Heating for the Russian climate is an indispensable attribute of any home. Previously, ovens were used for this, but they cannot provide a constant room temperature, unlike modern devices.

Therefore, in recent years, heating of a house with a solid fuel boiler has been increasingly used. This allows you to put firewood much less often and does not require heating early in the morning, since most devices are able to automatically maintain the required temperature. And how to properly heat a solid fuel boiler, we will consider further.

The heating device is warmth in the house

Many settlements have not yet been supplied with gas. Therefore, residents of such settlements have to look for an alternative to gas equipment. The best solution in this case is heating a country or private house with a solid fuel boiler.

It is gaining more and more popularity not only due to the ability to work on wood or coal, but also full autonomy.

Indeed, for a solid fuel boiler, neither gas nor electricity is needed. It can only work on wood, while maintaining a comfortable room temperature. However, such devices are produced in various modifications and in order to make the right choice, you need to at least briefly familiarize yourself with each of them.

Overview of the features of heating devices of the "Zota" brand

Solid fuel boiler "Zota" is manufactured within the walls of the Krasnoyarsk plant. It is of good quality and has established itself as an economical and efficient device. The first of the latest developments were the Topol solid fuel boilers, which are used to heat production areas and houses. The products have a steel body. Fuel loading is the main distinguishing feature of such equipment. The devices are equipped with two combustion doors, one of them is horizontal, the other is vertical. The user can load fuel through any of them.

The combustion chamber has a special design, which made it possible to achieve an efficiency that reaches 70%. Solid fuel boiler "Zota" has an electrical kit, which is controlled by a remote control. Among the advantages of the described equipment are:

- the ability to operate on any type of solid fuel;

- maintaining the required temperature in different operating modes;

- excellent economic performance;

- automatic transition to work using the long burning mode;

- high quality;

- affordable cost.

Types of solid fuel boilers

All equipment of this class can be divided into 2 groups:

- Automatic fuel supply

- Manual loading

The first include pellet boilers. In them, the role of fuel is played by granules, they are loaded into special bunkers and from there they enter the furnace. Such devices have a high efficiency and can work in automatic mode for weeks, without human participation in the process.

The latter, depending on the design features, are divided into 3 types:

- Classic

- Pyrolysis

- Long burning

They can use firewood and wood waste as fuel.

A traditional or solid fuel boiler for wood has been produced for a very long time, and structurally has practically not changed. In it, the combustion chamber is located at the bottom and is considered the hottest part of it. Most often it is made of cast iron or steel.However, such heating of a wooden house with a solid fuel boiler is rarely used, since it requires frequent maintenance.

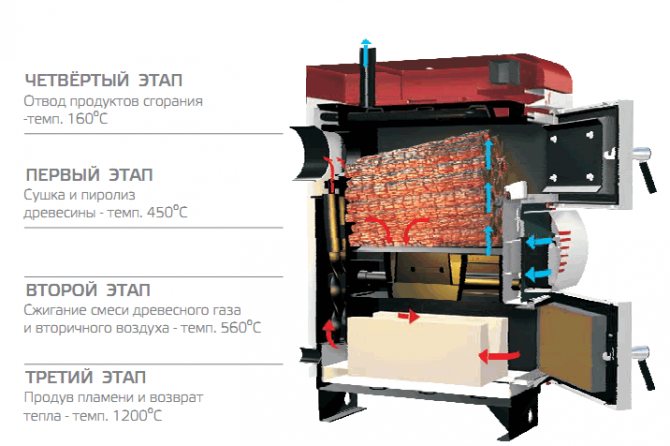

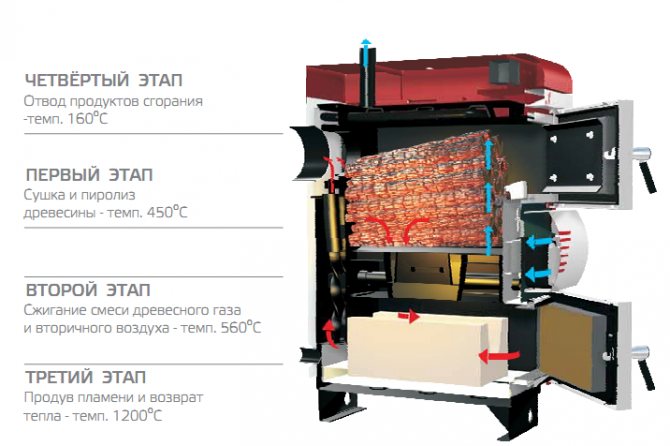

Pyrolysis machines are a new step in the solid fuel environment. Their work is based on the principle of decomposition of wood into solid residues and gases and combustion of the latter. The advantages of this device include high efficiency, minimal ash and soot formation. Among the disadvantages is the need to burn dry firewood with a moisture content of no more than 20%.

