Why does reverse thrust appear and how to eliminate it

It is recommended to install the boiler in such a way that the vent and the smoker are on the same side. Failure to comply with the rule in a small building is infrequent, but can do without consequences. In a high-rise building in windy conditions, this can cause pressure differentials. Violation of the norm in this case leads to the appearance of reverse thrust.

Often, a boiler that has not fouled before passes clouds of smoke into the room at the time of kindling after it has completely cooled down. For the normal removal of exhaust gases, it is necessary that the boiler room be warmer than outside. Violation of this rule leads to a natural result - the thrust will not be restored until the heating equipment warms up.

You can restore normal air circulation with the help of a simple technique - light the paper, after placing it closer to the chimney. In this case, the ash pan is left open, and the firebox door is tightly closed. Attempts are repeated until smoke appears from the chimney, indicating that normal thrust has been restored. After such a signal, you can safely start up the heating boiler, without fear that it will start to smoke.

Solid fuel boilers for home help create quite comfortable heating, and can help the heating system cope with increased demands. They have enough advantages, but from time to time they require maintenance, and always - careful attitude for the purpose of fire safety.

In this article, we will figure out the question that often arises among the owners, why the heating boiler smokes and what to do in such cases. Often, the problem lies in the chimney.

You can find out the price and buy heating equipment and related products from us. Write, call and come to one of the shops in your city. Delivery throughout the territory of the Russian Federation and the CIS countries.

Smoke from the boiler into the room

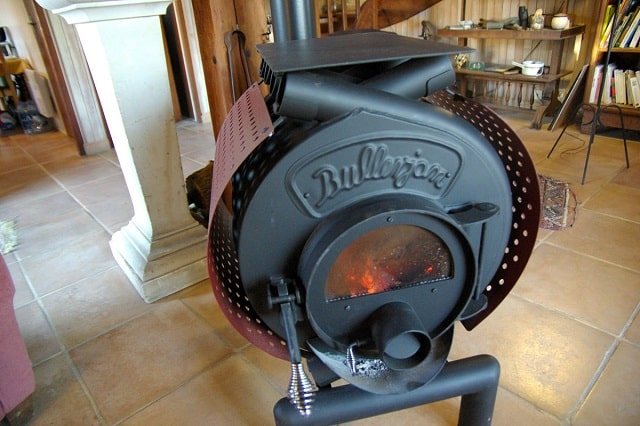

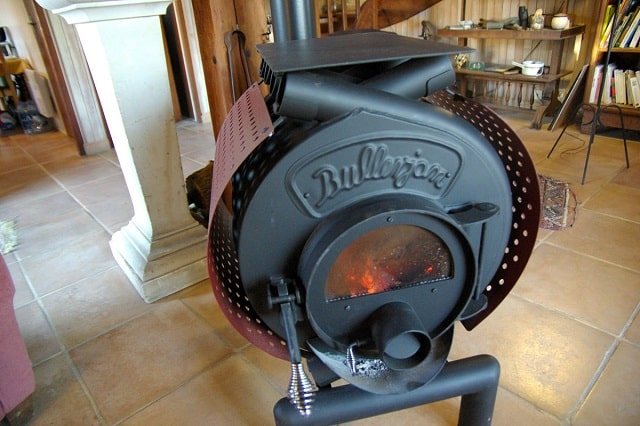

Buleryan kindling scheme

Conventionally, the scheme of kindling the furnace is divided into four stages. The first is the laying of firewood. First you need to open the chimney shimber (gasifier regulator) and the blower damper. After that, put large or medium-sized firewood into the oven through the loading door. On top, you can fill in wood chips and put a few crumpled newspapers for faster ignition. Next, light the wood and make sure that it burns, close the loading door. Do not leave the device for 10-20 minutes. During this time, the chimney and air pipes heat up. After 15 minutes, you need to check the draft: if the air "hums" (strong draft), then open both dampers by 20-30 degrees.

The second stage is kindling the stove. At this stage, the buleryan is heated, hot air begins to flow from the pipes. After a few minutes, it is necessary to close the dampers at 45 degrees so as not to glow red hot in the chimney. The third stage is the last cover of the dampers. It is carried out when there is no smoke in the combustion chamber (air is transparent). Moreover, the dampers cannot be completely closed; it is necessary to leave a gap on the gate and blower, approximately 1-1.5 cm in size.

After closing the dampers, make sure that smoke does not accumulate in the combustion chamber. If the air is smoky, then you need to slightly open the damper. The temperature should be kept at 130-150˚С. If it drops, open the flap slightly to allow fresh air to flow in. The fourth stage is the addition of firewood.

A sign indicating the addition of firewood will be a drop in temperature. If it does not rise even with the addition of air, then you need to make a new bookmark. To do this, for 2 minutes.you need to open the buleryan dampers (the draft should take out the rest of the smoke) and slowly open the loading door. Add firewood to 2/3 of the furnace (1/3 of the furnace should occupy the combustion zone). When working with the stove and organizing the room near it, observe the safety rules.

If smoke goes into the room from a gas boiler

A wall-mounted or floor-standing boiler and AOGV can smoke for two main reasons: malfunctioning chimney or poor gas quality.

