The need for a sensor

For a stable temperature with electric floor heating, it is necessary to maintain a certain time frame for disconnecting and connecting the electricity supplied to the heating elements. For this, when installing a warm floor, it is necessary to mount a temperature sensor in the warm floor.

Timely installation of the temperature sensor allows you to solve many issues. In the absence of such a sensor, it will be very difficult to maintain a comfortable optimal temperature, and an overconsumption of electricity is also possible, which will entail additional financial costs.

In the event of overheating of certain floor coverings, such as carpets, laminates, fumes that are harmful to health can be emitted.

Laminate flooring has the potential to deform due to overheating. If the sensor is installed in a floor heating system, these problems are removed automatically.

There are many different photos of the underfloor heating sensor on the Internet. Based on the many choices available, you can find the best option for your system.

Which means high power consumption

If the comparison of the values showed a large power consumption, this indicates that there are short circuits resulting from a violation of the integrity of the insulation of the wires. In this case, part of the floor will be very hot, and the other will not work. In this mode, the entire system will not work for a long time, and at the same time a lot of electricity will be consumed, which, of course, is uneconomical.

Electric mats power

This problem can be solved only if it is possible to remove the topcoat. If the cable was laid under the screed, it will be impossible to do this.

What is indicated by low power consumption

If the amount of power consumption is much less than that indicated in the product passport, then this indicates an open circuit. In this case, the resistance will be very high, which can lead to cable burnout. It is possible to determine the place of the break if it is possible to remove the entire topcoat or to dismantle its section.

Measurement of the insulation resistance of a warm floor with a megohmmeter

Action plan:

- you need to disconnect the warm floor from the thermostat and the power supply;

- the break point is searched for using a high-voltage generator and an audio detector. The principle of operation of such a device is similar to a metal detector. It passes along the floor surface and signals a loss of current - this is the breakage point;

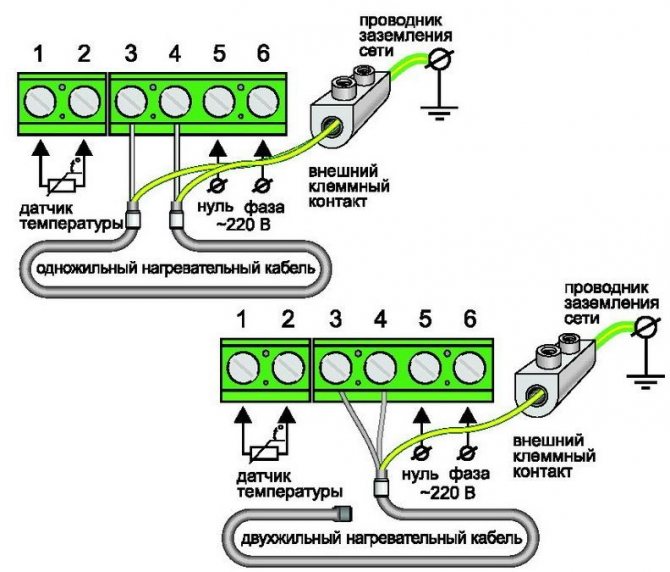

Diagram of a thermostat for a warm floor in the electrical network - revealing a break, the coating is dismantled in this place;

- damaged veins are stripped, connected with sleeves and compressed with press tongs;

- the heat-shrinkable sleeve is heated with a hair dryer, and when it cools, it shrinks and becomes a sealant for the restored wire;

- further, the installation of the floor covering is carried out.

