To make heating the house cheaper, some work is carried out independently.

The filling of the system is carried out: after renovation; after draining the system for the summer; when replacing the coolant.

Each type of heating system has its own nuances, so filling can take place in different ways.

Odnoklassniki

Periodicity of coolant replacement

If in apartment buildings the coolant is drained annually, then in private ones it is not necessary. It should be assumed that the water that has already circulated seasonally in the system is prepared:

- does not contain oxygen;

- as a result of prolonged contact with internal surfaces got inertia, which became the guarantor of the preservation of the contour materials;

- all salts and chemical compounds that, when heated, turn into sediment and scale, already dropped out, and the water became circulating without chemical activity.

If there is no danger of freezing the system, it can circulate one more and even two seasons. To determine the need for replacement, the coarse filter is checked - if it is relatively clean, then the water does not need to be changed.

As for antifreeze, the qualitative composition of the technology is changing every 5-7 years... However, in practice, it has been used for much longer.

Types of coolant for filling the heating circuit

Several types of heat carriers are used for heating systems.

Water

Cheap universal coolant:

- if you fill in distilled water, then there will be no scale and sediment;

- does not change properties when in contact with internal surfaces;

- safe for people;

- can spin in the system almost endlessly.

Disadvantages:

- Expands and destroys pipes when frozentherefore, in cold climates, you will have to buy antifreeze.

- Metal pipes are starting to rust.

- When using tap water, a large amount of salt crystallizes, therefore have to buy distilled water... If the water supply is poured, it is recommended to regularly clean the main units and, if possible, pipes from salt deposits. The process is time consuming and requires special reagents.

Antifreeze

Represents water solutions of ethylene glycol or propylene glycol with additives.

Photo 1. Antifreeze for heating systems from the manufacturer Termagent. Withstands temperatures up to minus 30.

- Allowed for use in heating systems only antifreeze with a composition designed for this. This liquid cannot be used anywhere else.

- Freezes at temperature from -30 ° to 60 ° C.

- Ethylene glycol antifreeze is toxic.

- Human-safe heat carrier with propylene glycol is expensive and needs to be replaced every 5 years.

- The new formulation on the market contains potassium acetate and formate. Suitable for areas with temperate climates - freezes at temperatures below -5 ° С... The cost is a more affordable option.

The correct choice of heating medium requires careful attention and consideration of certain factors:

- Sometimes the boiler operating instructions indicate the permissible types of liquid and others cannot be used. Some foreign manufacturers generally exclude the use of antifreeze - the warranty is void.

- The material from which the main units and pipes are made - the system must be made of chemically resistant pipes and assemblies... Antifreeze is incompatible with galvanized iron, because it changes properties upon contact.

- Certain types of formulations do not heat up well and give off heatif they are used, the system is designed with this in mind.

- Heat carrier should not contain toxic and poisonous substances.

- Most efficient system fluid has a low viscosity.

- Some types of coolant are designed for industrial use only.

- Heat carrier cost and the permissible period of its operation.

Which coolant to choose

The most affordable coolant is water, but it is better not to use tap liquid for the heating circuit, it contains a lot of impurities that provoke pipe corrosion, accumulation of deposits and damage to the heating elements of the boiler. The water must be softened and purified; for this, special filters and chemical reagents are used. You can buy ready-made distilled water, it is affordable and will ensure safe use. For heating pipes filled with soft purified water, the fluid is replaced every 5-10 years, when the efficiency of heat transfer begins to decrease. Such a coolant can be drained at the lowest point of the system, where a special branch pipe with a valve is installed. Drainage of a safe liquid is possible into the ground at the site.

In a house with periodic living, winter temperature drops to negative levels. At this temperature, the water in the heating system will freeze, damaging the pipes. Antifreeze has become a replacement for the freezing liquid.

The synthetic coolant is produced on the basis of alcohols. It provides high heat transfer and frost protection during the cold season. The benefits of antifreeze include:

- high boiling point;

- minimal corrosive effect on metal;

- low freezing point.

