Owners of water heaters are often faced with the fact that water drips (flows) from the safety valve. Unfortunately, today, in the age of modern technology, such a problem is troublesome. This is due to the complexity of determining the cause of the leakage of the water heater. Considering that it may be completely new, or the broken part has already been replaced several times, but it continues to drip anyway. To understand the main reasons for this unpleasant and annoying breakdown, first you need to find out what kind of part it is and why it is needed.

The device of the safety valve and the principle of its operation.

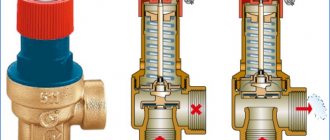

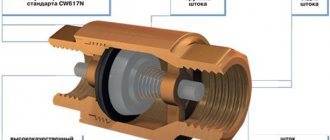

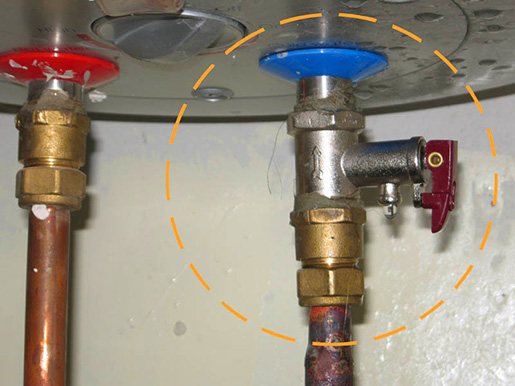

In fact, the accessory serves to relieve excess pressure inside the boiler. It consists of two cylinders perpendicular to each other. The cylinders are different in size and have a common cavity.

There is a valve inside the large cylinder that opens when water from the mains begins to flow. As the tank fills up, the pressure gradually rises. And as soon as the tank is full, it will become higher inside than outside and will cause the valve to close.

Inside the second cylinder there is also a valve, but with a more powerful spring. This spring is designed for the higher pressure that will build up when the water is heated. And when it exceeds the established rate, the spring will compress, opening the drainage hole through which water will drain.

Can a leaking boiler be repaired?

After it has been precisely established the reason why the water heater is leaking, you need to choose the optimal solution to eliminate the problem. Starting to search for the cause of the breakdown, you need to prepare the tools that you may need in the process:

- water drain hoses;

- screwdriver, adjustable, tubular and socket wrenches;

- multimeter.

The boiler device is not as simple as it seems at first glance. If you do not have certain skills, if you detect a water heater leak, it is better to seek help from specialists.

The first thing to do if a leak is noticed is to disconnect the appliance from the mains and drain all the water so that the tank is empty. Only after that, you can proceed to the examination in order to establish the cause. Depending on what caused the leak, the next actions will be determined. In some cases, you can solve the problem with simple repairs, in others, you will need to change the boiler to a new one. It is best to do this before the warranty period expires.

So, due to the leaks of the apparatus, in particular the tank, as evidenced by the appearance of water leaks from the joints of the pipes, it cannot be repaired, therefore replacement is required.

Leakage from above, if all the maintenance rules were followed and the magnesium rod was changed in a timely manner, also requires replacing the boiler, because repair is impossible. Replacing the boiler will also be required in cases where the magnesium rod has not been changed for a long time, which has led to rotting of the tank (if the inner surface is without enamel).