Existing types of floor heating sensors

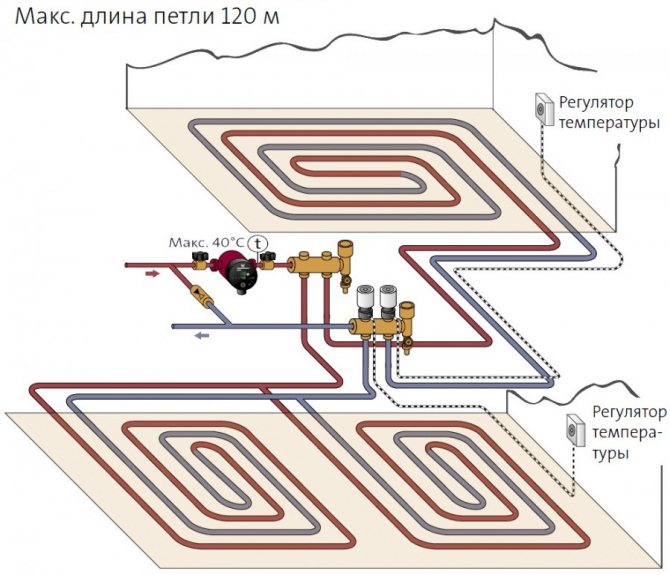

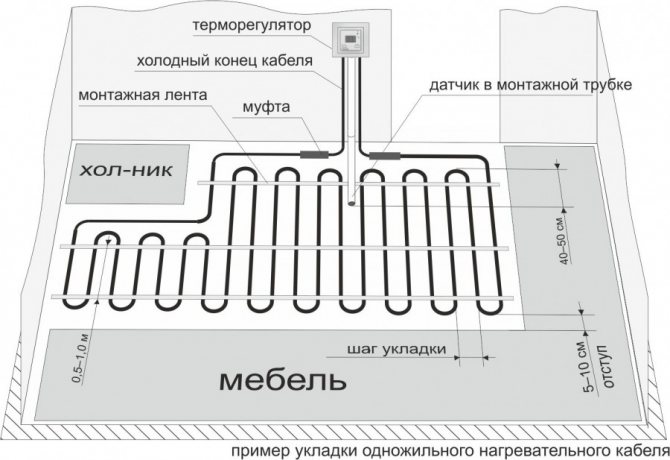

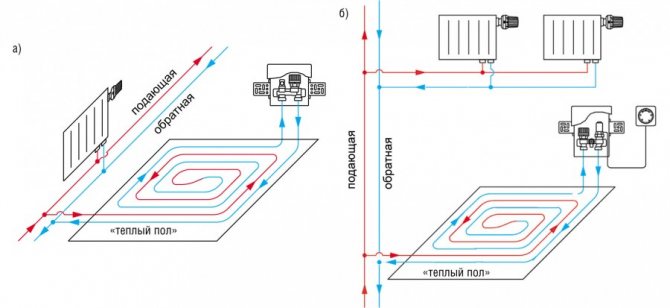

The underfloor heating temperature is controlled by a thermostat using a connected temperature sensor. It is positioned close to the heating elements, which contributes to a more accurate measurement of the ambient temperature. The existing sensors are divided into outdoor and indoor.

The outdoor sensor is designed to measure the room temperature, it is mounted close to the warm floor. The indoor sensor is placed close to floor screed heating elements.

The instruction for the underfloor heating temperature sensor informs that the temperature sensors are classified depending on the coating under which they are planned to be installed.

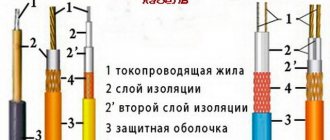

If you need to install them under linoleum, or laminate, or parquet, then a sensor is purchased in the form of a plastic cylinder with a wire. If the temperature sensor is mounted in a concrete covering, a screed, a device equipped with a protective shell is required.