First of all, it is necessary to inspect the chimney and carry out the following work:

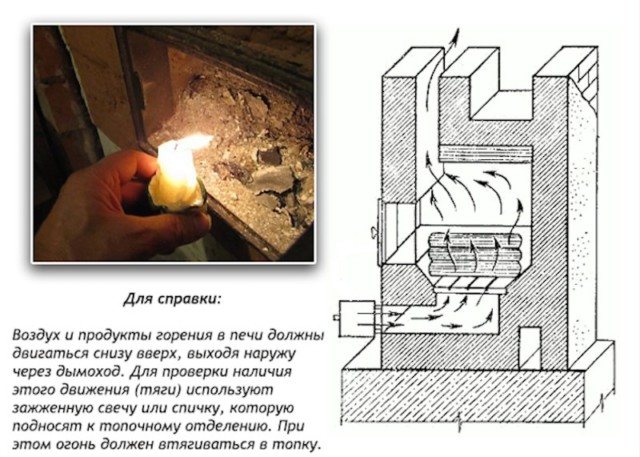

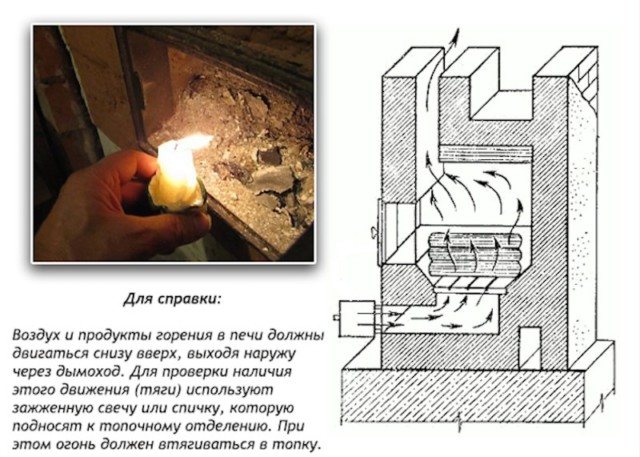

The presence of traction is checked. This can be done either with a special measuring device, or by holding a lighted match. The flame should deflect noticeably towards the boiler. If this does not happen, then the chimney for some reason does not draw smoke out.

View the pipe with a mirror and a flashlight. Remove snow and foreign objects if necessary. If you cannot do this yourself, call a chimney sweep. If you are heating with damp wood, you need to clean the accumulated tar from time to time. Replace the chimney with a suitable type and diameter for this model. For example, the Lemax Premium device requires a chimney with a diameter of 200 mm. Increase the length of the pipe, in your house its end should end above the ridge of the roof. Insulate it outside with glass wool. View the chimney for cracks

Pay special attention to the connecting seams. Remove right angles when cornering and make the transitions smooth.

In the room where the gas boiler is located, the air vent must be open. This is especially true in the cold season in high-rise buildings, where a layer of cold air can prevent combustion products from escaping.

If you produce heating with a gas boiler and use cylinders, and not a centralized gas pipeline, it is important to purchase high-quality liquefied gas from trusted manufacturers. This allows the Ross Lux model to do this.

Why is there smoke coming out of the chimney

The answer seems obvious: because the stove is heated, and fuel is burning in it (wood, coal, diesel fuel, gas). In our minds, these things are inseparable: if the stove is heated with coal, it always means dirt and a specific coal smell. We observe all this when heating a private house, especially in cold, calm weather.

It turns out that everything is not so simple: if the fuel is burned completely, then transparent air and carbon dioxide will flow from the pipe, and in cold weather we will see water vapor (fog). And the smoke that we see is the unburned gas phase of the fuel.

The question arises: where does this gas phase come from at all? If you heat with gas or liquid fuel, then everything is clear, but are coal and firewood solid? And why does this mysterious gas phase not completely burn out?

To understand this, consider the combustion process.

So we lit a match. If we extinguish it, we will see how white smoke goes from it. It is the volatile substances that make up it evaporate. If you heat the wood hard enough, it turns into gas by three quarters, the same whitish gas that we saw for a second when extinguishing a match, and in the remainder we get charcoal. At a temperature of about 200-300 ° C, this gas will ignite. The burning gas is the flame that we see.

These processes can be separated. If we heat wood without oxygen, we will turn it into gas, which is then burned in the burner, this is how a pyrolysis boiler works. During the war, even cars worked on wood.

If the temperature in the furnace is low or there is not enough oxygen in it, incomplete combustion of gases occurs, and we see smoke coming out of the chimney.

Coal burns in a similar way, because their composition is very similar: coal is the same wood that has turned into stone over millions of years. But there are also differences. There is more non-volatile carbon in coal, there are non-flammable mineral additives (ash), but there are less volatile substances: in brown coal there are about 50% of them, in coal 20-40%, and in anthracite only about 5%.

Let's remember how an ordinary village stove is heated. They put some firewood on the grate in the firebox and light it. When the firewood has flared up, they begin to fill in coal: at first a little, and then, when the first portion has flared up, fill in the main portion of coal.

At the moment firewood and coal are ignited, smoke is emitted: the temperature at this moment is still insufficient for complete combustion. When the main portion of coal was filled up, the burning lower layer heats up the upper layers, a gas phase is actively released from them, but neither temperature nor oxygen is enough for its combustion, since the grates are tightly closed with coal, and air is supplied from below through the grates and all oxygen is consumed in the lower layer. Gases, instead of burning and heating our house, simply fly away into the chimney. This is how the village stove is heated.

