The appearance on the market of solid fuel boilers with automatic feeding has greatly simplified the lives of many consumers for whom gas or electric heating is not available. The development of production has led to the creation of many models for various purposes. Knowledge of the device, principles of operation and types of automatic units will help to choose the most suitable and profitable option.

Features of boilers with automatic feeding

The elements of the boiler plant, which are directly responsible for the combustion of fuel and the transfer of heat to the heating system of the house, do not differ significantly from conventional solid fuel devices.

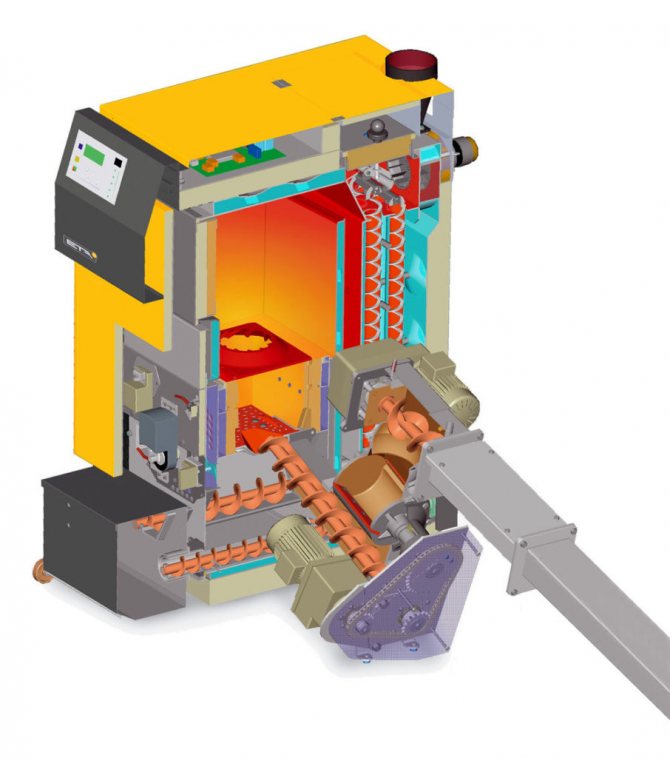

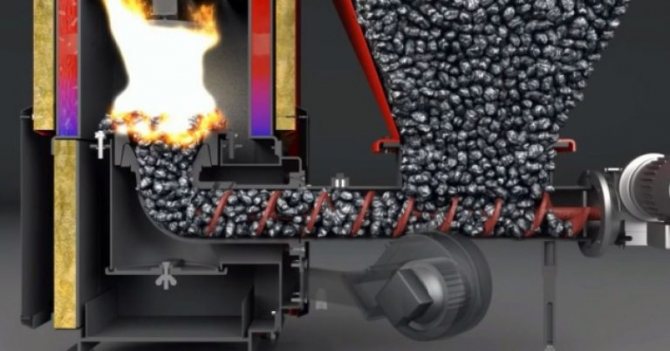

The main operational advantage of devices with automatic feeding is provided by the presence of three basic components in their design:

- a fuel bunker for one-time loading of large volumes of combustible materials;

- screw conveyor for regular transfer of fuel to the combustion chamber;

- complex automation responsible for the operation of the entire system.

The listed structural elements provide the possibility of long-term combustion without additional maintenance of the boiler plant. For the operation of such equipment, human participation is required no more than 1 time in 1-2 weeks, and sometimes less often.

Automation also regulates the amount of fuel supplied, which depends on the current coolant temperature and set in the settings. When the bunker is almost empty, the system notifies you to fill it up.

Many models also have the ability to automatically remove combustion products. That is, the entire process from ignition to cleaning in such units is carried out without human intervention.

Basic requirements for a heating system with a wood-fired boiler

Evaporative gas boilers are installed taking into account strict requirements:

- They must be installed in separate rooms.

- The smallest volume of the area of the room is at least 7 m.

- The boiler must be installed on a flat concrete or brick site with a thickness of at least 7 cm, and around the entire perimeter it should be 10-20 cm wider than the dimensions of the furnace itself.

- In the immediate vicinity, it is necessary to equip a place for storing firewood, since it must be dry before loading.

- At least 0.5 m - distance to the wall from the boiler.