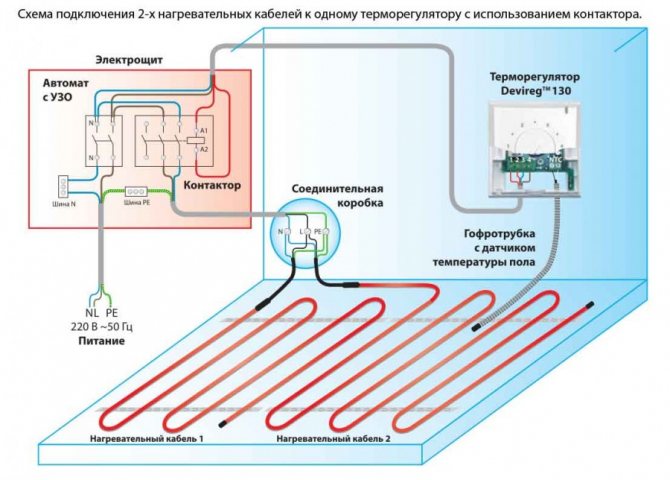

Connecting a warm floor without a thermostat to determine the health of the floor

The stoppage of the heat sensor may be due to breakdowns of the thermostat or warm floor. The performance of a warm floor can be checked by connecting it to a 220V network without a thermostat. After energizing, you must wait about an hour, if the floor becomes warm, then the cause of the malfunction is the thermostat.

When connecting a warm floor in this way, the system will operate at full power, and when heated to the set temperature, it will not turn off. In addition, electricity consumption will also increase.

