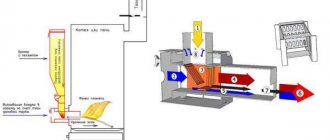

Intensive use of the chimney leads to clogging. The cross section decreases, the combustion products cannot pass quickly. As a result, the thrust decreases, the device starts to work in heavy duty, and the efficiency decreases.

To prevent the accumulation of soot, and the boiler functioned normally, the chimney must be made of appropriate materials according to well-executed drawings. In addition, it is very important to correctly calculate the diameter and section.

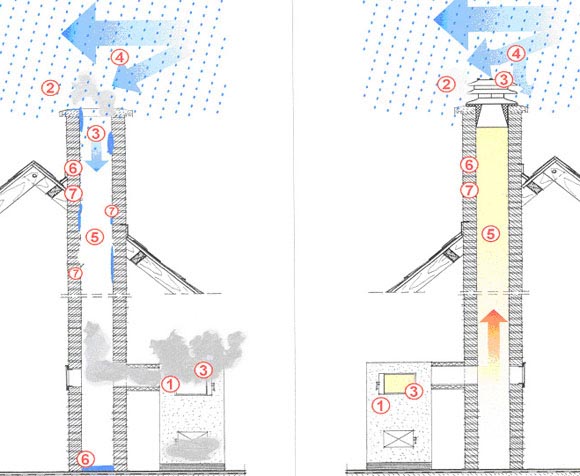

Thrust

When the system has insufficient traction, poor fuel burnout occurs. The result is the formation of soot. It gradually clogs the pipe passage, reducing its cross section.

You can, of course, achieve an increase in traction by increasing the cross-section of the chimney. But this will not lead to a positive result. The heat from the boiler will simply leave the room through the pipe. In order to be able to regulate the draft, the boiler is equipped with special dampers.

The appearance of draft is based on the difference in temperature between the room and the environment. The thrust becomes maximum when the cold weather sets in. A small temperature difference is enough so that the combustion products do not settle on the surface of the pipe, but go into the atmosphere. This can happen under one condition. The chimney must be properly designed and installed.

When the boiler starts to work, outside air is supplied to the combustion section. Thanks to this, the combustion process is supported. The exhaust gases are directed into the chimney and are rapidly thrown out.

With an insufficient pipe diameter, exhaust gases begin to accumulate inside the furnace. As a result, the hearth begins to fade, and there is strong smoke in the room.

The thrust force depends on several factors:

- Pipe length.

- The presence of turns.

- Bends.

For example, the presence of a right angle in a structure greatly reduces its permeability. This becomes noticeable when there is a decrease in atmospheric pressure. To remedy this situation, a special stabilizer is installed in the thrust.

Types and a short description of chimneys

Flue gas discharge devices differ into several types in terms of design and type of execution:

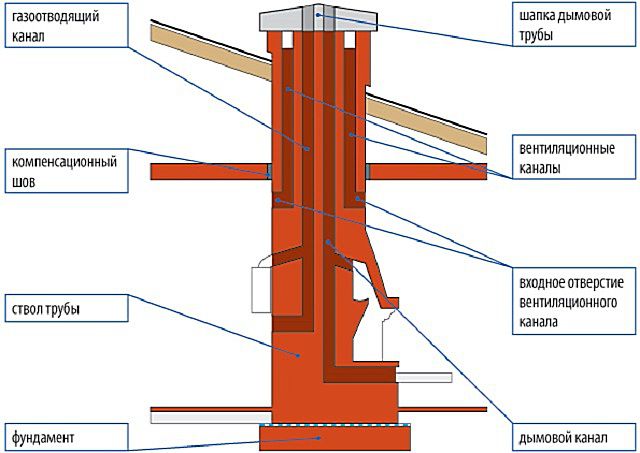

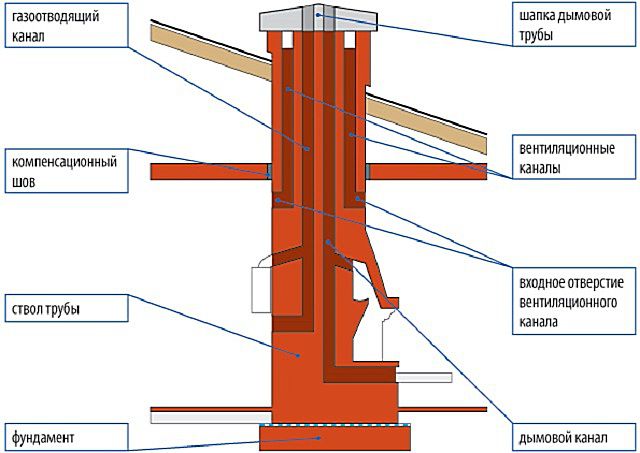

- Brick vertical ducts built into the inner wall of the house together with ventilation shafts. This also includes new types of built-in ducts - ceramic rectangular gas ducts.

- Chimneys attached to the outside of the wall of the house. Also made of red ceramic bricks.

- Vertical metal pipes running inside the building with access to the roof.

- Steel pipes for the removal of combustion products, located outside the cottage. They can be attached to a wall or to a free-standing lattice mast made of rolled metal.

In houses built of bricks or blocks, ducts for ventilation and removal of combustion products are provided in advance by the project. Most often, a brick chimney for solid fuel boilers is arranged in the inner wall of the building, adjacent to the furnace room. In older houses, you can find gas ducts attached to the outer wall and resting on a separate foundation.

The disadvantages of brick diverters are as follows:

- The inner surface of the brickwork consists entirely of irregularities and roughness, contributing to the intensive deposition of soot on them from the combustion of solid fuels.

- The rectangular design of the chimney has inferior aerodynamic characteristics in comparison with the round one and increases the resistance to the flow of gases, the force of natural draft is lower.

- Brickwork, attached outside the house, due to the temperature difference, begins to separate from the wall and a crack appears between them. If the extension was laid out later than the main construction proceeded, then the crack width may be even greater due to the foundation settlement.

- Condensation formed on the walls of the masonry penetrates into the pores of the material and destroys it under the influence of low temperatures of the outside air. The result is shown in the figure.

A vertical chimney made of ceramic bricks is quite suitable for connecting a solid fuel boiler, since it is durable and in good harmony with the exterior of a brick mansion. To eliminate its inherent disadvantages, it is necessary to modify the design of the gas duct or to execute it correctly at the construction stage, which will be discussed below.

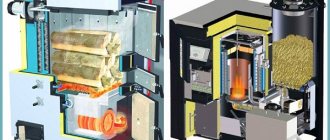

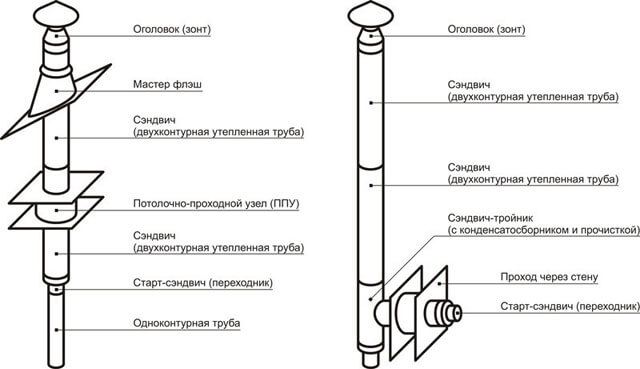

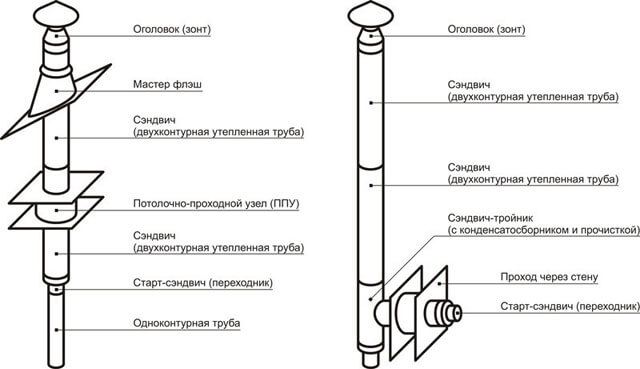

The construction of two steel pipes with a layer of insulation is a modern correct chimney. It is assembled from separate sections with a length of 1-2 m, which are lightweight, so even one person can do the job. The inner part made of stainless steel is smooth, soot does not settle on it, and condensate flows freely into the lower part of the structure, from where it is easily removed through a special pipe.

