It is quite possible to endure some time without household appliances and a TV set. The situation is much more serious if the operation of the gas boiler is interrupted during a power outage, even for a short period. It is especially unpleasant if the start-up of the power grid is delayed for an indefinite period. Do you agree?

On the forums, many masters argue that when the electricity supply is stopped with the gas equipment turned off untimely, the boiler may break. It is even worse if life-threatening carbon monoxide goes into the room. Are you ready to take such a risk, or is it still better to abandon an electrically dependent heating source?

We will not let you freeze or empty your pockets in vain, spending money on useless events. Let's talk in detail about what will happen to the gas boiler if the power supply is suddenly cut off. You will learn how to ensure the smooth operation of even the most expensive machine stuffed with electronics.

Which elements of the boiler depend on electricity?

Power outages for homes, not only in the hinterlands, but also in cities, occur quite often. They happen due to emergency situations, planned repair and technical work, breakdowns on the line. And the most unpleasant thing is that when the electricity is turned off, the operation of the gas boiler is paralyzed if it is of a volatile type.

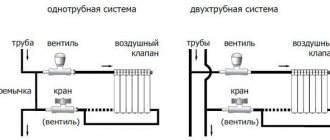

The nonvolatile gas boiler continues to function as usual, even if a power outage occurs on the power line. The only exception is if a pump works in conjunction with it, and a system of gravitational circulation of the coolant is not provided.

Non-volatile boilers have the simplest, basic set of functions. They are less comfortable to use than their volatile counterparts. But their work is absolutely independent of the supply of energy to the home power grid, moreover, they are less likely to fail.

In a heating circuit with a boiler of the simplest type, the set of basic elements is approximately the following:

- natural draft smoke exhaust system;

- heat exchanger;

- a gas burner with nozzles for supplying gas, which is located in the combustion chamber;

- gas supply and ignition unit;

- expansion tank;

- mechanical thermal sensor;

- control module, which includes the boiler ignition system (mechanical or piezo), temperature control;

- safety group (safety valve, pressure gauge, air vent).

Volatile devices are more complex in the device. But is electricity really necessary and important for the functioning of a gas boiler?

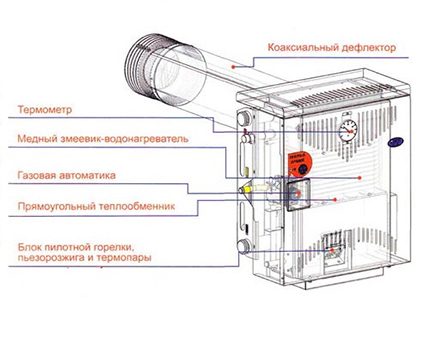

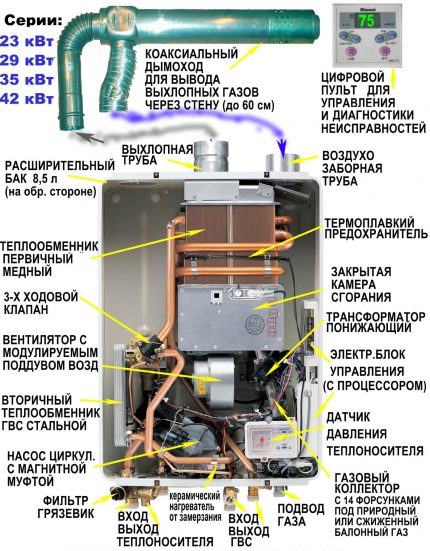

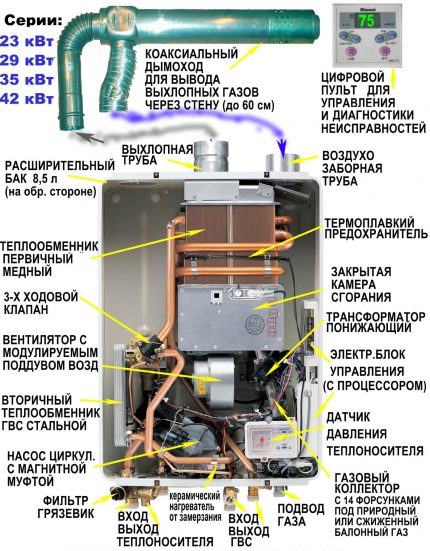

Depending on the model and brand, in addition to the same basic set of elements, in some cases, electronic and automatic type, they may include such functions as:

- forced ventilation system;

- built-in circulation pump;

- electronic system control module;

- shut-off and control valves on an electric drive;

- various sensors - water flow, temperature, flame supply, water pressure in systems, manostat, emergency complexes;

- piezo ignition unit with electric drive;

- automatic temperature controllers;

- notification and remote control system;

- display with the output of the current indicators of the device

Units of this type are more reliable and much more convenient to operate, and besides, they are economical. Automation can be set on and off modes, reducing fuel consumption, creating a comfortable microclimate at home, not worrying about safety and performance.