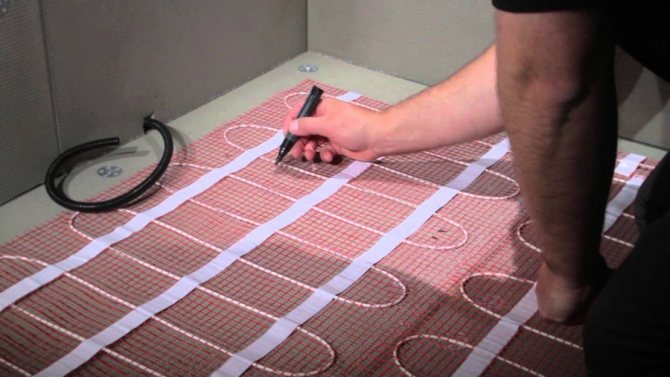

Installing sensors

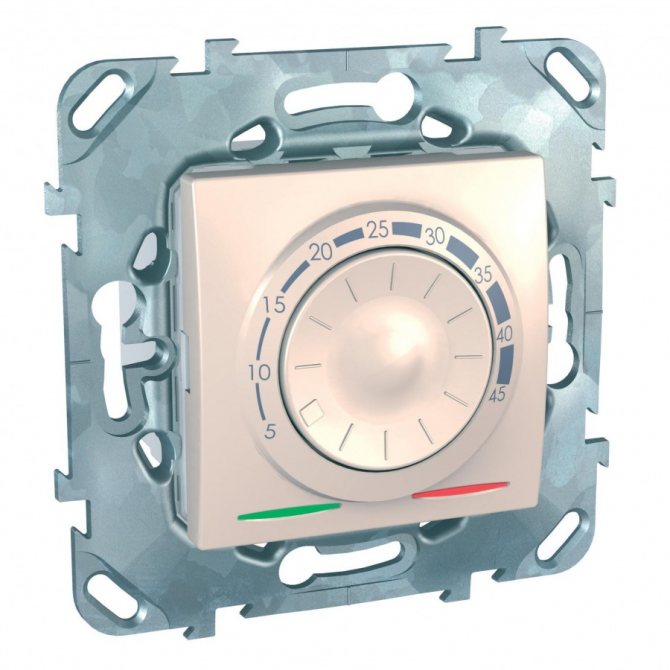

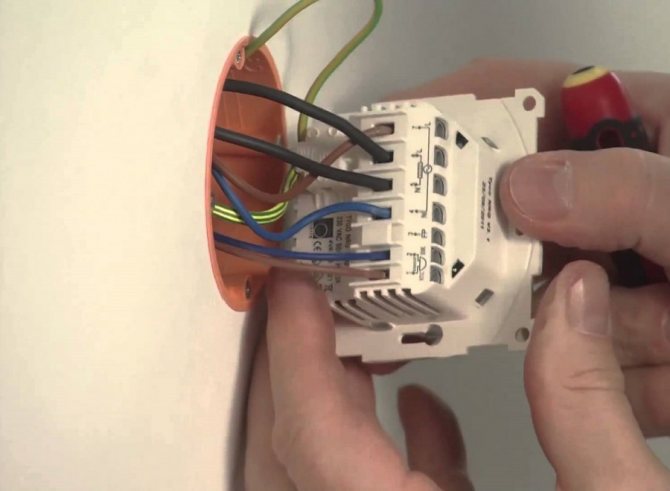

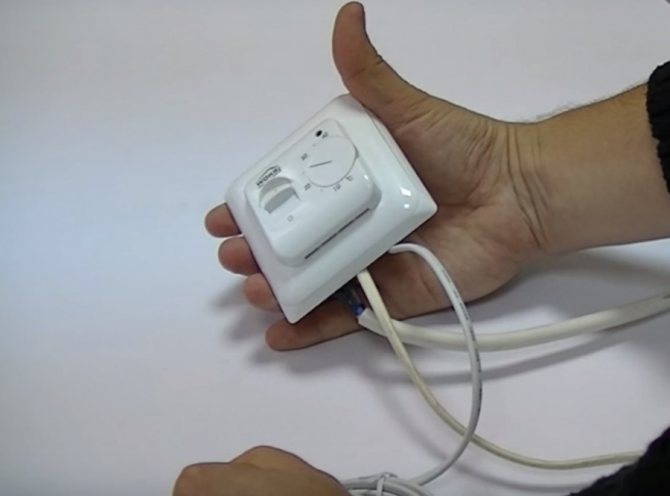

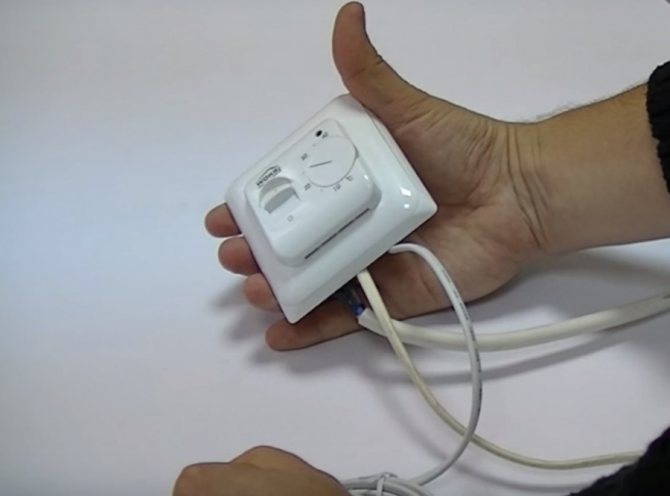

The sensors are installed to be able to automatically control the temperature of the warm floor. Therefore, it becomes necessary to connect the temperature sensor to the thermostat. It is precisely with the choice of a place for installing the thermostat that the installation process begins, directly of the temperature sensor.

The thermostat is installed away from other heating devices, these can be batteries, stoves, fireplaces, at a height of about one meter from the surface of the heated floor.