Rotting tank

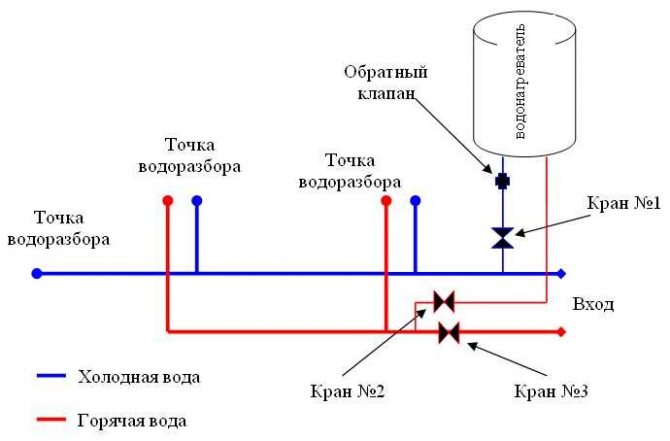

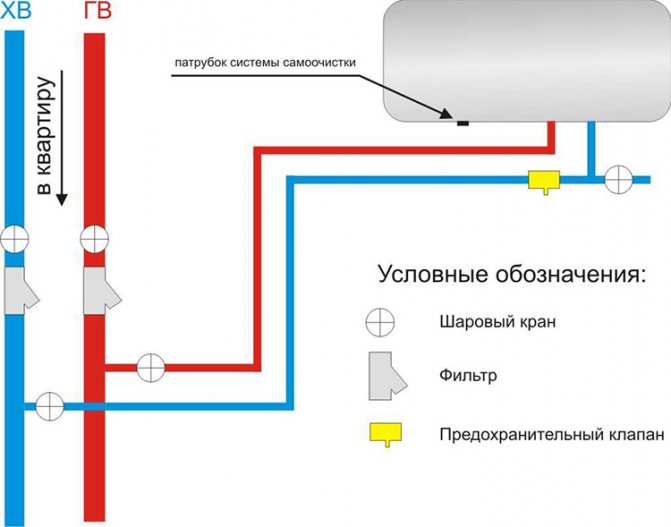

Alteration of the water supply system is also necessary in cases where the rules for connecting the boiler to it are violated, especially when using plastic pipes and the absence of a special safety valve.

The boiler tank is operational when only the valve itself is leaking.

To eliminate the leakage of the tank lid of a water heater, in most cases it is necessary to replace the heater.

If the tank itself is leaking, it is almost impossible to repair it, because the boiler is a monolithic structure, the inside of which is covered with enamel. If the enamel inside the water heater is damaged, it cannot be repaired. In this case, you will need to buy a new boiler.

Causes of the Leakage of the Safety Valve

- Dumping excess volume. When the liquid is heated, the volume inside the tank also grows. That is, when a full tank is heated, the volume will increase by 2-3%. This interest will be drained. Therefore, there is nothing to be afraid of, since dripping water is included in the process of household appliances.

- Component malfunction. It is worth distinguishing where the volume is being dumped, and where the component has failed. If the water heater is turned on, the water is heated, but not used, then a small amount of it should flow out. For an average operation of the water heater (cooking food, washing dishes), the liquid should flow out periodically and a little more than usual. Accordingly, with long work, for example, taking a shower, it will flow out even more. If water drips constantly, regardless of the level of work, then this indicates a breakdown of the device.

- Blockage. The spring opens the valve, but cannot close it, as pieces of scale or any other debris interfere. In this case, water will always flow out, even when the boiler is off.

- High pressure in the water supply. In this case, it will also flow all the time, regardless of the state of the boiler. In order to understand that the reason is precisely in it, and not in the blockage, it is necessary to measure the pressure of cold water in the water supply system. If it is greater than the set pressure, then the safety mechanism will come into action, and this will lead to a leak.

Tips for Extending Life

For the longest possible service life of the water heater without breakdowns, it is important to follow the manufacturer's recommendations for its installation and use. This applies to any technology that provides heating or water heating. When installing the boiler, it is important to provide grounding, magnesium anode, safety valve.