- The distance from the open door to the opposite wall is at least 1.3 m.

- The pipes and inner walls of the chimney must be made of strong sheet steel, and the diameter of the pipes must match the diameter of the chimney. And the gas outlet pipe should have a minimum number of bends and bridges.

Types of boilers by type of fuel bunker

There are two types of loading devices: built-in fuel bunker and mechanized storage. The battery life and the area occupied by the boiler plant depend on which of them the unit is equipped with.

Integrated fuel hopper

Models with a built-in charging device are equipped with a solid fuel container, which is located on the top or side of the main boiler chamber. The advantage of this design is the relative compactness of the heating system. However, in terms of battery life, models with a built-in bunker are inferior to units with a mechanized fuel storage.

Mechanized fuel storage

Here, a separate room or part of a room with a connected fuel supply system acts as a loading device. The volume of such a storage facility is sufficient to accommodate an annual supply of fuel.

The models are distinguished by a complex electronic automatic control system that fully regulates all work processes, as well as the presence of a remote control unit.

Methods of automatic fuel supply

According to the methods of fuel supply, units with a pneumatic conveyor and auger transmission are distinguished.

The choice of design depends on:

- the degree of noise during the operation of the heating installation;

- power consumption;

- the frequency of fuel delivery to the combustion chamber and other indicators.

Pneumatic conveyor

The combustible materials are delivered to the main boiler chamber by means of air, which is pumped in under pressure. The advantage of such models is that the fuel supply is carried out less frequently. As a result, the system will be able to operate without electricity for a longer time. However, the pneumatic conveyor makes more noise during operation and consumes a lot of electricity - about 1.5–2 kW / h.

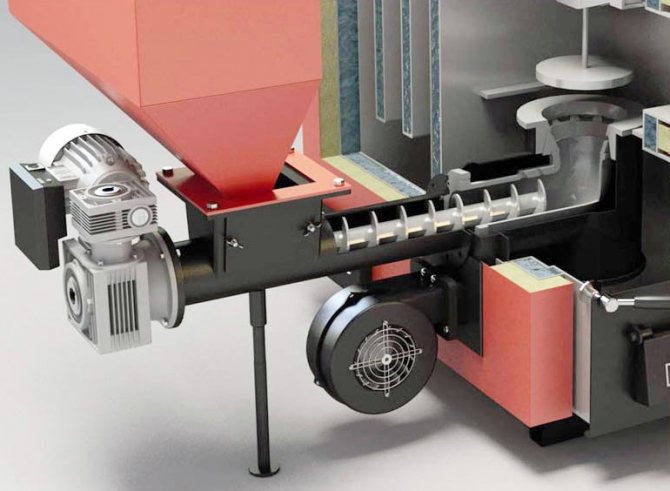

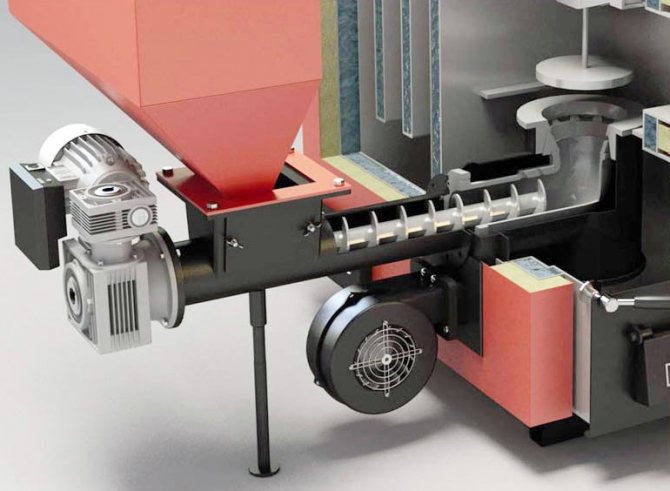

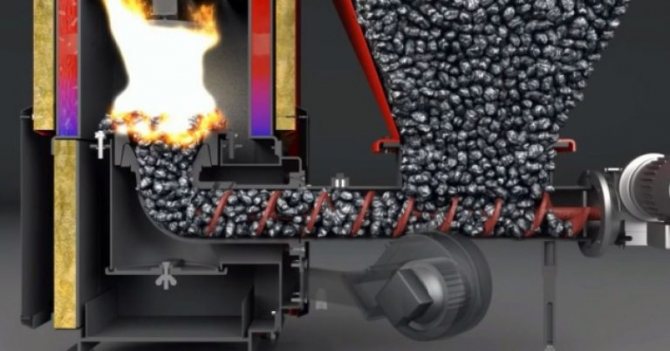

Auger transmission

This method is used in most household appliances and is considered the most reliable, but it is not ideal.