Let's see what happens in "modern" top-loading coal stoves and in other types of boilers. Boiler manufacturers strive to make the boiler cheap and durable, so the walls of the boiler, where combustion takes place, are made water-cooled. That is, the boiler is at the same time a part of the heat exchanger and does not burn out, since the temperature of the boiler walls is equal to the temperature of the water in the boiler (about 80 ° C).

Everything seems to be correct, but not quite.

| Automatic coal-fired boilers TERMOROBOT are a real savings in heating costs and an excellent alternative to gas, diesel and electric boilers. |

In order for the boiler to work with high efficiency (about 95%), it is necessary to supply a strictly verified amount of oxygen to the furnace: no more and no less.

If you feed less, there will be no complete combustion; if more, the excess air will simply heat up and go into the pipe, carrying away the heat and reducing the efficiency. The amount of air should be proportional to the amount of evolved gases.

In existing domestic boilers for long-term burning, there are no mechanisms for monitoring the correctness of the combustion process. Automation monitors the temperature and tries to regulate it by changing the air supply. As the boiler temperature rises, more gases are emitted. For their complete combustion, more oxygen is needed, but the automation just reduces the blowing in order to reduce the intensity of combustion. As a result, the released gases fly away unburned.

Even if there is enough oxygen, this does not mean that the entire gas phase will burn out completely: a high temperature is needed along the entire combustion path, and it is more than 1 m. In existing boilers, after 20-40 cm, gases hit the cold walls of the boiler, flowing around cold walls of the heat exchanger, they are partially extinguished and carried away into the pipe. We ourselves did not let them burn completely, as a result we not only got dirty smoke, but also let some of the coal “into the chimney”.

The second product of incomplete combustion is soot. During combustion, lumps of coal heat up, and micro-explosions and sparks are fired in them; we see the same thing when coniferous wood is burning. A spark is the smallest particle of coal, mainly carbon and ash. Carbon burns at temperatures over 800 ° C. Striking the water-cooled walls, these particles immediately go out and settle on the heat exchanger in the form of soot.

It is possible to fix the matter: for this it is necessary to destroy the process of combustion and heat exchange, to give the coal time to burn completely. We have implemented this principle in Thermobot - an automatic modular coal boiler house developed by us. IN boiler Thermobot there is an afterburner - a long hot channel into which the required amount of air is supplied. This explains its high efficiency and purity of exhaust gases: completely burnt coal is invisible and harmless carbon dioxide, water vapor and other products of complete combustion.

The solution is not cheap: such a boiler is more than 600 kilograms of special heat-resistant materials.Of course, it costs much more than traditional household heating boilers, but if this is not done, smoke will come from the chimney, and the fuel will not burn completely.

In this way, the problem of smoke lies not in coal, but in the way it is burned. Thermobot Is a new step in the technology of domestic coal-fired boiler houses. He is able to change the prevailing stereotypes and show everyone that coal heating is convenient, cheap and environmentally friendly.

viewing time 2 min.

automatic boilers Thermobot Is a modern alternative to outdated manual boilers when modernizing coal-fired boilers.

| 1. Heating in the house ..., or why it is better to install a Thermobot (Fairy Tale) 2How to reduce heating costs? |

Reverse thrust reasons

Backdraft is one of the possible reasons why the boiler emits smoke when the door is opened. It has already been mentioned above. If the combustible products are not removed through the chimney, but go to the living room, it is worth analyzing the cause of this situation and urgently starting to troubleshoot. As a rule, in this case, the exhaust gas sensor, built-in in units of all modern brands, also reacts.

For all that, a solid fuel boiler emits abundant smoke when the door is opened, contaminates the window on the door. The reason is usually the same. All gases circulate from the high pressure zone to the lower pressure zone. Natural draft appears when the chimney is brought to the optimum height.

You can check if there is a back draft by bringing a lighted match to the chimney. In the case of natural draft, the fire will deviate towards the boiler, but if the reverse draft is from the boiler.

The most common cause of reverse thrust is the weather. A gust of wind penetrates the chimney and prevents harmful waste from escaping. The same is true when the outdoor temperature drops. Sometimes you just need to wait until the pipe gets warmer, and the natural circulation of combustion products will improve.

It is also possible that the design and type of the chimney was chosen incorrectly. There may be damage. For the unimpeded removal of smoke, the pipe should have as few bends as possible. The diameter and types of the chimney are selected for each boiler based on its type and power parameters.

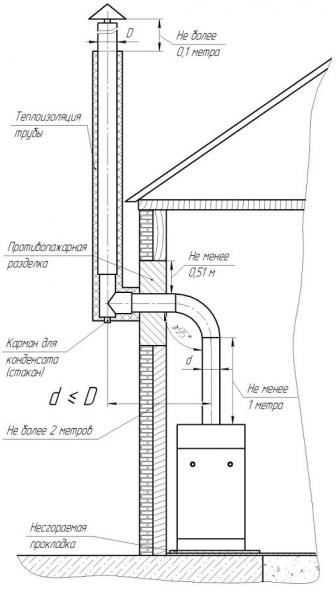

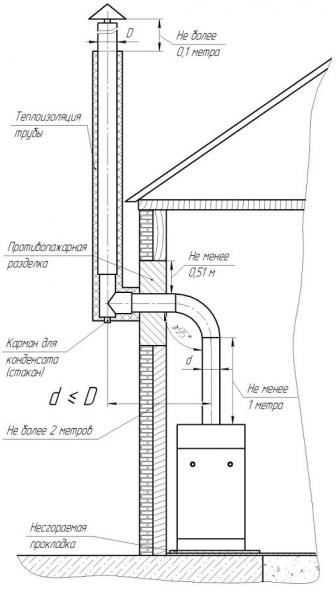

How to make a chimney for a stove through the wall

If, during the search for the reason why the potbelly stove smokes when the door is opened, it was found that the problem is not in contamination, then the matter is in the wrong design.

