Areas of use

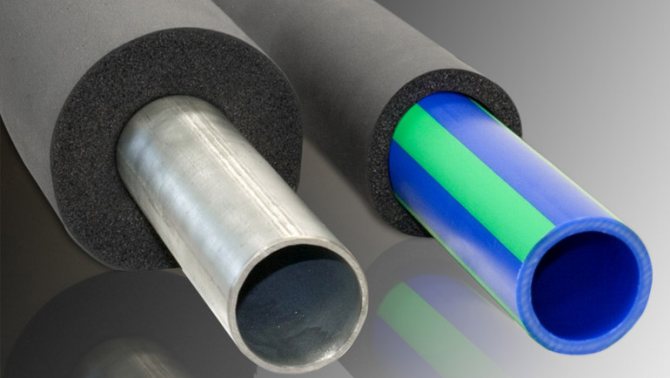

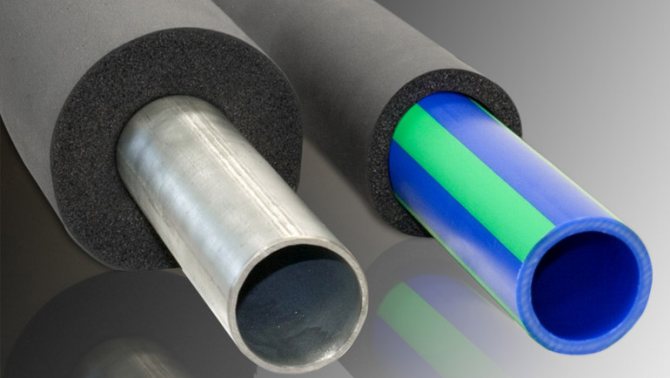

Foamed polyethylene shells are used for pipe insulation:

- Heat supply.

- Hot and cold water supply.

- Sewerage systems.

- Air conditioning installations.

- Ventilation ducts.

- Refrigeration equipment.

Insulation sheet based on foamed polyethylene is used to isolate:

- External and internal surfaces of the walls of buildings.

- Basements, foundation structures.

- Attic rooms.

- Roofs.

- Steam rooms, saunas, baths.

Foamed polyethylene bundles are used to seal:

- Interpanel seams.

- Cracks in window and door fillings.

Dimensions and diameters of insulation for polyethylene foam pipes

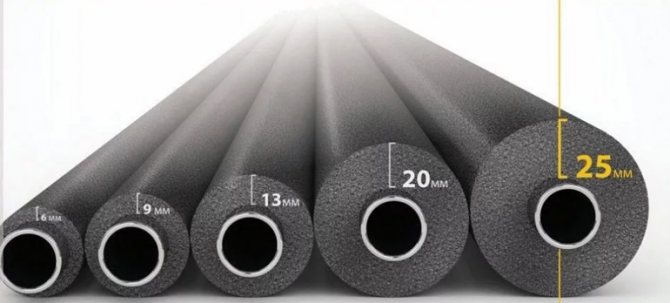

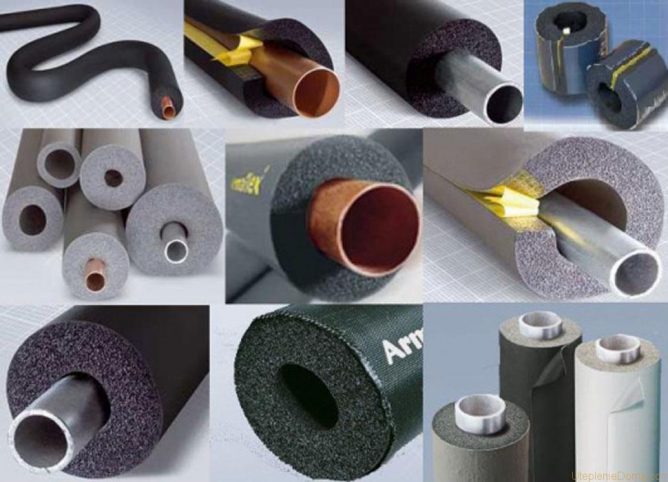

There are several types of heaters on sale, regardless of their purpose, all are created using the same technology, but have different thicknesses. Compared to sheet insulators used for walls and floors, pipe insulating material is produced in the form of cylinders or, in other words, shells with different outer and inner diameters, which makes it possible to carry out thermal insulation of communications under construction or already installed without problems.

