Long-burning pyrolysis boilers have high power and efficiency, while, if you install a more modern model, the automatic system will reduce human intervention to a minimum. A great convenience is the moment that one load is enough for a day, that is, the owner does not need to constantly monitor the fuel level. You can only throw in the required amount of firewood in the evening or in the morning and enjoy the heat. But, like any other technique, pyrolysis boilers, in addition to their strengths, have their own weaknesses, which you need to familiarize yourself with before installing such a unit.

How does a pyrolysis boiler work?

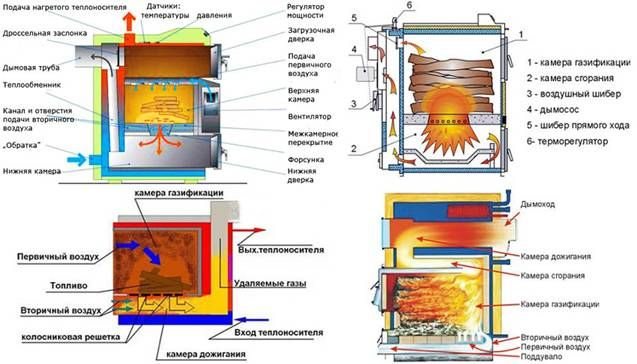

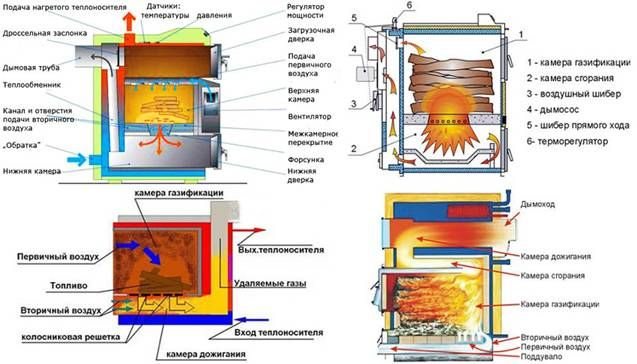

Long-term pyrolysis devices are a "laboratory" within which gas is extracted from solid fuels. It is he who is used in heating the house. Pyrolysis is a physicochemical process in which complex organic compounds decompose into simple components in the form of a solid, liquid or gaseous state. For this to happen, you need to provide a high temperature and limited oxygen access.