You can make and install a chimney yourself. For a potbelly stove, a metal version is more suitable than a brick one. For these purposes, the most suitable will be alloy steel with a special coating that protects the surface from the effects of oxides. Just don't use aluminum pipe - it will melt.

During the manufacture, you will need the following elements:

- Metal pipes for the base of the chimney. A diameter of 16 cm is suitable.

- Docking knees. Their number will depend on how many times the direction of the pipe will be turned.

- Protective cap for the upper part of the chimney.

- Condensation pocket.

- Seam sealant.

- Pipe clamp.

- Thermal insulation.

Drawing for the manufacture of a chimney for a stove through the wall

Important: To increase safety, the wall behind the stove and the pipe must be covered with a heat-resistant material, for example, asbestos sheets.

After all the materials are ready, you can proceed with the installation:

- First of all, a through hole is made in the wall. Moreover, if the wall is wooden, a special metal box is installed with a hole in the center, which is 5 mm larger than the pipe diameter. For a brick wall, a pass-through glass is used.

The box is filled with basalt glass wool, and the hole is filled with asbestos strips.

- Next, the first section of the pipe is placed on the potbelly branch pipe.At the same time, the design is complemented by a heat-resistant seal and a special clamp that will prevent the breakthrough of gases.

- A knee is placed that leads the pipe towards the wall.

- After the pipe is brought out, a branch pipe and an elbow are placed.

Example of an external chimney pipe

- Insulation of the outer chimney pipe is in progress. To give stability, you can fix the structure with brackets.

- A protective cap is placed on the top of the pipe.

Having figured out how the chimney is installed through the wall, you can also pay attention to the options for the chimney through the window for the stove and through the roof.

Thus, having studied all the necessary instructions, you can take a number of actions to clean the finished pipe or create a new one. Such measures will help get rid of the smoke of the potbelly stove.

This equipment is not too difficult to maintain.

However, due to the specifics of its work, it requires some attention during operation. Further in the article, we will consider ways to eliminate the most common problems and the reasons for their occurrence.

What to do if the boiler is "crying"

Condensate starts to flow out of the boiler when the return temperature is too low. This problem requires elimination, since such a malfunction reduces the service life of the boiler. At the same time, soot and soot accumulate inside the equipment. To avoid the occurrence of such a situation in pellet and wood boilers, it is necessary to ensure that the temperature of the coolant in the return line is at least 55 grams.

At the same time, 60-65 grams can be considered the best option. In order to ensure such operating conditions, use Laddomat or three-way mixing valves.

Reasons for overheating of solid fuel boilers and how to fix this problem

A solid fuel boiler can overheat mainly in two cases:

If the premises of the house consume less heat than the boiler itself generates. The features of this equipment are such that precise power control is simply impossible. As a result, the coolant heats up until it begins to boil and the excess steam is discharged through a special valve; Roughly the same situation occurs when the circulation pump stops functioning for any reason. In this case, boiling occurs as a result of the fact that heat removal from the boiler ceases to be carried out.

How can you protect your equipment from overheating? Experts advise using a special storage tank for this purpose, as well as a UPS (uninterruptible power supply).

The latter is necessary, first of all, to ensure the stability of the pump, the former is designed to take excess heat. In order to protect the boiler from overheating, it is worth using the WATTS STS-20 and REGULUS TSV valves.

Other common problems

Very often, owners of solid fuel boilers are also forced to solve the following problems:

Smokes. Poor pipe draft is the reason. Most likely, the air heating of a private house will simply need to be cleaned of soot; High fuel consumption. The problem usually lies either in the incorrect connection of the boiler (incorrectly selected power), or in the use of low-quality fuel or poor insulation of the room; Water flows from the chimney. In this case, the latter should be insulated; The burner is clogged in the pellet boiler. To avoid this, use only high quality pellets from certified suppliers.

General instruction

Buleryan's kindling scheme:

- Open the flue gasifier regulator.

- Open the blower flap.

- First, lay in chips or medium / large-sized firewood, add a little crumpled paper / newspaper;

- Fire wood, check combustion and close the oven door;

- Check for traction in 15-20 minutes;

- Approximately every 5 minutes, you need to cover the damper a little, but you cannot completely close it;

- Do not leave the stove during kindling;

- When the temperature decreases, you can add the next batch of firewood (use only large dry firewood);

You can also watch a detailed video instruction on kindling Buleryan:

After some time of use, you will gain the necessary experience and melting the buleryan will become a simple task.

The stove is melted

What kind of wood to heat?

Before using the stove, it is worth figuring out how to properly heat buleryan with wood, because not everyone can be suitable for this purpose. Any deciduous firewood is suitable for melting.