Modern boilers are crammed with electronics.When choosing a device, also install a voltage stabilizer to protect against power surges

The only negative, after a power outage, a volatile gas boiler will not be able to work fully. It is difficult to say which functions will be absent altogether, it depends on the boiler model. Some units have a combined control system - mechanical and electronic.

It is certain that forced ventilation, automatic control of the flame supply to the burner, pump, display, electronic control module, in general, all devices operating on an electric drive and a constant supply of current will not function.

But is everything so scary?

Why is water dripping from the heating boiler and how to eliminate the fistula with your own hands?

In fact, there are not so many reasons why the boiler leaked. First, corrosion can be the culprit. What is corrosion is the destruction of the metal structure under the influence of the external environment. Internal corrosion of a gas boiler is caused by the influence of oxygen in the water, external corrosion by combustion products.

The next reason for a leak may be the low quality of the metal from which the heat exchanger is made and the quality of the seams of its joints.

High pressure in the system, or water hammer also cause leaks in boilers. Burning out the walls of the heat exchanger also leaks.

In some cases, when water is dripping from the boiler and you think that your boiler is leaking, in fact, it may be condensate from the chimney, which flows down the chimney and enters the burner. If this situation occurs often, a moisture collecting cup should be equipped in the chimney. When it drips near the circulation pump, the bolt located in its center may have loosened. Tighten the bolt.

Below we will consider in more detail each case separately and describe what to do if this happens.

Wall thickness and corrosion

Heat exchangers installed in heat generators can be made of copper, steel and cast iron. Each has its own pros and cons. Copper heat exchangers are corrosion resistant and durable if the boiler is used correctly. Steel heat exchangers are the most common, due to their low cost, are resistant to thermal stresses, due to their ductility, but they are more likely to corrode.

Heat exchanger corrosion

Cast iron are resistant to corrosion, have a long service life, although they are afraid of temperature extremes and water hammer. Most manufacturers do not use anti-corrosion coatings. But in the latest models of Ferroli gas double-circuit boilers (Ferroli), the steel heat exchangers are covered with an anti-corrosion aluminum coating with environmental internal insulation.

On Baxi units, copper heat exchangers are coated with a special composition against corrosion. Protherm (Proterm), Buderus and Beretta have a cast-iron heat exchanger, which is coated with a special composition against corrosion. In addition, such a heat exchanger consists of separate sections, which can be changed in case of damage without completely changing the heat exchanger.

Wall-hung boilers Rinnai, Celtic (Celtic), Bosch (Bosch) are equipped with copper heat exchangers, Vaillant (Vilant) and Navien - from stainless steel, it is believed that they are less susceptible to corrosion.

The formation of corrosion is greatly influenced by the frequent feeding of the boiler. Ideally, the so-called "dead water" should circulate in the heat generator without oxygen. It is oxygen that contributes to the formation of corrosion.

If you often have to recharge the heat generator, you must eliminate the causes of the pressure drop in the unit. Oxygen corrosion forms an ulcer on the inside of the heat exchanger, which is very dangerous.As it grows inward, it forms rust through and destroys the heat exchanger.

Workmanship

The strength of the boiler depends on the quality of the welded joints. If the weld has cavities, irregularities, sooner or later this seam may leak. The void inside the seam is considered especially dangerous. Ideally, the seams should be X-rayed, but not all manufacturers do this.

Although boilers are pressure vessels and must be subject to increased manufacturing requirements, defect sometimes occurs. And, as a rule, it drips from the heating boiler after the end of the warranty. It is not always possible to weld the boiler inside and stop the leak.

It depends on how the heat exchanger is designed. In models where a bithermal heat exchanger is installed (the secondary and primary are in the same housing, heat exchange occurs due to the two-in-one design), this is problematic. But, even if you did this, as practice shows, it will not help you for long.

High system pressure

Excessive pressure in the system can also cause the boiler to leak. There are many reasons for high blood pressure. The main reason may be a malfunction of the expansion tank, air locks in the system, a clogged strainer, a malfunction of the safety valve, the make-up valve.