The standard length of the tubes is 2 m, and their thickness and diameter are different depending on the size. So, the thickness can be 6, 9, 13, 20 or 32 mm, and the inner diameter - from 6 to 200 mm (for industrial purposes, products with large parameters are used). To make the thermal insulation of communications more effective, different manufacturers in the production of thermal insulation products are guided by standard pipe sizes.

In order to insulate communications that are constantly under the influence of ultraviolet rays, they use PES with a colored surface that reliably protects the heat insulator. There is also polyethylene with a foil surface that protects the pipes from the effects of low and high temperatures. Another type is roll insulating material with special tape, such products are used to insulate communications in hard-to-reach places.

Insulation diameters for foamed polyethylene pipes.

Manufacturing technology

Low density polyethylene (HDPE) granules are poured into the hopper, where they melt and are evenly mixed. Further, the resulting mass is subjected to foaming with gas or special reagents. At this stage, pigments and modifying additives are introduced into the melt. Then the heated mass is pressed through an extruder to give the insulation to the required shape.

Advantages and disadvantages

Thermal insulation for polyethylene foam pipes is endowed with numerous advantages:

- High thermal insulation properties. Its application allows to reduce heat loss up to 75% and to provide liquids with the same temperature during transportation.

- Low hygroscopicity. Insulated pipes are less susceptible to corrosion, as they are protected from the penetration of moisture from the environment to their outer surfaces.

- Good vapor barrier effect. Condensation does not form on surfaces insulated with polyethylene foam; additional waterproofing is not required when insulating pipes.

- Ability to withstand temperature extremes in the range from -80 to +95 ºС. Thanks to this property, the insulation can be used in difficult conditions.

- Soundproofing qualities. Foamed polyethylene absorbs sounds from circulating fluid in communications, partially dampens the level of structure-borne noise.

- Low weight.Warming with lightweight polyethylene foam pipes will not lead to a significant increase in the load on utility networks.

- Easy to install - no special hardware required.

- Ability to quickly recover to its original shape after compression.

- Biological stability. Foamed polyethylene is resistant to the formation of fungal deposits and mold.

- Inert towards chemical elements. Polyethylene insulation does not lose its qualities from contact with various mortars, alkaline and acidic media, so they can be used to insulate pipes running through concrete structures or buried in the ground.

- Ecological cleanliness. Foamed polyethylene does not emit toxic substances, such insulation can be used for thermal insulation of pipes in educational institutions, medical centers, technological pipelines of food production, etc.

- Affordable price. For a relatively small amount, pipelines can be insulated along their entire length.

- Long service life - at least 30 years.

However, this insulation also has three main disadvantages:

- Low fire resistance. Expanded polyethylene quickly begins to melt when exposed to open flames and can spread combustion to nearby structures.

- Hypersensitivity to ultraviolet radiation. Foamed polyethylene under the influence of direct sunlight becomes brittle, crumbles and cracks. To compensate for this disadvantage, the insulation is covered with foil from the outside.

- Low mechanical strength. The insulation is easily damaged by a sharp object, and the gap can spread further along the length of the insulation. Therefore, damage must be immediately sealed with reinforcing tape.