Feeding is carried out by means of a screw conveyor, which operates almost silently and consumes less energy - about 80 W / h. The feed rate is automatically controlled.

The use of an auger guarantees the flow of fuel into the boiler, but when its length is more than 2 m, combustible materials are ground into dust.

Low price segment of wood-fired heating boilers

First of all, it is worth considering a homemade wood-burning boiler for heating a house. Significant cost savings are achieved by purchasing individual components (sheet metal and pipes) rather than a finished product. Although it will not be so easy to assemble such a unit with your own hands, nevertheless, with proper execution and a successful choice of a model, the efficiency of a homemade wood boiler can reach 70-80%.

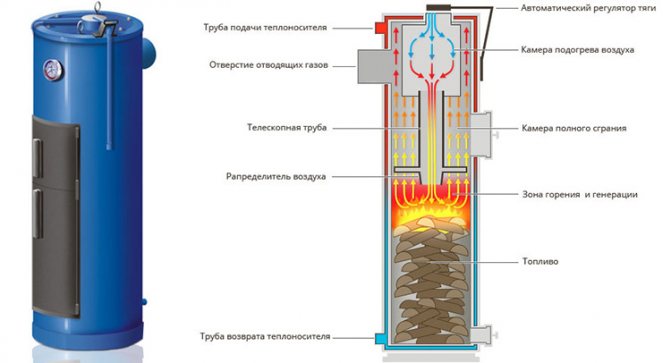

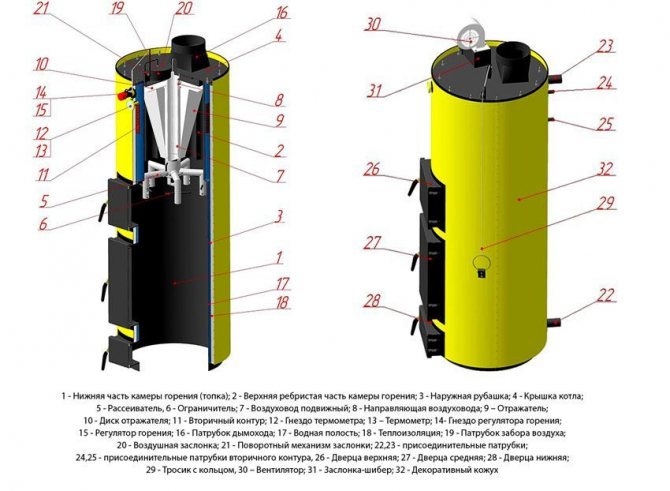

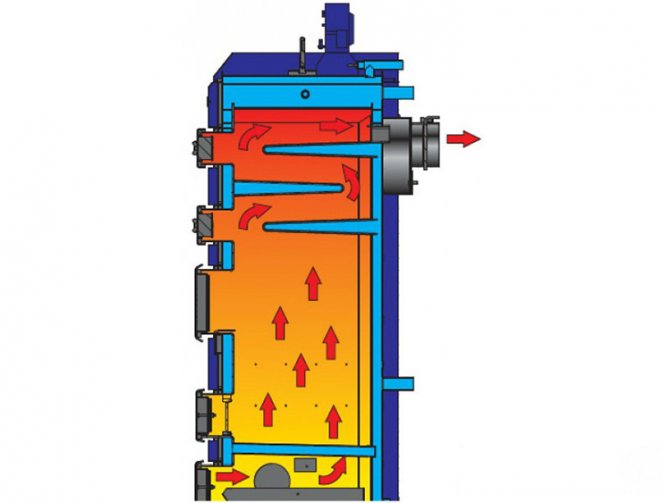

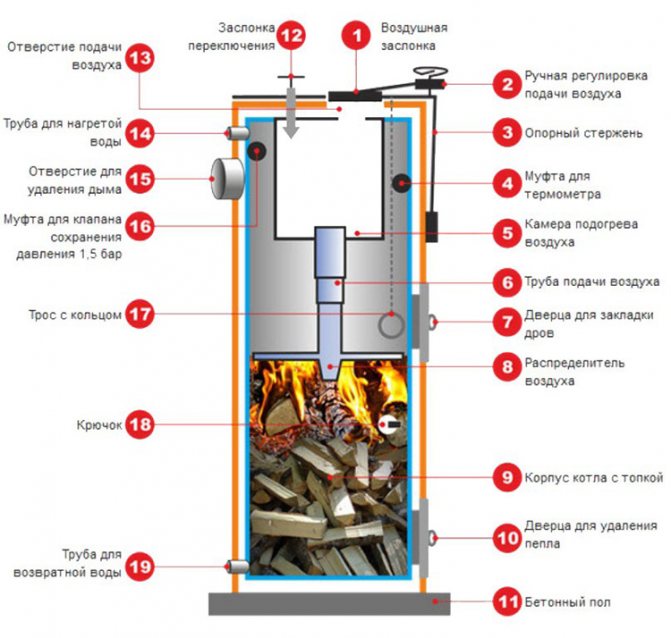

The simplest solution would be a standard bottom firing boiler design. It consists of a combustion chamber, an ash pan, a water jacket or register, a draft regulator, and a chimney. If you choose a more complicated design, then it can have all kinds of valves, smoke swirlers or mine combustion chambers. If desired, you can make a boiler even with an upper combustion type.

It is worth noting that the main disadvantage of a home-made boiler for heating a private house on wood is the high rate of fuel combustion. The boiler heats up very quickly, it gets very hot in the house, and after just a few hours the system cools down. To cope with this problem, some masters install a kind of battery - a container with water, in which they store a supply of warm water. It transfers heat evenly to the system and ensures a comfortable temperature for a long time. In some cases, the volume of such a container reaches 2-3 tons.

