Features of a septic tank

The main element of this design is a rectangular plastic tank. It consists of several interconnected chambers through which waste water flows. Here it is filtered clean and also clarified due to the presence of bacteria.

At such a septic tank there are several important pluses:

- non-volatility, because power supplies are not needed during operation;

- the similarity of the main characteristics with the popular Tank equipment;

- resistance to various external factors due to the presence of stiffeners and significant wall thickness;

- no need to use additional fasteners or concreting of the pit;

- increased productivity;

- the tightness of the body, possible due to the absence of seams;

- affordable price;

- the need for pumping out only once a year, which makes the operation of the system quite convenient;

- strength and durability of the structure.

Among the shortcomings, it is worth noting the lack of a system deep cleaning and odor filtration... However, this is what makes the autonomous operation of the equipment possible.

Benefits of a septic tank

The positive characteristics of the Termit autonomous sewage system include the following features:

- gravity drain without connecting to electricity;

- ease of use;

- inexpensive components;

- the septic tank is equipped with a flushing filter that does not require constant replacement;

- high quality molded seamless body made of polyethylene;

- two- or three-chamber cleaning system;

- the installation does not depend on the availability of groundwater at the site;

- autonomous work without human intervention;

- ten-year service life;

- varieties of models with the possibility of choosing a block of modular design.

Compared to an aeration system, a septic tank has one advantage - it saves energy.

The main types of construction

Septic Termit has an extensive range of models, which makes it possible to select equipment taking into account certain technical characteristics.

- Termit-Profi for 1.2 m³ is installed in houses, the area of which does not exceed 100 m². This design is suitable for a family of 2-3 people. The product serves not only shower, toilet and sink, but also household appliances such as a washing machine or dishwasher.

- Termit-Profi for 2 m³ is suitable for a dwelling with an area of 100-200 m². Thanks to this design, it will be possible to clean the drains coming from several toilets and sinks, as well as a bath, shower and washing machine.

- Termit-Profi 5.5 m³ is considered the most powerful septic tank, as evidenced by numerous reviews. This design is distinguished by increased productivity and the presence of 3 chambers, so that it will be possible to service not only plumbing fixtures and a washing machine, but even a jacuzzi. Moreover, each chamber is provided with a sealed cover, pumice, and fibers with anaerobic bacteria.

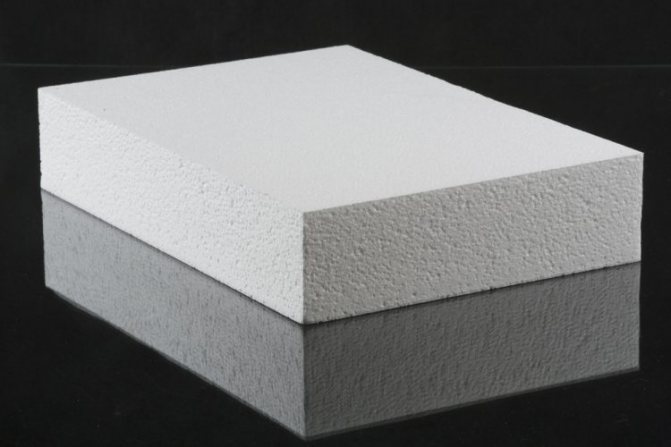

Complete information on extruded polystyrene foam

Extruded polystyrene foam what is it? Extruded (extruded) polystyrene foam is a synthetic material for thermal insulation, developed by an American construction company in the 50s of the twentieth century. It is made using foaming technology, it contains polymer compositions. The material is pressed through a special mold and joins into a single piece.

Produced in the form of slabs, substrates. It is found on the market as a decorative element. The standard size of the slabs is 600x1200 or 600x2400 mm.Standard sizes are established by GOSTs, but many companies change the dimensions by making plates of different widths. The most common size is 580 mm. The thickness of the elements varies from 20 mm to 10 cm, depending on the manufacturer.

The material is delivered to retail outlets in packages of several elements. The number of units in one package depends on the thickness of the products. For example, if the thickness of the slabs is 5 cm, the package usually contains 8 units of the product. With a thickness of 10 cm, 4 plates are packed.