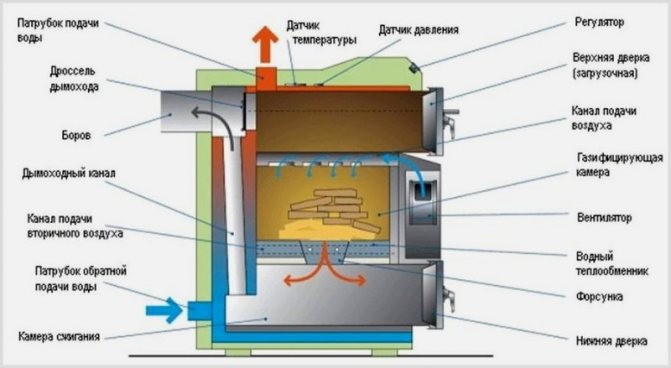

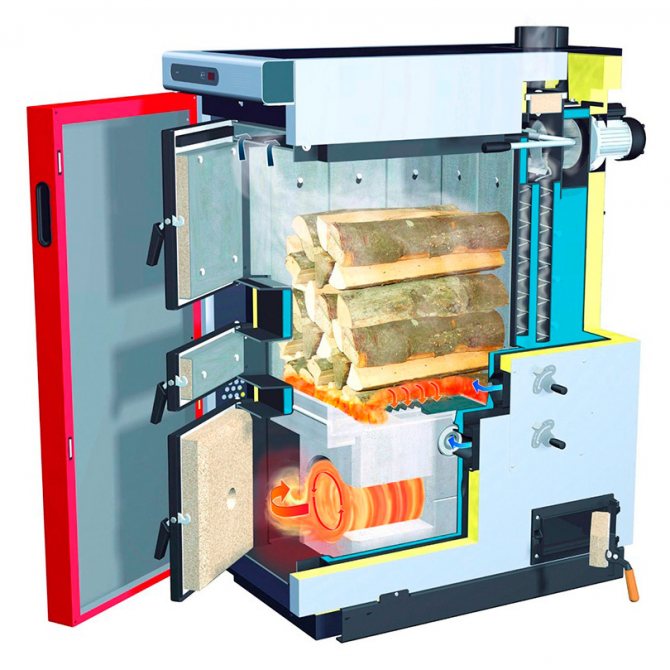

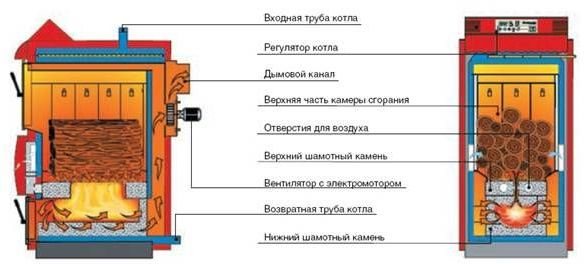

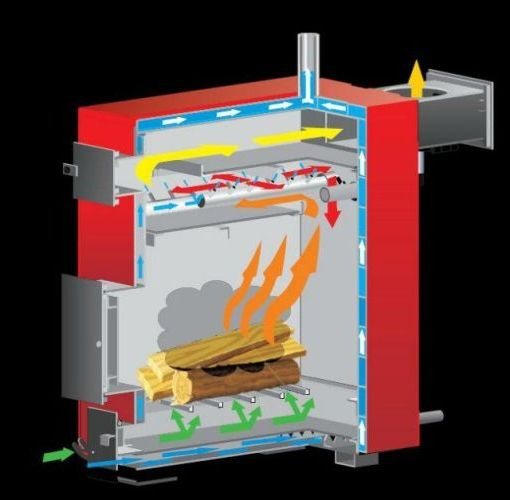

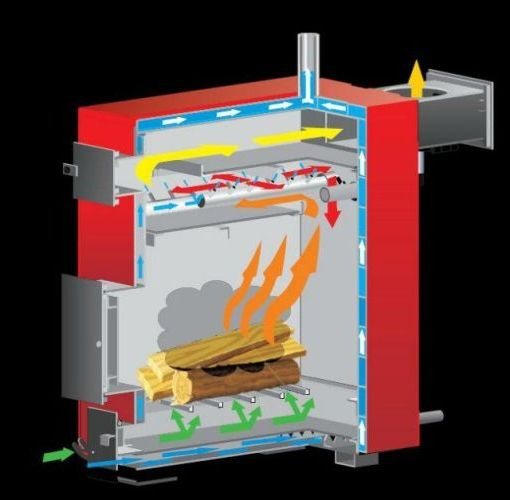

The design of the pyrolysis boiler has a two-chamber heating device, where in the upper part it heats up to 200-800 degrees, which contributes to the onset of an exothermic reaction of solid fuel. There is no oxygen, due to which there is a slow smoldering of the material. Decaying into CO and CO2, the mixture goes to the lower part of the boiler, where the combustion temperature is already kept at around 1100-1200 degrees. The two chambers are connected by grate bars. The result is the release of a large amount of heat (pyrolysis gas) intended for heating the house. The rest of the fuel that does not burn out is called coke or charcoal.

It is also worth noting that in the process of combustion of pyrolysis gas, it has to come into contact with a certain amount of active carbon at the outlet. This leads to the formation of a minimum amount of harmful impurities in the flue gases, which makes the operation of this installation safer. Thus, the bulk of the flue gas consists of water vapor and carbon dioxide.

It turns out that pyrolysis devices use not the solid fuel itself, but the gas produced from it. Thanks to this technology, these boilers show an efficiency of 85-90%, since here the material is burned with almost no residue. And at the very beginning of such an action, the material is dried, that is, from the moment of ignition to the last spark, a "useful" process takes place. And this is not to mention the fact that gas combustion is much easier to control, especially if the device is equipped with automation.

As for the duration and quality of work, then there are several fundamental points:

- weather conditions outside, in particular, temperature;

- the quality of thermal insulation in the house;

- what temperature they want to have in the house;

- what kind of fuel is used and what is its moisture content;

- how competently the heating system was drawn up and who was engaged in it.

If all the conditions (except for the first one) were fulfilled in accordance with all the requirements, then pyrolysis boilers of long burning, in comparison with their other solid fuel counterparts, show themselves much more efficiently.

How the pyrolysis system works

The concept of pyrolysis heating devices is quite simple, but in practice it gives a significant advantage in the form of increased efficiency. To begin with, it is worth emphasizing the difference between the design of such boilers from the technical device of conventional solid fuel systems.As mentioned above, the boiler has two combustion chambers - this is the peculiarity of the equipment. One performs the traditional task of organizing a place for burning fuel, and the second just provides the pyrolysis effect. What is it? While the first chamber extracts energy, for example, directly from the wood, the second processes the gas released during the primary combustion. Unlike the first stage of combustion, the pyrolysis process involves the addition of oxygen to increase the efficiency of thermal energy storage. In essence, the principle of double processing of the same batch of fuel is implemented, which undoubtedly has a positive effect on saving and increasing boiler productivity.

Suitable fuel

Pyrolysis boilers run on almost any type of solid fuel. This can be wood, coal (brown or black) or peat. Depending on what material is chosen, it will often be necessary to refuel the boiler. Since many users prefer to stock up on fuel in advance, it will not be superfluous to know what it should be.