Coniferous varieties to use Not recommended, because of them, the chimney quickly becomes clogged. If you heat the stove with an apple, pear, cherry, etc., little heat will be generated.

The best fuel for buleryan will be oak or acacia due to its hardness. An important condition is that the wood should not be too wet.

Can I use other fuels?

- Coal. Buleryan stoves come with special operating and fire safety instructions. If you follow these instructions exactly, then it is forbidden to heat the stove with coal alone, a large amount of heat from burning coal can melt the metal. You can use brown coal, but only with firewood. Many sources on the Internet describe many ways how to heat Buleryan with coal, but you should not rely on them, these methods may not be safe.

- Working off. According to the instructions, mining cannot be fuel. Its use will lead to burnout of pipes and the destruction of the furnace.

- Briquettes. Peat briquettes are an ideal fuel, they have good heat transfer and do not degrade the performance of the kiln. Briquettes are difficult to buy in a store, they are usually ordered on the Internet, but suppliers mainly sell only in large quantities, which is inconvenient for personal use.

- Sawdust, wood chips and tree bark. Lighting with sawdust, wood chips and tree bark is not prohibited - this is a good way to save money and reduce the use of good firewood. In order to use this type of fuel, you must first melt the stove with wood, and then add wood waste.

- Pellets. The method of melting with pellets is similar to that used for melting with sawdust, wood chips and bark. Since pellets are made of wood, they are also suitable for buleryan, but before that a special mesh is installed.

How to lay firewood correctly?

First of all, chips are laid for kindling. You can set it on fire using different ignition means. After the firewood is laid. The furnace operates in normal mode or in gas generation mode. Continuous normal operation will shorten the life of the boiler. It is important not to use damp wood, this will damage the chimney over time.

For a longer service life of the stove, it is necessary to periodically clean it; for this, it is enough to burn special briquettes if the chimney begins to clog.

How to reduce consumption?

- Use dry wood.

- Clean the chimney regularly.

- To heat the stove with wood from acacia, oak and aspen - they are the hardest.

- Insulate the chimney.

Optimum temperature

Before purchasing a buleryan stove, you need to decide on its size. This affects what area the boiler can heat. The period between laying firewood is long - 8-12 hours. To always maintain a comfortable temperature, it is enough to periodically add firewood.

The optimum temperature depends on the size, power of the stove and the volume of the firebox. The principle of operation is similar to a conventional potbelly stove, but the efficiency is higher, so the bulleryan will warm up a large room quickly enough.

General fire safety rules

- Do not add too much wood.

- During melting, do not leave the stove, constantly check the presence of draft.

- Do not use only coal as fuel, as this can cause the metal to melt and spread fire.

- Watch the stove closely while burning.

- Clean the chimney regularly.

- Read the instructions carefully before use.

If the gas boiler smokes

In addition to errors associated with improper installation of equipment, fuel quality plays an important role in the operation of the unit. This issue is especially relevant when using liquefied gas from a cylinder.

After the combustion of clean fuel, a small amount of dry soot remains. Flakes of this substance accumulated in the pipe can be easily removed. It is enough to knock on the chimney from the outside and remove the crumbling soot through the technical window.

After combustion of gas with a large number of impurities on the walls of the chimney, gradually narrowing the gap, greasy soot sticks. It is quite difficult to cleanse this substance. A regular pipe brush may be useless. In such a situation, it would be best to disassemble and clean the smoker separately.

Quite often, a gas boiler smokes due to improper adjustment of the flame intensity. If the user, in violation of all instructions, turned on the burner of a cold boiler at full power, then the appearance of smoke will be a natural result. The problem can be avoided by gradually increasing the combustion temperature after kindling.

Common operating problems

The main problem during the operation of buleryan is the release of combustible gases that cannot burn out due to the moisture of the wood and are released in the form of condensation. To solve all the problems of operation, it is enough to use exclusively dry firewood, otherwise the emitted gases will settle on the surface of the pipes and form growths, leading to a blockage.

Despite the fact that sellers say that you can drown bulleryan with anything, in fact it is not. Firewood and wood products are best used as fuel. This can be a big disadvantage for those who find it more convenient to heat with coal.

Why does Buleryan smoke?

Buleryan may smoke due to the absence of traction or the furnace has not been serviced for a long time, i.e. the chimney was not cleaned, similar situations occur if the stove was still heated with damp wood. These problems can be eliminated by mechanical cleaning of the pipes with a special metal rod or by cleaning with special chemical briquettes. After cleaning the chimney and in the presence of draft, the smoke will not come out.

It can also smoke due to the fact that the damper is completely closed, that is, the smoke simply has nowhere to go. As stated in the instructions for melting the stove, the damper should not be closed, only slightly covered.

To prevent smoke from being thrown into the room, you must follow the rules for installing chimneys. There should be no tall trees or buildings nearby, and the pipe should also rise above the roof and the ridge of the roof by at least 500 mm.

Can't melt

At the beginning of operation, it is a pleasure to use buleryan - it does not take up much space, heats up the room well, saves firewood. But, if over time it becomes more and more difficult to melt the stove, this means that, perhaps, the chimney is clogged and it is necessary to clean it. There are two ways to clean the stove: mechanical (to break through the build-ups formed in the chimney with a special metal rod), chemical (to heat the stove with special braces, which, when burned, eliminate the blockage).