However, such options are acceptable only for those who like to work with their hands and have enough time for this. All others prefer to buy cheap factory products from domestic producers.

Please note that it is better to purchase a ready-made boiler not from folk craftsmen, but from trusted manufacturers with high-quality equipment and production facilities. The fact is that in an industrial environment, the quality of the fit of welds is much higher than it is possible to do at home. The method of painting and the quality of paints and varnishes are also important - heat-resistant paints designed for high temperatures are used in production.

As a rule, a cheap wood burning boiler has a simple structure and is made of sheet steel. It is desirable that its thickness is at least 4 mm. As for the power, it can be quite high - it does not affect the price. The disadvantages of equipment from the lower price segment are their service life and fuel consumption. Typically, factory products are designed for 5-10 years of work.

Nevertheless, subject to not very intensive use and free access to lumber, such equipment can be purchased.

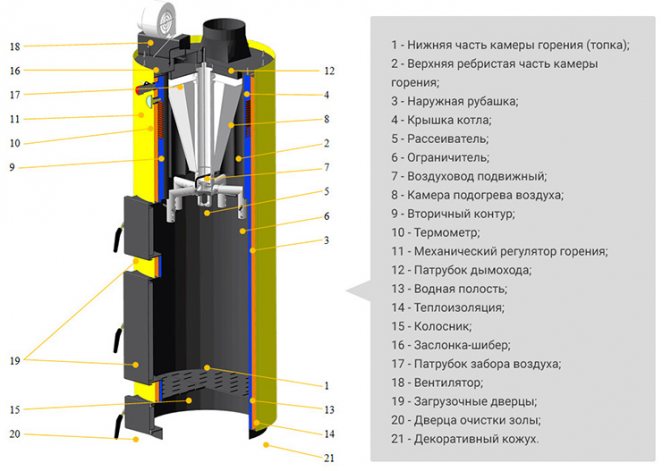

Pellet automatic units

One of the most common types of heat generators is wood pellet systems. The principle of operation of pellet boilers is in many ways similar to other automatic units, but there are also characteristic features.

If you trace the similarities and differences, as well as the advantages and disadvantages of such models, it will be easier to choose the appropriate option.

Principle of operation

The basic design of pellet systems is no different from other common automatic heat generators. The fuel bunker is loaded with combustible materials, from where they are gradually poured onto the auger conveyor. The shaft transfers the pellets to the combustion chamber, where the heating agents are heated.