Two types of antifreeze are used:

- ethylene glycol - the composition belongs to toxic substances, it cannot be poured into an open-type heating system. It is odorless, so it is difficult to spot a leak. The advantage of the substance is its affordable price;

- propylene glycol - the composition is safe for health and is suitable for use in open-type heating networks. The disadvantage of the substance is the high cost.

Once every 5 years, you will need to drain the ethylene or propylene glycol-based antifreeze with your own hands and replace it with a new one. The draining of synthetic compounds is carried out with extreme caution, and disposal takes place at special landfills.

Non-freezing compounds are sold in the form of concentrates, before pouring them into pipes, it is necessary to dilute the substance with water according to the manufacturer's instructions.

Preparatory work before injection of thermal fluid

Before filling the heating system, preparatory work must be done.

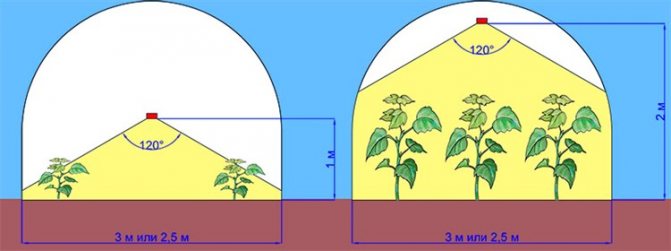

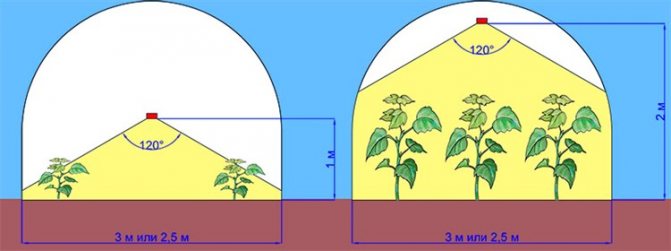

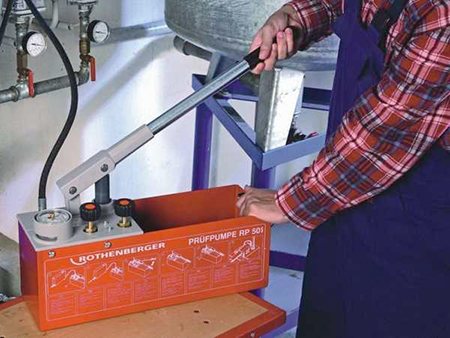

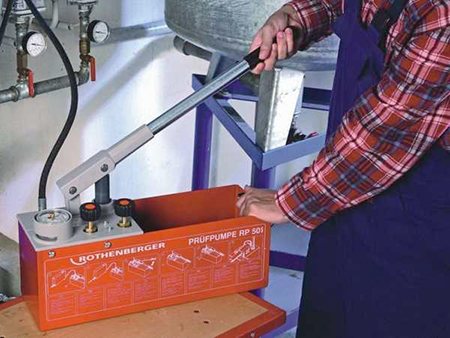

Crimping

Pressure testing is a serious part of the commissioning work that is carried out before the first start-up of the system, as well as before each heating season. This is the name of the hydrodynamic testing of the system. in conditions that exceed the subsequent real load in complexity. This is a test for the strength of the pipeline, all connections and assemblies, as well as points of entry and exit into the building, underfloor heating systems, equipment and boiler rooms.

The principles of conducting are regulated by SNiP:

- The temperature in the building should be above 0 ° C.

- Selection of pressure test should not exceed the limit valuesspecified by the manufacturer.

- The value of the crimping pressure must exceed the operating pressure. by 50%.

- In private homes, the crimping pressure is on average in the range 2-6 atm.

- Systems in old houses are tested with underestimated values, cast iron radiators also set a limit to the maximum value - no more than 6 atm.

- When selecting the optimal value of the pressure test it is important to use technical documentation for pipes and equipment, it follows from the admissible maximum for the weakest link in the system.

- Testing with water, even if antifreeze is poured into the system, pressure testing with working solution is done secondarily.

Parameter control

Competent pressure testing is carried out only by a specialist with the appropriate knowledge and experience. Parameter check and control requires special equipment.

Recommended parameters:

- above workers one and a half times, not less than 0.6 MPa.