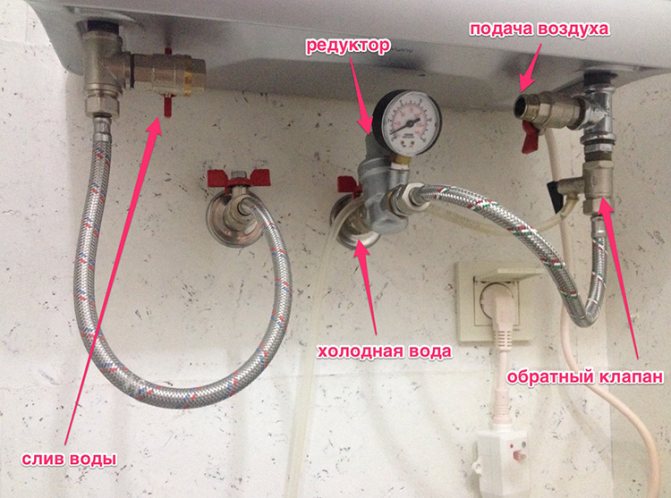

- Before installing the device, be sure to check the pressure in the system. Normal indicator: up to two atmospheres. If the indicator exceeds more than 3 atmospheres, this pressure must be reduced, for which a reducer is installed in front of the device, which will prevent an increase in temperature.

- The optimum temperature for the boiler is up to 50 ° C; it is not recommended to set more than this value.

- Clean periodically (2-3 times a year), it is important to monitor the condition of the rod.

- It is recommended to connect the device to the water supply system through a special magnesium filter, which is better purchased simultaneously with the purchase of a water heating device. This will reduce the hardness of the water if they are very high or there are a lot of impurities in the water.

If the boiler is leaking, you need to try to determine the cause of this unpleasant phenomenon as soon as possible and eliminate it. And in order to avoid breakdowns of this kind, you need to follow the rules for operating the water heater, periodically clean it, and replace worn out elements.

Eliminate the leak in the water heater

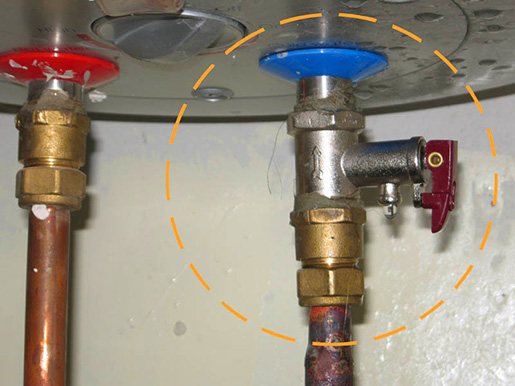

- Replacing the safety valve.

! Attention: It is strictly forbidden to operate the water heater without this component.

- If the reason is high pressure in the line, then a pressure reducer must be installed at the water inlet to the apartment. With it, you will be able to regulate the pressure of the fluid coming out of it.

- If the leakage is associated with the discharge of excess volume, then a flexible, and, preferably, transparent hose can be attached to the drain hole, the end of which should be taken out into the sewer or any suitable container.

What to do if a valve is dripping on the water heater?

During the operation of the water heater, the question often arises - why is it dripping from the valve on the water heater? If it drips from the non-return valve after heating the boiler, this situation indicates that everything is in order with your element, the protective assembly perfectly fulfills its function - liquid discharge during heating, when the pressure on the tank walls increases due to the thermal expansion of water in it.

Water discharge reduces the head inside the boiler. You need to put a plastic transparent tube on the fitting and take it to the sewer system. It should only be taken into account that not all devices have a water drain from the boiler, for example, it is absent on Ariston, a tee tap should be installed.

But, if this happens all the time, you should pay attention to the following points:

- Firstly, the assembly could lose its protective properties due to wear - the spring stretched out, the poppet device burst.

- Secondly, it could break down due to the happened water hammer, which occurs when the pressure in the water supply system rises sharply, for example, at the moment the water is turned on after it is turned off. In addition, in this case, all the debris that has accumulated in the pipes flies through the system at great speed and clogs the protective assembly. It could also become clogged with scale if the boiler tank itself has not been cleaned for a long time.