The type of fuel material has the following nuances in combustion:

- soft tree varieties burn on average in 5 hours, while for hard species this time is 1 hour longer;

- brown coal takes 8 hours to complete conversion, and black coal takes 10 hours.

Many people prefer wood, but it can be replaced with other organic fuels - wood waste, fuel pellets and briquettes, peat, coal, waste from the food industry, which contains cellulose. Any fuel should have a moisture content of no more than 30%, and even better - 20%. Otherwise, there is a possibility that combustion by-products and too much steam will be released during combustion. And if the first ones are harmful to the health of the residents of the house, then the steam can disable the system, as it will lead to the formation of soot and tar. And this not only reduces heat transfer, but also puts system parts out of order. In addition, steam is the reason for a decrease not only in heating, but also in poor combustion, because it is practically impossible to make an ordinary fire from wet firewood.

Therefore, if it is not possible to buy ready-made fuel, then its preparation should be done correctly. Here you not only need to chop wood, but also thoroughly dry them and provide them with protection from moisture. Only in this case can you be sure that in winter the pyrolysis boiler will heat the house properly.

Varieties

Non-volatile pyrolysis boilers

There are two main groups of boilers based on the principle of demand for fuel:

- Volatile (in such boilers, only full-fledged solid fuel with a moisture content of no more than 25% is used).

- Non-volatile (sawdust, wood chips and other products with a moisture content of 50% or more can be used as fuel).

It is non-volatile types that have become more widespread, since there is a possibility of using various types of waste, and the process of using itself is much easier than that of dependent boilers. (Read more about different types of fuel for pyrolysis boilers in).

Another classification based on functionality is as follows:

- The steam generator is pyrolysis.

- Single-circuit pyrolysis boiler (the room is heated by heating water in the system with one water circuit).

- double-circuit (not only heats the room, but additionally supplies hot water).

From what areas and types of premises such a boiler heats, its size, equipment, equipment and types of fuel used depend. In large industries, industrial gas-generating boilers with a whole complex heating system have been installed for a long time.

It is useful to know the owners of small carpentry workshops that the existence of pellet boilers simplifies the task of recycling production waste, since the main fuel is briquettes or pellets from wood chips. A plus of such heaters is in a compact size, and the process is ensured when installing additional equipment.

This is how the size of the unit is minimized, unlike, for example, large generators without a fan or where a pyrolysis attachment is used.

Another distinguishing feature of these boilers is the design feature, which provides heat not by heating the water in the system, but has an air-heating principle. This simplifies the heating of the room so that there is no need to dilute the water system in small rooms.

Features of operating and starting the system

The operation of a long-burning pyrolysis boiler has its own characteristics that distinguish these units from other solid fuel models. It has already been said above that the device has two chambers separated by dampers. But few people know that before starting the entire system, it is necessary to preheat the loading tank (up to 500-800 degrees). Only then can you start loading fuel.

The device works as follows:

- placing solid fuel in the foreflow;

- thermal distillation of the material;

- the transition of the generated generator gas into the combustion furnace;

- the heat exchanger recovers the heat of the flue gases;

- control of the supply of air flows to the antechamber.

If you follow this sequence of actions, then a slow oxygen-free combustion of the material will take place in the boiler. And this already leads to an increase in the efficiency of the release and combustion of pyrolysis gas, due to which a comfortable temperature will always be maintained in the house throughout the day.

Manufacturing of pyrolysis ovens

When deciding how to make a pyrolysis oven with your own hands, it is necessary to take into account the area and type of space served. The work is carried out on the basis of drawings, for the creation of which it is necessary to determine the size and shape of the body, to clarify the type of location of the compartment for stowing solid fuel and the afterburner.

Materials and tools

For the manufacture of a metal pyrolysis combustion installation, the following set of auxiliary materials and tools should be assembled:

- steel sheets 3-4 mm thick, grade St20,

- steel corners 50 mm - 4 pieces,

- pipe d50,

- reinforcement elements,

- chimney pipes d120,

- bricks - 15 pcs,

- electric welding machine plus electrodes,

- electric drill, grinder,

- hammer, building level, tape measure, marker.

For the manufacture of a metal installation for pyrolysis combustion, one should not forget about the grinder

When choosing materials for the independent manufacture of a gas generator, it is worth giving preference to high-quality and reliable resources, the efficiency of the device and the safety of operation depend on this.

Drawings and calculations

You can make a drawing of the product yourself, based on the image of the selected unit. Further, taking into account the features of the device, the required power is calculated. To do this, first determine the required power of the installation in the flame combustion mode, then calculate the parameters in the gas generation mode.