- not new networks are tested under pressure 1.25 higher than workers, not lower than 0.2 MPa.

- in private houses up to three floors heating works under pressure no more than 2 atm.

- in multi-apartment five-storey buildings 2-6 atm

- in buildings with more storeys 8 - 7-10 atm.

These values are amended on site based on the condition of the system components..

In private houses, fittings, radiators, etc. are often in better condition than in apartment buildings.

According to the rules, in apartment buildings, such work can be carried out every 5-7 years.

Preparatory stage

After installation of heating networks, they are flushed. This will remove any chips and debris trapped in the pipes during installation. If you ignore the flushing, debris will damage the pump or heating boiler.

Before pumping in the coolant, the system is pressurized. To do this, a special compressor pumps air into it, filling pipes and radiators with it. The pressure is injected above the standard by 25%, about 2 atmospheres. The pressure gauge is periodically taken, the pressure drop should not exceed 1% in 15 minutes. You can pressurize the heating with water, you need to pump it under a pressure of 1.5-1.8 atmospheres and monitor it throughout the day. If no leaks are detected, water is drained and antifreeze is pumped.

Good sealing is not only the absence of fluid loss, it excludes the airing of the circuit. The ingress of air provokes the emergence of traffic jams, making the heating operation ineffective.

Filling the heating system

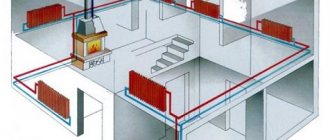

The filling methods for open and closed heating systems differ.

