Many modern heating systems are controlled by automatics and need a constant supply of electricity for correct operation. If there are regular interruptions to the energy resource, experts recommend buying a backup generator. When the lack of electricity is rare and does not last long, it is enough to install a progressive inverter for the heating boiler.

It converts the direct current coming from the battery into alternating current and allows the heating equipment to function fully for a certain period of time even in the absence of electricity. Let's take a closer look at the main characteristics of the device.

General device characteristics

An inverter is primarily a DC-to-AC converter. In parallel, it changes the transmission amplitude and generates an output signal of a suitable frequency. The device cannot charge the battery and control its current capacity by itself.

Many modern manufacturers equip their products with related elements, additional chargers and a control unit. Such models are already classified as uninterruptible power supplies (UPS) and have the ability to solve a wider range of tasks.

Manufacturers give a big guarantee for the uninterrupted operation of inverter equipment for boilers - from 10 to 12 years at 600-620 active cycles and battery discharge at the level of 80-83%

Integrated into the heating system, they monitor the presence of current in the network and, in the event of a sudden emergency power outage, for some time support the full operation of the equipment.

In this way, preventing the potentially possible freezing of water in pipes and radiators (in the winter season), breakdown of individual parts of the system and other unpleasant problems.

The inverter, equipped with an additional battery, allows the heating equipment to work for a long time and with high quality even in the absence of a centralized electricity supply

Simple, low-cost products perform only one direct function - providing the boiler with energy to operate for a certain amount of time. Complex progressive modules have extended potential.

In addition to their main mission, they act as stabilizers and equalize the voltage in the system, thus protecting the equipment from unnecessary load and failure.

Why is it needed for a gas boiler

If you do not focus on energy independence, then a fully functional modern gas boiler requires an electrical connection to power the control board with a controller, a circulation pump and a group of control units that can be distributed around the house. Such a combination of equipment allows you to completely and accurately control the heating of the house, raising the heating to a higher level, ensuring high comfort of life in the house. If this is the case, then when the electricity is cut off, the heating, unfortunately, stops completely.

In order not to be left without heating, a backup power source for the gas boiler and all auxiliary equipment should be foreseen in advance. Options include a gas or diesel (petrol) generator, an uninterruptible power supply (UPS), or an inverter.

The installation of a generator requires a large capital investment, which is why UPS and inverters are more common. In them, electricity is stored for future use in batteries and, if necessary, is given to the load, the boiler.More often, if the electricity is turned off, it is not for long, so that the energy stored in the batteries is quite enough so that the boiler does not stop and the coolant does not cool down.

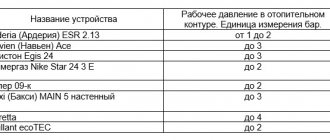

The main requirement for any backup power source for a gas boiler is a stable sine wave and amplitude in terms of voltage at the output. The gas boiler does not have any own converters or stabilizers, therefore any jumps or deviations will affect the quality of the controller, the readings of the sensors. The sinusoidal shape is critical for a circulation pump. The more correct the shape of the sinusoid, the more stable the frequency of the current. The better the pump works.

Household and computer UPSs give out a signal only partially like a sine wave, more like alternating rectangular pulses. For the purposes set, this is enough; computer and office equipment have their own power supplies that convert the input voltage.

Summarizing all of the above, it becomes clear why uninterruptible power supply units and inverters for heating boilers are designed and manufactured separately and with an increased requirement for the characteristics of the output signal.

Complete set of inverter energy sources

In the modern market of household related equipment, inverters are presented in several versions. Some brands produce the most simple units that work only as voltage converters.

The rechargeable battery is not initially included in the set of such modules, but its connection by design is allowed, and the user can purchase this element separately in the future.

It is necessary to purchase inverter equipment only in the regional official representative of the manufacturer. There, in addition to the product, the buyer will be issued a warranty card for service and, in the event of problems identified in the first working days, they will replace the product with a serviceable

Some types of inverters have a built-in battery of a certain, as a rule, small capacity, however, it is not possible to increase its volume due to external additional batteries.

Devices of this type maintain the operation of heating equipment for a short time and for the most part serve so that the owner can correctly disconnect the system from the power supply in an emergency.

A basic battery is built into universal units. The expansion of the device's capacity is carried out by adding external batteries. In this way, the operating time of the device is increased from several hours to several days.

Product design features

The inverter has optimal dimensions and resembles a parallelepiped in shape. Placed on the floor in the immediate vicinity of the boiler or mounted on the wall (if provided for by the design features of the purchased model).

The working battery transmits direct current 12 V. The inverter absorbs it and converts it into alternating current with a traditional voltage of 220 volts, and also monitors the state of charge of the battery itself

In advanced models, a control unit with a boiler switching system and a basic storage battery are located inside the body. The first node controls the availability of energy and timely switches the equipment to an autonomous mode of operation if there are interruptions in the supply of the resource in the central network.