Additional information: It is possible to produce polystyrene foam as a floor covering. The modern market offers materials for laminate, parquet, linoleum. It is possible to manufacture decorative elements on the basis of the material. They look exactly like plaster.

Advantages and disadvantages

Like any other material, extruded polystyrene foam has advantages and some disadvantages. It is worth familiarizing yourself with them before purchasing and using them.

Advantages of extruded polystyrene foam:

- Moisture absorption within 0.2%. This indicator means almost complete water resistance.

- The minimum indicator of thermal conductivity. At a standard temperature of 25 ° C, it is about 0.032 W / m * K. If we compare the conductivity of heat, according to the indicators, the following is obtained: 55 cm of brick is equal to 3 cm of expanded polystyrene.

- Withstands deformation well. You can use it for masonry under the blind area, lay after the foundation.

- Does not react with inorganic chemicals.

- Withstands significant temperature changes, the indicators do not change at air temperatures from -50 to + 75 ° C.

- According to the documentation, the material can be used for at least half a century. During this time, the characteristics will not change.

- Environmentally friendly substance. It is used not only as insulation, but, for example, for the production of light disposable plates or other types of cheap dishes. Children's toys are made from it.

- Has a minimum weight. A small thickness is sufficient for good insulation.

In addition to numerous positive characteristics, there are some disadvantages:

- comparison with other types of insulation shows that the price of the material is high;

- strong flammability. In the process of combustion, harmful substances, black smoke are emitted;

- under the influence of infrared rays is destroyed. To maintain performance, it is necessary to hide from direct sunlight;

- manufacturers assure that rodents do not start inside the insulation. Indeed, they do not live inside, but often make channels for movement;

- solvents destroy the structure.

In addition to the listed disadvantages, low vapor permeability can be added to them. Sometimes this is a plus, but if you insulate a wooden house, fungi and mold may appear. As a result, an unpleasant odor appears in the home, and dampness is constantly felt.

Application area

Extruded gray polystyrene foam has a wide range of applications. It is mainly used for insulation works. The scope of use is limited only by temperature indicators (not higher than 75 ° C). The material can be laid in damp places, in the ground.

Usually, the scope of use is limited only by financial capabilities. The high cost makes it impractical to use in many places. In places where there is no need for high technical characteristics, instead of PPP, ordinary foam is used, the reviews about which are also positive, in order to save money.

Used for insulation:

- concrete or wood floors;

- walls inside the building or outside the building. Compatible with any material;

- wells. Often, concrete rings are covered with a material for additional protection;

- blind areas;

- surface of the earth. To prevent the destruction of the structure, paint is applied. Even a thin layer will prevent deterioration of the composition.

In addition to these areas, the material is used in road construction. It is part of many refrigeration units, as an extrusion insulation. Used in agriculture. Roofs and underground floors are insulated with expanded polystyrene. One of the promising areas is the production of sandwich panels.