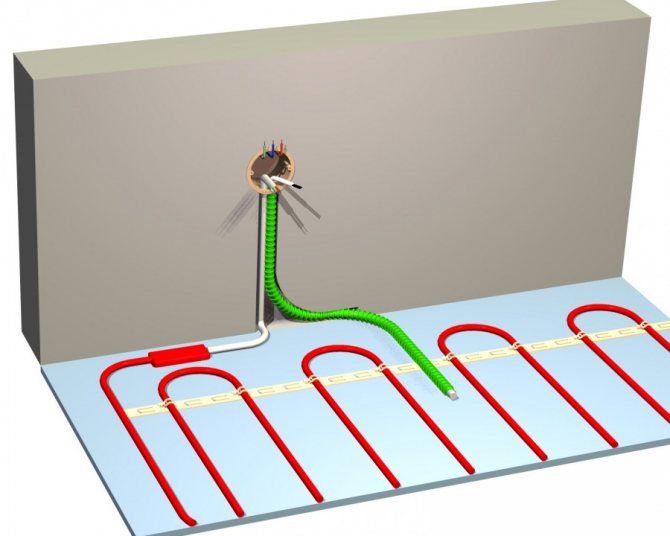

The mount is practically no different from a regular outlet. Next, two grooves are grooved, one for the power wire from the heating element to be connected to the thermostat, while the other is needed to connect the sensor.

The question arises of how to install a floor temperature sensor so that there are no difficulties in repairing it, if necessary. In order to avoid such situations, the electric wires are laid in plastic pipes placed in the prepared grooves, which will make it possible to easily make the necessary repairs.

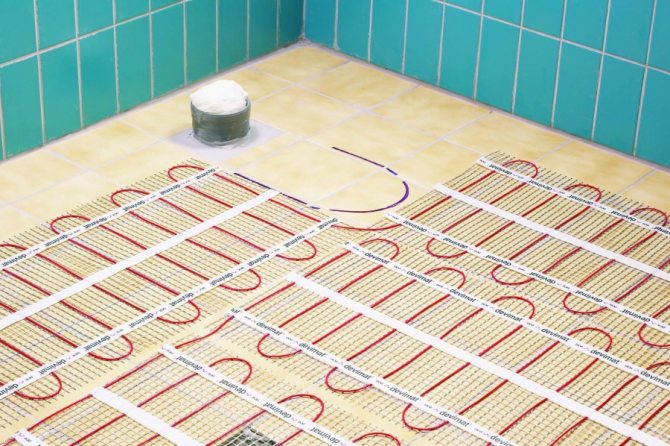

It should be borne in mind that the tube with the temperature sensor cable located on the floor should be located in the center of the gap, between the floor heating elements and about one meter from the vertical wall where the thermostat was installed.

The outlet of the pipe must be sealed with tape in order to avoid getting inside the solution. After installing the sensor, it is advisable to fix the pipe where the cable with the temperature sensor is located using available means.

If you are installing a film warm floor, then the sensor is installed under any sheet of the heater, having previously laid thermal insulation for the efficiency of the heating system.

Sliding gate operator - the choice of automation, the best materials for manufacturing and the characteristics of the operator