Next, the volume of the fuel load is calculated, which is necessary to provide the required power. For this, the mass of the fuel is calculated, taking into account that the resource burns out only by 80%. It should be remembered that the efficiency of a homemade pyrolysis focus is on average 50%.

At the end, the volume of the furnace is calculated, taking into account that the load factor should not exceed the industry standard value of 0.63.

Site selection and preparation

When choosing a place for installing a stove structure, it should be borne in mind that the space around any hearth must comply with fire safety requirements:

- a platform-base is made in the form of a platform with a flat surface made of non-combustible materials,

- the dimensions of the base must be larger than the parameters of the structure being erected,

- a distance of at least 80 cm is maintained between the unit and the walls of the room,

- wall surfaces are covered with heat-resistant facing materials.

To ensure safe operation, the floor surface of at least 1.2 m in front of the heating unit is reinforced with a non-combustible coating.

Manufacturing and installation

The work is carried out in the following order:

- At the initial stage, the necessary blanks are made in the form of elements for vertical racks. Further, horizontal components are measured along the width of the installation, after which the frame parts are welded. In the manufacture of the walls in the front panel, holes are made for the firebox and ash pan, equipped with fasteners for installing hinged doors. For the installation of the grate and the pallet with perforations separating the combustion compartment from the afterburner, corners are attached to the inner surface.

- It is necessary to cut a blower with a damper into the side wall. To do this, a blower is harvested from a short piece of pipe by drilling a hole for the damper axis. The damper axis is made of the reinforcement, to which a steel disk is welded, the parameters of which correspond to the inner diameter of the blower.

- Starting from the bottom, the body parts are welded, then a grate with a partition element is laid. Then the lid is welded on.

- A branch with an angle of rotation of 90 ° is welded into the hole in the cover to connect the body to the chimney. A hog is attached to the outlet - a horizontal section with a length of 1 m. It is needed in order to delay the exit of gases from the afterburner.

An example of making a pyrolysis oven with your own hands

The gate damper, which is installed at the end of the horizontal section, is performed according to the same principle as the blower damper. But in this case, the diameter of the gate should be less than the inner diameter of the pipe, and a sector in ¼ of the base is cut out on the disk.

Operating rules

Trial ignition of a self-made pyrolysis heating unit is performed with an open slide gate. A small amount of solid fuel in the form of shavings and chips is placed on the grate and ignited. Next, they put small logs, close the door and flap, regulate the power with the help of a blower. Since the gate has a cut, this does not allow to completely block the chimney.

To create optimal conditions for the efficient operation of long-burning furnace units, the following recommendations should be followed:

- in the manufacture of metal pyrolysis devices, chimneys should be made of a removable type. This greatly simplifies the cleaning of the structure from combustion products,

- use high-quality fuel resources, especially if the pyrolysis structure is used for heating residential premises,

- the moisture content of solid fuel should not exceed 21%, otherwise it is fraught with a decrease in the efficiency of the heating device.

Since the fuel in the pyrolysis equipment burns out almost completely, there is no need for frequent cleaning of the ash pan and chimney. In this case, it is necessary to promptly eliminate possible malfunctions, for example, if the door is deformed, it should be repaired or replaced. If there are cracks in the seams or other defects, it is important to stop operation and carry out repair work.

Despite the fact that the efficiency of a home-made pyrolysis structure for a house is somewhat inferior to industrial designs, the efficiency of such an installation is an order of magnitude higher in comparison with traditional options for a wood-burning stove. In addition, it is attracted by the availability of materials and the simplicity of the work on the manufacture of a heating system with your own hands.The economy of fuel consumption and ease of maintenance are also impressed by the fact that there is no need for frequent loading of fuel for the operation of pyrolysis units.

It is not difficult to create a pyrolysis combustion heating device with your own hands, but you need to act with great precision, developing your own drawings or using ready-made options.

Pros and cons

Like any other technique, pyrolysis boilers have their pros and cons. It is imperative to get acquainted with them. Firstly, this will allow you to prepare your house for such a heating system, and secondly, it will save you from unnecessary financial costs, because such a unit is not very cheap.

If we talk about the strengths, then they are:

- these models are easy to maintain, even simple breakdowns are quite capable of eliminating themselves;

- if there is no main gas supply, then a pyrolysis boiler is the best alternative in cold weather;

- one load of fuel lasts up to 15 hours, while other traditional solid fuel boilers require "refueling" every 5-8 hours;

- the level of efficiency reaches 85-90%;

- safe from the point of view of ecology - during combustion, almost 100% of the material is utilized, while there are no toxic impurities in the flue gases;

- CO2 concentration is 2-3 times lower than in other solid fuel analogues;

- during operation, very little ash is formed, so the need for cleaning occurs much less often, and the system lasts much longer;

- the coolant heats up much faster, so you don't have to wait long for comfort.