How to pour into a closed

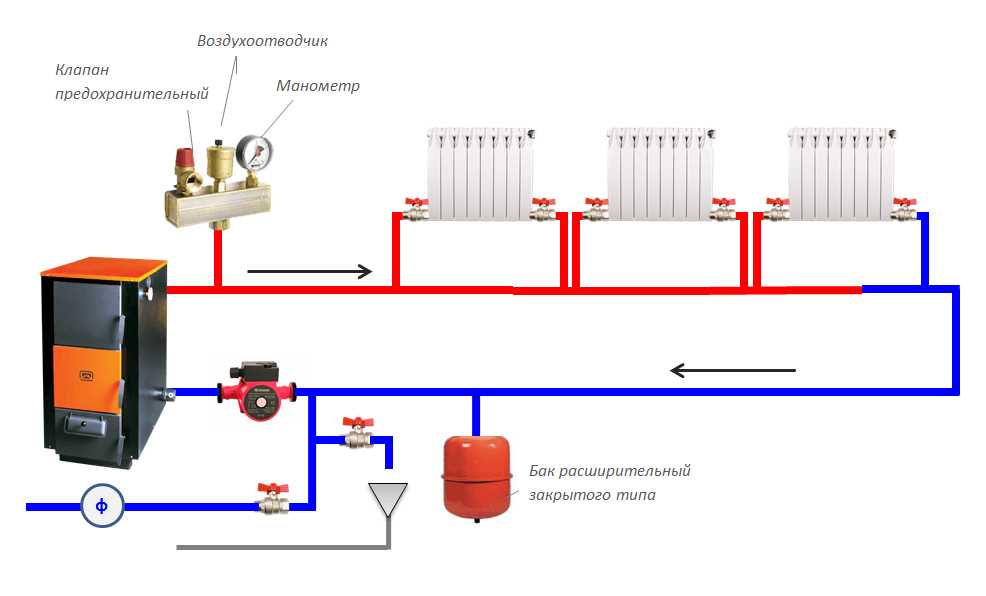

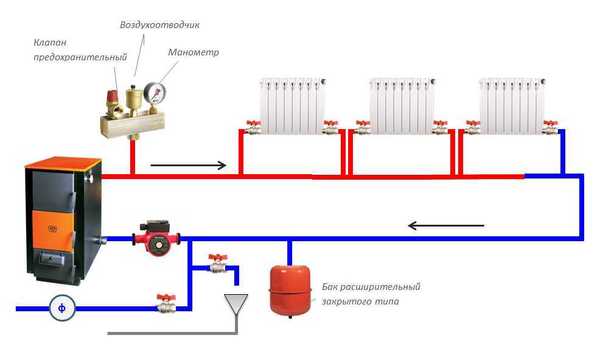

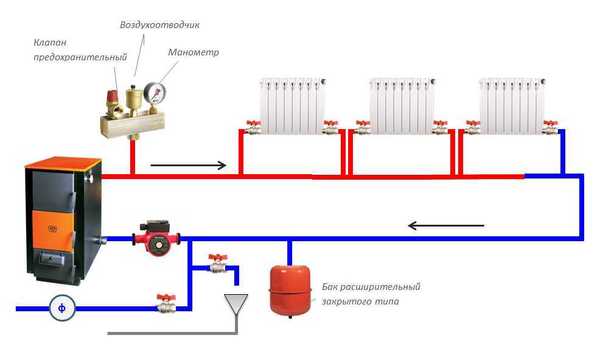

The closed system is equipped with sealed expansion tank, which is set arbitrarily.

Attention! It is not recommended to use the upper tier of the system for filling the coolant. In this case, air comes out through the coolant layer, saturating it. When heated along the entire circuit air locks are formed.

The best option is to supply the coolant through the bottom valve:

- from the water supply;

- from a tank, a well with a pump.

Photo 2. Scheme of a closed heating system. A sealed expansion tank and a pump are mounted in it.

The process itself is carried out at the beginning of the heating season or after renovation work.

High quality antifreeze can be overfilled every 5-6 years.

If the liquid is supplied not from the water supply, then a pump will be needed. The source is a well or tank. Filling process:

- It is better to fill the system with two people.then it will be easier to control the pressure.

- The heating medium is pumped with the heat source turned off.

- All shut-off valves open, remains closed only drain.

- Radiators also overlapexcept for the most distant ones in each branch.

- The coolant supply is connected: the circuit, boiler and tank are filled.

- From the beginning of the process, the air outlet is monitored: it should exit through the safety group valve and the drain at the top of the line.

Important! It is recommended to set the security group for a system with any type of boiler and type of fuel.

- The radiators are opened, starting from the first from the boiler. The taps are opened, the air is vented through the Mayevsky cock, after filling the radiator is closed again. This process is repeated with all branch radiators.

- When the batteries are full trapped air is released from the circulation pump.

- Next, the heat source is activated and at the same time the pump is turned on.... The system is being pumped - without radiators.

- When the pipes are hot enough, the taps on each battery open. In this case, it is necessary to once again check the air outlet from each.

- If done correctly, the pressure stabilizes and is no more than 2 bar.

- The process is repeated for each branch., in the last turn, the coolant is poured into the warm floor.

If the heating is designed with a manifold, then branches are filled in separately, the air is discharged through the manifold valves.

Attention! In the case of a branched structure, pumping and heating of the system is carried out only after filling in all parts.

The process takes a lot of time and requires care. If the main points are missed, air may remain in the system, which subsequently will create problems in the operation of the heating.