One of the latest technical solutions for the removal of waste gases is a metal coaxial chimney. The principle of its operation is that combustion products exit through the internal section, and air from the street enters the combustion chamber through the space between the walls. Such air ducts are allowed to be used in conjunction with heating units, in which such a possibility is provided. As a rule, these are installations with forced air injection and a closed firebox. To make sure of this, it is imperative to study the technical data sheet for the product.

Additional features of the chimney

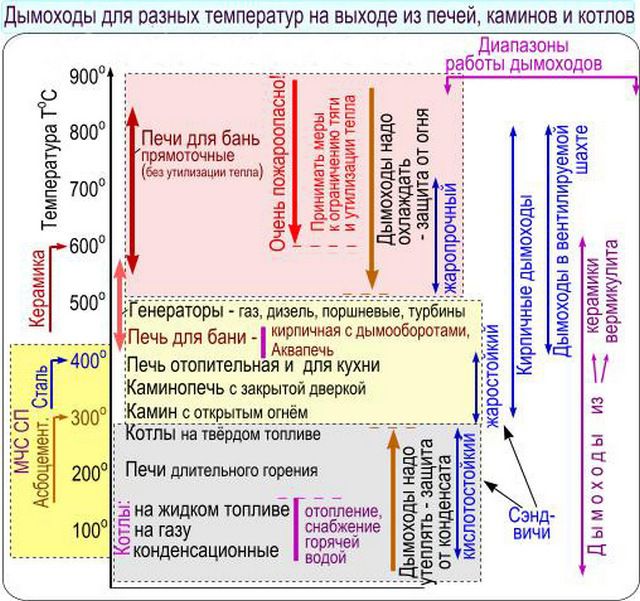

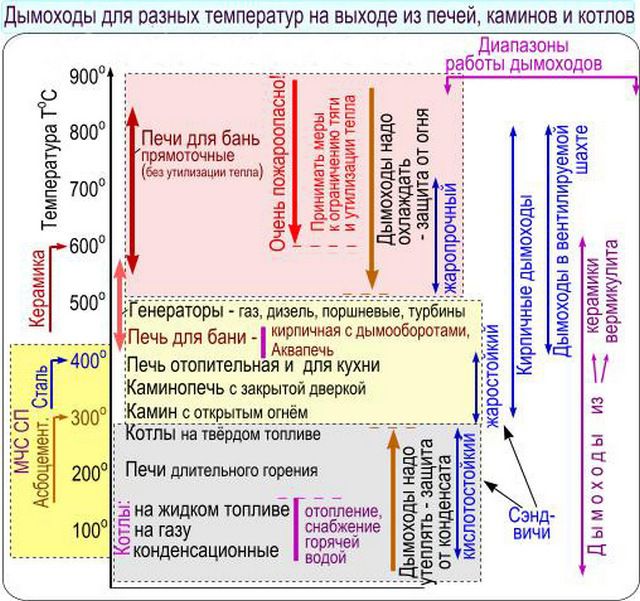

It should not react to high temperatures. Therefore, in a solid fuel boiler, a chimney is installed, made of especially heat-resistant materials. When coal or wood is burned in such a boiler, the smoke temperature is much higher than the gas combustion temperature. For example, the smoke temperature of a gas boiler does not exceed 200 degrees. When burning wood, the temperature can exceed 300 degrees. If the boiler is fired with coal, the temperature reaches 600 degrees. Sometimes there is a jump in temperature. It begins to rise when unpinning.

It is forbidden to strip the combustion chamber with solid fuel, gasoline, or other flammable substances. This option can cause soot to ignite due to a burnt-out chimney. It is strictly forbidden to try to remove dirt in this way.

Chimney selection

It is not easy to choose a chimney for solid fuel heating devices, since the materials for them and the options for execution are presented in the trade network in a huge variety.

To choose a specific chimney design, a number of important parameters must be taken into account, including:

- flue gas temperature - each material of its manufacture has its own temperature maximum, therefore, the degree of their heating should not exceed the set parameter;

- pipe gas pressure - today, each type of tubular product is designed to function at a certain value of this characteristic, implying natural draft or pressurization,there are also universal models on sale;

- presence of condensation - brick pipelines must be operated under certain conditions that exclude the possibility of condensation;

- corrosion resistance - there are 3 classes of resistance of chimneys to corrosive processes, but only two of them - 2nd and 3rd are designed for solid fuel units;

- minimum distance to easily flammable materialsthat can ignite from high temperatures - this parameter is indicated by the manufacturers in the technical documentation for the pipelines.

To find out some of the above parameters, it is necessary to calculate the chimney for a solid fuel boiler. It is advisable to entrust these calculations to an experienced design engineer of heating structures and systems.

How to calculate the chimney cross-section

When choosing, you must first measure the existing section of the branch pipe. It must be the same size. It is desirable that the sizes match. If the diameter is larger, there will be a drop in pressure, and the traction force will decrease. It is forbidden to operate two solid fuel boilers with one chimney. Each must be equipped with a separate pipe. With the correct selection of the diameter, as well as competently made installation, there will always be good traction.

Section size (sq. M) is determined by the formula:

volume of consumed fuel (m3 / s) / gas velocity.

The chimney can have a different cross-sectional shape:

- A circle.

- Rectangle.

For normal operation, you can use any option, however, a circular section is still much preferable. When the smoke moves inside the pipe, it spirals around. Any foreign part in the pipe creates opposition to the movement of the gas flow.

If the inner surface of the pipe is rough, the gas velocity will decrease. When smoke, in a circular motion, collides with a right angle, an abrupt change in trajectory occurs, mixing occurs. As a result, soot settles in the corners.

It will require constant, thorough cleaning.

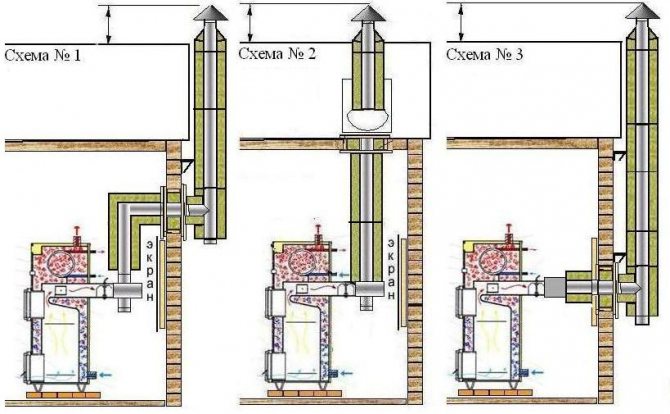

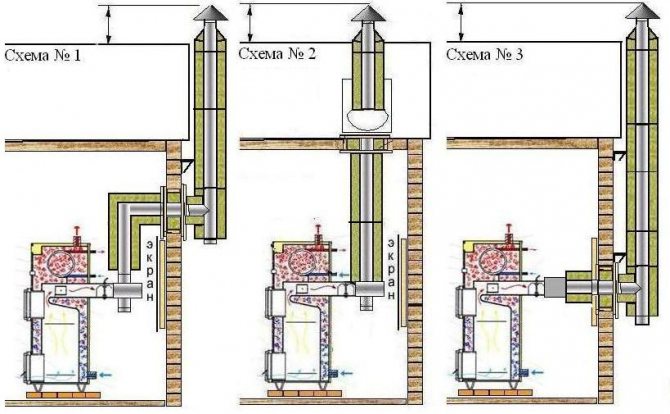

Mounting options

Craftsmen traditionally try to make chimneys round or oval. This section provides better gas evacuation. But when using some materials, you have to be content with a rectangular or square sectional shape. Most often, these options are resorted to when working with bricks.

Chimney calculated separately for each boiler taking into account the structure of the building. However, the basic design principle does not change. Its purpose is to provide good traction.