When installing the stove, the correct installation of external chimneys is necessary. If the pipes are installed incorrectly - there are hills nearby (trees or buildings), or the pipe does not rise enough above the roof of the house and the ridge, the smoke will not be able to escape through them, but will go into the room. It is impossible to melt the stove under such conditions.Check the correct installation of the flue pipes.

It is important to familiarize yourself with the instructions before using, it describes in sufficient detail how to heat buleryan.

Other problems

According to user reviews, the main problems of Buleryan stoves are precisely the throwing of smoke into the room and the release of carbon monoxide, which is harmful to health. Other problems can arise from improper operation, use of damp wood, or stove failure. As mentioned above, you cannot use coal as fuel, so as not to burn out the walls of the boiler.

At the beginning of use, smoke from the paint will be emitted, but after a few fireboxes this problem will disappear by itself. In addition, the outer pipes have to be insulated for better heat transfer.

What to do when a solid fuel boiler smokes real example

The reasons for the smoke of a solid fuel boiler may be different. Often, when such a situation arises, the owners of the units immediately look for information on the Internet, analyze sites and forums to find real reviews and comments, how to establish the cause of the problems and fix them. Here's one of those examples.

One of the members of the forum complained that having installed a solid fuel boiler of the Dragon TA brand with a classic stainless steel chimney, after two years of unquestioning work, the unit began to smoke. Combustion products began to come out of the chimney inside the boiler room, from all doors during the firebox.

Kindling was carried out with various types of firewood: spruce, birch, aspen. We used dry, raw and frozen firewood ... The boiler functioned perfectly for two years, and then the situation changed. The owner is sure that the weather conditions have nothing to do with it. The ventilation works great.

The actions of the boiler owner were as follows:

- He took apart the chimney and cleaned it.

- I rewound all connections of the structure with aluminum tape.

- Cleaned out the entire boiler.

- He insulated the chimney with 10 cm ROCKWOOL stone wool.

The solid fuel boiler still smoked inside the boiler room, but the pipe stopped. The owner did not understand what was the matter, why the boiler was smoking.

After much reasoning and communication with people faced with a similar problem, it was still possible to establish the reason, which was as follows.

The owner spent two years heating the boiler with dry chopped aspen and birch logs. In the real season, the cold came already in October, so the dry firewood ran out, and a car of raw birch firewood was bought.

When using dried firewood, dry soot accumulated in the chimney, which could be removed simply by tapping on the vertical part of the chimney with a stick. And everything is clean and tidy. Damp birch logs tightened the walls of the boiler and chimney with tar.

The owner has carried out all the necessary cleaning procedures for the boiler. Removed the tar. And that's it - the problem disappeared.

A solid fuel heating boiler is a good heating medium. But remember that it also requires periodic maintenance and safety rules.

The boiler fumes: causes and remedies

What problems arise during the operation of solid fuel boilers

1. When loading fuel into the boiler, smoke escapes into the room - The main reason for the boiler puffing up is insufficient draft in the chimney, lack of supply air for combustion. Check the condition of the chimney. And the main thing is to consult with engineers about the height and diameter of the chimney.

2. Resin adheres to the inner walls of a solid fuel boiler - Raise the operating temperature of the boiler to a level of at least 75 degrees, clean the boiler, install a three-way mixing valve to control the temperature of at least 61 degrees entering the boiler. Use quality fuel!

3. Periodically, water appears under the solid fuel boiler - This is condensation.This process manifests itself when the boiler return temperature is below 51 °; to solve this problem, it is necessary to increase the boiler temperature to 75 ° and install a three-way mixing valve to maintain a stable return temperature of at least 55 °.

4. There is black smoke from the chimney - There is not enough supply air for combustion, or poor quality solid fuel is being used.

5. The fuel in the boiler does not burn - The chimney draft is weak. Cleaning is required for the chimney or you need to increase the cross-section-height of the chimney of a solid fuel boiler. Study the boiler manual, adjust the regulators.

6. The boiler often clogs up - Increase the boiler temperature, use a better quality fuel. There is not enough air flow or draft in the chimney.

7. Firewood burns normally, but coal does not burn - The chimney size does not match the boiler output.

8. When the water is heated, the pressure in the heating system rises strongly - The expansion (compensation) tank is damaged or has insufficient volume.

9. What safety group should be set for a solid fuel boiler - The safety group must comply with the manufacturer's requirements specified in the instructions for the boiler.

10. The solid fuel boiler cannot raise the temperature in the heating system - Raw fuel with insufficient calorific value is used, replace the fuel with a more caloric one. For example, briquettes or coal. You need to use more or less dry fuel.

The main problems with solid fuel boilers arise from improper installation and selection of a chimney for the boiler. Also, the operating temperature of the solid fuel boiler plays an important role, as well as the temperature of the heating return line (water that enters the boiler) must be at least 55 °. When buying a boiler, analyze the fuel market, consult with specialists on boiler installation schemes

Also, it is worth paying great attention to the type of boiler and the types of fuels on which a solid fuel boiler can work.

There are four main types of solid fuel boilers - universal boilers, wood-fired boilers, pellet boilers, combined boilers. These boilers are very different in terms of comfort and quality of work on a particular type of solid fuel.