Differences in work can be traced at the stage of fuel supply:

- After starting the auger, the mechanism directs the pellets first into a flexible hose or plastic tube, which dumps the pellets into the dispenser.

- In the metering device, the second shaft measures the required portions of fuel and transfers them to the petal valve.

- The shutter opens and the pellets are dumped onto the third auger, which transfers the measured amount to the firebox.

The described algorithm may vary slightly depending on the implementation of a particular model.

Benefits

The economic and operational benefits of pellet heating systems are mainly related to the advantages of the type of fuel used.

Wood pellets are not inferior to traditional combustible materials in terms of calorific value, but they have a number of advantages:

- lower cost;

- economical consumption, which leads to a longer operating time without additional loading;

- increased environmental friendliness;

- the minimum amount of combustion products in the ash pan.

As for the advantages of the boilers themselves, as a rule, they are smaller in comparison with units operating on other types of fuel.

disadvantages

In addition to the listed advantages, there are also disadvantages.

Since the flame in most pellet models has a horizontal direction, overheating of the boiler structural elements may occur. In addition, the efficiency and power of such equipment is lower.

What are the fuel briquettes

Briquettes differ in shape and material of manufacture.

Differences in shape

There are three main forms of fuel briquettes: pini-kei, ruf, and nonstro. Their difference is only in the maximum density that can be achieved in each of the forms. In terms of chemical composition or mass calorific value, there are no differences between Eurowoods.

Fuel briquettes pini-kay

The highest density is from 1.08 to 1.40 g / cm 3. Sectional shape - square or hexagon. There is a through hole in the center, which provides better air movement and briquette combustion.

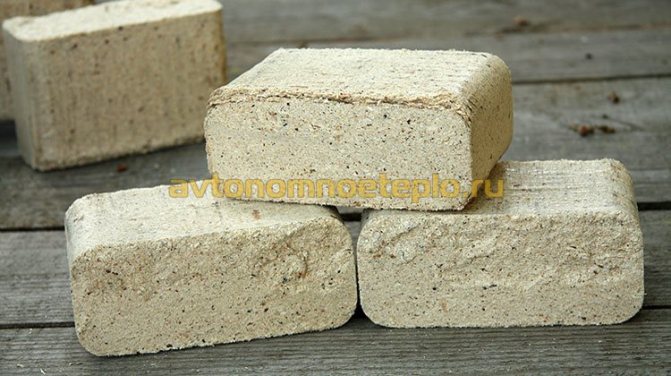

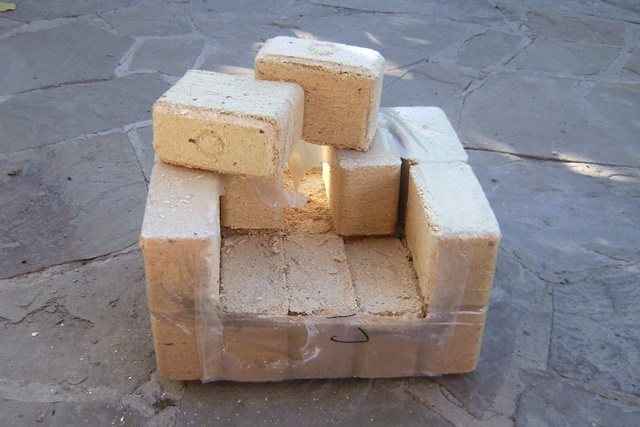

Fuel briquettes RUF

Fuel briquettes from roof sawdust, in the form of bricks. They have a small size and the lowest density - 0.75-0.8 g / cm 3.

Briquettes Nestro

Fuel briquettes have a non-linear cylinder shape and an average density of 1 - 1.15 g / cm 3.

Peat briquettes

Peat fuel briquettes have a special shape that is not like the others. And due to the high ash content and the presence of other harmful impurities in the composition, they are not recommended for use at home. Such briquettes are suitable for industrial furnaces or boilers capable of operating on low quality fuels.

Peat fuel briquette

Differences in material

Eurowood is made from sawdust, seed husks, rice and buckwheat, straw, tyrsa, peat and other materials. The material affects the calorific value of the fuel briquette, ash content, the amount of soot released, the quality and completeness of combustion.