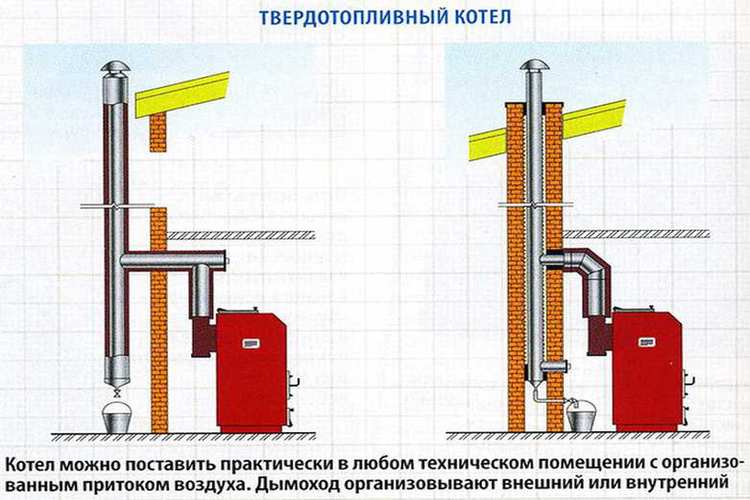

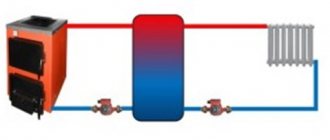

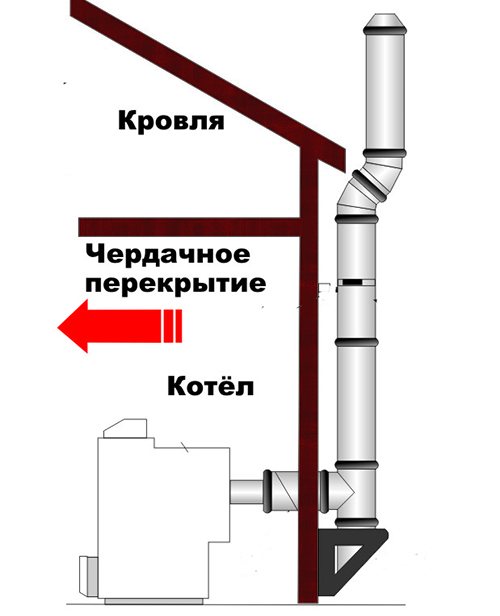

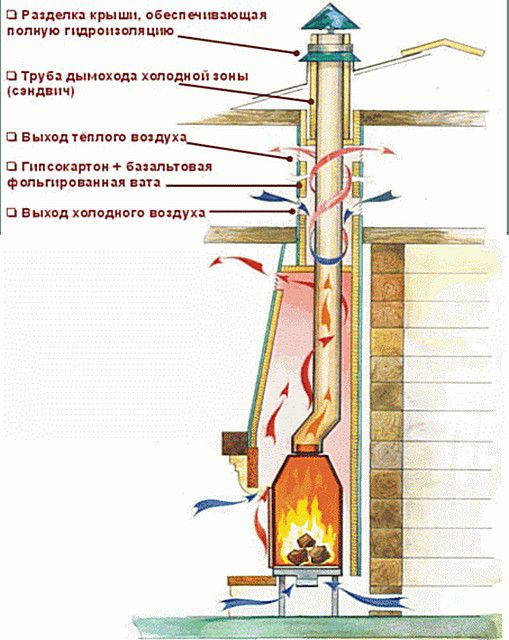

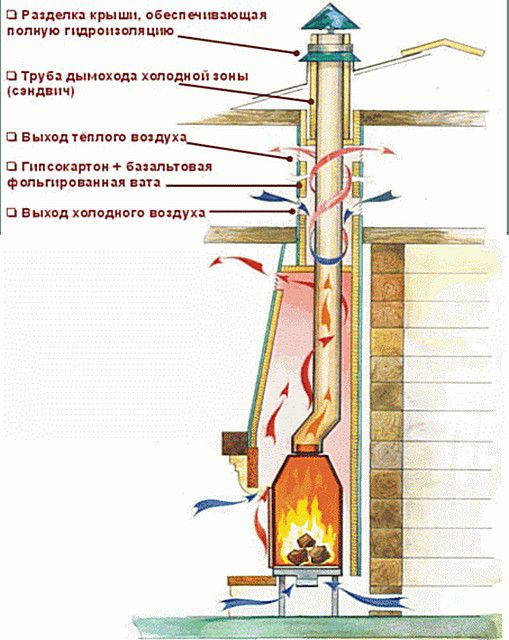

The simplest is a chimney with a straight pipe, passing through the ceiling, attic and roof. It has the simplest structure, which makes it as effective as possible. The walls of the chimney, when heated, additionally give off heat to the room. This solution is perfect for a two-story country house.

Another common option is a chimney, which exits through the side wall of the building and is attached from the outside. It practically does not occupy the internal space of the house. If the tightness of its walls is broken, gaseous products of combustion will not enter the premises.

The solution with a side outlet of the pipe has one significant drawback: the walls of the chimney quickly cool down. This means that condensation will accumulate on them. It also increases fuel consumption for heating your home.

What materials should be made of exhaust pipes

With a wide variety of materials, only a few types can be used for the operation of the chimney. The main ones are:

- Brick.

- Metal.

- Ceramics.

The most popular are pipes made of bricks. They are able to withstand very high temperatures. Its maximum reaches 1000 degrees. Today, on the roof of modern expensive cottages, you can see the original pipe made of Eurobrick.However, upon closer examination, you will notice that pipes inserted inside are visible from the brick chimney. They can be made of steel or ceramic. The explanation is very simple. One brick is not good for normal work. In other words, it will work, but not for very long. It will be quickly destroyed by corrosive condensation. Therefore, an insert is inserted into the brick pipe. Free cavities are filled with insulating material.

Sandwich pipes made of ceramics are able to withstand very high temperatures. It can exceed 1200 degrees. This value is much higher than the maximum smoke temperature after coal combustion.

Such a pipe is not afraid of condensation and any atmospheric phenomena. Condensate drainage takes place through a special cream hole. Sometimes for this, an additional container is made under the end of the watering can. The ceramic chimney is installed on the facade or inside the building.

The Schiedel Uni chimney, if soot ignites, is able to cope with this thermal stress. When burning, the soot heats up to a temperature of 1100 - 1200 degrees.

Disadvantages of ceramics

They do not differ in their beautiful appearance. Their cost is much higher than their steel counterparts. Installation of such pipes requires construction skills and experience. These pipes remain popular with low-income consumers.

Metal chimney

For its manufacture, use ordinary steel or stainless steel. Unfortunately, steel chimneys cannot withstand

aggressive environment. When the boiler is running continuously, the pipe will become unusable in a very short time, it can cause a fire.

The used stainless steel contains special additives consisting of several chemical elements

- Titanium.

- Nickel.

- Molybdenum.

It is they who save the stainless steel from corrosion. For installation

boilers use the following steel grades:

- 316.

- 316 L.

- 321.

They contain substances that allow steel to withstand temperatures in the range of 700 - 800 degrees. These steel grades are not afraid of condensation, they are neutral to acids, do not react with other aggressive substances.

The cost of a chimney made of stainless steel is available to the average buyer. It is considered the most suitable for installation in a solid fuel boiler.

Glass chimney

Very rare. Its positive qualities include:

- Low thermal inertness.

- Corrosion never occurs.

- Original look.

The cost of such a design is very high. Therefore, it is very rare. In addition, its installation is very laborious and costs a lot of money.

Features of the structural device of chimneys

The smoke coming out of the combustion chamber rises up in a spiral, while its speed increases. For this reason, they try to make the chimney as smooth as possible without turns, otherwise the trajectory of the combustion products changes and the traction force may deteriorate.

The cross-sectional shape of the chimney structure for a solid fuel boiler is of great importance. The optimal solution is considered to be a round or oval pipe opening, since then the most efficient removal of flue gases is ensured.

If, when arranging chimneys for solid fuel boilers, make the cross-section square or rectangular, then in the process of movement of smoke from the firebox, swirls are formed, the thrust force decreases, and soot and soot quickly collect. The selection of this parameter, as well as the length of the pipeline for the smoke exhaust structure, is carried out individually for the boiler, heating system and household.