Long burning - their principle of operation was developed in Russia and has no analogues in the world yet. It is a new generation boiler not only structurally, but also in terms of operation. Its main advantage is its simplicity of design and the ability to service it once a day when operating on natural moisture fuel. A solid fuel wood-fired boiler has the most accurate power control and can produce a given amount of heat.

The Zota Poplar M20 boiler is a solid fuel boiler fired with coal and wood. Reviews of the people.

Solid fuel boilers are an excellent solution for cottages and summer cottages where there is no way to supply gas. Fortunately, coal and firewood are in bulk in our country and they are inexpensive. Therefore, we will consider one of the most popular models of medium-power solid fuel boilers - Poplar M20 from Zota. Production - Krasnoyarsk, Russia.

The Poplar M20 model is an upgraded version of the conventional Poplar with a lot of improvements and improvements aimed at increasing the burning time and increasing efficiency and heat transfer.

The average price at the end of 2020 is 35,000 rubles, so this model is included in the category of popular budget boilers. Boiler power can be seen from the model name - 20 kW. Zota is a Russian company that has long established itself in the heating equipment market.

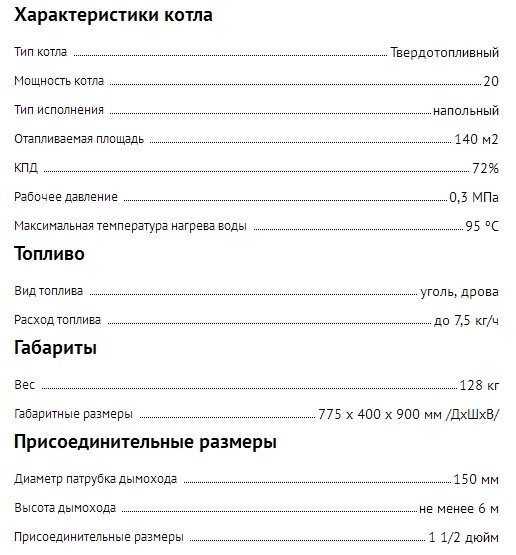

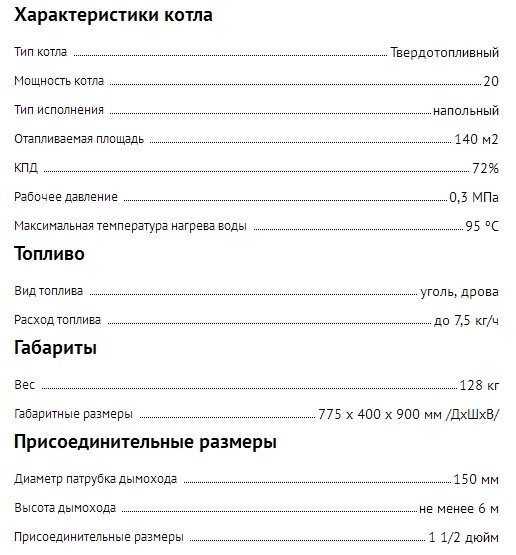

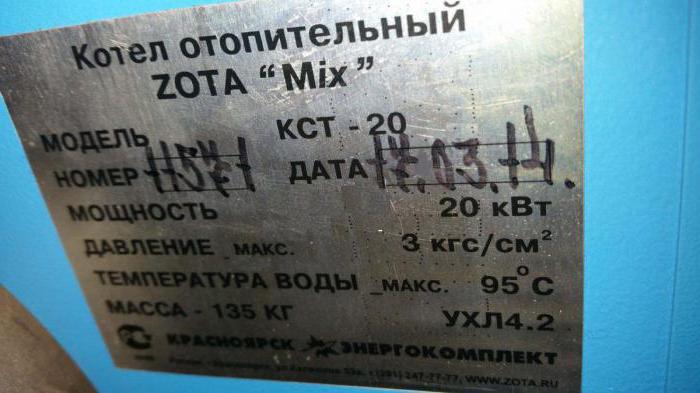

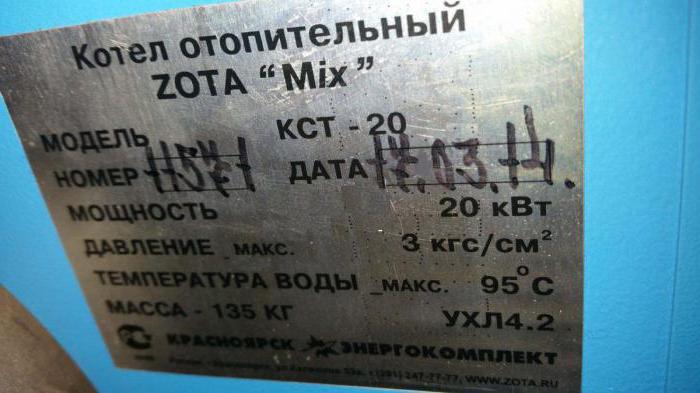

You can see the main characteristics in the photo below:

As you can see, the area of the heated premises is declared as much as 140 square meters, the majority of people use Poplar 20 for cottages of 90-150 square meters.

You can heat both with wood and coal. Of course, users often use coal, and firewood only for kindling. Still, coal burns longer and heat transfer is higher. According to reviews, it is quite enough to load a 12-liter bucket of coal 2 times a day (in severe frosts -30) in order to maintain a comfortable temperature of 23-25 degrees in a room of 120 square meters.

IMPORTANT - the Topol model is intended primarily for the southern regions of Russia, where the temperature does not drop below -15. If you are looking for a boiler for the Central and Northern part, for Siberia - then pay attention to specialized long-burning boilers - there is, of course, Buderus ahead of the rest of the planet.

Boiler features

The first thing that makes it different from other models is top loading. It is very convenient to fill in coal.