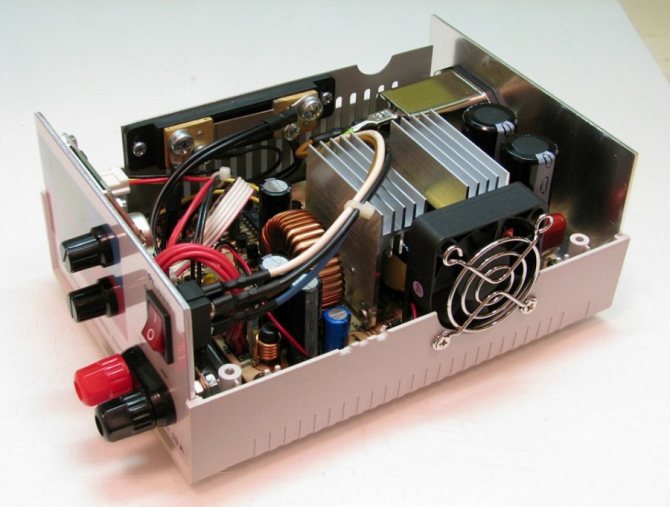

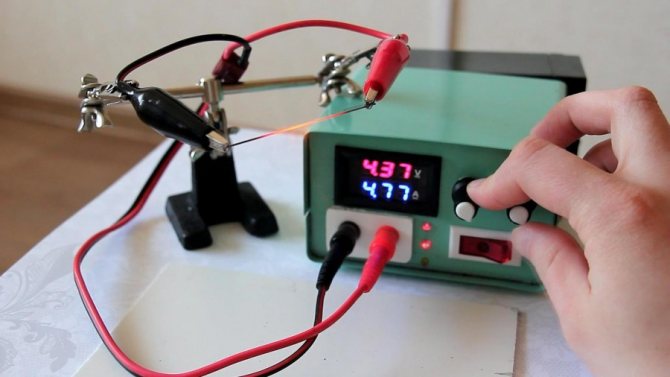

DIY power supply: step-by-step instructions on how to make a homemade, adjustable, universal and pulse model

Calculation of the cross-section of an electrical cable: formulas, tables, online calculator for quick and accurate calculation

System check

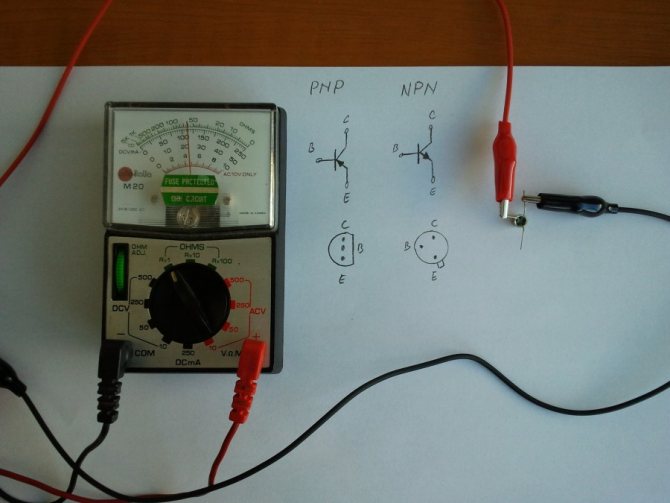

After finishing the installation of the underfloor heating system, before applying the screed, it is necessary to check its performance. If this is not done, then it will be almost impossible to make any changes when you have already done the screed. Pre-measure the resistance of the temperature sensor of the warm floor and its elements.

The operability is considered confirmed if the deviations of the resistance indicators are within no more than 10% of the declared passport data.

It is advisable to connect the thermostat to the mains using an individual line from the electrical panel.Having previously checked the electrical connections, the underfloor heating system is turned on for a short time to revise its performance.

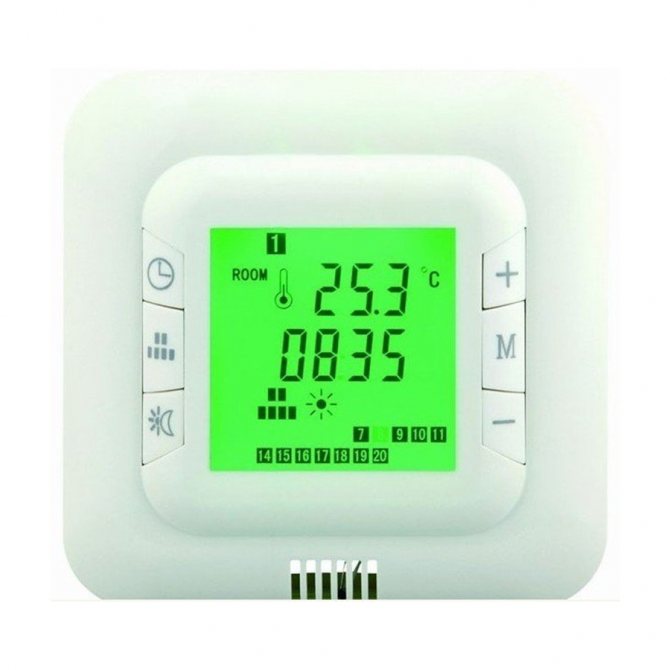

After switching on, the thermostat should respond with a light bulb signal, while heating the elements of the warm floor at the same time.