In these cases, the solution to the problem can only be the installation of a new safety element. - Thirdly, it is possible that a faulty protective assembly was originally installed. According to users, this is often found in Termex models. Here, only the diagnostics of the safety device can help, which consists in measuring the relief pressure and measured using a pressure gauge. If the measured value is less than 7 bar and more than 9 bar, then the protective assembly must be replaced. This value is average and depends on the machine model.

- The fourth factor, water leakage from the check valve, may be the desire to "hide" the protective device and the failure to comply with the basic requirement for correct operation - the length of the section between the protective assembly and the boiler should not exceed two meters, otherwise pressure will increase and leakage.

Only reinstalling the safety assembly as required will help here. Sometimes it is possible to understand that a faulty element is installed only by replacing it with another one. To do this, you need to invite a master, they usually have a valid check item in stock. Replacing it costs about four dollars.

If you replaced the safety assembly and drips from it (methods of eliminating leaks from the Themex boiler valve are described here), it is likely that its nominal pressure does not correspond to the manufacturer's declared pressure, which is indicated in the instructions for the device.

Another possible reason is that the heating temperature is too high, as a result, the constantly increased pressure inside the tank, the optimal temperature is 60 degrees.

The next reason for water leakage from the safety valve may be an increased pressure in the system.

Often, due to the traditionally deplorable state of water mains, the pressure in the system is increased to provide water to the upper floors of high-rise buildings. If the initial installation of the safety element was carried out taking into account the nominal line pressure and the manufacturer's recommendations, then when it rises, the valve will not cope with its functions.

The spring is set to a pressure of seven kg, if the pressure in the water main becomes higher, the safety assembly begins to leak. The installation of a gearbox with the appropriate parameters will help to eliminate this cause - a device that reduces the pressure in the line.Gearboxes differ in both the type of installation and characteristics, therefore, for the selection and installation, you should contact the specialists.

Reducers differ in performance, i.e. by the volume of liquid flowing through it per unit of time, by the connection principle - threaded and flanged, by the adjustment range, by the maximum pressure and temperature of the water. Connecting a gearbox will cost you $ 8-10.

These are the main reasons for a valve leaking on a water heater. In most cases this is normal, you need to sound the alarm when this does not happen and there is a danger of explosion of your unit.

Typical breakdowns and repair methods

The types of valves listed above perform ambiguous functions and differ in design. There are also differences in the reasons why they become unusable, and ways to eliminate the breakdown.

The main purpose of the gas valve is to regulate the pressure of the gas supplied through the nozzles to the burner. You can adjust the flow so that the chamber receives from 25 to 100% of the flow. It all depends on what type of gas is to be used in the operation of the equipment, how much air will be supplied for normal combustion.

In fact, this is an electromagnetic device, the main operation of which is carried out only when connected to a power supply. However, when its solenoid coils are de-energized, the gas valve acts as a safety component. In this case, it tightly closes the channels through which the gaseous fuel moves.

The charge generated by the thermocouple of the gas water heater or heating boiler hits the electromagnet (coil) of the gas valve, as a result of which the metal washer of the stop valve is magnetized to the coil. The washer opens the diaphragm so that the gas can pass to the igniter and burner block nozzles.

When the flame attenuates or decreases below the standard values, the thermocouple stops generating electricity. As a result, the coil holding the washer is demagnetized. The blue fuel channels are closed.

The need to take action will be indicated by a drop or increase in static pressure, i.e. inlet pressure when the boiler is not in operation. For units processing main gas, it must be at least 17 mbar. For boilers powered by liquefied fuel - at least 35 mbar.

The list of typical gas valve failures includes:

- Violations in the electrical circuit supplying the electromagnetic device. In this case, all wiring and contacts in the connection areas should be checked with a multimeter. If a break is detected, it is eliminated in a trivial way: by replacing the damaged wire, stripping and tightening the contacts.