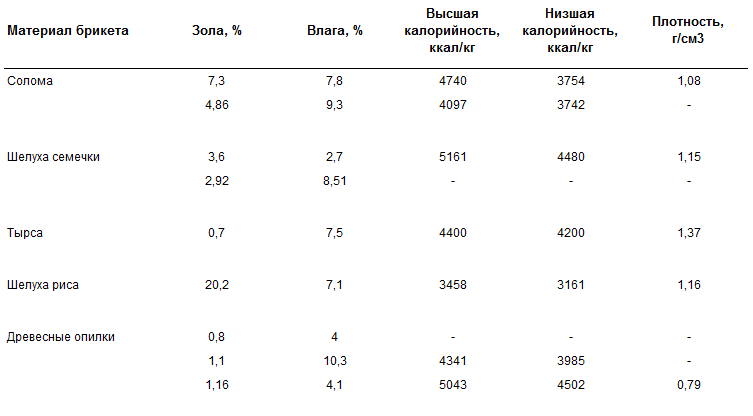

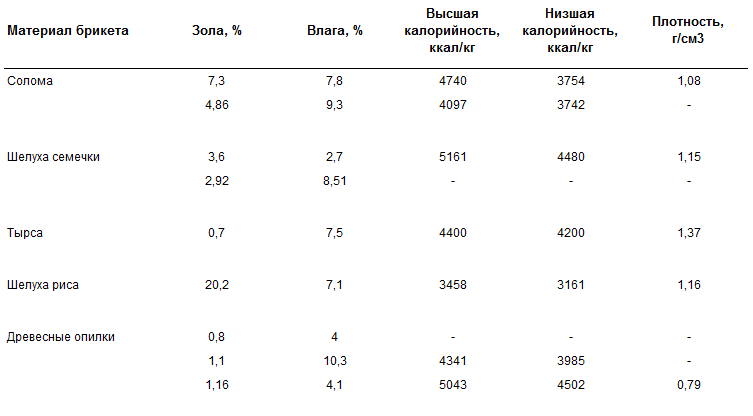

Below in the table is a comparison of the characteristics of briquettes from different materials - husks, seeds, rice, straw, tyrsa and sawdust.Such analysis shows not only that briquettes from different materials differ from each other. But also the fact that even briquettes from the same material differ in quality and properties.

All data are taken from real test reports of fuel briquettes.

Caloric content, humidity, ash content and density of fuel briquettes from different materials of manufacture.

Comments to the table

Seeds. The highest calorific value is in briquettes from seed husks - 5151 kcal / kg. This is due to their low ash content (2.9-3.6%) and the presence of oil in the briquette, which burns and is of energy value. On the other hand, due to the oil, such briquettes more intensively pollute the chimney with soot, and it has to be cleaned more often.

Wood. On the second place in terms of caloric value are sawdust briquettes - 5043 kcal / kg at 4% humidity and 4341 kcal / kg at 10.3% humidity. The ash content of wood briquettes is the same as that of a whole tree - 0.5-2.5%.

Straw. Straw briquettes are not much inferior to seed husks or sawdust and have a good potential for use. They have a slightly lower caloric content - 4740 kcal / kg and 4097 kcal / kg, and a relatively high ash content - 4.8-7.3%.

Tyrsa. Tyrsa is a perennial herb. Such briquettes have a fairly low ash content - 0.7% and a good heat transfer of 4400 kcal / kg.

Fig. Rice husk briquettes have the highest ash content - 20% and low calorific value - 3458 kcal / kg. This is even less than that of wood, at 20% moisture.

Automatic wood chip and coal boilers

This option of automatic units should be preferred by residents of regions where the cost of coal is comparable to the price of pellets. Otherwise, their operation will be more expensive.

The main advantage lies in higher efficiency rates. However, coal gives off a significant amount of soot and tar, which leads to less environmental friendliness. Maintenance of equipment is performed more often, as more ash is released during combustion.

For coal-fired boilers, there is a requirement for the size of the pellets of combustible material: from 4 to 25 mm in diameter. This is necessary for the smooth operation of the auger conveyor.