Why and in what cases it is necessary to measure the resistance of an electric floor heating

Resistance measurement is the most effective way to check the health and efficiency of electrical heating systems.... Knowing its value, you, according to Ohm's law, will be able to determine not only the electrical, but also the thermal power of the floor. The efficiency (efficiency) of such heating systems is close to 100%, respectively, almost all consumed electrical power is converted into heat.

You just need to compare the resulting values with the indicators declared by the manufacturer of the system, or, if they are unknown, with the average standard values, which I will discuss below, in order to find out if the floor works correctly and if it works at all.

Measuring the resistance of an electric floor heating is a mandatory step in its installation... Manufacturers recommend measuring this indicator:

— before installation, as soon as you remove the heating cable kit from the box. So you can make sure that it is in good working order, and its characteristics coincide with those stated in the passport or on the package;

— before pouringwhen the elements are surface mounted. It is during the installation of mats or cables that the probability of damaging it is maximum. Therefore, before filling it with a screed, tile glue or other solution, you need to make sure that the parameters have not changed;

— After the completion of all work, just before connecting the thermostat. Often, the installation of a thermostat is not done immediately, but only at the final stage of repairing the room, when a lot of time has passed since the installation of the mat. Therefore, you need to make sure once again that it is serviceable and can be connected to the network;

In all three cases, the resistance values must be the same!

Also, measuring the resistance of an electric floor heating is the main and most accessible method for diagnosing its operation... Yielding in simplicity only to the dialing tester, but giving incomparably more information. If, in addition to this, you check with a megohmmeter for possible current leakage, you will be 100% confident in the operation of the heaters.

Replacing the sensor

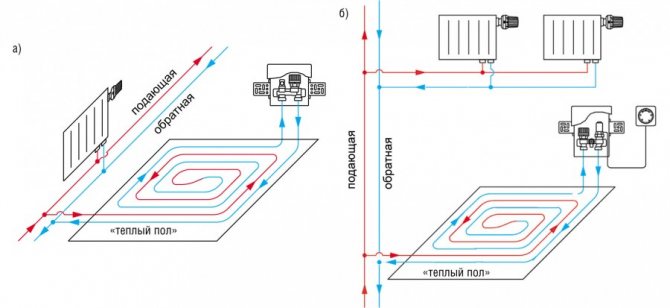

It happens that a situation arises when the underfloor heating system stops working. In this case, the question arises of how to check the floor temperature sensor. The reason can be found out using the diagnostics carried out by the tester.

DIY welding machine: simple instructions for creating and using the device

Checking the transistor - instructions for various types and rules for connecting a multimeter (85 photos)

DIY power regulator: calculation of characteristics, connection diagrams, assembly and verification (instruction + video)