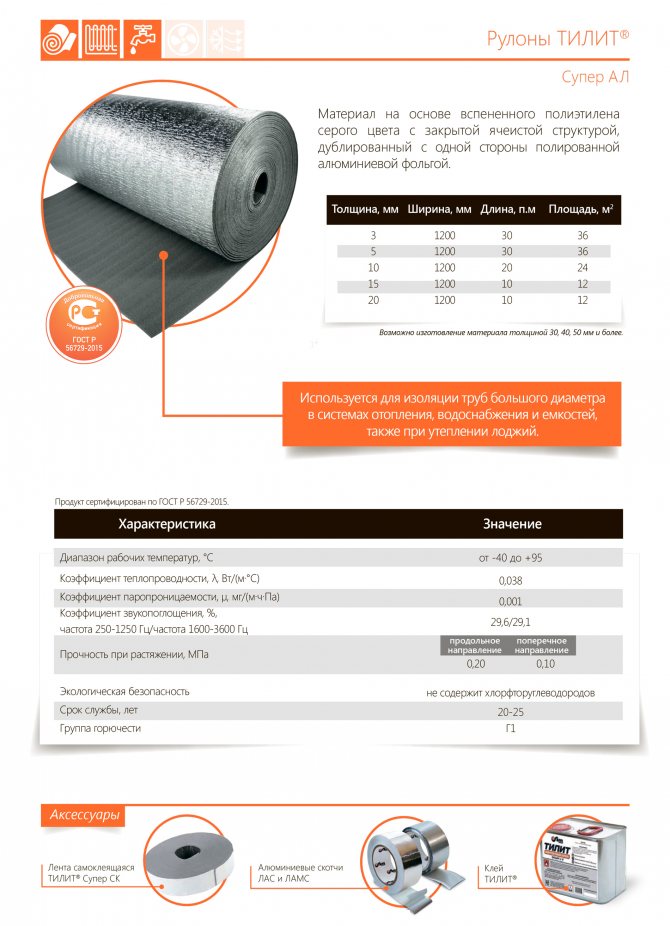

Specifications

Thermal insulation for polyethylene foam pipes has the following technical characteristics:

- thermal conductivity - 0.03-0.04 W / m * K;

- maximum temperature in the coolant - 180 ° C;

- density - 25-40 kg / m³;

- hygroscopicity - up to 2%;

- vapor permeability - 0.001 mg / m * h * Pa;

- tensile strength - up to 0.3 MPa;

- modulus of elasticity - up to 0.7 MPa;

- sound absorption coefficient - 25-55%;

- operating temperature range - ± 120 ° С;

- service life - 20-80 years.

The data differ depending on the type of polyethylene. The lowest rates are for uncrosslinked PE. Heaters made of physically cross-linked polymer are distinguished by the highest rates. Due to constantly developing technologies, the characteristics of foamed PE are periodically improved.

Basic requirements for heat-insulating materials for pipes

Products for pipe thermal insulation must have:

- Low coefficient of thermal conductivity. The thickness of the foamed polyethylene insulation depends on this indicator. Communications in apartments run in cramped conditions, for their insulation, not only effective, but also small-volume materials are needed. The use of thin-walled shells as a heater for pipes will allow you to save more usable area in these rooms.

- Hydrophobic properties. Moisture reduces the insulating properties of any insulation, and with a large accumulation it can form the so-called cold bridges.

- Resistance to mechanical stress and environmental conditions, since pipes have to be insulated in open areas or under a layer of soil.

- Heat resistance. This requirement must be met by heaters used to insulate pipes for hot water supply and heating.

Requirements for heaters

A good thermal insulation material must meet the following requirements:

- Minimum thermal conductivity... There is a direct relationship - the lower the thermal conductivity, the less the thickness of the insulation should be.Of course, the amount of insulation is not always important, but sometimes this quality turns out to be important, especially when it comes to industrial facilities.

- Moisture resistant... Since insulation is often used outdoors, the insulation material must withstand moisture and dampness well. Good material does not deteriorate due to such influence and does not lose its characteristics.

- High strength... Insulation must withstand all external influences, such as precipitation and weather events. The slightest damage to the thermal insulation can cause the pipeline to stop, therefore, the ability to resist mechanical damage must be high.

- Resistance to temperature extremes... Any insulation material must not only withstand every external impact without damage, but also withstand well the high temperature of the liquid that moves through the pipeline.

If the material meets these requirements, then it may well be used for pipeline insulation.

Classification types and dimensions

Thermal insulation materials made of polyethylene foam are divided into types according to several criteria:

- The structure is stitched and unstitched.