A failure of the safety valve is indicated by constantly leaking fluid from the tube. High pressure can not only crack the boiler, but also cause an explosion. Make sure that the pressure gauge and the relief valve are in good working order, sometimes the valve is jammed due to the formation of a layer of salts on it. Wash it in citric acid.

Heating boiler safety valve

The pressure on the valve and in the expansion vessel must be checked regularly. When installing an expansion tank, it is necessary to calculate the volume of the coolant. How to calculate - there is a calculation formula, and the average value is -1.5 atm or 0.2 atm lower than in the system. For preventive maintenance, do not forget to flush the filters at the inlet and outlet of the heating circuit; after making up the system, it is necessary to air the batteries.

Burnt walls

The cause of the leak can be burnout of the combustion chamber wall. Steel and cast iron burn out when carbon escapes from their composition, so the metal on the combustion chamber becomes thicker. As a rule, burnout occurs when the combustion chamber height is incorrectly set, the burner power is set incorrectly, the burner is not adjusted to the minimum and maximum power, the flame is too high.

Burnout occurs when the boiler is constantly operating at maximum power, this happens in the event of insufficient insulation of the housing or when the heat generator is selected without taking into account the heated area.

When purchasing a boiler, read reviews on the Internet and give preference to positively reputable manufacturers. It is better to buy a heat generator of slightly higher power, with reliable flame modulation and entrust the setting to specialists.

How to stop a leak with your own hands

How to fix a leak - the algorithm for eliminating a leak is the same both on solid fuel boilers, such as Don, KChM, and gas boilers, for example, on AOGV, Alixia 24, Ariston (Ariston), Daewoo, Arderia, Electrolux.

- Turn off the device.

- Drain the water.

- Wait until the boiler has completely cooled down.

- To remove the heat exchanger, we will describe how to do it below.

- Solder, eliminate the fistula.

What a heat exchanger looks like - it is a metal or cast-iron body, heated by a burner flame and transferring thermal energy to the liquid that is inside it.

To disassemble it and solder it yourself, you need to remove the front panel, protective casing and combustion chamber protection using a long screwdriver. Then disconnect the sensor wires and pipelines suitable for the heat exchanger, try not to damage the pipes and pipes, hold them with a wrench.

In order to then connect everything correctly, you should first take a picture of the insides of the heat generator. Then disconnect the fan and smoke detector. When removing the heat exchanger, do not use force or make sudden movements, do everything very carefully.

If you find a breakthrough between the circuits in the tube, it is impossible to close such a hole, you will have to change the heat exchanger. It is impossible to weld the heat exchanger, you should use a gas torch soldering.

Brazing the heat exchanger

In order to do the soldering with your own hands, you must first clean up the place where the fistula formed. This can be done with fine sandpaper. Soldering is carried out with a gas-oxygen mixture with a solder containing the same chemical elements from which the heat exchanger is made.

It is impossible to use tin in this case, since such repairs after a while will again lead to the formation of a fistula. After soldering, a protective coating, such as a layer of aluminum, should be applied to the problem area.

Prevention of fistula formation

When buying a heat generator, carefully review the quality of the soldering of the connecting seams, both on the water and on the primary heat exchanger, there should be no sagging or irregularities.

Adjust the burner according to the instructions in the instructions. To avoid the appearance of fistulas, it is necessary to take timely measures in the presence of high pressure and airiness in the system. Avoid frequent replenishment of the system with water, find out the cause of the pressure drop in this case and eliminate it.

boilervdom.ru

Are power outages dangerous?

Sellers of non-volatile devices and uninterruptible power supplies tell customers blood-curdling stories that look quite believable. A person who does not understand anything at all about the boiler design will believe that in the event of a power failure, the gas supply to the burner continues.

What is really going on? When the temperature sensors, the electronic control unit and the pump are turned off, uncontrolled combustion of fuel in the combustion chamber occurs, which means that the liquid in the heat exchanger overheats.

Accordingly, the pipes do not withstand, they deform, and the water from them bursts, extinguishes the burner of the atmospheric gas boiler. Gas enters the room and creates an explosive situation or simply poisons people and animals. And if the boiler is equipped with a pressurized ventilation system - to the street. This is also unsafe and not environmentally friendly.

Do you agree that it sounds believable and scary? Have you already decided to run for a non-volatile boiler? But in vain!

Do not avoid carrying out maintenance on gas appliances and their components. Testing will show their performance, especially after power outages

In fact, electrically dependent boilers occupy a leading position in the sales market. They are installed in summer cottages, private houses, with owners who spend half a day at work, non-residential premises in which long-term repairs are being carried out.