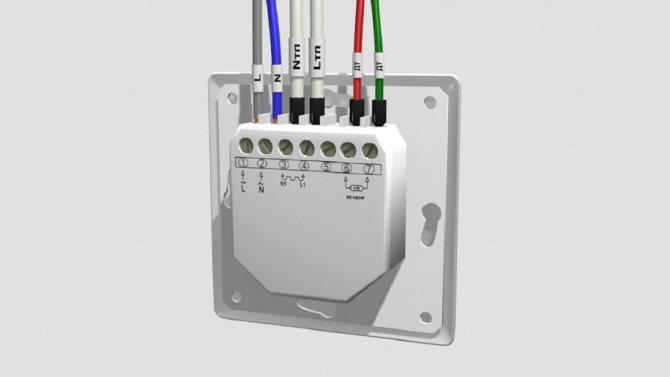

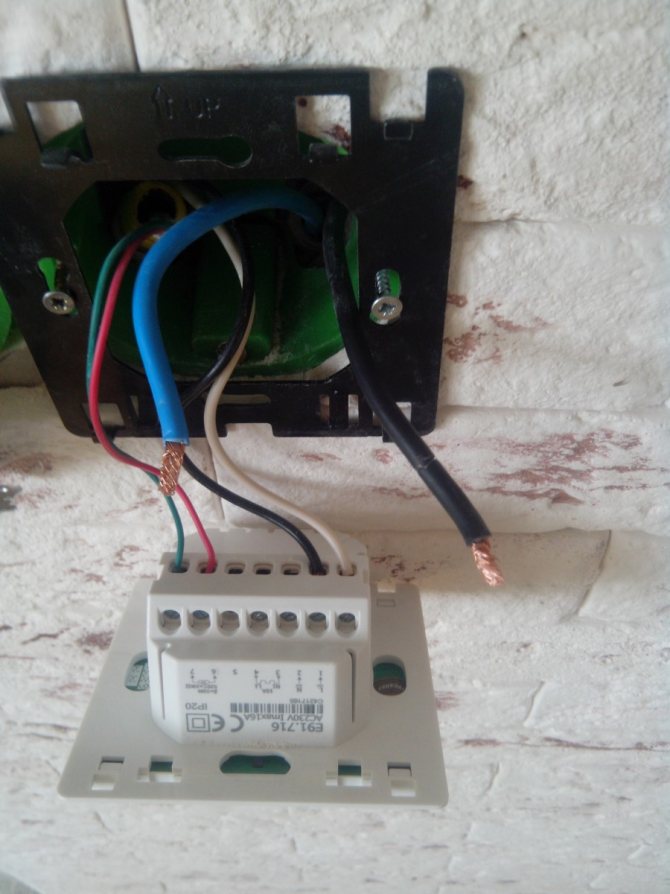

First you need to check the input wires, this can be done by disassembling the regulator body. Turning on the power supply, use a tester to check the voltage. If it is absent, all elements are checked, up to the output contacts. The wires of the thermal elements are disconnected from the de-energized regulator and further check is carried out.

The resistance, directly of the sensor itself, is checked with an ohmmeter. In case of its malfunction, it is not repaired, the sensor is dismantled and a new one is installed.

When installing the underfloor heating system, you can make sure that installing the temperature sensor and connecting the temperature sensor with your own hands is an easy task.It will be much more difficult to install thermal control equipment if it was not installed in a timely manner, along with the installation of a warm floor. But in this case, the situation is fixable.

With a temperature sensor, the entire underfloor heating system has the ability to work correctly and create a comfortable microclimate in your home.

Temperature sensor malfunction symptoms and steps to replace it

In addition to stopping the operation of the system, a malfunction of the temperature sensor is signaled by the flickering of a red light on the panel or its color changing to green when turned on. A fault warning may appear on the display. And you will have to replace the underfloor heating sensor with a new one with your own hands.

This is not difficult at all if you follow the order of actions:

- Dismantling a faulty sensor begins with a power cut.

- The device is then disconnected from the wires connected to the terminals on the rear panel. Their location may be separate from the pad clamps, but they can be easily identified by the “sensor” label next to them.

- The resistance of the disconnected sensor is checked. It should be indicated in the device passport and is usually in the range of 5-15 kΩ. If the real resistance corresponds to the passport, the malfunction is hidden in a bad contact.

- For complete confidence, it is worth reconnecting the wires to the terminals. If the sensor works, but its resistance differs from that indicated in the passport, and the difference is more than 20%, the device needs to be replaced.

- It must be removed from the corrugated tube and placed there a new device with wires connected to it to the same length as the failed one.

Photo of underfloor heating sensors

How do I charge the battery correctly? Step-by-step instructions with photos, videos and useful tips on how to restore charge at home- Insulating tape - the best insulating materials, their properties, characteristics and application features

Backlighting of the apron - features of lighting the working area and the choice of optimal light sources (110 photo ideas)

Read here! How to connect an LED strip: basic installation methods and connection options (85 photos + instructions)