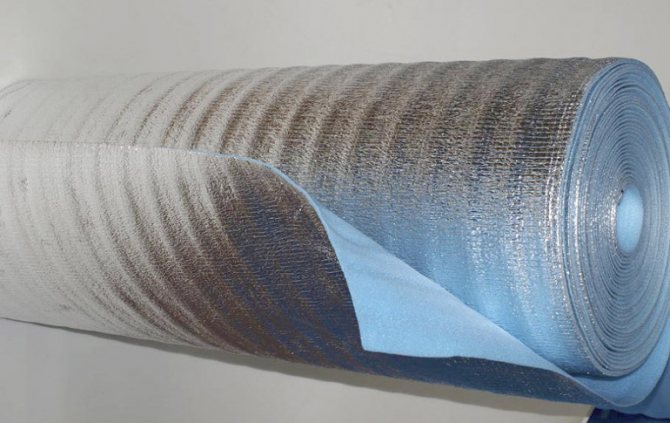

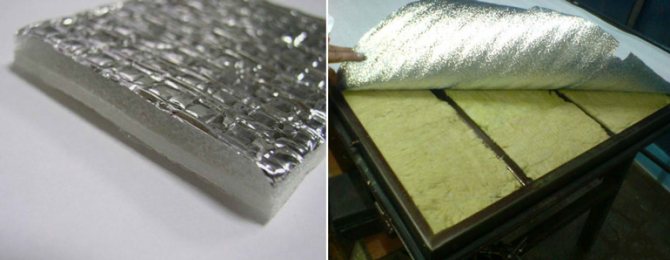

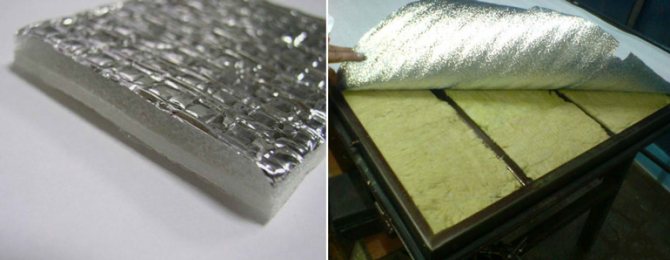

- By the type of surface finish - uncoated, foil-coated with aluminum on one or both sides, with a protective polymer coating.

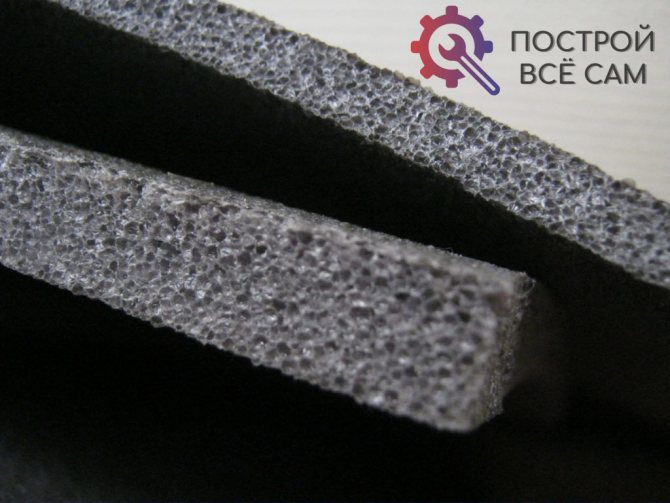

The rolls have a width of 60 to 120 cm, a length of 2 to 30 meters, the sheet thickness in them is no more than 5 cm. Tubes are produced in lengths from 1 to 10 meters with a wall thickness of 6–32 mm and a diameter of 6 to 160 mm.

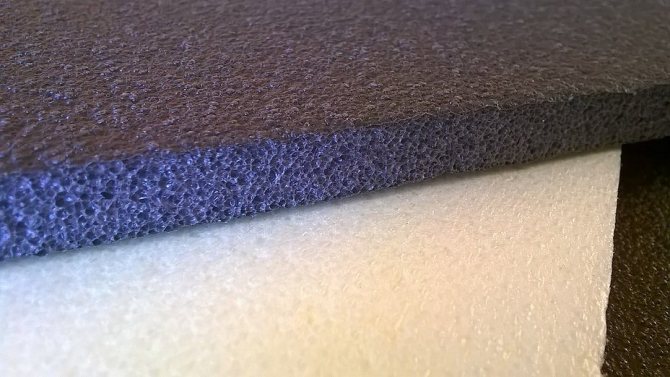

Stitched

Crosslinked polyethylene foam is called, the structure of which is modified at the molecular level under the influence of external factors. The result is a material with very small closed cells that is more resistant to stress.