The extended firebox is another convenient design solution that allows you to load longer logs inside.

The only thing that upsets is the rather thin walls. The wall thickness is 3 mm (if we take, for example, some models of Buderus boilers, then there is a thickness of 5 mm), therefore, when firing with coal, it is not known how long the boiler will last, whether it will burn out quickly, and so on. Fortunately, I personally have a friend who heats his private house of 120 squares with this particular model - Poplar M20, the boiler has been serving for the second year and so far everything is fine. He burns with coal of the middle fraction, sometimes with wood (when the coal runs out).

Runtime without loading, coal or pellets?

It is stated that the boiler at full load can work up to 10 hours. In reality, this figure is slightly lower, and even if the furnace is completely loaded with coal. But 6-7 hours is not bad at all.

Is it possible to heat with pellets - you can often see on the forms and such a question from the new owners of Topol.The answer here is obvious - of course you can, this is how much money you will waste - a lot. It is several times more efficient and cheaper to heat with coal, and even coal of poor quality.

You can throw in huge pieces of coal (the main thing is to get into the furnace) and the boiler will heat and heat. Compare yourself - a ton of high-quality coal costs 3,500 rubles, low-quality - 2-2.5 thousand per ton. A ton of pellets - as much as 6,500 rubles. The difference is already 2 times!

Boiler pluses

- Undemanding to the quality of coal - a very unpretentious boiler, you can load any coal without problems. This is really a very big plus, because it is not always possible to get a particular type of coal. Here you download any - small, large, etc.

- Of course, the price is low. The cost is 35 thousand rubles - more than budget with good quality.

- Possibility to install a thermostat (there is a special fitting for it) - to improve draft and increase the boiler burning time.

- The ability to install an electric heating element is an additional option, the price depends on the power of the unit. For example, for 6 kW the cost will be 6000 rubles, for 15 kW - 7600.

Cons of the boiler

There are many disadvantages of Poplar boilers, but they all stem from the cost - the boiler is budgetary and there is nothing to expect super-results from it, as from boilers costing 2-3 times more. Steel 3 mm, for such a price this thickness is exactly what it should be.

