the ability of fossil fuel to decompose when heated without air access to combustible gases (gas generation or pyrolysis). The firebox is divided into two chambers. In one, gas generation takes place, in the other, the resulting mixture of gases is burned. Air supply to both chambers is controlled by automatic equipment;

- long burning.

Long-burning boilers are divided into two types:

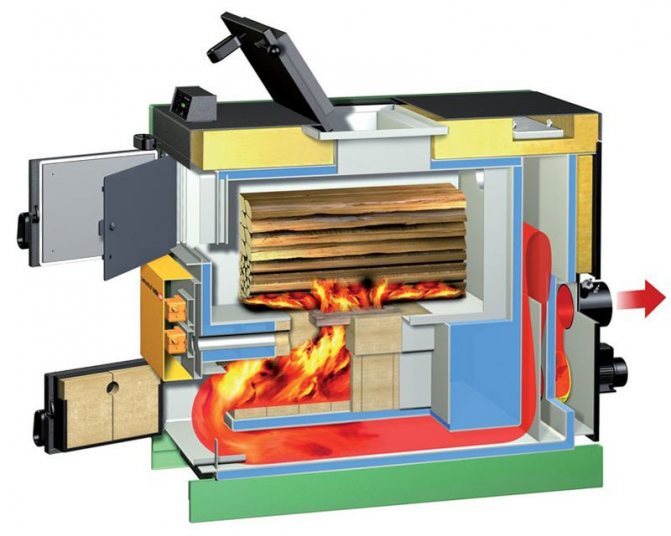

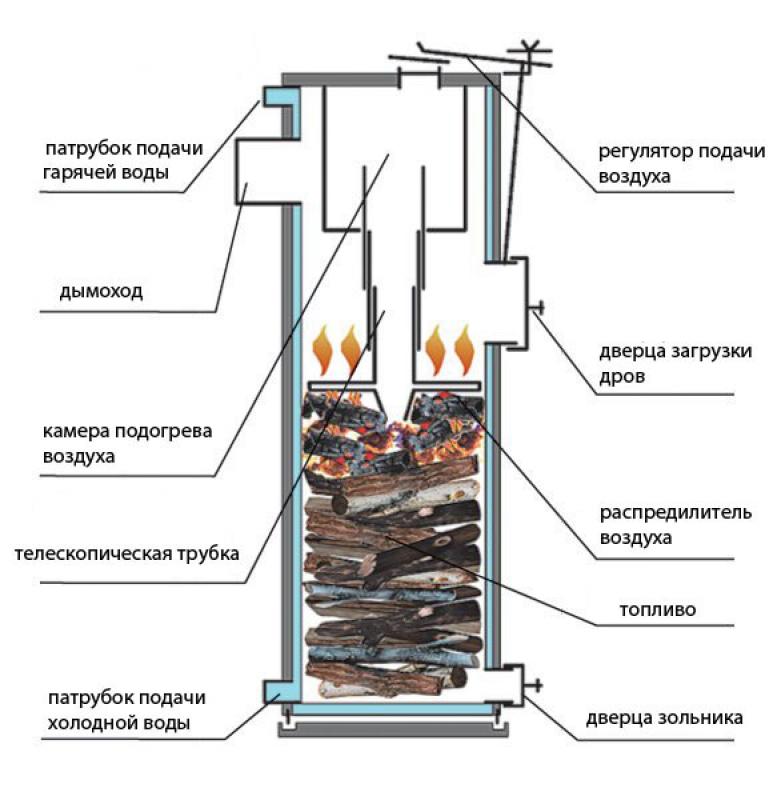

- top burning... The increased volume firebox has an upward-elongated shape. Fuel is ignited from above, air is supplied strictly to the combustion zone. Due to this, the fuel load is burned longer than in a direct combustion boiler;

- forced air... It is blown by a fan through the duct. When the desired temperature of the coolant is reached, the controller turns off the blower and the air duct is closed by a damper (lowers under its own weight when the fan is turned off). After the coolant has cooled down, the fan starts up again and ignites the glowing coal.