But for the sake of fairness, it should be said that pyrolysis boilers also have their drawbacks. Among them are:

- high price - the pyrolysis device costs 1.5-2 times higher than other boilers;

- pyrolysis boilers have one circuit, which makes it impossible to heat water for domestic purposes (except for special configurations);

- the device is powered by electricity, which means that if it disappears, then the boiler will stop heating;

- the fuel must have a certain moisture content (up to 20%) and if this requirement is violated, the boiler will not work;

- Despite the development of modern technologies, it did not work to make the pyrolysis models fully automatic - refueling is done only manually.

Although the disadvantages may seem significant enough to someone to refuse such an acquisition, in fact, they are much more effective than their counterparts. Moreover, this has been proven by more than one study. But they completely burn fuel, which gives the maximum efficiency in heating and leads to minimal heat loss. Such moments fully pay off all the disadvantages.

Organization of DHW in the boiler

The infrastructure for hot water preparation in the equipment is formed using three components - a heat exchanger, a boiler and circulation channels. In the heat exchanger, water is directly heated under the influence of thermal energy, which is generated during the combustion of fuel. By the way, the use of the boiler specifically for the DHW function in some systems with automatic control allows the equipment to be turned off immediately after bringing the water temperature to the desired mode. The water ready for use is directed either to the boiler or directly along the circuits to the consumers. A modern boiler allows you to keep about 30-50 liters of hot water for a variety of needs. If more capacious storages are required, then it is worth initially selecting separate boilers, which are not part of a single boiler design, but are connected through their communication channels. Such a tank can contain up to 200 liters, and industrial models - about 500 liters.

The nuances of choosing a pyrolysis boiler

Having familiarized yourself with the strengths and weaknesses of pyrolysis boilers, you can already think about buying such a unit. But this purchase will be rational if there is an opportunity to always stock up on dry firewood.

When it is not possible to fulfill the requirements for fuel, it is recommended to pay attention to boilers that are combined. That is, they burn 80% of the pyrolysis material and 20% of the traditional one. You can also use them with other fuels, the moisture content of which does not exceed 50% - wood waste, peat, coal, etc.

It is best to purchase a boiler with a loading chamber that can accommodate firewood up to 65 cm. The inner coating is also important, which ideally should be made of high-quality ceramic concrete. It is it that allows you to maintain an optimal temperature regime inside the chamber, which ensures uniform combustion of fuel and protects the walls from burning out.

If you purchase a pyrolysis boiler with natural draft, then such a device must have an automatic regulation system. In this case, the fan speed will be controlled by the controller, which, in turn, receives signals from temperature sensors and water pressure devices. When the indicators begin to exceed the norm, the controller will automatically adjust the air flow to each of the chambers, and may even shut it off altogether. The only thing that is required of the owner is to set the temperature mode on the boiler display.

Some modern manufacturers of pyrolysis boilers have improved their models, creating the ability to work with another water circuit. This addition allows hot water to be supplied and can be switched on separately. This option is provided by the fact that the hot water coil is placed in the water jacket of the system. Therefore, during the movement of warm water, part of the heat goes to the second circuit, due to which an average temperature is obtained. Such designs have additional protection that prevents water from boiling in the event of a sudden power outage.

Pyrolysis boilers can heat not only the residential building itself, but also the adjacent outbuildings, where there is no plumbing. In this case, you need to pay attention to specially designed unit designs. In such models, there is no water jacket on the body. It is replaced by an air heat exchanger. It is capable of heating a square from 100 to 1000 sq. m. Of course, boiler modification plays a decisive role. But in any model there is an air damper that helps control combustion. This can be done manually or with a chain drive.

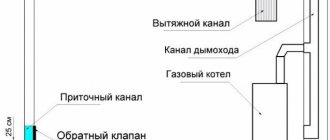

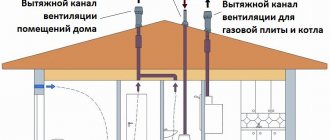

Finally, it is worth mentioning about the chimney for such boilers. Since there is no mechanical induction of traction, the chimney must provide the proper traction force, otherwise, all the smoke will go into the living rooms. For this, a special fan must be provided in the design.

Depending on the future operating conditions, a modification of the long-burning pyrolysis boiler is also selected. If a really high-quality unit is chosen, then the fuel in it will burn for at least 8-10 hours, and it will require replacement no earlier than in 18-20 years.

How to choose a solid fuel boiler for long burning

When choosing a long-burning boiler, you should pay attention to:

- The power of the model you are interested in. If preference is given to a double-circuit unit, it is worth choosing a boiler with a water circuit, capable of heating a volume of water sufficient for the needs of the family.

- Hot water circuit capacity. Its characteristics must be correlated with the need for hot water.