Device and installation

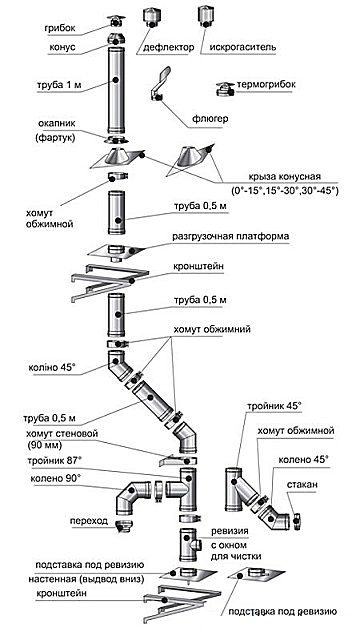

When the installation of a metal chimney is carried out, work begins from the bottom, gradually moving up. Pipes can be connected in several ways:

- By the movement of smoke.

- Condensate

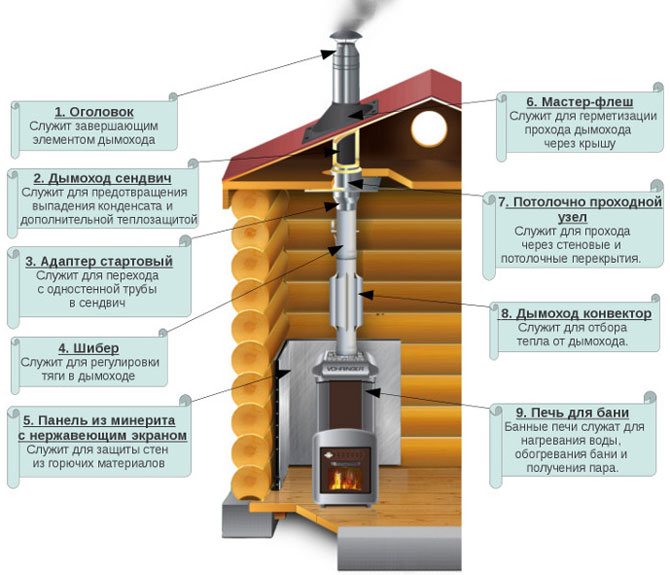

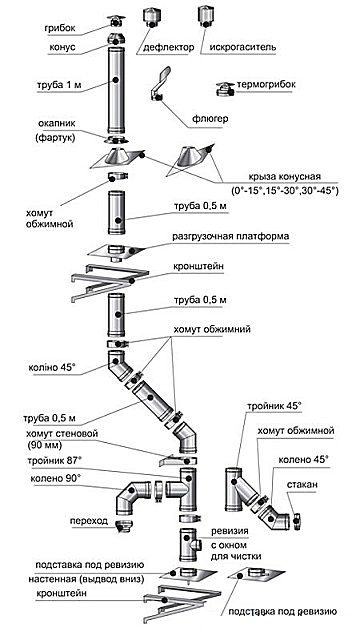

When the boiler is connected to the chimney according to the first option, the installation takes place from the boiler. The second option, on the contrary, is to the boiler. A metal structure consists of several parts:

- Glass.

- Sandwich pipes.

- Condensate collector.

- Spark arrester.

- Head.

- Cleaner.

To create a reliable connection the following are established:

- Adapters.

- Tees.

The joints are fastened with clamps from the outside.

Fire requirements

The operation of a solid fuel boiler is accompanied by the heating of exhaust gases to temperatures above 300 ° C. During the afterburning of soot, it can increase up to 1000 ° C. Naturally, in such conditions, without compliance with fire safety requirements, the likelihood of a fire is high.

In fire safety standards for chimneys the following requirements are indicated:

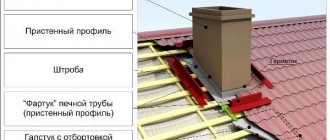

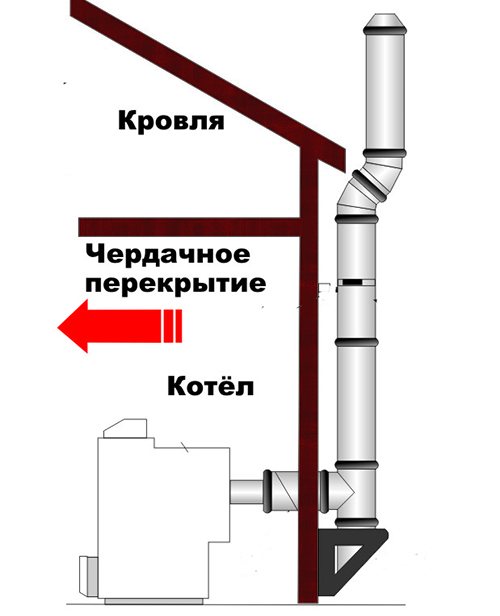

- When passing the chimney through ceilings and roofs, it is required to leave special gaps. If the structure is insulated, then the gap should be 50 mm. When using a steel structure - 250 mm. The gaps must be filled with non-combustible thermal insulation materials. If the pipe passes through concrete floors, then the breaks can be avoided. But when installing a chimney for a solid fuel boiler, a hole is cut in the stove that exceeds the pipe diameter by 10 mm.

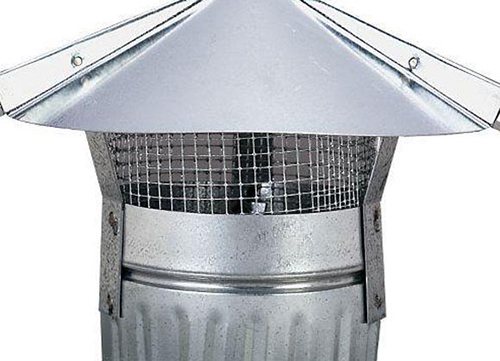

- If the pipe will exit through a bitumen-based roll roof, then a special spark trap must be installed. It is mounted directly on the head of the structure. This element does not affect the traction force, but excludes the ingress of hot fuel particles onto the roof.

- It is allowed to use only basalt wool as interfloor insulation. This mineral insulation does not burn or deform. The entire chimney should be insulated.

- The chimney is connected to the boiler outlet using a special adapter. If not, then you can use a steel pipe. When installing a smoke evacuation system in a wooden building, all adjacent surfaces are treated with fire retardants and covered with materials with appropriate characteristics.

- The length of the horizontal elbow for a solid fuel boiler cannot exceed 3 m. In cases where the horizontal section is longer than 1 meter, it should be installed at a slight angle.

- The chimney system must be installed at a distance of at least 1 m from the load-bearing elements of the building.

- Regular chimney maintenance is required: removal of soot and condensation.

- The pipe for a solid fuel heating boiler must be located at least 8 m from other buildings.

These requirements can vary significantly depending on the climatic conditions at the construction site. For this reason, before proceeding with the installation, you should contact the fire department for detailed instructions.

Technological requirements

The following technical requirements must be observed:

- A dedicated area must be provided to disperse the smoke. It is a vertical pipe installed behind the nozzle of a solid fuel boiler. The accelerating section is made one meter high.

- The chimney is installed only vertically. A deviation of no more than 30 degrees is allowed.

- The presence of deflections is prohibited.

- Length is very important (3 - 6 meters).

- Three horizontal sections are allowed. Moreover, the length of each should not exceed half a meter.

- The height of the head over the roof must exceed 100 cm.

- Fastening the pipe to the wall is carried out with a step of 1.5 meters.

- To create a sealed joint, the pipes are abundantly lubricated with a heat-resistant sealant.

To obtain ideal draft, it is necessary that the chimney design has a minimum number of turns. A flat pipe is considered the best.

The chimney can be installed inside or outside the building.For the first option, it is necessary to protect the pipe so that it does not come into contact with combustible materials. A special metal screen is used, installed in the place where the pipe passes through the ceiling. The chimney must be at a distance of more than 25 cm from the wall.

Outdoor structures look much safer. They are much easier to maintain. Masters consider this method to be the most preferable one.