The second unit (battery) provides power to all electronic elements of the boiler for the entire period of power outage or until the end of the charge.

How are devices classified?

Almost all inverter devices are integral elements of a UPS (uninterruptible power supply) and perform the same function - converting DC current from the battery into AC.

In the event of an unexpected power outage, the backup power supply system is activated, and the heating equipment instantly switches to autonomous operation. This allows you to maintain the full functioning of the heating for a certain period of time - from several hours to several days.

According to the principle of operation, the devices are divided into three types:

- Off-line (backup);

- Line-interactive (line-interactive);

- On-line (double conversion).

Each type of device has its own specific characteristics and capabilities that allow solving diverse tasks. After a thorough study of the parameters of all three devices, choosing the best option for yourself will not be difficult.

Operating principle of off-line units

The off-line model has a simple design and is considered a backup. When the power grid operates in standard mode and demonstrates stability, and the voltage does not "jump" between extreme values, the device "sleeps" and does not participate in the operation of the household heating system.

If the current level drops to 175 V, the unit switches the heating boiler to battery feed. As soon as the situation recovers, the inverter UPS reconnects the heating equipment back to the mains.

The off-line device is ideal for working in conjunction with a gas heating boiler, but only if there are no problems with voltage stabilization in the central power grid

Each transition from the main power source to the autonomous one and vice versa lasts no more than 10-15 seconds and does not affect the functionality of the heating equipment in any way.

The operating range of most off-line converters is in the range of 170-270 V.

Advanced inverter converters are usually equipped with informational liquid crystal displays and current regulators. They do not have an active cooling system. Due to this, the work process is absolutely silent and does not interfere with the tenants with annoying sounds.

With a constantly "jumping" voltage, switching from the main system to the autonomous system occurs too often and leads to a rapid deterioration of the batteries and the device itself. Stabilizers are not included in the set of the device, therefore, when connected, both at the input and at the output, the mains voltage does not change.

Therefore, we recommend reading our article on how to choose a voltage stabilizer for a heating boiler. Read on for more details.

Depending on the manufacturer and model, the back-up devices can effectively operate with electrical equipment from 300 to 3,500 watts. Some products provide for cyclical operation and the ability to prevent the communication fragments of the heating system from freezing during the day or more.

How do Line-interactive modules behave?

Line-interactive (Line-interactive) device is a switching type device and is considered the best option for universal equipment. Structurally, the product consists of an off-line source, a converter, a switching relay and a low-frequency stabilizing device.

In the standard operating mode of the unit, heating equipment consumes the resource of the central energy main. The output voltage is controlled by a stabilizer and special filters (for some models), which smooth out the arising noise and neutralize the interference of the network to which the boiler itself is connected.

A gas boiler connected to a line-interactive converter equipped with an additional external battery can operate from 8 to 10 hours (depending on the battery capacity)

Line-interactive units supply useful energy to electrical appliances for a very short period of time (no more than 20 minutes).

To provide heating boilers with a resource, they use not ordinary linear devices, but improved products with an expansion function, providing for the connection of an additional external storage battery. Such devices can keep the boiler running for a longer time (up to 10 hours, depending on the manufacturer).

The line-interactive converter puts the battery into operation extremely quickly (approximately 2-4 seconds). The output stream of the device can be pulsed or sinusoidal. Experts recommend installing the second option on heating boilers.

The built-in current stabilizer allows the equipment to work correctly without switching to a battery with an extended voltage range. The device provides backup power from the battery and equalizes the mains voltage. The disadvantages of products include the impossibility of correcting the flow frequency of the current and the minimum smoothing of the sinusoid (no more than 20%).

Features of on-line devices

Online devices operate continuously.

The conventional wiring diagram for heating equipment in this version is built in the following sequence:

- central electrical network;

- inverter uninterruptible power supply;

- boiler.

The principle of operation of the device is reduced to the repeated transformation of the general parameters of the electrical network. At the first stage, when entering the inverter, the alternating voltage is converted into a stable equivalent with an indicator of 12 V.

Then the reverse maneuver takes place and at the output of the inverter device, the voltage turns into an alternating voltage with a value of 220 V.

In online systems, the battery acts as a buffer and is constantly recharged. In parallel, the output converter is activated inside the battery and forms a variable from the constant voltage with indicators of 220 V 50 Hz, which does not depend in any way on the voltage generated at the input

The main advantage of a system of such a plan is to provide the power supply unit of the heating boiler with high-quality voltage. Among the minuses, there are only two positions: the high cost of conversion equipment and the low level of productivity.