- Frequency and ease of maintenance. It is worth making sure that there is no difficulty in loading or cleaning the ash pan. If you have a choice, you should give preference to a model equipped with a volumetric hopper. In this case, the ash pan will be cleaned every three months, the burning time can be up to five days.

- Body and coil material. For the former, cast iron is preferred. For the second, copper or steel.

Advice!

If there is a lot of people in the family, you should pay attention to the model with a built-in boiler. Installing a heat accumulator will not be superfluous.

Review of well-known models

Among modern pyrolysis boilers, the companies BUDERUS, VIESSMANN and VIADRUS are especially popular and reliable. This is due to the fact that the quality is fully consistent with its price. Manufacturers take a responsible approach not only to the selection of materials, but to the assembly of devices itself. The boilers are fully automated, and this also applies to the ignition process itself.

Let's consider each manufacturer in more detail:

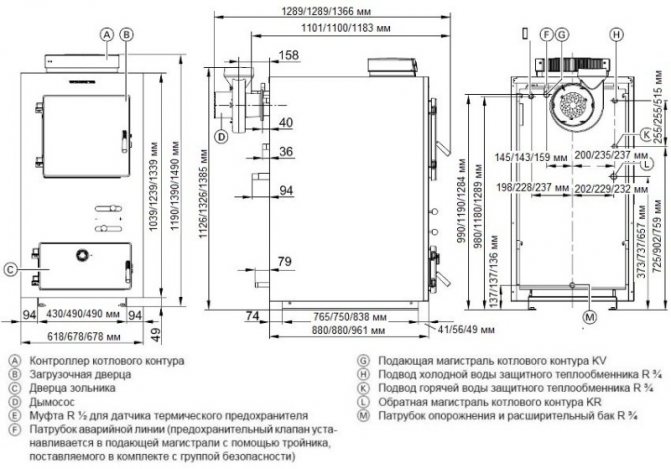

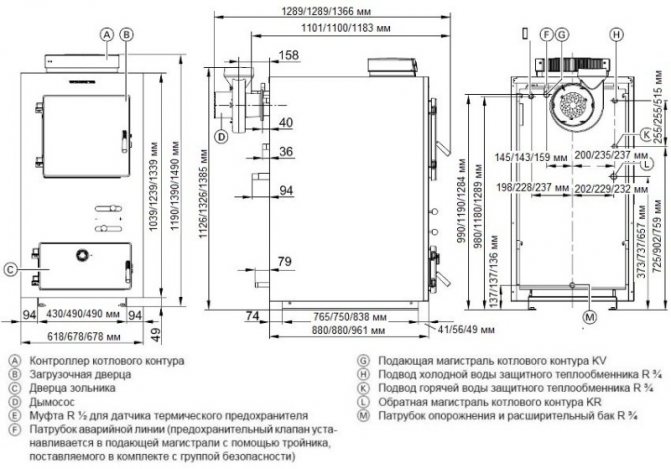

- Vitoligno 100-S by VIESSMANN - premium class (Germany). These units have a power rating from 25 to 80 kW, the efficiency level reaches 88%. The line of such models has a working pressure of no more than 3 Bar. The temperature indicator of the supply pipeline is 95 degrees, and the return pipe is 55 degrees. Logs up to 50 cm long can be used. The Vitoligno 100-S has an automatic control system that consists of a controller and a set of sensors. There is a fan in the chimney duct, which provides traction, as it serves as a smoke exhauster. The controller regulates the operation of not only the fan, but also circulation and network pumps, as well as three-way boiler piping valves.

- BUDERUS - premium class (Germany). Such boilers also have a number of their advantages, in particular, their efficiency is 88-90%, while their power varies within 20-40 kW. The working pressure here is the same as in the previous analogs - 3 Bar. The temperature indicator of the supply is 95 degrees, and the return is 55 degrees. But in this cauldron you can use 10 cm longer logs. Such boilers can be made of either cast iron or steel. Perhaps one of the most pleasant features of the BUDERUS models is the aesthetic appearance, because not everyone has the opportunity to hide the boiler out of sight.

- VIADRUS Нefaistos P1 - middle class (Czech Republic). For refueling, you can use pellets. This is convenient because the boiler is loaded only once a week and does not require refueling anymore. Although, for the sake of fairness, it should be said that the duration of the work largely depends on the volume of the bunker. The entire system is controlled by automation. For safer operation, the burners are equipped with a fire extinguishing system connected to water. VIADRUS products are in no way inferior in their technical characteristics to the Germans, but at the same time they are much cheaper than their counterparts.

Of course, on the modern market there are many different models, both domestic and foreign. When preparing for a purchase, you should study the general technical characteristics of pyrolysis boilers, and then, focusing on your finances, choose a specific model.