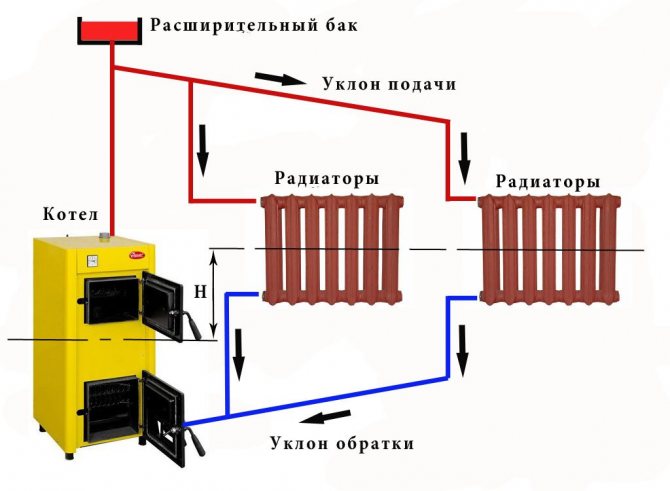

How to upload to the open

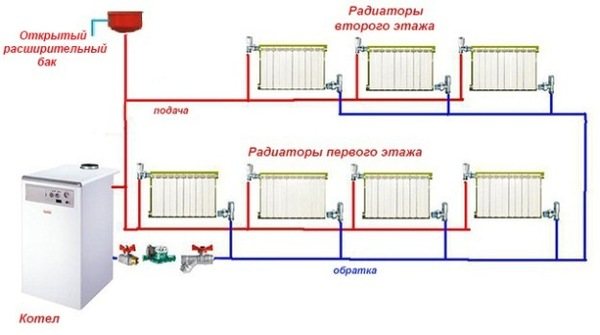

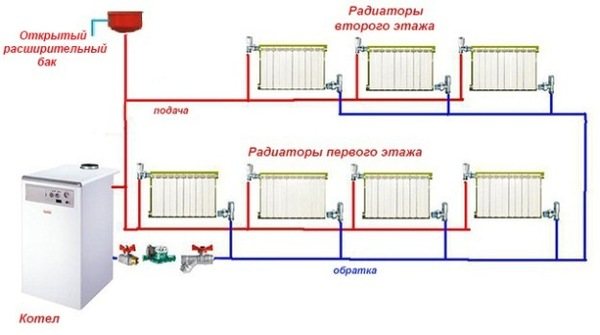

It is an open container with a lid, which is also a convenient entrance for water to enter the system. It is filled with a regular bucket or a pump is connected. The difference in filling lies in the pressure in the circuit: it is equal to the usual atmospheric. The coolant is in contact with the environment - an expansion tank is installed at the highest point of the circuit.

Photo 3. Scheme of an open heating system in a two-story building. The circuit is filled with a coolant through a special reservoir.

Filling process:

- If a pump is used, then you need a large container for feeding in certain volumes.

- Water is poured gradually, intermittently - so the air will be able to escape. If the pump is turned on, the pressure in the circuit should not exceed two atmospheres. The water is stopped when the expansion tank itself begins to fill.

- Further, air is released from all radiators and system components. For this, Mayevsky's valves or taps are opened until the liquid appears.

- Then water is added to the system. Most of the air is removed by itself through the expansion tank, after starting the heat source, this process is intensified. In an open system, the problem of air locks is not as acute as in a closed one.

Evaporation occurs from an open tank, therefore from time to time you will have to top up the water.

The contour is filled from belowif there is a corresponding connector.

Methods for filling the coolant

There are several options for filling a closed heating system with liquid:

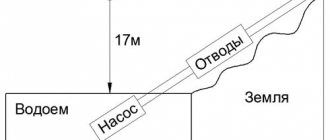

- For filling, you will need a pump that will supply water directly from a well or other source. We connect the delivery hose of the device to the drain pipe, on which you must first open the shut-off valve. It should be said that when performing such work, you should open all the shut-off and Mayevsky taps (for air outlet) in order to allow water to get to any point in the system.

- Expansion tanks in such mechanisms are mainly mounted to the pipe using a thread, which makes them very easy to remove. This will give you access to the pipe. Using this hole, you can pour water into this system. Very often, expansion tanks are installed at the highest point, which makes the procedure even more convenient.When water is visible from the pipe, you can finish filling and mount the expansion tank in place.

To create after this pressure in the system, you can remove the nipple, which is located at the top of the tank and pump it to the required value with a conventional pump.

It is very important to constantly monitor the pressure gauge so as not to exceed the pressure level in the system and not to provoke an accident. As you can see, it is relatively easy to pump water into such structures, but it is very important to follow the sequence.

How to pour coolant into the heating system with our own hands, see the video:

How to add water to a heating structure

In a closed and open heating structure, the coolant is added in different ways.

Closed

The system must be kept at a constant pressure, which depends on the total volume of the coolant in the circuit.

During operation, the amount of fluid decreases, so you should regularly recharge the circuit through special make-up valveslocated at the point of lowest pressure - in front of the pump.

Photo 4. Make-up valve for the heating system. With it, you can top up the coolant with a closed heating circuit.

Openly

In an open system, the problem of coolant leakage is more relevant - the evaporation of hot water from the tank requires constant monitoring and replenishment of the system.

The liquid is simply poured into the tank.