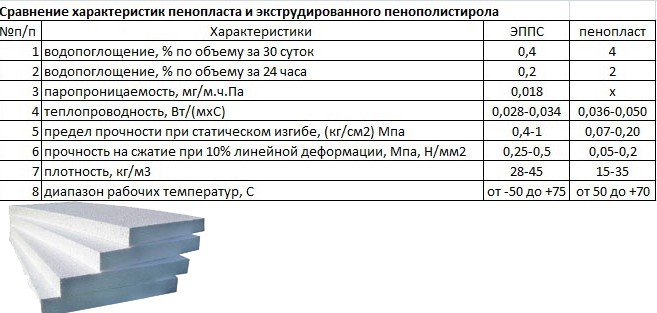

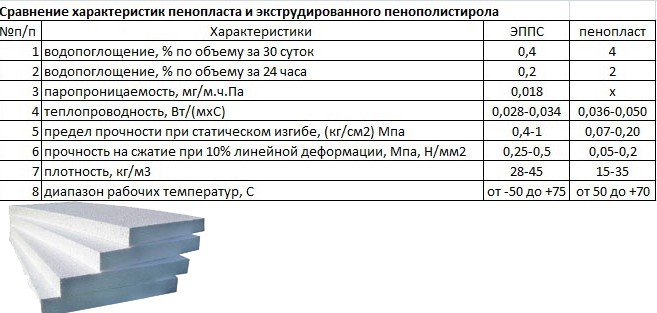

Technical characteristics of extruded polystyrene foam

The material has one of the highest technical characteristics on the market for insulation products. Any gas has a much lower thermal conductivity than solids. For air, the indicator is 0.026 W / m * oC. Extruded polystyrene foam is about 90% air mixture. It has a thermal conductivity of 0.03 W / m * oC. Almost like air, which means that the heat is retained perfectly.

The material is produced with various density indicators. Manufacturers offer from 25 to 47 kg / m3. The higher the number, the greater the strength. As the density increases, the strength increases from 20,000 to 50,000 kg / m2.

Water is poorly absorbed by polystyrene foam. In about a month, one tile is able to absorb about 0.4% of its own volume if it is completely immersed in water. Further, the percentage of absorbed liquid does not increase, but stops. Vapor permeability is minimal. It is 0.0128 Mg / (m * h * Pa). Often, companies specializing in repair work suggest not using a vapor barrier, limiting themselves to using only polystyrene.

The insulation is able to withstand temperatures ranging from -50 to + 75 ° C. It can be used in almost any climate. High flammability, the class varies depending on the addition of additional substances, from G1 to G4.

Some models have a special notch at the edges. Made to increase the adhesion of the slabs by insulating the seams. This innovation does not allow the formation of layers of cold between the elements, ensuring full heat retention.

Tests have been carried out with expanded polystyrene. Their meaning is repeated freezing, thawing of wet tiles. It was determined empirically that, without changing the technical characteristics, the material can withstand 80 cycles. For users, this information is useful: for about so many years the composition can withstand during operation.

Additional information: in comparison with polystyrene, expanded polystyrene wins about 2 times in terms of heat retention. Strength increased, thickness decreased. Compared to other insulation materials, the sound permeability is not very high. The lack of ease of installation is compensated for. It is completely safe for health.

Material selection rules

The demand for expanded polystyrene is high, increasing annually. In order for the insulation to serve as long as possible, to perform all the required functions without failures, it is necessary to make the purchase correctly. Each manufacturer claims that their product is the best on the market, but this is not always true.

Selection rules:

- Polystyrene is designated by two numbers. If the marking is below the index 28, you should refuse to purchase. Checking is mandatory, some brands of the product are not suitable for facade work, they will not cope with the insulation of the house. Choose material with an index of 40 and higher. The PSB-S-40 brand, a self-extinguishing composition, has proven itself quite well.

- Before buying, look at the standards on the basis of which the production was carried out. Many manufacturers make slabs not according to GOSTs, but their own specifications. Possible low-quality goods. Typically, the density is reduced, thereby lowering the cost. You should not be guided by the number of the brand, be sure to familiarize yourself with the characteristics.

- To ensure the high quality of the product, you can break off a small piece from the edge. If small balls are visible at the fracture site, the styrofoam is probably of low grade. The break should have polyhedrons of the correct shape. The broken piece is even. The test shows the production method: extrusion, performed on professional equipment, or a handicraft method, like a simple foam.

- Purchase goods from reputable manufacturers. These are "Penoplex" URSA, Knauf and "Technonikol" - Russian. "Basf" or "Novakhimikals" - foreign.

Do not forget that the production of expanded polystyrene is a complex technological process. Manufacturing methods differ for many manufacturers. Some are safe, others can be harmful to human health.

Manufacturer brands

Each brand of expanded polystyrene manufacturer differs from competitors in some features. To understand the variety of the proposed choice, it is worth considering the products of each manufacturer in more detail.

Knauf

Manufacturer from Germany. Production is represented by numerous variants of polystyrene foam.