Modern coal-fired boilers are equipped with an electronic control unit and an automation system that makes the heater's operation safe and efficient.

For regions with unstable power supply, non-volatile boilers are produced, the automatic operation of which is provided by thermogenerators, thermocouples, bimetallic plates and lever systems.

Methods for calculating the amount of coal for the winter

Most owners of private houses prefer to make blanks for the entire heating season.

In the European part of Russia, it lasts from September to April. A distinctive amount of coal is spent in different months depending on climatic conditions.

Other factors affecting solid fuel consumption:

- boiler brand and design;

- type of heating;

- coal grade;

- technical characteristics of the building, etc.

3 common methods for calculating coal consumption used by owners of private houses:

- Practical. It is used if there is no technical documentation for the boiler and it is necessary to experimentally determine the coal consumption for a conditional period. To do this, it is recommended to buy 100-150 kg (several bags) of fuel and see how much it is spent to maintain a comfortable temperature in the house for 1 day during the week. Based on the result obtained, you can calculate the consumption for a month or for the entire season.

- Exemplary. It consists in knowing the average, experimentally established rate of coal consumption in the European part of Russia. For example, to heat a house with an area of 100 m² you need: in September and April 1 bucket (8 kg); December, January, February - 3-4; in March and October - 1-1.5. By multiplying the rate by the number of days in each month and summing the results, you can get the amount of coal for the entire heating period.

- By boiler power. It is based on a standard formula - 1 kW should be used for heating 10 m² of area. In practice, this figure is achieved in severe frosts.Less fuel is consumed at average seasonal temperatures. For example, a house of 150 m² needs a 15 kW boiler. To maintain a comfortable temperature during the day, you need to spend 15 x 24 = 360 kW of energy. 1 kg of hard coal gives 7.5 kW. To heat the house you need (per day) 360 / 7.5 = 48 kg. By correcting for the device's passport efficiency, a more accurate result can be obtained.

In April, September, the calculated indicator of coal fuel consumption decreases by 50-75% from the peak winter months; in March, October by - 30-50%.

Heating engineers call the latter method of calculation conditional and capable of giving an error of up to 15-20%.

Which coal to choose for the furnace?

The fuel is selected in accordance with the recommendations of the boiler manufacturer.

The fact is that there are several types of coal, and they differ significantly in characteristics:

- brown coal... The most common and of the least quality: burns quickly, smokes and emits an unpleasant odor, generates a lot of waste: structure - earthy, color - brown or black, heat capacity: 16-22 MJ / kg, cost: 3.5-4.5 thousand rubles ... per ton;

- coal... Black with metallic or resin sheen. Good quality and at the same time affordable cost. There are several varieties, the most common is long-flame coal: heat capacity: 26-32 MJ / kg, cost: 5.5-7 thousand rubles. per ton;

- anthracite... Gray-black with a luster of glass or metal. The highest quality and most expensive: heat capacity: 32-36 MJ / kg, cost: 8-10 thousand rubles. per ton.

The use of the "wrong" coal leads to cost overruns or damage to the heater. So, when anthracite burns in the optimal mode, the temperature in the furnace reaches 2200-23000C. When loading such fuel into a conventional steel boiler, designed for brown coal, it will quickly burn out.

Or you will have to "hold back" the combustion by cutting off the air supply, due to which the efficiency of anthracite will drop sharply and the cost of purchasing this expensive coal will be unjustified.

Anthracite

Another example: long-flame coal due to high humidity is unsuitable for a pyrolysis boiler - condensate is abundantly formed in the chimney, which mixes with the combustion products and turns from this into a viscous resinous substance. These heaters require gas-fired coal.

There are toxic types of coal containing more than 2% sulfur. It is strictly forbidden to use them as fuel for furnaces and boilers: during combustion, sulfur oxide (sulfur dioxide) is formed, poisoning the air and destroying metal parts.

The best fuel for the boiler

Each of the fuels has pros and cons. The most expensive types are briquettes and pellets. It is convenient and safe to use them, but not everyone can afford the cost of raw materials. The most economical and efficient type of coal is anthracite; it also has the highest value of all coal grades. Anthracite should be used with caution, as the fuel produces a high temperature and the boiler elements may not withstand it.