Recommendations for the revision and arrangement of chimneys

It is better to improve the existing brick chimney for a solid fuel boiler by taking a number of measures. One of them, the sleeveing of the mine, is done with the aim of:

- change the rectangular section of the channel to a round one and thereby improve its aerodynamic characteristics;

- make the inner walls of the flue smooth to prevent soot from settling;

- additionally insulate the space between the round sleeve and the square opening and protect the material from the effects of condensation.

The essence of the event lies in the fact that a round metal pipe of the corresponding diameter is inserted into the rectangular channel along its entire height. On the side, 2 holes are cut out in it, one above the other, the first is for connecting the outlet from the boiler, and a hatch is mounted in the second - revision. To avoid the ingress of precipitation, the outlet is closed with a decorative umbrella, a deflector - a spark arrestor or a rotating weather vane. Insulation, usually basalt wool, is stuffed into the cavities formed between the round pipe and the rectangular channel.

The destruction of the material of the walls of the mine from the effects of condensate is possible by insulating them from the outside with plates of basalt fiber 80-100 mm thick. If the channel is located in the inner wall of the house, then it is necessary to insulate its upper part, which is located in an unheated attic and above the level of the roof. Attached smoke shafts should be lined with heat-insulating material entirely, sheathing the insulation from the outside with galvanized metal 0.5 mm thick.

Performing a brick chimney device in order to connect a solid fuel boiler to it, you can use modern ceramic materials. They are rectangular blocks with a circular channel inside.

From such blocks, the main shaft is mounted to remove combustion products, and from the outside it is lined with masonry made of decorative stone such as "bassoon" or another, depending on the exterior of the cottage. In this case, additional insulation is not required.

Since ceramic blocks and their installation are not cheap, a cheaper option can be used during construction - to make the same sleeve casing with a metal pipe with insulation.

Pipe height

This size is determined by SNiP, which sets certain parameters:

- If the roof is flat, the chimney should rise 1.2 meters above it.

- If the chimney is located near the ridge, and the distance is less than 1.5 meters, it should rise 0.5 meters or more above the ridge.

- When the pipe is located in the range of 1.5 - 3 meters to the ridge, it should not be below the ridge line.

- If the location of the chimney from the ridge exceeds 3 meters, its height should be on a line passing from the ridge, maintaining an angle of 10 degrees, relative to the horizon.

To determine the height of the chimney, a large number of indicators are taken into account. The parameters presented above apply only to gas equipment. To make an accurate calculation, you must use the services of a specialized company.

Conditions for reliable work

In order for the smoke exhaust system to work as efficiently as possible, it is necessary to take into account all possible factors that can interfere with the ideal operation of a solid fuel boiler and proper circulation inside such a device:

Diameter - one of the most important parameters, which is taken into account when erecting an exhaust gas removal system.The cross-sectional area of the pipe of the solid fuel boiler must match the cross-section of the chimney. The ideal shape is a circle, while the inner diameter should be as flat as possible. Even the smallest protrusions inside can significantly reduce the flow of hot gases and reduce draft.

Height - this parameter may be different and depends, first of all, on the power of the solid fuel boiler. A chimney that is less than 5 meters high cannot be installed according to regulations.

To accurately calculate the height of the boiler pipe, complex formulas are used, the averaged values for boilers of various capacities are given below:

| Power, kWt) | Diameter (mm) | Height (m) |

| 18 | 130 | 7 |

| 28 | 150 | 8 |

| 45 | 150 | 9 |

| 65 | 200 | 10 |

| 90 | 250 | 11 |

The higher the power of the solid fuel boiler, the higher the chimney, the cross section also increases in proportion to the power of the boiler.

Material - the pipe can be made from various materials, but the most suitable for this purpose are stainless steel, brick and asbestos pipes:

- Stainless steel - the smoke exhaust system made of such material is very convenient for installation. Such systems are made of stainless steel pipes, which are assembled after the boiler is installed.

- Brick - material that has been used for such purposes for many years. This material is also suitable for the chimney of a solid fuel boiler. The disadvantage of a brick smoke exhaust system is its high cost, the installation process takes a very long time.

- Asbestos pipe - a chimney made of this material is ideal when it is necessary to lay a pipe through the ceilings and the roof of the building. Asbestos is a fireproof material, but it has a significant drawback - high weight.

- Warming - this procedure is necessary to avoid excessive formation of condensation inside the metal pipe. Typically, the stainless steel kits sold on the market have a double construction, filled with a special heat-resistant insulation between the layers of metal. You can independently insulate a steel pipe using brickwork, inside which a chimney is placed. There is no need to insulate a metal pipe indoors.

- Bends - when installing a pipe, regardless of the material from which it is made, no more than 3 bends are used. If the smoke exhaust system has a greater number of curvatures, then the draft and the speed of gas movement through the pipe will significantly decrease.

Fire safety engineering

Installing a chimney is allowed in accordance with the requirements:

SNiP 2.04.05-91U.

DBN V 2.5-20-200.

NAPB A.01.001-2004.

Installation should only be carried out by professionals. The chimney cross-section must correspond to the value indicated by the manufacturer in the instructions supplied with the boiler.

The required chimney height is usually recommended by the manufacturer or must exceed 5 meters.

If there is a horizontal section, its length should not exceed one meter.

The design must provide for the possibility of condensate drainage, as well as cleaning the flue gas duct.

How to connect a chimney

All connections of parts to the nozzle of a solid fuel boiler are made with a heat-resistant sealant that can withstand temperatures in the range of 1250-1500 degrees.

When there is no correspondence between the diameter of the chimney and the size of the chimney outlet, an adapter is installed to create a tight joint.

How the parts are collected

Any single-wall, as well as a sandwich with insulation, are assembled with only one option: "the pipe is inserted into the pipe." The joints of the chimney parts do not require the installation of additional clamps.

If the structure is made of special, stainless steel, the assembly is carried out only by condensation. In this case, condensate, as well as the resulting tarry deposits, will never get outside, they will drain along the pipe walls directly into the condensate drain.

If a revision is used in the chimney and tees are installed, the assembly of all parts is performed "by smoke". The assembly of vertical parts extending from the tee is carried out "by condensate".

If it is necessary to make a sleeve for the channel, the gap formed between the pipe and the channel must be more than 4 cm. It is necessary when the metal expands during heating.

In order for the parts of the chimney sandwich to have a more rigid fastening, rivets are installed or self-tapping screws are screwed in.

Chimney fixation

The pipe is attached to the wall only with special materials.

The single-wall structure must be fastened with an attachment pitch of 1.5 meters on all vertical pipe sections.

If the chimney sandwich does not have a support structure, each element must be secured.

If the system uses a 45-87 degree tee, or a 45-90 degree elbow, the installation is carried out so that the load on the rotating parts of these parts is completely eliminated.

If an additional support is required for installation, use a floor stand installed under the revision.

When the chimney rises above the roof more than 1.5 meters, a bracket is mandatory installed under the stretch.

Passage through ceilings

To make a passage through the wall of a house or its overlap, it is necessary to use the building codes that are in force in Ukraine today.

If a sandwich chimney with insulation passes through wooden walls, a travel sleeve must be installed and another layer of thermal insulation is applied.

When the chimney is installed through the roof, the builders must install a special additional part of the pipe, the so-called "roof". Another additional layer is created, consisting of fireproof insulation materials.

The final stage of construction

When a brick chimney is wired, its upper part is closed with an additional part - an end.

Usually the top of the pipe is covered with a deflector or a beautiful fungus.

If the roof covering of the building is made of a fire hazardous material, such as bitumen shingles, a special spark arrestor is mounted on the top of the chimney.

If a gas boiler is installed in the house, installation of the deflector is strictly prohibited. According to current regulations, the top of the pipe of the gas appliance is always kept open.

Installation rules

From everything written above, we can conclude that in order to know how to make a chimney for a solid fuel boiler, you need to perfectly know the characteristics of the material used, have a clear plan of action and a pipe laying scheme from the boiler to the roof. To do such work yourself, and even without the proper skills, is almost unrealistic. It is much easier and safer to purchase a finished product in a store and assemble it or invite a specialist.