Heaters are used:

- Knauf Therm Compack. Universal, used for any kind of household thermal insulation. It has a low thermal conductivity coefficient of 0.032 W / mk, high sound insulation properties. Airborne noise reduction index is 47 dB, impact noise is extinguished if the indicator does not exceed 24 dB. Due to the indicators, it is well suited for insulating small rooms.

Supplied with slabs 1х0.6 m long. Thickness 5 cm. Vapor permeability 0.033 mg / mchPa

- Knauf Therm Roof Light. The density is low, 10-15 kg / m³. used to retain heat on the truss frames of houses. Characteristics: heat conductivity 0.034 W / mk, steam conductivity - 0.035 W / mk.

- Knauf Therm Wall - for wall insulation. The indicators coincide with previous designs, with increased mechanical strength. 60 kPa is an indicator of compressive strength. The choice of plate sizes is wide. Thermal conductivity: 0.033 W / mk, vapor conductivity: 0.032 mg / mhPa. G3 - flammability class.

There are Knauf Therm Flor models, suitable for floor insulation, with a low thermal conductivity of 0.03 W / mk and Knauf Therm 5 in 1. The latter stands out for its maximum strength among all the models of the company. Withstands up to 17 t / m2.

URSA

The URSA expanded polystyrene manufacturer from Russia presents several product options.

| Model / Specifications | URSA XPS N-III | URSA XPS N-III-G4 | URSA XPS N-V |

| Thermal conductivity | 0.032 W / mK | 0.032 W / mK | 0.033 W / mK |

| Application temperature | from -50 to +75 | from -50 to +75 | from -50 to +75 |

| Water absorption | 0.3% of the volume in 24 hours | 0.3% of the volume in 24 hours | 0.3% of the volume in 24 hours |

| Vapor permeability coefficient | 0.004 mg / mhPa | 0.004 mg / mhPa | 0.004 mg / mhPa |

| Compressive strength | 25 t / m² | 25 t / m² | 50 t / m² |

Products differ from other manufacturers by increased strength indicators. The material is indispensable for professional construction. One of the most durable options that can withstand significant loads.

Penoplex

Domestic manufacturer of expanded polystyrene. Has a wide range of models. Plates can be used for various insulation options.

The following types of products are distinguished:

- Penoplex Wall

| Characteristics | Value |

| Thermal conductivity | 0.03 W / (m × ° K) |

| Density | 25.0-32.0 kg / m³ |

| Compressive strength | 0.20 MPa |

| Water absorption | 0,5% |

| Fire resistance | G3 |

| Temperature range | -50 ... +75 ° С |

- Penoplex Foundation

| Characteristics | Value |

| Thermal conductivity | 0.03 W / (m × ° K) |

| Density | 29.0-33.0 kg / m³ |

| Compressive strength | 0.27 MPa |

| Water absorption | 0,5% |

| Fire resistance | G4 |

| Temperature range | -50 ... +75 ° С |

- Penoplex Roofing

| Characteristics | Value |

| Thermal conductivity | 0.03 W / (m × ° K) |

| Density | 28.0-33.0 kg / m³ |

| Compressive strength | 0.25 MPa |

| Water absorption | 0,5% |

| Fire resistance | G3 |

| Temperature range | -50 ... +75 ° С |

- Penoplex Comfort

| Characteristics | Value |

| Thermal conductivity | 0.03 W / (m × ° K) |

| Density | 25.0-35.0 kg / m³ |

| Compressive strength | 0.20 MPa |

| Water absorption | 0,5% |

| Fire resistance | G4 |

| Temperature range | -50 ... +75 ° С |

- Penoplex 45

| Characteristics | Value |

| Thermal conductivity | 0.03 W / (m × ° K) |

| Density | 35.0-47.0 kg / m³ |

| Compressive strength | 0.5 MPa |

| Water absorption | 0,4% |

| Fire resistance | G4 |

| Temperature range | -50 ... +75 ° С |

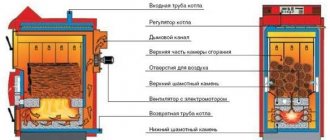

How the device works

The design assumes availability of 2-3 reservoirsconnected through the appropriate channels. Wastewater flows through them, being filtered clean.