- Clogged gas valve. The channels of the device can periodically become clogged with mineral particles coming along with low-quality gas, elemental carbon deposits and calcium salts formed in the event of condensation in the supplied fuel. The simplest mechanical cleaning saves.

- Failure of the thermocouple. Often it requires a complete replacement due to the complete burnout of the working edge. At the same time, no current is transmitted to the electromagnet, as a result, the boiler does not ignite at all or is blocked after a couple of minutes of operation.

- Mechanical damage to the gas valve. For example, the washer shown above. It either ceases to press tightly and ensure tightness, or does not respond to adjustment, due to which an uncontrolled volume of gas enters the chamber. To eliminate it, either the valve or the damaged part is replaced.

- Short circuit to the body of the winding of the electromagnetic coil. Most often it occurs due to short-term overheating and subsequent melting of the plastic sleeve, on which the coils of the electromagnet are wound.

It is clear that the list of all breakdowns can be divided into two groups: violations in the electrical part and mechanical damage to parts.

We immediately warn you that when carrying out any repair measures for which it will be necessary to remove the housing of the unit, it automatically deprives the owner of the right to use the manufacturer's warranty. In addition, neither the company nor the organization with which the service contract is concluded will not bear the slightest responsibility for a negative result.

It happens that instead of learning how to correctly repair the solenoid valve of a gas boiler, the owner of the unit tries hard to turn it on. At the same time, he continuously presses the button of the gas supply device, trying to start the burner. This is absolutely impossible to do.

If you independently open the gas flow path, the boiler burner will still not ignite. But the gas will flow uncontrollably into the room, while the owner will literally hold his finger on the trigger. What is the threat? At best, mild poisoning, at worst - an explosion.

In some cases, the water heater can be repaired by yourself. However, the process is not as easy as it might initially seem.

The first step is to understand the cause of the problem. To do this, it is worth preparing and taking tools that may come in handy during the inspection:

- hoses (needed to drain fluid);

- screwdriver;

- keys (end, tubular, adjustable);

- multimeter.

After that, be sure to disconnect the device from the mains, drain the liquid. The tank of the device must be empty. Only after these manipulations do they proceed to inspection, identifying the causes of breakdown or leakage.

In some cases, the problem is solved with a small repair. In others, a complete replacement of the water heater with a new one will be required. It is advisable to do this before the warranty period expires.

Here's what to look for when examining:

- Water leaks appear in the butt areas of the pipes. The cause of the malfunction is a leak in the water heater tank. No repair possible. The boiler will have to be changed.

- Leakage is observed at the top. If the device was regularly properly looked after, the magnesium rod was replaced on time, and there is still a leak, the repair will not help. We'll have to buy a new boiler. Also, the entire water heater must be replaced if it has an old magnesium rod that has not been replaced during long-term operation. This provokes rotting of the tank (in the case of an unenamelled inner surface).

- The tank cap is leaking. In these circumstances, a new heater is installed.

- Leakage directly in the tank. The most unpleasant situation - the leak comes from the bottom of the tank. The most likely scenario is the build-up of sediments corroding the bottom of the reservoir. No repair possible. The fact is that the water heater is an integral device with a single body and enameled inner walls. When the enamel surface is broken, it cannot be repaired.

The first place a plumber will check is the drain valve. It is located at the bottom of the tank. Responsible for draining sediment from the water heater. The valve is easily replaceable, so this situation is the most simple.

It is important to remember that not every small puddle of water found at the base of a water heater is due to a leak. Condensation can form on pipes and appliances that surround the water heater. As condensation builds up, the liquid will drip and accumulate on the floor. This is especially true in basements or in wet weather.

We suggest that you familiarize yourself with How to install a corner on a bathtub all types of borders and how to install them

Boiler design and operating systems are more complex than you might think. For this reason, the most optimal way is to order repairs from specialists or purchase a new device.