Here are some recommendations on how to properly make a chimney for a solid fuel boiler:

- Always mount structural elements from the bottom up.

- If you use tees, elbows, or other similar items, secure them with metal clamps. Make sure that the joints are outside the slabs.

- For tees, install support brackets.

- After every 2 m of the chimney, attach it to the wall, making sure that the chimney does not bend.

- Do not allow the channel to come into contact with any communications, be it a gas pipe, electrical wiring, etc.

- When you lead the chimney through the roof or ceilings, maintain a distance of 15 cm between the pipe with insulation and 30 cm - without insulation.

- If, when installing the chimney, you cannot do without creating a horizontal section, make sure that its length does not exceed 1 m.

- The diameter of the chimney for a solid fuel boiler must be calculated in accordance with the characteristics of the heating equipment (its capacity), the length of the channel and the characteristics of the building.

- When installing the chimney, take into account that the structure can deform due to regular temperature loads and changes. To avoid damaging the entire system, install a flexible adapter. If you did not install it for some reason, attach the pipe to the bracket not too tightly - leave a margin of 10-15 mm in case of temperature shifts.

- For roofs made of combustible materials, a spark arrestor must be installed on the chimney. You can buy it or make it yourself from a metal mesh with cells of no more than 5x5 mm.

In order for the chimney to serve you for a long time and not break down, make it a rule to look inside the pipe at least once every six months, check its condition and clean it if necessary. Finally, we suggest watching a video about chimneys for solid fuel boilers:

Chimney for a solid fuel boiler: installation of chimneys for solid fuel boilers

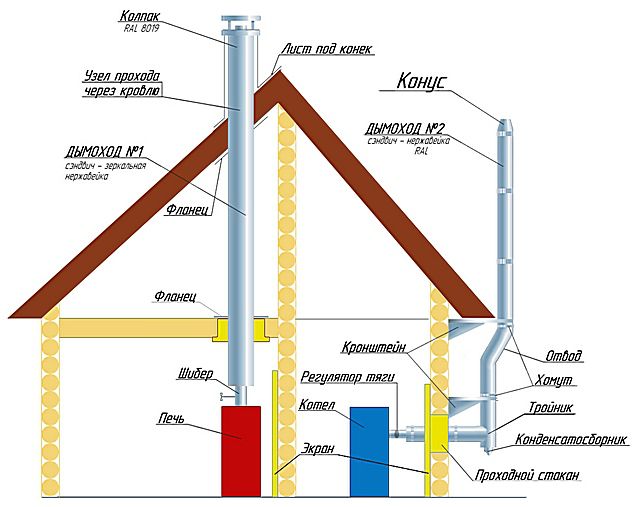

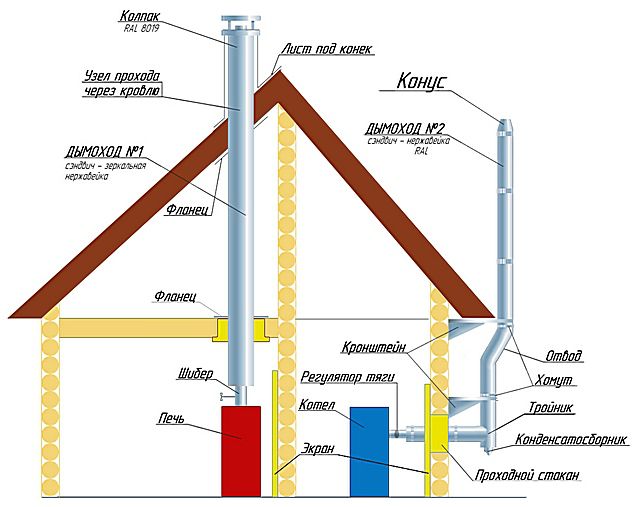

The chimney is one of the most important elements of the autonomous heating system of the house, without which it cannot function correctly and safely. It can be made of metal or ceramic pipes, or lined with bricks. Its main purpose is to remove gaseous waste from the combustion of fuel from the boiler, and prevent them from entering the premises of the house.

Chimney for solid fuel boiler

The chimney for a solid fuel boiler should be distinguished by increased efficiency and reliability, since the efficient operation of the heater itself, and therefore the temperature in the rooms, depends on it. In order for the process of removing gases to proceed normally, good draft is necessary, which determines the efficiency of the chimney system.

To select the correct chimney for a particular boiler, it is necessary to study the technical characteristics of the system, which will help you learn about its performance and quality.

Since the whole pipe structure is mainly aimed at achieving good traction, this property should be considered first.

What ensures reliable chimney draft

As mentioned above, good and consistent draft is the main requirement for any flue system. Draft occurs when there is a difference in temperature - hot air from the heating boiler rises upward, carrying with it the gases formed during combustion.

Other important factors affecting the intensity of the draft are the difference in pressure in the furnace and in the atmosphere, temperature differences in flue gases, the strength and direction of the wind, uneven combustion of fuel, and others.

The temperature regime in wood-fired boilers after the transfer of heat to the heating circuit can vary from 100 to 350 degrees, and with some high-calorie types of fuel it can reach even higher values. When the boiler is fired up, the temperature rises sharply, and in the transition to the standard operating mode, it stabilizes. All of these factors directly affect traction.

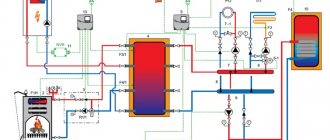

Diagram of the dependence of the type of heater, temperature in the chimney and the material of its manufacture

The presented diagram shows the approximate values of the temperature at the outlet of heating devices of different types, the corresponding degree of danger or vulnerability of various chimney systems, the recommended materials for the installation of chimney pipes.

In addition, it is necessary to take into account the design of the chimney - its length and size of the cross-section of the pipe, the number of bends and the presence of knee turns, as well as the degree of smoothness of the inner surface.

Optimal for good draft is a straight round chimney

If the chimney is straight, does not have turns and is narrowed towards the outlet, then the thrust in it will be as high as possible, since the hot air rises upward according to the principle of a spiral - additional turbulence of the flow is created.

If all the above parameters are not taken into account, then the removal of combustion waste will encounter obstacles in the way in the form of uneven walls and turns. This can lead to mixing of air and gases at different temperatures, which often leads to the opposite effect, directing smoke into the room. Therefore, when erecting a chimney, it is necessary to reduce or completely eliminate the device of bends and bends if possible.

Rules for the efficient operation of the chimney

For the safe and efficient operation of the chimney system, which is designed to create a comfortable atmosphere in the house, it is necessary to adhere to certain requirements for this design. These include:

- Ensuring stable traction, as mentioned above.

- Resistance of chimney materials to high temperature exposure.

- Protection against moisture penetration and condensation.

- Resistance to aggressive environmental influences and gases escaping through the channel.

Building codes indicate the following requirements for chimneys:

- The chimney must rise to a height of at least 5 meters.

- If metal parts are used for this element of the heating system, they must be made of stainless steel with a thickness of at least 0.5 mm.

- The diameter of the metal pipe must correspond to the size of the pipe of the metal boiler or slightly exceed it.

- The metal chimney should not have more than three turns or bends, and their radius should not be less than the diameter of the chimney.

- A brick chimney is more complex in its design, and consists of several chimney ducts. At the bottom of each of them there should be a chamber or pocket for collecting soot deposits. Doors are installed on each chamber, which make it possible to clean the channels while reducing the draft in the chimney.

All these requirements contribute to the rarefaction of the exhaust gases, the creation of good draft and, as a result, the efficient operation of the boiler.

Chimney designs

Since the smoke comes out best along a spiral trajectory, the optimal shape of the chimney for the chimney will be its round or oval cross-section, which will provide the most efficient exhaust of gases. When choosing a square or rectangular cross-section, it usually happens with brick chimneys, the draft is noticeably reduced, unnecessary air swirls are created in the corners and the smoke can even go in the opposite direction. In addition, much more soot deposits are collected on the inner surfaces of such a pipe.

For each specific building and heating boiler, individual parameters are selected, but the design principle remains the same, the purpose of which is to create good traction.