In general, the functioning of the Termit septic tank is carried out in 5 stages.

- First, the drains enter the primary tank. Here, all insoluble particles fall to the bottom in the form of sediment.

- The liquid enters the second chamber, while the floating sediment does not penetrate here. Mechanical cleaning is carried out in the second tank. It is about settling the liquid.

- In the third chamber, anaerobic bacteria enter the water, causing decomposition and partial dissolution of wastewater. The remaining liquid passes through a suitable element, which ensures filtration at the level of 75%.

- After purification and partial clarification, the liquid passes into the irrigation system.

- Already in the soil, additional treatment of effluents takes place, because bacteria continue to break down organic matter. As a result, the water will become completely safe, since it is filtered clean.

Technological characteristics and principle of operation of the installation

The septic tank consists of a horizontal rectangular plastic structure. There are three treatment tanks inside the structure, in which a gradual stage of wastewater treatment takes place. The compartments are connected to each other by an overflow pipe installed in the body. The installation is designed for a family of three with permanent living conditions.

The septic tank is independent of electricity, under the influence of which the treatment technology and soil tertiary treatment of sewage channels works. The principle of operation of the station consists of 5 stages:

- The effluent is collected by gravity in the first tank, where large particles are separated from small ones, forming a sediment.

- The second tank has a high height, which allows large substances and sediment not to overflow with water. This allows mechanical cleaning by settling. With each overflow into the purification compartment, heavy fractions are dispersed.

- The third compartment completely eliminates all particles and harmful components under the action of anaerobes, which decompose the remaining insoluble parts of the waste. Suspended particles float to the surface, where they pass through the pumice stone of the filter device, being cleaned by 60-70%.

- The enlightened water enters the irrigation dome intended for irrigation of agricultural plants.

- Final purification is carried out by soil prefiltration. Microorganisms living in the soil oxidize chemical deposits under the influence of oxygen, making them sanitary. The effluent at the outlet is 95% purified.

Installation and maintenance of a septic tank

As mentioned earlier, during operation of the Termit equipment bacteria are used, which are responsible for the processing of organic matter and its splitting into carbon dioxide, as well as water and minerals. Accordingly, after cleaning, the wastewater needs additional filtration in the soil. It is for this reason that it is important to carefully select a suitable installation location. So, it is necessary to take into account not only the composition of the soil, but also the level of groundwater.

For the installation of a septic tank several tools are required:

- 2 pipes;

- fitting;

- sand with cement;

- insulation.

The installation of a septic tank is carried out in 4 stages..

- First, you should prepare the pit. Its width should exceed the dimensions of the septic tank by about 25 cm.

- The device is immersed in the dug hole. For this purpose, it is better to use a special technique.

- Then you need to make a mortar of sand and cement in a 3: 1 ratio. The mixture is poured into the pit until the pipes are completely covered.

- Next, the installation of the pipeline necessary for the discharge of wastewater after cleaning and the filter is carried out.

In order for the septic tank to serve for a really long time, it is worth taking care of proper care. So, the sewer system needs remove silt at least once every 2 years. For the best functioning of the septic tank and the decomposition of waste, it is necessary to use the appropriate bacteria.

Extruded polystyrene foam THERMIT XPS

Extruded polystyrene foam (XPS) is produced by extrusion. It is obtained by mixing granules of general-purpose polystyrene with granules of dye and modifying additives at elevated temperature and pressure with the introduction of a blowing agent and subsequent extrusion from the extruder. After extrusion, the extrudate is gently cooled and finished. Due to the high-tech manufacturing process, XPS has a uniform, closed-cell structure, with a mesh diameter of 0.1-0.2 mm,

low thermal conductivity and high strength characteristics. Extruded polystyrene boards THERMIT XPS, THERMIT XPS 35, THERMIT XPS 40, THERMIT XPS 45 are intended for use in industrial, housing and communal and agricultural construction, as thermal insulation of zero cycles, basements, wall fences, ceilings, roofs and the elimination of "bridges cold ". Also, plates are used in the refrigeration industry, in the construction of roads and railways, in the construction of gas and oil product pipelines and airfields. It is possible to carry out thermal insulation of both under construction and already erected buildings and structures.