Smokes - there are a lot of comments precisely because the boiler smokes when you open the door to load the next portion of fuel. This can occur both due to poor draft (a problem in general for all boilers), and due to the diameter and height of the pipe, due to the fact that the pipe is not insulated.

Well, and most importantly, it smokes due to the fact that the design of the chimney is such that the chimney pipes inside the boiler coke (they are small in diameter - 50 mm and there are 8 of them) and they need to be cleaned often. So an indispensable attribute that will come in handy for using the Poplar boiler is a metal pipe brush.

The shurovka grate will sooner or later all burn out, because there is direct contact with the burning coal, as a result - it becomes red-hot and slowly but surely burns out. Although it has a thickness of 1 cm, it is not known how long it will last when fired with coal.

User reviews

Here we have summarized the responses of the people so that you can understand how the boilers generally work.

Winter, outside the window -23. At 7 in the morning I fall asleep a bucket of coal, the temperature is 70 degrees, I don't do anything else. Around lunchtime, the temperature in the pipes is already 40 degrees. After lunch, I throw in another bucket of coal - the heat sets in)) I like the boiler because it is unpretentious to the quality of coal, we have nowhere to take selected coal, the quality is so-so. Yes, it does smoke, but it is not critical, the average burning time on a bucket of coal is 8-9 hours.

The second review from 2020 - fresh useful information directly from the user (3 years!) - (to enlarge the text, click on the picture)

As you can see, in the category of budgetary TT-boilers, Zota Poplar M20 occupies a noticeably high position, many put it, because the price-quality ratio is quite good. If you have the same boiler, we will be glad to see your feedback in the comments.

More reviews on boilers:

- Combined boiler Teplodar OK 15

- Gas double-circuit heating boilers and prices for 2020. The most bought models and their review.

- The Vira Armada 20 boiler is a wood-fired boiler with a water circuit. What is good about the reviews of the people.

- Review of the solid fuel boiler Teplodar Cooper Pro 22

By Blogsdna

Heating system with solid fuel apparatus

The use of devices of this type, although in demand, is not as popular as gas. This is due to the need to constantly add fuel for solid fuel boilers and monitor the operation of the device.However, there are several ways to simplify the operation of a solid fuel boiler:

- Automatic fuel loading

- Turning on the device together with the electrical

- Automation of water supply

The first is easily done by connecting pellet equipment to the heating system. In it, the fuel supply is carried out automatically and human participation in this process is not required. Such heating of a private house with a solid fuel boiler is permissible even in the case of non-permanent residence in it.

The second method is considered the cheapest in terms of labor costs and the most popular. In the primary ring of the system, two devices are connected in parallel. In this case, the electric only maintains the minimum water temperature. And the main source of heat is solid fuel.

The last method involves turning on the accumulator tank. It accumulates the coolant prepared by the boiler during the day, with the aim of its further consumption at night, when there is no manual fuel loading. Such a system can be automated.

Each of the schemes has the right to exist and the choice of the optimal one depends on various factors.

Kinds of kindling

Most of the devices of this type operate on various types of fuel:

- Firewood

- Peat briquettes

- Granules

- Anthracite

- Cox

- Brown coal

Moreover, their calorie content is different, and the effective operation of the device depends on it. Therefore, those who purchase such a boiler should take into account that when burning less high-calorie fuel, the power drop can be up to 30% (at permissible humidity) and even more at natural humidity.

There is one more nuance. Usually, the manufacturer indicates the best way to heat a solid fuel boiler and which fuel should be taken as the main one. It is advisable to comply with these requirements in order to achieve maximum efficiency and to make heating a country house with a solid fuel boiler as convenient as possible.

For example, when recommending to heat with brown coal, it should be used as the main one, and fine-grained fractions should be added only to the hot layer and in small portions.

Briquettes - can be peat, straw or wood. It is ideal to use only those that are produced by pressing. Briquettes disintegrating into sawdust may only be used together with firewood or brown coal, so as not to damage the boiler.

Pellets can also be made from straw or wood waste. They are pressed, like briquettes, and are most often used in special solid fuel boilers.