- A straight pipe that goes out through the attic floor and the roof has a simpler structure and is much more efficient in operation, because, when heated, it gives off heat to the rooms through which it passes. It is good to install a straight pipe in a two-story house, since the heat emanating from it will additionally warm the room on the second floor.

- The chimney that goes out through the wall and is fixed to it from the outside has its advantages - it does not clutter up the premises and is completely safe for the residents of the house, since if the gases discharged from the boiler leak out, they will not enter the living space.

Its negative qualities include the rapid cooling of the chimney, which means higher fuel costs. in addition, in such chimneys, the likelihood of rapid accumulation of condensate is much higher.

Video: types of chimneys and requirements for them

Since chimney systems can be built from various materials, each of them must be considered.

Brick chimneys

It is known that brick stoves with a chimney made of the same material are traditionally heated with wood and coal, so this type of chimney system can rightfully be considered a long-standing test of time.

Brick chimneys can have complex duct configurations

The internal structure of the furnace may include a fairly branched network of flue ducts - it depends on its design and the number of additional built-in functional elements. However, all channels always converge into a packing tube, which is a continuation of the furnace. In this part, a metal valve can be installed, with the help of which the gas outlet is regulated. A solid fuel heating boiler may well be connected to such a pipe already in the house.

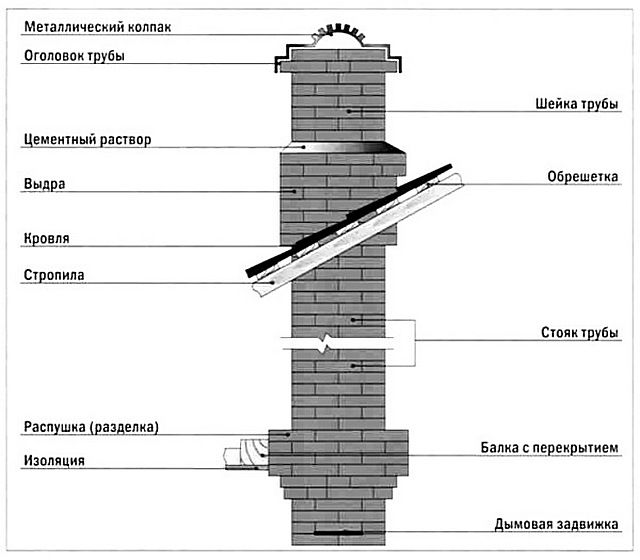

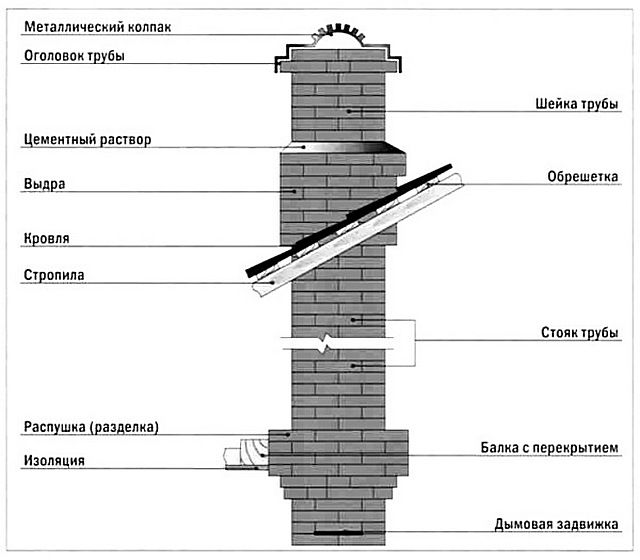

- The attachment pipe is laid out of bricks in a bandage, in accordance with the ordinal scheme of masonry. This part is not brought to the ceiling by 5-7 rows - the distance will depend on the height of the ceiling and the design of the heater.

- Next, the laying of the fluff begins - the expansion of the outer part of the pipe while maintaining the internal size of the chimney hole. The fluff plays the role of reliable thermal insulation of the chimney, in which a high temperature is created during the firebox, from wooden beams and other combustible floor materials.

Typical layout of a brick chimney

- The fluff can have a different number of rows - this depends on the thickness of the interfloor overlap, but it should rise after entering the attic or into the room on the second floor, at least one or two rows.

- Next, the riser is laid out - it passes through the attic or the second floor, and when approaching the rafter system, this part of the pipe expands again by half a brick. This area is called an otter and consists of eight to nine rows of masonry.

- The otter is designed not only to act as a thermal insulation of the chimney duct from the rafters and roofing material, but also as a barrier against the penetration of precipitation into the holes between the roof and the pipe walls into the attic.

- The otter is finished with a slope-like cement finish and flows into the neck of the pipe, which is the same perimeter dimension as the riser.

- The neck consists of six to seven rows of masonry, and then the final part follows - the head, consisting of two or three rows.

- To protect the pipe channel from the ingress of precipitation and various debris, a metal umbrella or cap is fixed on top of the head.

A brick chimney made of high-quality fire-resistant bricks can withstand temperatures of 800-850 degrees - that is, when used in conjunction with a solid fuel heating boiler, there is also a huge margin of safety. However, due to the fact that the channels of the brick chimney do not have an ideally smooth surface and a rectangular cross-section that is not optimal for the exit of smoke, soot deposits will be deposited quickly enough inside. Therefore, very often a metal pipe is installed inside a brick chimney.

Another very original modern method to optimize a brick chimney is to install a special polymer flexible hose made of a special material inside the channel. A typical example is FuranFlex chimneys. After the sleeve is stretched along the entire length of the brick pipe, it is filled with hot steam, creating the necessary pressure so that the FuranFlex expands over the entire cavity of the brick channel, giving it the required optimal rounded shape. Under the influence of steam, high temperature and pressure, the walls of the inflated sleeve polymerize within one and a half to two hours, creating a monolithic high-strength and heat-resistant channel, which is guaranteed to serve for more than a dozen years.

Refractory brick prices

Refractory brick

Video: poster demonstration of innovative technology "FuranFlex"

Metal chimneys

For the device of chimneys, ordinary steel pipes or stainless steel pipes are used. The first of them are used less and less, since they are very susceptible to corrosion from very aggressive environmental influences - changes in temperature and moisture. Therefore, more often nowadays, stainless systems are used, which are produced by many firms in any configuration.

Manufacturers of metal chimneys produce all the necessary parts for installing the system

- Such systems have a fairly high resistance to high temperatures, withstanding peak values up to 500 degrees - for a heating system boiler, this is more than enough.

Such chimneys work quite effectively for a long time, and are amenable to some adjustments if necessary. For example, when the pipe enters the furnace, a special element is installed - a gate, which allows you to adjust the draft to the required level.

However, if the draft is clearly insufficient, and no adjustments help to correct this moment, then you need to look for the reason in the poor-quality sealing of the pipe joints, as a result of which gases can leak into the room, or vice versa, a parasitic air leak is created, which reduces the draft in the boiler area.

After assembly, the very first test of the system may show signs of insufficient thrust. In this case, it is necessary to immediately revise the entire structure, since the appearance of carbon monoxide in the rooms is deadly to humans.

If the installation is done with high quality, taking into account all the rules, then the stainless steel chimney will become a reliable and safe option.

Metal chimneys can be installed both outside and inside the building

- Sandwich pipes are becoming a popular option for chimneys. Most often they are used when installing a chimney system outside the building. They do not need thermal insulation, since they have a heat-resistant layer of insulation material.

Chimney sandwich pipe structure

This type of chimney has certain disadvantages, which can sometimes be decisive when choosing a chimney.

- The sandwich pipe has a rather high price, especially some of the individual elements of the system. At the same time, the service life is relatively short - it is only 12-15 years.

- Over time, depressurization of the joints on the joints of parts is possible.

However, the advantages of such a design are still much greater:

- ease of installation and compactness;

- no condensation forms in such a pipe;

- ideally smooth inner surface and pronounced turbulence of the gas flow do not allow soot deposits to form on the walls;

- non-susceptibility of the pipe material to the influence of an aggressive environment and high temperatures;

- increased fire safety of such a chimney system.

Thanks to these qualities, this type of chimney system is becoming more and more popular. It, like a regular stainless pipe, can be installed inside the house or outside, fixing it to the wall with special brackets.