The use of extruded polystyrene foam plates THERMIT XPS, THERMIT XPS 35, THERMIT XPS 40, THERMIT XPS 45 as thermal insulation can significantly save energy spent on heating insulated buildings, structures and structures; reduce the weight of building structures; reduce the consumption of other building materials and increase the service life of building structures. The use of THERMIT extruded polystyrene foam boards as an insulating layer contributes to an increase in the energy efficiency of insulated buildings, structures and structures, which meets the requirements of the Federal Law of the Russian Federation No. 261-FZ "On energy saving and on increasing energy efficiency". Thus, extruded polystyrene foam boards THERMIT XPS, THERMIT XPS 35, THERMIT XPS 40, THERMIT XPS 45 can be called a highly effective thermal insulation material.

Extruded polystyrene foam boards THERMIT are chemically inert, do not emit substances harmful to the health of living organisms. They fully meet the requirements of the hygiene of residential and public premises, in confirmation of which there is an appropriate sanitary and epidemiological conclusion.

Owner reviews

I ordered Termit for a summer cottage, designed for 2m³. I installed the structure together with a friend, and I had to order special equipment, because it turned out to be unrealistic to load the septic tank on my own. Connection and installation of all communications did not cause any difficulties.

Igor, Kazan

We have been choosing a septic tank for a very long time. As a result, we purchased Termite for 5.5 m³. Volume was the deciding factor. In addition, the compact shape and significant wall thickness won over. Very happy with this septic tank.

Sergey, Barnaul

I took the Termit septic tank for the dacha. Installed it together with her husband. Installation is quite simple, moreover, instructions were attached to the equipment. The device has been in operation for six months already. It does not clog and cleans drains perfectly. I added bacteria only once in the spring and will add it in another six months.

Elena, Pskov

Among all the septic tanks on sale, special attention should be paid to the Termit design. Its advantages are non-volatility and affordable price. You can install the structure yourself, which is an additional advantage of the equipment.

Structural elements

On the basis of THERMIT SP building boards, the factory produces finished products and systems to simplify and shorten the installation time. Structural elements based on THERMIT SP have all the qualities of the initial material - they can be painted, plastered, mosaic and tiled.Unlike drywall or MDF, which are traditionally used in the interior for the manufacture of various structures, THERMIT SP building boards have absolute moisture resistance, which allows them to be successfully used in humid rooms.

THERMIT SP element CORNER

THERMIT SP building board with one-sided coating, from the inner side of which a part of the material is selected so that an angle of 90 degrees is obtained. The use of THERMIT SP element ANGLE allows you to save time on interior decoration, during finishing work, erection of partitions, steps. Using the THERMIT SP blank, the CORNER element is easy to manufacture functional and beautiful shelves, racks, tables, racks and other interior elements. The material is easy to process and install, weighs little and has high strength. And the installation of structures does not require a frame, due to the rigidity of the plates.

THERMIT SP element BOX

THERMIT SP building board with one-sided coating, from the inner side of which a part of the material is selected to obtain a U-shaped box with sides of a given width. THERMIT SP element BOX is used for decorative finishing of premises, including those with high humidity, in interior and exterior works. Allows you to easily hide communications (pipes, wiring), and the surface of the box will be ready for any finishing.

THERMIT SP element with longitudinal and transverse grooves

THERMIT SP serrated element is a blank for creating or finishing any objects with rounded parts.

The THERMIT SP notched element is based on THERMIT SP building board with a double-sided coating. On one of the sides of the workpiece, notches are applied at regular intervals - longitudinal (21 pcs) or transverse (89 pcs). Available in two versions, the THERMIT SP notched element can be used in countless ways - it can be curved partitions, steps, columns or decorative screens for washbasins and bathtubs, furniture for wet rooms, finishing of arched openings of windows and doors - and much more. To create the desired shape of the THERMIT SP, the knurled element is simply bent.