The best for standard boilers will be DPK grade coal - it has good efficiency and a lower price. Firewood is less efficient than coal, but in areas where there is no access to other fuels, they are a good alternative. Such species as birch, ash, beech and oak have the highest caloric content. But in any case, firewood will cost consumers more.

When choosing raw materials for solid fuel boilers, one should be guided by the recommendations of manufacturers - this way you can make home heating more efficient with minimal fuel costs. You also need to rely on the specifics of the location. Sometimes even the cheapest raw materials will not be affordable, taking into account delivery to remote areas.

Each owner of autonomous heating should know how to heat the boiler correctly. This will make it possible to efficiently use solid fuels and extend the life of the heating system.

How to use solid fuel plants correctly?

The efficiency of the TT boiler reaches its maximum when burning in the optimal mode, they are guided by the color of the flame:

- red... Sign of insufficient air supply. Fuel burns longer, but does not burn completely. This leads to a decrease in efficiency and the formation of smoke, which is very harmful to the environment. The exhaust temperature is low and condensation forms abundantly in the chimney. In combination with "bad" smoke, it forms a caustic cocktail that is hazardous to health (do not drain near edible plants);

- yellow... Optimal combustion mode, air is supplied in sufficient quantity;

- white... Sign of excessive air intake. The draft is too strong, the fuel burns out quickly, the lion's share of the generated heat is carried away into the chimney.

The temperature of the coolant in the "return" must not be allowed to fall below + 500C. Otherwise, moisture condenses on the heat exchanger and reacts with the sulfur in the smoke to form sulfuric acid. The latter corrodes the heat exchanger.

Features of the boiler furnace in winter

Winter is the period of the most active operation of the heating system. To prevent vital devices from failing in severe frosts, you should take care of preparing the boiler for winter in advance. For this, the system is preliminarily cleaned from soot - chimneys, channels, grates. This will allow the heating to operate at maximum efficiency and extend its service life.

In winter, it is very important to maintain a stable temperature in the home, which means that periodically you will have to fill the firebox with raw materials. You can increase the efficiency of one bookmark by installing a heat accumulator. It is able to accumulate the heat generated by the system, quickly warm up the radiators and water supply. As a result, even after the fuel has completely burned out, the coolant in the system will remain hot for several hours. This is especially true for night hours, when it is not possible to regularly feed the boiler.

Preparing the stove for kindling

Before lighting a stove or boiler after a long period of inactivity, do the following:

- inspect the firebox for cracks. Through them, poisonous carbon monoxide will enter the room. Found cracks are welded or covered with clay mortar (brick oven);

- check the condition of the chimney. If there is debris or bird nests, the smoke exhaust duct is cleaned. It is also necessary to remove soot: it narrows the chimney and is capable of catching fire, which will lead to damage to the structure, and possibly a fire;

- clean the firebox from soot and wipe it with a dry cloth;

- remove flammable objects and materials near the heater.

Now, if coal is available, the boiler can be fired.

How to properly melt?

A coal stove or boiler is melted in the following sequence:

- open the firebox door and close the blower;

- paper is placed on the grate and chips, cake or other flammable material are placed on it. There and then, in the form of a hut or a well, they lay in a small amount of firewood. Set fire to paper;

- close the firebox door and open the blower. In the future, each time before opening the door of the firebox, the blower is closed, and after the door is closed, it is opened;

- after the combustion of the wood bookmark, fine coal is laid on it in a thin layer;

- after the coal burns out, it is stirred up with a poker to prevent caking. Otherwise, air will cease to flow into the firebox;

- the main fuel is laid on the burned-out fine coal - coarse coal with a layer thickness of up to 60 cm;

- the blower flap is slightly opened so that the optimal combustion mode is established in the firebox.

When firing up the boiler with forced air supply, instead of opening the damper, the controller controlling the fan is turned on and the desired temperature of the coolant is set on it.