There are two types of cross-linked polyethylene foam:

- Chemically cross-linked (CS PPE). The molten polymer is mixed with blowing agents and treated with chemicals.

- Crosslinked by radiation method (FS PPE). The foamed polymer mass is exposed to a pulse-beam accelerator, which regulates the molecular structure of the material with a stream of electrons.

The cross-linked polyethylene pipe insulation is more durable, elastic and dense. It has a shape memory effect for insulated structures.

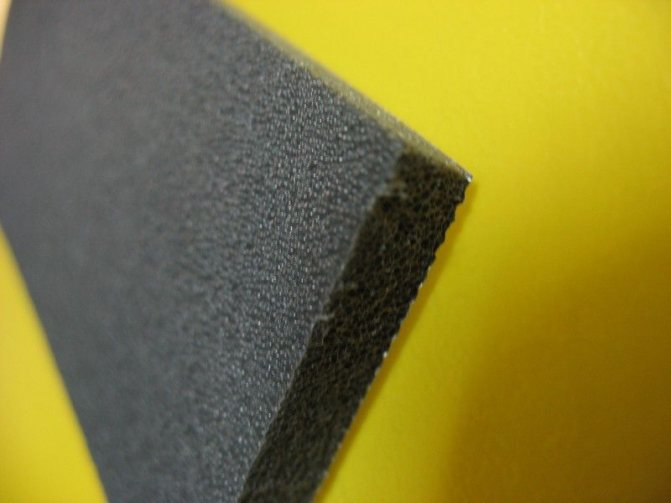

Unstitched

Uncrosslinked polyethylene foam is designated by the letters NPE. Formed in the process of processing polyethylene with gaseous reagents (a mixture of propane-butane or freon). This type of insulation has a structure with larger gas-filled cells.

Cut

Foamed polyethylene pipes, which have a technical slot along their entire length, can be easily put on already installed lines. To install them, you do not need to dismantle pipe sections. The edges of the halves are joined end-to-end and glued with metallized tape.

Whole

The thermal insulation material is in the form of hollow cylinders with a solid surface. They are installed on the pipe during the pipeline assembly process.

Foil

The material is coated on one or both sides with a thin layer of aluminum foil or metallized film. The maximum adhesion of the layers is achieved by thermal welding. To increase the heat-reflecting effect, the foil is polished. Foil insulation made of foamed polyethylene has:

- Higher coefficient of thermal insulation.

- Shock absorbing qualities.

- Fire resistance.

- UV resistant.

Varieties and their differences

Foam polymers are divided by types of manufacture, on which the quality and price of products depend:

| Uncrosslinked polyethylene foam | It is made of budget material, so its price is lower. It is used for laying insulation layers or packaging electrical equipment. It is rarely used for other purposes. |

| Chemically crosslinked polyethylene foam | To create this type of material, chemicals are used. additives (most often hydrogen peroxide or other catalysts). As a result, polyethylene is obtained several times better and denser than non-crosslinked polyethylene. |

| Physically cross-linked polyethylene foam | For production, solid-state electron emitters are used. Radioactive substances are located around the polymer raw materials and pierce microscopic holes with electrons. The density of the material in this way becomes as high as possible. This type of product is excellent for the production of tubeshell, creating a protective layer around the pipe, but it does not cope well with thermal insulation. This is the most expensive type of polyethylene foam. |

We recommend that you familiarize yourself with: Arrangement of a horizontal stove chimney

Overview of manufacturers

I have heard many positive reviews about heaters Vilatherm, Isolon, Penoline, Merilon, EnergoFlex and Thermaflex.

- Vilatherm

Vilatherm is produced by a Moscow company. The material has a fine-mesh structure with closed pores, is hygroscopic, absorbs shock and noise, and is environmentally friendly. Due to the high air content, it has high thermal insulation properties.

The assortment consists of harnesses and cylinders. Insulation in a cylindrical form is suitable for insulating pipes both in new, installed objects, and for existing, operated pipelines.