Expert opinion on the PROTHERM PLUS 3 boiler

All experts agree that this boiler is quite powerful, but it has its drawbacks. When loading coal, the thermal power is 17 kW. At this time, if you use firewood, then this indicator will be at the level of 13 kW. Ultimately, this was reflected in the temperature control range. The maximum can only be set to 90 degrees. With this power, this is quite small.

In addition, the experts noted the low pressure in the lower chamber, which is equal to 3 bar. In this case, the outlet for the connector has a diameter of 12 mm. It should also be noted that the height of the loading compartment is at the level of 28 cm. All this can create certain difficulties in the operation of the pyrolysis boiler. The combustion chamber, in turn, has a volume of 32,000 cubic meters. see, and only 22 liters of water are placed in the boiler.

It should be borne in mind that the dimensions of this model are far from compact. Its height is 107 cm, width - 52 cm, and depth - 36.5 cm. At the same time, the total weight is at around 190 kg. This boiler is produced in absolutely any color. Additionally, the reliability of the internal sections, which are made of cast iron, can be noted. The average metal thickness is 4 mm.Of the shortcomings, experts note the lack of the possibility of installing a simple accumulator. At the same time, the built-in automation leaves much to be desired.

Owner reviews

Anna Limeyko, 32 years old, Zaporozhye

I am a mother of a little son who is now 5 years old. When we were 3 years old, we were diagnosed with an allergy, and it was not possible to identify a specific irritant. Therefore, the doctor advised us to move out of town. So my husband and I decided to convert our dacha into a country house. There were no special questions with this, except for the heating. Friends gave us a solid fuel boiler and my husband connected it to the system. On the very first day of his work, his son had a terrible cough. As it turns out, such a unit produces a large amount of harmful impurities, which provoked an attack in the child. Having decided to change the boiler, we settled on a pyrolysis unit, and absolutely did not regret it. Firstly, we refuel it only in the evenings, and secondly, we have had it for more than a month now and our son has never had any health problems. And this is not to mention the fact that this boiler produces a minimum of ash and soot, which is why it is quite easy for me to take care of it.

Anatoly Reznichenko, 45 years old, Volgograd

I got the house from my parents. Heating there has always been only from a wood-burning stove, as in fairy tales. Having moved there, I decided to modernize the house. Since I understand these systems, I immediately settled on the version of a long-burning pyrolysis boiler. True, I had some problematic moments with the choice of fuel. But through experiments, I came to the conclusion that the best and most effective material is dry wood (moisture content not higher than 20%). At the same time, I recommend harvesting firewood 0.5 m long. And if we are to take a tree, then it must be pure wood, that is, the legs from old chairs or tables are not suitable. The fact is that they are processed not only with paint and varnishes, but also with all kinds of impregnations. That is, in the process of their combustion, toxins that are very dangerous to health can be released. Also, pyrolysis boilers can be filled with briquettes and pellets for heating, wood waste, some types of peat. When selecting a fuel or its alternative, you need to take into account the following moment: when the flow rate of the primary and secondary air is selected correctly, while the air humidity indicator is normal, then there will be no release of combustion by-products. Otherwise, high humidity can lead to the appearance of not only unwanted water vapor, but also tar with soot. And this will lead to a deterioration in the heat-conducting characteristics of the gas, which can provoke the damping of the boiler.

Alexander Nesterenko, 45 years old, Pskov

I have been interested in the topic of pyrolysis boilers for a long time. When I started to find out the prices for such a device, I was amazed. The minimum cost of this heating unit starts at $ 1,000, while, if you take a domestic manufacturer. And imported models are even more expensive. Therefore, I became interested in the question of self-assembly of pyrolysis boilers. As it turned out, a custom-made boiler is 1/3 cheaper than buying a ready-made unit.

Oleg Belozerov, 31 years old, Kazan

I want to leave my opinion about such a boiler. This device has an order of magnitude larger volume of the loading chamber, due to which I refuel it only in the evenings. This model is perfectly adapted to our latitudes, so no failures were observed during 2 years of operation. I would also like to say that such a boiler has a function for heating the air supplied to the combustion chamber. This boiler is very similar to the Polish model of the Irleh company. But since there is heating here, the quality of ignition of pyrolysis gases is much better. I would also like to say about safety, as my wife and I are waiting for replenishment. Despite the fact that the boiler is in the furnace, children always know how to find passages to any room.So, the loading compartment has a door combined with a ignition latch, and is also equipped with an additional hinged door. This allows not only me to carefully use the boiler, but if the child appears close, then he will not immediately open all the doors. Blago is a great option for houses with an area of 100-200 sq.m.