A lot depends on whether you are ready to use solid fuel in heating your premises, as it will take a lot of time and effort when using manual fuel loading, so you should immediately decide whether you need a manual or automatic boiler.

And do not forget to call and consult - this will give answers to many questions, it will also show the level of engineers who offer you quite specific equipment!

Why does the cauldron smoke

Let's figure out why the boiler is smoking, and what are the main possible causes of this phenomenon. The problem is most likely in the chimney.

Here is a list of suspected faults in this assembly leading to poor traction:

- The chimney is clogged. In winter, snow could get into it or it could freeze. Also, a foreign object could get there from above or soot could gradually accumulate. All of this can be the reason why there is no craving.

- When stoking on wood that is not sufficiently dried, tar accumulates, which greatly narrows the diameter of the pipe and increases the thickness of its walls, preventing it from warming up enough.

- The chimney diameter or type does not match the model's capacity.

- Insufficient height at which the pipe ends. In this case, the pressure difference will not be enough for natural draft to occur.

- Crack or leaky joint in the chimney. Too abrupt changes in direction and pipe bends, where cold air blockages are formed.

Also, the reason may be a sharp change in the weather. In the cold season, the thrust is stronger than at high temperatures. With strong gusts, the wind blows into the pipe from above.

Unsuitable or poor quality fuels also lead to smoke. For example, gas with a large amount of impurities, damp firewood, the ingress of foam or other synthetic materials into a solid fuel boiler

You should also pay attention to the degree of opening of the gate.

Smoke goes into the room if air does not enter the boiler room during the operation of the boiler. For safety reasons, there must be an air supply from the same side of the house to which the chimney is brought out. Otherwise, strong winds may cause pressure drop and smoke generation inside the building.

A clogged boiler or a too low flow area of the grate can also cause smoke. The device also smokes at the very beginning when firing up, due to the fact that the chimney has not yet heated up.

Smoke reasons for old stoves

If the age furnace smokes, then among the main reasons are: overturning of the draft, adhesion of soot, damp chimney, unsuitable type of fuel material, the appearance of deformations or wear of heating equipment.

Overturning thrust

If the stove smokes, this may mean a decrease or overturning of the draft. A similar process occurs as a result of long downtime of the furnace. This changes the direction of movement of air masses, as a result of which the smoke is not removed outside, but remains inside the premises. If there is no draft in the chimney, the main reason may be a mechanical blockage of the channel for the removal of combustion products.

This phenomenon does not depend on the ambient temperature or the design features of the chimney system.

If there is no good draft in the heating stove, then the following options are provided to solve a similar problem:

- Open and warm up the chimney hog in the attic.

- Open the cleaning door to warm up the chimney.

- Place ignited flammable material in the flue duct.

After the restoration of normal traction, it is recommended to carry out periodic prevention of the appearance of air congestion.

Soot build-up

The most common reason for a decrease in draft is the adhesion of soot inside the chimney, chimney and stove hog. Even a minimum thickness of 3 mm of soot can lead to a decrease in heat transfer, a deterioration in traction and a fire.

Insufficient chimney insulation or burning softwood contributes to the formation of soot. An available option to remove the blockage is to clean the chimney system. Activities are carried out as follows:

- A clean rag is wrapped around the free end of a metal rod, which is lowered into the pipe. After that, the walls are thoroughly cleaned from dirt.

- With a slight adhesion of soot, you can use special compounds that are added to the firebox to the fuel material. In this case, combustion is accompanied by the release of compounds that contribute to the destruction of existing contaminants. The most affordable option is coarse rock salt.

Damp chimney

Prolonged downtime of the stove leads to the formation of condensate in the chimney and further smoke from the heating equipment. To warm up the system, it is enough to open the lower iron flap to clean the surface from soot, and place a lit flammable material inside - sawdust, paper, wood chips or dry alcohol. After thoroughly warming up the chimney and leveling the draft, you can start kindling the stove.

Unsuitable type of fuel material

In some cases, smoke occurs due to the wrong choice of fuel, which is not suitable for a particular type of furnace.

For example, coal or solid fuel units can easily smoke if dry wood is used for kindling, rather than coal or peat briquettes.Unlike a wood-burning stove, in such devices, the dimensions of the blower correspond to the dimensions of the combustion compartment, therefore, when using wood fuel, the cooled air masses do not warm up sufficiently and remain in the room along with the smell of smoke and soot.

The problem is solved by shortening the blower compartment or using the appropriate type of fuel.

The presence of deformations in the structure

Another obvious reason for the deterioration of draft is the appearance of deformations in the structure of the chimney or furnace furnace. Cracks, potholes and crevices become a cold bridge, which leads to a decrease in the combustion temperature. The fuel material burns worse, and the potbelly stove begins to smoke.

Self-elimination of such defects is carried out as follows:

- Preparation of mortar for plastering based on clay, sand and asbestos in a ratio of 2: 1: 0.1, as well as a liquid cement primer.

- Thorough cleaning of the area with deformations to improve the adhesion of the solution to the surface.

- Surface treatment with cement primer.

- Filling and leveling defects with a binder.

- Application of finishing plaster on the treated surfaces.

Important! Defects in tiles are filled with a special solution made of chalk and a building plaster base. Items with serious damage must be replaced.

Structural wear

The next serious reason why the stove smokes may be structural wear as a result of long-term operation, negative effects of high temperatures, condensation and soot adhesion.