How to pour antifreeze into an open system

This is where you should buy safe propylene glycol. It's all about the open expansion tank, communicating with the atmosphere. Since it is located within the house (usually in the attic), small amounts of fumes can enter the living quarters. In general, pouring antifreeze into an open system is impractical. It is better to remake it closed, from where it will not evaporate.

The diluted concentrate is poured through an expansion tank or make-up valve using a pump. In this case, all Mayevsky air taps installed on the radiators must be open. As the filling progresses, the taps close, after which the coolant level is brought to about 1/3 of the expansion tank.

Types of pumps for pumping liquid

Filling an open system is not a problem in terms of equipment - a simple bucket is sufficient. To speed up the process and more convenience, it uses a hand pump or a device powered by electricity.

A closed system, on the other hand, only filled with pump, the coolant is supplied under pressure.

Any pumps are suitable for these purposes., specialized - no for pumping antifreeze into the heating system.

Vibrating

Vibratory submersible pumps are completely in the liquid. This is how the popular works "Kid"which is used in wells and boreholes. This device is quite suitable for pressurization up to 4 atm... It is also useful for the system that this pump is equipped with filters.

Drainage

This is also a submersible device, but there is a difference from the previous type of devices: the unit skips inclusions, the maximum size is indicated in the data sheet.

Using such a device, measures are taken to prevent foreign particles from entering the system.

Selecting a container for the pumped liquid, another feature of this type of device is taken into account: a float mechanism that turns off the unit if there is little liquid left.

Self-priming centrifugal

These pumps work while staying on the surface - the hose is immersed in the liquid. Due to their high power, they are used for filling the system and for crimping.

Manual piston

A convenient economical unit with a reservoir, equipped with a pressure gauge, which allows you to control the pressure. Requires significant physical effort.

How to pump up the heating system

The heating system consists of a boiler, piping and heating devices. In the middle of the entire system, fluid moves. In order for the room to warm up perfectly, you need to regularly monitor the level of the circulating liquid and, if necessary, add it.

- - hose;

- - clamps;

- - pump (if there is no water metering unit or the system is filled with antifreeze).

To pump an open-type heating system, it is enough to pour water into the expansion tank. A venting mechanism in an open system is not intended. As the pipeline, boiler and heating devices are filled, air will rise up and exit through the expansion tank. An open heating system is not common and is used in old-style houses.A modern heating system is always of a closed type, in which a filling and a drain valve are assumed. To pump a closed-type heating system, connect the hose at one end to the water meter assembly, and at the other end to the filling cock. Secure all connections with clamps. Open the water meter and the tap on the heating system. If you have a system for checking pressure, pump water until the meter of the device for determining the pressure value shows 1.5-2 atm. The pressure in the water supply system allows filling the heating system without the use of additional devices. After the system is completely filled, you just have to air it out using a specialized device supplied on the bypass. If you do not have a water metering unit, pump the heating system using a water pump. The principle is the same as when using a water metering unit. Connect the hose to the pump outlet, the other end to the filling cock, open the cock, turn on the pump. With the use of a pump, you can pump the heating system if you fill it with antifreeze. It is correct to apply non-freezing liquid only for example, if you do not live in a house and visit it sometimes, for example, a house outside the city. Do not forget that if you have a heating boiler under warranty, then when you pump in the heating system with antifreeze, you automatically lose the boiler warranty service. After filling the heating system, turn on the circulation pump, release the air, close all taps. After that, you can use the system for the target direction.

- how to fill the heating system with water

How to pump up the heating system

Coolant drain technology

- To drain, you need a hose that connects to the boiler nozzle. The other end is located in the sewer or in a separate container.

- The boiler shuts down.

- The hose is connected to the return valvelocated under the boiler (if it is not there, then the location is indicated in the technical passport).

- The valve opens, and the liquid is drained, then closed again.

- After that, the system is filled with air., for this, Mayevsky's taps are opened at the highest point of the contour. Then they drain again.

- Now they start the air again, but this time they open all the available Mayevsky taps. The liquid is drained again.

- Finally, the hose is reconnected from the return valve to the supply valve.... In this case, the hose is placed as low as possible in relation to the tap.

Important! It is impossible to drain the underfloor heating system in this way, to drain this branch you will need a special compressor.