- Izolon, penoline

OJSC Izhevsk Plastics Plant produces two types of sheet insulation with a thickness of 1 to 5 cm under the Izolon trademark:

- NPE - from unstitched.

- PPE, PPE -L, PPE - NR, PPE-NKh - from cross-linked polyethylene foam.

Isolon has a very low heat conductivity coefficient. It reliably protects the room from steam and moisture.

Heat-insulating mats and pipe insulation Penolin are produced by CJSC Information Technologies Plant LIT. It is available in various thicknesses and colors, the width of the blade is 110 and 125mm. It is possible to cover the insulation with aluminum foil, plastic metallized film and other materials.

- Merilon

Insulation pipe MERILON (Czech Republic) is produced with an inner diameter of 15 to 110 mm and a wall thickness of 6 to 18 mm, which causes a different degree of insulation. Foamed polyethylene Merilon has an extremely porous structure.

It is moisture-proof, not subject to decay. The structure with many air cells provides it with good thermal insulation properties.

- Energoflex

Energoflex is an environmentally friendly polyethylene foam insulation that meets all European standards in quality. Freon is used for its manufacture, so the material resists the diffusion of water vapor better.

It is used to protect various pipes, containers and fittings from heat loss. Thermal insulation is produced in the form of sheets, rolls and sleeves of various diameters.

- Thermaflex

(Netherlands) produces a wide range of pipe and sheet heaters for engineering systems operating in the temperature range from -80 to +110 ° C. Thermoflex has low thermal conductivity and high resistance to water vapor diffusion, retains good elasticity at subzero temperatures, does not absorb moisture and does not decompose.

Forms of release and popular manufacturers

On the domestic market, polyethylene insulation is presented, made in the form of sheets, hollow inside sleeves and bundles. Sheets are used in situations where it is necessary to finish a wide flat or slightly curved surface.

Sleeves are needed to insulate pipes: a special cut can be made in solid insulation, thanks to which the material is simply "put on" the pipeline without dismantling the system elements. Bundles are required to seal the seams between panels and joints of window or door frames.

Domestic brands

In Russia, materials and "Energoflex" are the most widespread.The first pays the greatest attention to ensuring the safety of pipes, the second - to the waterproofing characteristics of the insulation. At the same time, Energoflex uses freon for the production of polyethylene, and not a propane-butane mixture, like other manufacturers. As a result, a better resistance of the material to water vapor diffusion is achieved.

Products of the Izokom, Teploflex, Quick-Step and Jermaflex brands are also in good demand. The listed companies produce polyethylene only in rolls, which is why it is rarely used to insulate heating systems.

How to choose

When choosing a polyethylene foam insulation, consider the following factors:

- The size and location of the insulated structure. You can insulate the floor using roll materials, heating and sewage pipes - with a shell. Bundles are suitable for sealing gaps in doors and windows.

- The density of the material. The higher the density of the insulation, the greater external loads it can withstand, while maintaining its shape and properties.

- Convenience of installation work.

- The maximum level of heating of the coolant and the lowest temperature in the environment. This criterion influences the choice of the wall thickness of the insulation.

- The reputation of the manufacturer.

approximate price

Average prices from different manufacturers are:

- Vilatherm: a sealing strand with a cross section of 6 mm - from 3.5 rubles / r.m.

- Merilon: foil-coated (3 mm, length 30 m) - 1450 rubles / roll, 10 mm thick, 15 m long - 2100 rubles / roll.

- Energoflex: pipe insulation: 16 rubles / roll (22 × 9 mm); 150 rubles / roll (110/13 mm).

- Penoline: with a thickness of 2 mm, the cost is 450 rubles; with a thickness of 5 mm - 1030 rubles.

- Thermoflex: 750 rubles / roll (25 m length, 2 mm thickness).

What to look for when choosing

When choosing thermal insulation, the location of the pipes, the density of the material and its size are taken into account:

- To ensure tightness, it is important that the diameter of the insulating tube matches the size of the pipe itself: the material must be in close contact with its surface.