The opinion of professionals about solid fuel boilers for long burning

The main advantage of this boiler is its design simplicity and ease of maintenance. With the help of an automatic system, you can set the required power so that the device produces only a certain amount of heat. Then the unit will do everything on its own. Reviews of solid fuel boilers for long burning indicate the high quality of the product and a long shelf life.

Experts point out the following advantages of the devices:

- Relatively low construction cost;

- The ability to combine different types of fuel to reduce costs;

- Low fuel price - firewood is many times cheaper than electricity;

- Independence - the automatic system itself controls the fuel supply;

- High heat output and constant water temperature maintenance.

Selection recommendations

The choice of the most suitable model depends on many factors. First of all, you need to decide on the type of fuel, the prices for which may differ depending on the region.

After that, it is worth calculating the area that is available for the installation of the boiler system, and taking into account the wishes for the autonomous operation time. This will help to determine the most acceptable boiler dimensions and the capacity of the fuel bunker, which will significantly narrow the search.

To take full advantage of the potential economic and operational benefits of automatic boilers, when choosing, you need to pay attention to the following parameters:

- boiler power (must correspond to the area of the heated room);

- the presence of economical modes;

- exactingness to the quality of fuel, its ash content;

- reliability and safety of long battery life;

- reproducible noise in various modes;

- the presence of the function of automatic ignition and ash collection;

- consumed electricity;

- the ability to operate from rechargeable batteries;

- the size of the ash collection bin and the convenience of its cleaning;

- efficiency of work with different types of fuel pellets and in different modes;

- the presence of a remote control or the ability to additionally connect it.

You also need to pay attention to the appearance of the boiler, including the quality of the welds.

Review of the best manufacturers and prices

Many models of heating units are available to the modern consumer. It is rather difficult to make a choice in such a situation. Understanding popular models and manufacturers will help simplify things.

Germany

German-made boiler equipment is a quality standard. The models have a high level of efficiency and operate without failures. It is not surprising that the systems made in Germany have the highest cost, about 450-600 thousand rubles.

First of all, it makes sense to pay attention to heating systems Buderos, Heiztechnik and ThermoFLUX.

Prices for solid fuel boilers Buderos

solid fuel boilers Buderos

Italy

Among the models of Italian production, there are many universal options. For example, the Lamborghini Ecologik series boilers can operate on wood, coal, peat and briquettes. And after the installation of additional equipment (an adapter door, a pellet burner, auger and a hopper), pellets are also suitable as fuel.

Italian models are of the middle price category. Marketed brands: Lamborghini, D'Alessandro Termomeccanica, Faci.

Prices for solid fuel boilers Lamborghini

solid fuel boilers Lamborghini

Turkey

Turkish boiler plants belong to the middle price segment. They have an automatic feeding system of good quality and are equipped with a convenient control panel. One of the most popular manufacturers is Totem, which produces silent boilers with simple temperature control. Also known are the brands Emtas and Termodinamik.

Russia

Russian automatic boilers are in constant demand in the domestic market. Manufacturers have achieved significant success thanks to the introduction of modern design methods, new manufacturing technologies and continuous improvement of structures.

The models have an attractive appearance, high-quality assembly, good automation and benefit in terms of price. Their cost starts from 80-100 thousand rubles, which is relatively inexpensive in comparison with imported counterparts. The most famous brands: Danko, Pereko, Obshchemash Peresvet, Obshchemash Valdai, NMK Magnum.

Japan

Japanese products are characterized by a high degree of automation. Many additional built-in functions greatly enhance the usability. Also, the models are distinguished by an ergonomic shape and high-quality materials for manufacturing, as a rule, steel with anti-corrosion treatment.

Prices for Japanese-made automatic solid fuel boilers are not inferior to the cost of models from Germany. Most popular brands: Kentatsu, Rinnai.

Prices for solid fuel boilers Kentatsu

solid fuel boilers Kentatsu

Serbia

The Serbian manufacturer Radijator produces universal, highly environmentally friendly units that are equipped with an overheating protection system and are resistant to ash deposits. Allow you to get an efficiency of about 90%. Pass a mandatory quality check.

China

Most Chinese products are not of high quality and reliability. The exception is the units of the Chinese brand Roda (Turkey is usually the country of origin). The design of the models allows for easy cleaning of the flame tubes, which maintains high combustion efficiency. The average cost of such equipment is 150 thousand rubles. Study the best radiators for an apartment at the link.