Nikolay Kulikovsky, 29 years old, Uzhgorod

And we have a Teplolov-type boiler installed in our house. It has a fairly simple design that even my girlfriend can handle. At first I used clean firewood, but as it turned out, such a boiler works great from waste wood (pieces), pressed briquettes and wood logs. But it should be said right away that the volume of the loading chamber is designed for elements from 40 to 90 cm. But in order to achieve the effect, the diameter of one log must be at least 10 cm, but not more than 25 cm. I also add sawdust there, but not so much. Another advantage I would like to note is the possibility of adjustment, and this, in turn, makes it possible to save money. One download is enough for us for 11-12 hours, while the area of our house is 94 sq. m. We were completely satisfied with this purchase.

How to make yourself

Today, many craftsmen make a pyrolysis boiler with their own hands. Their approaches and design options differ from each other. Some masters make their own calculations and drawings, others order professional diagrams. Which path to choose depends on the level of training and skills of each master.

Self-production is a complex and time-consuming process. You will need to prepare a certain minimum of materials, tools and equipment, perform a phased assembly and check the operation of the unit.

Approximate boiler manufacturing scheme.

Required tools and materials

Heat-resistant metal or cast iron can be used as a material for the manufacture of the body and chambers, but in order to save money, simple carbon steel 5 mm thick is most often used. The consumption for this scheme will be 7.5–8 square meters.

In addition to the main material, you will also need:

- metal pipe for the manufacture of a heat exchanger (diameter - 57 mm, wall thickness - 3.5 mm, length - 7–8 m);

- metal pipe for making a chimney (diameter - 159 mm, wall thickness - 4.5 mm, as well as diameter - 32 mm, thickness - 3.2 mm, length of both - 1 m);

- profile pipe for air ducts (size - 60 x 30, wall thickness - 2 mm, length - 1.5 m, as well as 1 m each size 80 x 40 and 20 x 20 mm);

- fireclay bricks for lining chambers (12–15 pcs);

- steel strips: 20 x 4 (7.5-8 m), 30 x 4 (1.5 m), 80 x 5 (1 m);

- temperature sensor.

The amount of material required for the manufacture of the boiler will depend on the chosen implementation option, its layout and dimensions.

The main tools that will be required for self-assembly:

- apparatus for electric welding;

- angle grinder;

- electric drill;

- set of locksmith tools.

Assembly of internal parts

For a high-quality assembly, accurate cutting of sheet metal to the specified dimensions is required. It is difficult to do this on your own using a grinder, therefore, it is better to entrust this stage of work to specialists who will perform the work with the help of professional equipment. If the cut is perfectly straight, then the seams will turn out to be neat.

The assembly of prepared materials can be divided into the following main stages.

Metal sheets are connected and welded in accordance with the scheme. The result is a two-chamber design.

Inside the compartment for loading fuel, a wall and air ducts are welded to the rear of the chambers, which are made of a profile pipe 60 x 30 mm. Holes are pre-drilled along its entire perimeter to evenly distribute the supplied air.

A metal pipe is cut into the wall of the combustion chamber for the secondary air supply. A pipe is welded to it. It must be connected to the boiler with a 20 x 20 profiled pipe.

Next, a heat exchanger is made. Cut the pipe into 10 pieces of equal length. Take two flat metal sheets and cut round holes in them for the diameter of the workpieces. The pipes are inserted into the plates and welded.

The heat exchanger is fastened to the inner boiler body, a throttle valve is made, then the back wall is welded.

The inside of the chambers is lined with fireclay bricks. To do this, it needs to be cut, grinded and adjusted to the place of installation. The higher the boiler power, the longer the gas gap of the nozzle should be - from 140 (15 kW) to 280 mm (50 kW), width - 34 mm.

A wall is welded to the front panel of the fuel chamber with pre-cut holes for the outgoing and incoming air pipes.

Then the lid is welded, and a hog in place of the damper.

The entire boiler structure is framed with external metal panels. For the manufacture of the casing, sheets with a thickness of 4 mm and corners are used.

For their high-quality fixing on the workpiece, holes are made and welded.

The doors are reinforced with fireclay bricks and installed on the front panel. For their manufacture, it is better to use cast iron plates.

After completion of the assembly, the welds are processed. It is advisable to cover the top cover of the boiler with a primer and insulating material.

Threaded rods will be needed to regulate the operation of the air dampers.

The boiler is completely covered with an outer jacket. An air duct is made from a professional pipe. To create forced draft, a fan is welded onto it. To optimize the combustion process, the lower chamber is also lined with bricks.

It is imperative to install a safety group on the boiler: air outlet, emergency pressure relief valve, monometer.

Check

The assembled structure must be checked before starting operation.

A well-functioning system has the following qualities:

- the heat exchanger is sealed;

- a pyrolysis torch in the combustion chamber appears 15–20 minutes after ignition;

- the temperature of the gases in the chimney does not exceed 60 ° C;

- only carbon dioxide and steam should escape from the chimney.

After a successful check of the equipment, you can proceed to the installation and operation of a home-made system.