Power outages, as mentioned earlier, are quite frequent. And for some reason there is no data on hourly large-scale tragedies of carbon monoxide poisoning or explosions.

In addition, such a dangerous device would not be certified and could not comply with GOST in any way, which means that gas workers will not be allowed to operate it.

Now for the technical details. In fact, there is a reliable system in the devices that ensures the shutdown of the boiler in the event of force majeure, including a power outage.

Problems of long-burning boilers

During the operation of long-burning boilers, such as, for example, Stropuva boilers, the following problems may arise:

- Detonation. Most often, this phenomenon occurs when the device is first started. The process is accompanied by humming sounds and the appearance of smoke. The detonation is caused by too much draft in the chimney. The situation can be saved by installing a chimney draft regulator. This device automatically reduces the air flow.

- Black resin is leaking from the lower door. Too much tar formation in a solid fuel boiler occurs when the temperature in the combustion chamber is below 55 degrees. In most cases, the problem can be solved by increasing the set temperature on the boiler regulator. In some situations, specialist intervention will be required to balance the operation of the system. Also, low-quality fuel can be the cause of a large amount of tar.

- Fuel combustion occurs faster than the minimum time. The reason may be too high heat consumption (discrepancy between the unit capacity and the volume of the room) or poor fuel quality. The problem can be solved by installing an additional heating device, measures for warming the room or switching to the use of fuel with a higher calorific value.

- Poor temperature control. The reason may be that the device is already working at 100% of its capacity, or the chimney draft regulator is faulty. The measures described in the previous paragraph or the repair of the draft regulator will help to solve the problem.

Gas supply cut-off safety devices

As part of the automation of a gas boiler, a shut-off valve is often used as a fast-acting shut-off system, popularly called simply a cut-off valve. Unlike other shut-off valves, the valve has an automatic actuation.

Its main purpose is to supply gas to the burner at the required pressure at a given power and to completely cut off the fuel supply in the event of a malfunction. This process is carried out by means of control devices with built-in sensors.

Gas piezo units are non-volatile, but can be used for both types of boilers

Automation differs in the type of ignition - piezo ignition and electric ignition are distinguished.

Piezo ignition - this is when the start is done manually, by pressing a button. It monitors the operation of the flame - a thermocouple, which is heated by an igniter and generating a constant current, ensures the open state of the valve.

As soon as, for some reason, the pilot burner stops supplying an open flame, the solenoid valve closes and the gas flow stops. Piezo ignition is a volatile automation element.

Electric ignition unit connects to the power supply. The launch is carried out from an electric spark in an automatic mode. This system is volatile and in the event of a power outage, the device valve shuts off the gas supply.

It looks something like this. The differential relay has two contacts. During normal operation of the heater, one block is closed. When there is any change in the operation of the boiler, for example, the power is turned off, the second unit is triggered, and the first one is opened. The relay moves, the diaphragm flexes and the gas supply is cut off.

How long do they turn off the electricity?

If you, having lived for a year or two in a settlement, have not experienced frequent and prolonged power outages, this does not mean that they will not happen.

Nobody is insured and practically nowhere. Even in places close to large cities, there were cases of weekly blackouts due to weather conditions.

In 2020, because of the strongest freezing rain, entire settlements of the Moscow region sat without stable heating for a week.

Usually, the period for which the supply of current is interrupted depends on its cause:

- Short-term shutdown for a period from half an hour to 2 hours due to a scheduled check of networks or exceeding the limit consumption.

- Elimination of emergencies of a simple nature, connection of new subscribers - from 3 to 6 hours.

- Short circuits, KTP malfunction - 12-24 hours.

- Serious accidents associated with negative weather conditions, inability to quickly repair the line - from 1 to 3 days.

If the first 3 situations are quite bearable in terms of timing, then subject to weak thermal insulation of the house structure or the presence of tenants who are contraindicated in coolness, the latter option is highly undesirable. In addition, even these terms cannot guarantee that even after their expiration, the power supply will resume, it is better to play it safe.

Many people put an alternative source of heating, for example, a stove, a fireplace, and this is undoubtedly a reasonable combination, when someone is constantly at home and can control the heating, but it is much easier and even cheaper to install a backup power supply system.

How to choose a redundant power supply?

The most popular option is an uninterruptible power supply, or UPS for short. It provides a secondary power supply to the device in case of a short-term power outage on the line.

Most often it is used to provide power to a computer, so that a person has time to modify, save information and exit the system in normal mode in the event of a power outage from the main source.