How to choose an inverter device

First of all, it is necessary to determine whether the inverter for a gas or solid fuel boiler is compatible with the selected type of power supply. Some versions of boiler equipment conflict when a device is connected with the "line-interactive" mechanism of action, due to the absence of a through neutral. The most popular option is "on-line", which can be explained quite simply: the boiler is supplied with high quality voltage.

Watching the video, selection criteria:

Additionally, the power of heating equipment is taken into account, which must correspond to the capacity of the UPS battery. This will ensure sufficient battery life for the equipment.

By the way, the duration of operation of the backup power supply is also important, which should be considered when buying, especially if the task is to select an inverter for a gas or solid fuel boiler that can maintain the operation of the heater for several days.

Overview of the characteristics of popular models

CyberPower CPS 600 E

The Victron PracticVolt-0212-1 / 100 device can be considered as an example of an "on-line" system. Its advantage is that there is no delay when switching to the backup power supply. In addition, this option is able to provide up to 7 hours in a row of autonomous power supply to the heater. The package includes a maintenance-free battery with a capacity of 100 Ah, a charger and the inverter itself for a gas boiler. The price of the entire set of equipment is 36,000 rubles.

Another option is the CyberPower CPS 600 E.Its price is only 11,500 rubles, but in terms of technical characteristics, this performance is in no way inferior. The inverter converts DC voltage to AC equivalent and corresponds to a load of 600 VA. Input voltage range: from 170 to 270 V. It is possible to increase the capacity of the device. The kit includes a 100 Ah battery. Another solution of the same brand is CSP 1000 E. Such a device feeds an inverter heating boiler for 14 hours, its price is about 22,000 rubles.

Advantages and disadvantages of equipment

The inverter is convenient in that it is not tied to a specific type of constant voltage source. The unit can be powered using a conventional car battery, a generator set with a simple signal rectification principle, or from UPS batteries.

If the module does not have a built-in charger, the owners will have to personally control the level of capacity and the degree of discharge of the device.

Among the main advantages of the device:

- a wide range of models and the ability to choose a product with an almost ideal output sine wave;

- correct operation with all sources of rated voltage and direct current;

- reasonable cost in comparison with other similar units of similar power;

- no restrictions on increasing battery capacity and the duration of autonomous operation.

Disadvantages include criteria such as:

- lack of control over the level of charging / discharging of the battery;

- setting the response threshold is not subject to additional correction;

- the need to equip an external communication circuit for automatic activation in case of a power outage in a residential area;

- high cost of "fancy" modules with a wide range of possibilities.

The final choice of a suitable device is strictly individual. It all depends on how much the voltage "jumps" in the network, how often consumers are disconnected from the supply of the resource by the central electrical system and how long you have to sit without light.

Basic rules for choosing a module

When planning the purchase of an inverter for a boiler, you need to pay close attention to such parameters as:

- input voltage and current indicator;

- output voltage level;

- the degree of distortion of the output voltage sinusoid;

- actual conversion factor;

- total output power.

For household gas boilers, mainly inverter installations 12-220 are used. These units convert the 12 V DC battery voltage into a 220 V sinusoidal voltage with minimal distortion.

The sine wave of the inverter output voltage should not exceed 3%. These indicators mean that the waveform is as close to sine as possible with minor deviations towards a sharp drop or cut-off peak.

It is possible to acquire a more powerful bundle of units (24-220 converter and 24 V battery), but at the same time it is necessary to find out exactly what maximum input current the inverter is designed for.

Only after receiving this information should you start buying.

Inverters offered in the domestic market are initially designed for low quality electrical networks. The units have all the surge protection features and the option to allow the user to set upper and lower voltage limits down to volts

The controller and control unit of popular gas boilers usually consume a power of about 150-200 Watt. Responsible for the correct circulation of the heating fluid in the system, the circulation pump takes another 125-150 watts. To determine the indicator of the required power of the inverter, these data must be added and multiplied by 2.5 to take into account the amount of starting current at the time of starting.

The finished figures must be multiplied by 1.2 again to take into account some power reserve. Memorize or write down the received data. When buying an inverter, make sure that the base power declared by the manufacturer will certainly exceed the calculated values.

Device and principle of operation

Regardless of which of the three schemes a particular UPS is made according to, its key elements are battery and inverter... A battery (in the most powerful models - a battery of batteries) is an energy storage device, when the power is disconnected from the external network, an inverter is powered from it - an electronic converter that generates an alternating current at the output with a given voltage and frequency. In uninterruptible power supplies, gel or AGM batteries with a nominal voltage of 12V are used.