Before buying a metal chimney, it is necessary to make accurate calculations and determine its location in advance. It is enough to make a pencil sketch with the indicated dimensions, including the height of the wall, as well as the distance between the installed solid fuel boiler and the wall, and provide it to the seller or manufacturer. According to this scheme and according to the technical parameters of the heating boiler, any set of elements necessary for the assembly of the entire chimney system will be selected.

Video: installation of a solid fuel boiler chimney from sandwich pipes

Ceramic chimneys

Ceramic chimneys are very popular

Having installed a solid fuel boiler, it is quite possible to pick up a ceramic chimney for it, which is resistant to high temperatures, reaching 850-900 degrees, and is insensitive to their changes. It is especially well suited for long burning heaters. High-quality ceramics are fireproof and perfectly resist various negative influences, are not subject to active formation of condensation.

The inner surfaces of the channel are almost perfectly smooth, which prevents the collection of large amounts of soot. However, in low-quality products, the surface can be quite porous, and during operation it will absorb moisture abundantly, and therefore collect soot deposits. This can lead to the failure of the entire chimney, therefore, when purchasing pipes, you need to pay special attention to this point.

In addition to the resistance of ceramics to high temperatures, these chimneys have other advantages over metal or brick. These include:

- resistance to corrosive processes - ceramics does not enter into any chemical reactions;

- similar chimneys are suitable for all types of stoves and boilers operating on any fuel;

- the material is quite easy to process and fit the elements and their installation;

- by themselves, ceramic pipes accumulate heat well, thereby reducing fuel consumption;

- such chimneys, with proper installation, are watertight, due to the absence of numerous seams;

- high density and strength of the material, which will not allow gases to penetrate into the house through the walls;

- enviable durability - the operation of such a chimney can be carried out for 30 ÷ 35 years.

Usually, ceramic chimneys are of a multi-layer structure:

Multilayer structure of a ceramic chimney

- internal chimney duct - ceramic pipe;

- middle intermediate layer - heat-insulating fire-resistant material - usually mineral wool;

- outer, facing layer - a special chimney refractory figured brick. It can be solid or prefabricated - consist of separate parts.

After the installation of the entire chimney is completed, a special metal umbrella must be installed on top of it, which will protect against contamination from the outside and precipitation.

Video: example of installing a ceramic chimney

Special sets of ceramic linear elements are also available for quick and reliable assembly of the chimney system. Their design can imply an external rectangular shape and a round passageway inside, with thermal insulating air cavities between them. As a rule, the kit includes all the necessary parts - from the lower inspection window and the condensate drain pan, to the upper head and umbrella over the pipe.

Direct ceramic flue set

To choose the right chimney for a solid fuel boiler, you must definitely consider the characteristics of the most popular of them. An important point will be the price of the overall design of this system, as well as its durability and the degree of complexity of installation. Having evaluated all the parameters and compatibility with the type of boiler and the design features of the house, you can make a choice and buy the kit necessary for installation.

Manufacturing materials

Since the chimney during operation heats up to 500 ° C and above, its walls must be made of refractory materials.

These fully include:

- asbestos cement;

- brick;

- metal;

- glass;

- ceramics.

Each of these materials is good in its own way. But most often only 3 of them are used to create chimneys.

Chimneys are made of this material.

Brick structures

Brick has long been used to create smoke evacuation systems. It has proven itself perfectly in combination with traditional stone ovens. It is not surprising that they began to use it to create chimneys for modern solid fuel boilers.

The brick structure can have a complex configuration with many additional channels. But they all converge to one place: the tube. The boiler is connected to the latter.

- The packing pipe is laid out in accordance with the ordering scheme. It never reaches the ceiling. Usually a few free rows are left. Their number depends on the size of the boiler and the distance to the ceiling.

- The chimney attachment goes into the fluff. The latter is an expansion of the outer diameter of the pipe, but the inner size of the chimney does not change. The fluff is used to retain heat inside the system and to protect adjacent combustible materials.

- There is a riser behind the fluff. Its diameter does not change when passing through the floors and the attic. Only when approaching the rafters does the external dimensions increase again, but only by half a brick. The extended portion of the riser is called an otter. It protects the attic from precipitation that can penetrate the gap between the pipe and the roof. It also protects the rafters from the heat.

- At the top of the chimney system, the otter passes into a pipe that has the same cross-section as the riser.

- From above, the pipe channel is closed with a cap. It prevents sediment and debris from getting inside.

Brick chimney is also popular

Brick chimneys are very reliable... They can easily withstand temperatures up to 850 ° C. This is more than enough for a solid fuel boiler. Unfortunately, the inner surface of the smoke exhaust duct cannot be called even. Therefore, a lot of soot will accumulate inside. It is solved by the problem of inserting a metal pipe of a suitable section or a special polymer sleeve inside.

Metal chimneys

They are made of steel or stainless steel. Steel pipes are used much less often, since they are more susceptible to corrosion due to humidity and temperature extremes. Stainless steel is cheaper and lasts longer. In stores you can find a variety of configurations of such chimneys.

The main advantage of metal systems is that they can be modified if necessary... For example, a chimney damper can be installed inside the pipe, which allows you to control the draft.

Sometimes this element does not improve traction. This means that the problem lies in the insufficiently tight fit of the chimney joints. This is very dangerous, because carbon monoxide can start to penetrate into the room. However, such a problem is found out, as a rule, immediately after assembling the system, and it is not difficult to fix it.

Recently, the so-called sandwich chimneys... They are used when removing pipes through the wall. They do not need to be additionally insulated, since the thermal insulation is inside them.

Sandwich pipes have a significant drawback - a short service life. Add in the high cost and you end up with a not-so-attractive purchase.

Of the advantages, it should be noted:

- Smooth inner surface.

- Corrosion resistance of the system.

- Simplicity of arrangement.

- Compact dimensions.

Actually, because of these qualities, such a solution has become popular. Sandwich pipes are installed both inside the building and outside.

Ceramic products

Chimneys made of ceramics are the ideal choice for long-burning solid fuel heating boilers. They are able to withstand temperatures up to 900 ° C. Virtually no condensation forms on the ceramics.

The inner surface of ceramic pipes is not much inferior in smoothness to metal chimneys. Soot hardly accumulates in them. But this is only for quality products. Chimneys made of poor ceramics have a porous structure. This means that it constantly absorbs moisture and accumulates soot deposits. This will quickly lead to a malfunction of the system, therefore, when buying ceramic pipes, you need to pay close attention to the quality of the material.

The advantages of ceramics include:

- Corrosion resistant. This material is chemically neutral.

- Compatible with any type of TT-boilers.

- Ease of installation and processing.

- Good heat storage resulting in lower fuel consumption.

- Good tightness when properly assembled.

- Long service life.

Ceramic pipes are always three-layer... The inner layer is directly ceramics. The middle layer is insulation. The usual use is mineral wool. The outer layer is a special brick designed to create chimneys.

Frequent errors and problems during installation

The most common mistake is the lack of insulation of a single-layer pipe. Inside the house, this can lead to a fire of combustible structures and objects and burns to people. In the open air, the lack of insulation causes many very unpleasant consequences:

- combustible gases cool very quickly, the draft decreases, combustion products or even carbon monoxide can enter the room and cause people to be poisoned. During frost, even reverse thrust is possible - an extremely dangerous phenomenon;

- a very large amount of condensate settles on the walls, which leads to a rapid failure of the pipe.

It is impossible to mount the flue without a deflector or at least a hood - snow and rain should not fall into the head and channel.

It is necessary to provide for the access of the required amount of air to the boiler - there must be a special window constantly open in the boiler room.

The chimney must be straight. If absolutely necessary, inclined and horizontal sections with a length of not more than 1000 mm each are allowed and the total length of their projections onto the horizontal is not more than 2000 mm. The angle of inclination is not more than 30 ° from the vertical (45 ° is allowed).

The length of the chimney is increased by the sum of the lengths of the projections onto the horizontal.

If the chimney passes in the same place with the ventilation ducts, then it must be higher than the other ducts, the ventilation ducts must be covered with a cap located below the head of the gas duct. This protects against possible ingress of combustion products into the room.