Of course, an ordinary uninterruptible power supply from a computer is not suitable for a gas boiler. The maximum that he can do is to extend the functionality of the device by 2-3 minutes, since at the output it gives an approximation of a sine wave or a meander, and the boiler requires a pure sine. Consider this when purchasing the device.

A competent choice of UPS for the boiler will allow you to ensure the supply of fuel even in the event of a power outage on the line

Ideally, an uninterruptible power supply with a capacity of 300-600 W is suitable, with the ability to connect a battery up to 600 A * h. The capacity of such a battery will last for 3 days.

But if you, for some reason, want to save money, please note that:

- 50-100 A * h, will prolong the operation of the boiler for a period from 3 to 8 hours;

- 200 A * h - enough for about a day of uninterrupted functionality.

More than a day of shutdown requires a more powerful power source. And here it is best to choose an inverter gasoline generator, which also has a pure sine wave. With the help of these devices, the gas boiler will work in a stable mode after disconnecting the load.

Dead water

Any heating system must circulate "dead water".

No rust or other build-up occurs in copper heating pipes. Therefore, there is no need to consider the insides of the pipes. It is better not to use galvanized elements in the heating system, as they quickly rust.

Due to dead water, air is released from the system, so the water circulates without oxygen. Since there is no oxygen in the system, boilers and radiators made of steel do not rust. It can be concluded that "dead water" is needed in the heating system. If it is necessary to add water to the system, then an urgent need to look for the cause of the pressure drop. If not removed, the steel radiators and boiler will suffer. It is not recommended to drain water from the heating system unnecessarily.

In an open heating system, it is necessary to leave a small hole on the cover of the expansion tank to release air. If a large hole is made, oxygen will flow into the tank. It would be better to arrange a closed heating system.

What will happen after the power supply is restored?

One of the most pressing consumer questions is whether the volatile gas boiler will turn on automatically after a power outage?

Depending on the boiler model, after the electricity is reconnected, it can ignite automatically or only after manual start. Devices with piezoelectric ignition will require mechanical activation.

Devices with an atmospheric burner, as well as units with the aforementioned pressurized system, are able to turn on independently, and even without losing the set automatic parameters, if they are equipped with an electric ignition and a pressure switch.

However, auto power on does not always work either. After a large number of subscribers are de-energized, with the resumption of electricity, the pressure in the gas pipeline may drop for some time, respectively, the pressure switch is triggered, the equipment does not turn on and it can only be started manually later.

For those for whom this question is relevant, it is enough to install a delay relay or, as it is also called, a "time relay". Then your boiler will not start immediately, but after some time, when the pressure in the gas pipeline will most likely equalize.

The time relay allows you to delay the auto-start of the electric ignition until the presumable equalization of the gas pressure

In some cases, the electronic control module displays an error after the power supply. This means that there was a small emergency before the shutdown. The decoding of the code can be found in the instructions for the heater.

By the way, not all of them can be eliminated on their own; to solve individual problems, you will need to call a specialist from GorGaz or a service department.

High blood pressure

If the pressure in the system exceeds the design pressure, the boiler may leak. Each boiler is designed for a specific pressure value. If overheating occurs and the pressure rises, then the volume of water will increase. As a result, the solder will crack and the boiler will flow. This will happen in the absence of an emergency valve. If it is installed, then you can avoid such an unpleasant situation.

The emergency valve and pressure gauge should be checked periodically. They may be defective. Then you cannot prevent the accident. It happens that the valve starts to wedge. In this case, you need to unscrew it, and then soak it in citric acid. After that, you can screw it back and check the operation.

It is recommended to drain the water once a year and check the membrane tank.

If the maximum pressure in the heating system is 1.5 atmospheres, then the air pressure in the membrane tank will be sufficient for 1 atmosphere.

Many people believe that there is no pressure in an open heating system, where an expansion tank is arranged. But this is not true. There is pressure in any heating system. Any pressure can be made in a closed system, though. But in an open heating system, it is also present. It can be assumed that the boiler, which is designed for a pressure of 1.5 atmospheres, can be used in a building that has 4 floors.

Conclusions and useful video on the topic

How to choose a UPS for a gas boiler correctly. Purchase criteria and nuances:

So, as we found out, a power outage will not spoil expensive volatile equipment. All systems dependent on electricity will simply shut down and the gas supply will be cut off by a shut-off valve.

And if you also have a UPS installed, you will not even notice a short-term interruption in the supply of current to the line.

Please write your comments in the block below, ask questions, post photos on the topic of the article. Tell us about how your boiler “behaved” after turning off and starting the power supply. Share useful information that will be useful to site visitors.