It is in the output stage of the inverter that the a number of features, extremely important in our case:

- All equipment designed to operate from a 220 V household network is designed for a sinusoidal supply voltage (the so-called "pure sine"). At the same time, the generation of a signal of this shape by the output stage of the inverter is quite complicated, and the oscillogram from cheap inverters will differ very much from a pure sine - they use simple pulse converters. First of all, this can cause malfunctions in the control electronics of the gas boiler, and secondly, it will significantly increase the inductive losses in the windings of the electric motors of the circulation pumps. A noticeable hum of electric motors will be a characteristic signal of incorrect operation of the inverter. Long-term operation of an imperfect inverter with an inductive load can cause overheating and breakdown of the power transistors of the output stage and, as a result, complete failure of the UPS.

- To protect the output stage of the inverter from overload, protective circuits are included in it, completely disconnecting the load when the current consumption is exceeded. Since circulating pumps, like any device that has an electric motor, when switched on, consume power several times more than the nominal, when connected to an inverter without sufficient power reserve, it will go into protection mode, leaving your heating system without power.

We offer you to watch an overview of the device from Inelt, we will come back to it later.

List of popular models and manufacturers

Many domestic and foreign companies, firms and organizations operate in the electrical engineering market segment. Some of them are licensed, others develop their own technologies and offer customers unique, progressive and competitive products at a very reasonable price.

Device

Inverter Energiya PN-500 is an inexpensive practical device that provides uninterrupted power supply for modern low-power boilers. Manufactured at the production facilities of ETC Energia - one of the leaders in the domestic electrical market.

ETC Energia inverters fully comply with all GOSTs and requirements for household electrical equipment. Environmental safety and quality of products are confirmed by international certification certificates issued by the company

Connecting one basic storage battery to the device provides full autonomous operation of the fuel boiler for 6-7 hours. If you connect a second battery, the operating time will double.

The unit produces a pure sine at the output, which contributes to the preservation of the expensive electronic "filling" of modern heating boilers. When the operation of the central electrical system is normalized, the inverter automatically switches to voltage stabilization mode and protects the boiler from sudden power surges.

Device "Elim-Ukraine"

has been in the electrical equipment market for over 10 years and is highly respected by customers.

Devices produced under this trademark have a switching power supply, LED indication, pleasant to the eye, and demonstrate an extremely high level of efficiency (up to 98%). Produce a pure sine wave signal without distortion or overvoltage peaks.

Inverters are also convenient because they work correctly with both gel and car batteries.

Equipped with protection against overheating, general overload and deep discharge of the battery. One of the expansion options allows you to connect an additional battery of any capacity to the equipment to maintain the autonomous operation of the heating system even in the absence of voltage in the central trunk networks for a day or more.

Rucelf UPI-400-12-EL unit

Rucelf UPI-400-12-EL device belongs to the category of line-interactive energy sources. It has a built-in stabilizer, which evens out the current flow in the presence of even a minimum mains voltage without using the battery. This makes it possible to economically use up the battery life without overloading and prolonging their service life.

Important advantages of Rucelf UPI are completely silent operation and effective supply of devices with the necessary power supply during an emergency power outage.

Reasonable cost is another characteristic feature of the products of the Russian company Rucelf.

Thanks to this, customers can create a full-fledged autonomous infrastructure to feed heating systems during an emergency power outage or power surges.

Types of inverters for a heating boiler

In heating systems used for domestic purposes, the following types of uninterruptible power supplies are used, which are classified depending on their functional characteristics:

- backup inverters for a gas boiler can work with a complete power outage;

- line-interactive inverters for a gas boiler;

- systems that perform double conversion - inverters for gas heating boilers, working when connected to the network.

Comparative characteristics of the operation of each type of inverters for a heating boiler:

Gas heating backup inverters are the simplest type of systems. They are connected to the heating system on an ongoing basis and have the most affordable price. The operation of inverters for gas boilers occurs both at undervoltage and with a slight overestimation, transferring their voltage to all consumers connected to the network.

If the voltage drops to a critical level, then the battery energy of the inverter for the gas boiler is converted into mains voltage for subsequent transmission. The power of such inverters for a gas boiler with a battery is usually low. In addition, some of the uninterruptible power supplies operate cyclically, turning on and off on their own as needed. At the same time, during operation, the devices do not create noise, since they do not require forced cooling.

Double conversion devices are the most common inverters with a battery for a gas boiler, which are suitable for both domestic and industrial use. They differ into the following types:

- low-power devices with a built-in battery;

- devices powered by rechargeable batteries.

Line-interactive devices - have a very low power, due to which the price of such an inverter for a heating boiler is not very high. Reliability during operation is achieved due to the presence of a voltage stabilizer in its design.

Inverters for heating boilers are powered by a separate battery, which can provide operation for up to 10 hours. At the same time, the voltage range that can be converted thanks to such a source is wider than when using linear devices.However, a significant disadvantage of such inverters is the low stabilization accuracy.