- The thickness of the walls depends on the temperature in the coolant and the lower limit of temperature values in the external environment, as well as on the purpose of thermal insulation: protection against freezing, preventing moisture from appearing on the surface or ensuring the desired temperature on the coating requires the selection of a thermal insulation layer of different thicknesses.

Note! In places where pipes are located on the surface under the rays of the sun, polyethylene foam with a protective polymer layer is used.

One of the important parameters when choosing is the size of the cells of the material. The smaller the size, the greater its ability to retain heat:

We recommend that you familiarize yourself with: Overview of fittings for installing copper pipes

| Appointment | The size |

| insulation for cold water pipes | 9 mm |

| insulation for heating and hot water systems | 13-20 mm |

| screed pipes or in walls | 6 mm |

Instructions for use

There are several general rules that must be followed when installing foam insulation:

- The surfaces of the objects to be insulated are prepared in advance. They are cleaned and leveled, cracks and seams are closed.

- All equipment should not work during the thermal insulation work.

- The joints are glued with glue, and the seams are held together with self-adhesive tape.

- There should be a small space between the work surface and the insulation material - an air gap.

- Heat insulators made of polyethylene foam are not recommended to be installed with an overlap, but only end-to-end.

- Foil insulation is mounted with a shiny layer towards the room.

For thermal insulation of the door leaf, it is enough to cut a blank from a sheet of polyethylene foam by measure and fix it on top with a finishing material. On the surface of the enclosing structures from the inside of the house, foamed thermal insulation can be laid under drywall, which will significantly reduce heat loss.

It is better to insulate the balcony or loggia with polyethylene foam with a protective film from ultraviolet radiation or foil material. It will reliably protect these structures from moisture and street noise, while their area will decrease slightly.

What should be a modern insulation

In addition, it meets all the requirements for modern thermal insulation materials:

- High mechanical strength, ensuring the integrity of materials during transportation and installation;

- Low thermal conductivity, which, in fact, is responsible for maintaining the temperature of the coolants;

- Chemical resistance, implying the use of insulation in various environments, such as concrete, lime, cement;

- Ease of installation, ensuring fast and high-quality work;

- Small thickness, allowing to save pipe laying area;

- Environmental friendliness, which is expressed in the absence of harmful effects on the environment and humans;

- Affordability (foamed polyethylene insulation is an order of magnitude cheaper than other types of insulation with other advantages;

- The wide temperature range that polyethylene foam can withstand allows it to be used in a wide variety of conditions;

- Long service life, makes it possible to save on repair work.

Features of pipe insulation work

The installation of pipe insulation is often performed after the assembly of the pipeline. It is impossible to put on one-piece cylinders on the mounted sections of the pipeline, therefore, products with ready-made cuts are used or cut during installation. The edges of the cut sleeves are fixed with special tape after installation on the pipes.

Installation should begin with surface preparation of the pipes:

- Thorough cleaning of dirt and dust.

- Any abrasive material can be used to remove rust. They need to rub the pipe well, then wash with warm soapy water. The dried pipe can be painted or primed.

I usually glue the outer pipe insulation along the cuts and at the joints. If the pipes are inside the building, then it is not necessary to glue the insulation along the entire length. You can simply fix it with one tape.

Features of installing thermal insulation in places of pipe branching, see the video.

Insulation installation

Consider the features of installing insulation on the communications under construction and already assembled. So, in order to perform thermal insulation of pipes at the assembly stage, you will need to carry out the following steps:

- place pipes in cylinders;

- process the joints with adhesive;

- fix the joints with special tape.

Do-it-yourself installation of insulation.

If you need to install the material on an already finished structure, then:

- each cylinder must be cut according to the dimensions of the insulated pipelines;

- cut the cylinders lengthwise and put them on the pipes;

- securely glue the cuts and joints.

With proper installation, the thermal insulation material will last a long time without reducing the initial properties and deformation.

How to calculate insulation for your home

If you need to insulate the walls of the house from the inside, then you need to measure their width and height in all rooms. Then multiply these parameters to calculate the area of each wall separately, and sum the values obtained to determine the total area of insulation. Further, from the amount received, you need to subtract the area of the window and door openings in order to determine the required amount of thermal insulation material.

Pipe insulation is calculated even easier - according to the total length of the pipelines to be insulated.