What is it needed for

A storage water heater is a sealed container that contains a constant volume of liquid. Usually, when a person has consumed some of the hot water, it is replaced by cold water. The problem arises when no one uses the water, and heating continues.

As you know, when water reaches tw 90 ° C, it expands by 3%. This means that in a 60-liter boiler, almost 2 liters of "additional" liquid is formed, which will have nowhere to go if the valve is not installed! This situation will lead to an accident.

But safety valve functions don't end with accident insurance.

He is also needed:

- To prevent warm water from returning from the tank to the water supply;

- To prevent water hammer (smoothes the pressure at the inlet);

- It was possible to drain the water from the heater during repairs.

- With a complete shutdown of the water supply, you do not have to refill the boiler.

Don't rely only on thermostats. They control the degree of heating of the water and do not allow it to boil. But, like any other device, they sometimes fail. The consequences of such a breakdown are too dangerous to risk.

Model tips

As mentioned above, water heaters are sold with a safety valve.

In this regard, when buying a new model, especially a brand one, you do not need to worry about the selection of a part.

The need to purchase arises in three cases:

- you have already received a used boiler without piping elements;

- the fuse is lost when moving;

- the valve is broken or worn out.

Knowing the boiler model, you can easily select a new element. In the operating instructions for the equipment, you can find the parameters of the limiting pressure - the same should be stamped on the body of the new part.

The diameter of the thread must match the dimensions of the mounting nipple and cold water piping. In addition to the device itself, you will need a linen thread on the pipe or a rubber gasket if a flexible eyeliner is used.

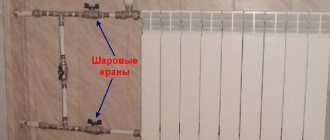

Sometimes a valve is installed between the boiler nozzle and the fuse to drain the water.

This is a permissible, permitted piping scheme, but on one condition - the valve must be mounted on a horizontal outlet from the water supply line.

There should be no shut-off devices between the safety valve and the water heater.

Varieties of valves in a gas boiler

The normal operation of gas equipment designed for heating sanitary water and preparing the coolant is ensured by a wide range of systems, parts, devices, each of which we clearly perform the important function assigned to it.

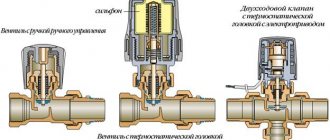

There are the following types of valves in the design of gas boilers:

- Gas valve. A component of the gas system responsible for the proportional supply of blue fuel to the gas burner, ensuring a stable combustion process in accordance with the commands of the electronic board. This electromagnetic device also includes shut-off and control valves.

- Safety valve. Component of the hydraulic system designed to discharge the excess coolant from the heating circuit in case of exceeding the standard pressure values.

- Three-way valve. Detail of the hydraulic system of double-circuit boilers only. Redirects the flow of heated water from the heating circuit to the DHW during consumption for hygienic purposes. Depending on the class of the boiler, it can be with or without a servo drive.

All of the listed types of valves involved in the operation of a gas boiler can be replaced or repaired in the event of a breakdown.

Let's take a look at the technology for restoring their performance. Having mastered simple repair principles and techniques, you can significantly increase the service life of the boiler itself.

Water drips at night

It is very important to distinguish between natural water discharge and failure of component parts.When hot water equipment is connected to the electrical network, in the absence of its operation, a small amount of it should flow through the connecting part of the valve device, including the night hours.

When the appliance is operating in a medium load mode, which includes regular washing of dishes and cooking food, water flows out of the valve device periodically, in a volume slightly exceeding the usual amount. Continuous leakage, including overnight, may indicate a device failure.

Water flows from the boiler

The main reason for water droplets leaking at night is clogging of the fitting or the inside of the fittings with scale or debris. The spring mechanism that opens the valve is not able to close it at the right time, so water flows out even when the hot water equipment is turned off. An equally common cause of night water leakage is too high pressure readings in the water supply system. In order to check the working water pressure, it is measured in the main water supply.