The consumption of firewood in a solid fuel boiler will be minimal if they are dry, only then it is possible to achieve maximum power from the boiler and extend its service life. Otherwise, the useful energy content of wood will be significantly lower.

Reviews of boilers from the Zota Master series

Solid fuel boilers "Zota Master", according to buyers, have a high degree of thermal insulation. The heat exchanger, which is built into the unit, is of a combined type. The case is insulated with basalt cardboard, and there are ventilation holes on the door trim, which are necessary to cool the surface of the device. Consumers love that the ash pan door has an air damper and a knob screw that can adjust the primary air flow.

It should be noted that the efficiency of boiler equipment depends on the degree of gas density, as well as on the design of the heat exchanger. When it comes to boilers of the "Master" series, they use a combined heat exchanger. It includes a tube compartment, which, according to users, has the qualities of reliability and is easy to clean. The manufacturer has provided for the installation of a mechanical regulator. The boiler is capable of operating in a semi-automatic mode. The assembly ensures the tightness of the door, as well as the accuracy of the adjustment.

The described solid fuel boiler "Zota", reviews of which are quite often only the most positive, has a combustion chamber, it is designed for the most efficient combustion of coal. The device can also use firewood. If you choose a unit with a higher power than the others, you can put 70 cm of firewood in it.

Experts recommend

The operation of a solid fuel boiler will be effective only if the correct fuel is selected for it, as well as regular maintenance of the device. And in order to determine for yourself how to heat a solid fuel boiler, and to achieve maximum efficiency, professionals advise:

- When striking wood, a large amount of smoke is emitted, therefore it is recommended to place larger logs at the edges, and small kindling in the middle

- The use of peat in densely populated areas is not recommended due to the release of large particles into the atmosphere and the release of a sour odor

- For the complete combustion of anthracite, a massive hearth is required, therefore, when it is used, when extracting the ash, larger fragments are sifted out and reused

How to properly heat the boiler

How to remove soot from a coal boiler

The soot contains a non-combustible residue that turns into slag during combustion. An additional problem is that, under the influence of high temperatures, low-quality coal leads to increased formation of condensate, an acid that can corrode the metal of the heat exchanger.

The boiler is cleaned in several stages:

- It is necessary to remove ash from the ash pan, the chamber located immediately under the firebox and which is a capacious box, closed by an airtight door. The ash pan is taken out, the ash is poured.

- Slag removal is performed with a special tool, the appearance of which resembles a curved awl. The build-ups are removed along the perimeter of the heat exchanger and from the grates.

In addition to regular cleaning of the boiler, measures are taken to prevent increased soot formation. The main reason why the heat exchanger becomes clogged with soot is the insufficient combustion temperature of the fuel. Layer-by-layer stacking of firewood mixed with coal can solve the problem of increased soot formation.

How to clean the chimney of a coal boiler

Correct operation of heating equipment includes measures to reduce the formation of soot in the chimney during boiler operation, as well as regular maintenance and cleaning of pipes. The SNiP stipulates the need for routine maintenance at least twice a year.

Pipe cleaning is carried out in the following ways:

Mechanical cleaning method - correct cleaning of chimneys is carried out with a special brush. Flexible plastic rods are set on the rod. If necessary, the brush can be extended by means of connectable flexible strips. Cleaning is carried out from the roof and the soot is removed through special inspection chambers. The largest layers of soot accumulate on bends and chimney adapters

During cleaning, they are given the most attention. Cleaning chemicals - available as fuel additives. It is enough to place the bag in a burning coal to effectively clean the chimney

Chemicals are used as preventive measures and cannot completely replace the need for mechanical cleaning. Reduction of soot emissions from coal combustion. Preventing the formation of soot is the best measure for controlling flue wall deposits. As a preventive measure, several methods are used. A soot trap is installed, the required coal combustion temperature is provided, the chimney design is changed and a deflector is installed to improve the draft characteristics.

All of the above measures are aimed at maintaining the operability of both the boiler itself and the chimney.Acidic condensate leads to rapid burnout of the heat exchanger and chimney.

Correct operation of a coal-fired boiler includes: competent choice of fuel, kindling and maintaining combustion in the chamber, preventing increased soot formation and regular maintenance of the heating unit and chimney.