Violation of the integrity can lead to the formation of cracks and holes, which reduce the draft in the chimney. Not only the design of the stove is subject to destructive effects, but also the chimney, the walls of which can be deformed under the influence of unfavorable temperature processes.

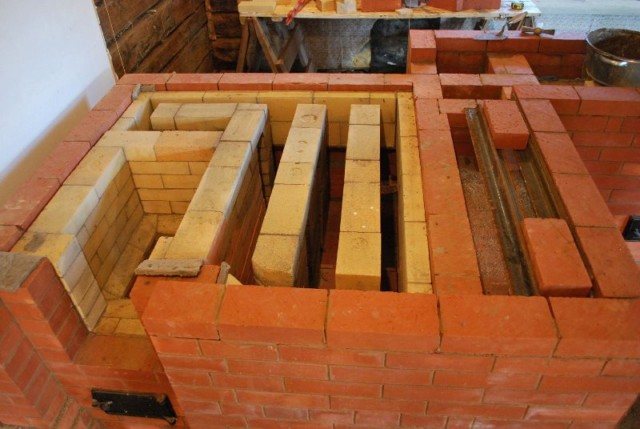

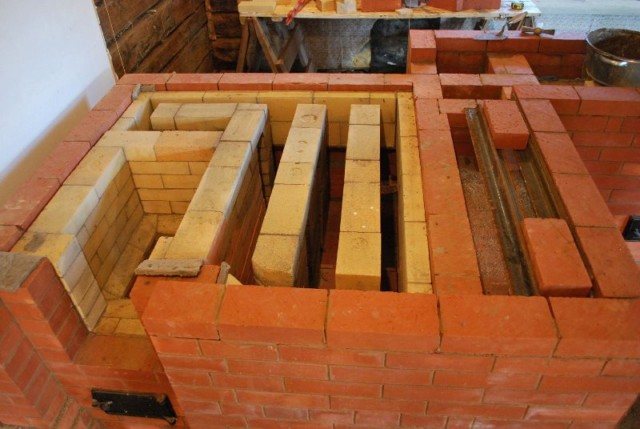

To eliminate wear, it will be necessary to repair damaged areas. For this, the following activities are carried out:

- Preparation of high-quality heat-resistant bricks for the restoration of worn-out areas.

- Removal of damaged elements and oven mortar from masonry. Surface cleaning.

- Preparation of a mortar from clay and sand, application to a prepared base.

- Laying new bricks, leveling the surface.

Important! The new layer of masonry mortar should be 1-2 cm thicker than the old one.

Troubleshooting solid fuel models

Solid fuel boilers may have the same chimney-related causes of smoke as the gas appliances described above. When firing it is necessary to use well-dried raw materials. It should be stored in well-adapted places with low humidity levels. Do not use synthetic materials as fuel.

Wood-fired boilers such as Buderus Logano SW, Stropuva S and Zhitomir D should only be fired with dry wood. To be able to use different types of fuel, you need to purchase combined devices such as KST or Smoke. You can experiment with the degree of opening of the gate in hot air models, such. If smoke appears, make the chimney opening larger.

Provide air supply to the boiler room. For safety reasons, the window must be constantly open during the operation of the boiler during the heating season. The solid fuel apparatus must be cleaned regularly. This is especially true if it is coal or diesel, working on mining, since these types of fuels clog the burner especially quickly.

Troubleshooting

All possible answers to the question "Why?" described above. And now the second question "What to do?" If a solid fuel heating boiler is smoking?

For kindling, you need to choose only dried logs, which should be stored under special covered sheds so that moisture gets minimally on the fuel. You don't need to use artificial materials as fuel.

Heating devices such as Buderus Logano SW, Stropuva S and Zhitomir D are fueled only with dried wood. If you want to use different types of fuel, you should think about purchasing universal units, for example, KST or Dymok.

It is possible to test the degree of opening of the gate in hot-air versions of such a brand as Siberia. If smoke appears, the chimney opening should be made larger.

It is required to ensure the flow of air masses to the boiler. According to safety rules, the window must be open all the time while the boiler is operating during the heating season. The solid fuel boiler should be cleaned from time to time.

Shed for firewood from a profile pipe and polycarbonate

Causes of boiler fuming

Some signs help determine what to look at in the first place when fumes and soot appear in the room. Conditionally, the causes of smoke can be divided into 4 groups:

- Clogged chimney is one of the most common problems. This can be either a foreign object that has entered from the outside, or the result of using low-quality fuel.

- The discrepancy between the chimney power of the boiler or the height of the building is less common and is detected almost immediately, at the very first heating. In a situation where at first everything was fine, and then began to smoke, this reason should not be considered.

- Damage to the chimney is the least likely case. But if the boiler gives off smoke at the beginning of a new heating season, then inspection of the pipe should be one of the first tasks.

- Weather conditions affect natural draft in only two cases: a low chimney height and an incorrect location of the fresh air inflow point.

The smoker should be raised above the roof ridge. The diameter of the pipe is selected in strict accordance with the power of the boiler: a small cross-section simply cannot cope with the removal of smoke from a serious firebox. You should also avoid right angles in places where the pipe changes direction - this makes it difficult for air to circulate, which is not the best reflected in the draft. Visual inspection allows you to identify these shortcomings and eliminate them.