Modern pellet boilers for solid fuels are distinguished by a high level of efficiency and economical operation. Pellets are used as fuel - special pressed granules, for the manufacture of which woodworking waste is used, which makes the equipment environmentally friendly. Boiler power is sufficient for full heating and hot water supply to the building.

Manufacturers offer various types of boilers, differing in design features and power, which can reach from 15 to 100 kW. One of the leaders in this area are devices from Zota and Cooper, which are distinguished by high performance characteristics.

Technical conditions for the installation of a pellet boiler

In general, the rules for installing a PC are similar to those for solid fuel boilers. The complete package of requirements for the pellet boiler piping scheme is indicated by SNiP and the manufacturer's instructions.

Registration of the PC with the supervisory authorities is required if the total power exceeds 200 kW, and for a single boiler - 100 kW. Therefore, owners of adjoining plots can install such a boiler on their own. However, since all PCs are hazardous objects that, due to improper installation or operation, create preconditions for accidents or even an explosion, it is recommended to invite thermodynamic specialists at the stage of design work, equipment selection and installation.

To install a PC, you will need to have technical conditions that reflect the following requirements for the piping scheme for pellet heating boilers:

- PCs must comply with the design documentation and manufacturer's instructions.

- The design of the boiler elements must comply with the design and operational documentation.

- In the passport of the PC, the data must be indicated: heated volume, bunker volume, type of permissible fuel, efficiency, maximum temperature of flue gases and coolant, maximum pressure of the working medium, diameter of the chimney, diameters of supply and return pipelines, electrical power.

- Before installing pellet aggregates, it must undergo factory hydraulic tests, which is indicated in the passport. In general, the PC must meet the requirements of GOST 23660 and GOST 24444.

If all the conditions of the plant for transportation, installation and commissioning are met, the life of the PC must be at least 20 years with the operating hours of 200,000 hours.

Advantages of using pellet boilers

- Saving time and effort. Automation of the fuel supply process and the ability to set the desired temperature or, even, program the inclusion of different modes at a certain time of the day, provides ease of use.

- Rapid heating and maintaining the desired temperature. Due to the high efficiency of pellets and the significant power of heating devices, it is possible to quickly achieve and maintain the desired temperature regime for a long time, including in large rooms.

- Convenience of storage. The main requirement for pellet storage is low humidity. Otherwise, the type of fuel is much more convenient: it does not leave a lot of dirt and dust, like coal, and is not explosive, like

- Low level of electricity consumption, which is required only for the operation of the automation and the fan.

- Environmental friendliness of pellets. This type of fuel does not emit toxic substances during combustion.

Boilers "Teplodar" on pellets

Boilers "Teplodar" on pellets have a well thought-out design, small size and high power.Universal devices can be easily converted, if necessary, to firewood or gas. The body of the boilers is sheathed with basalt cardboard, which ensures more efficient heating of the coolant and safety during operation.

Engineers of our company have developed efficient models of pellet boilers "Kupper OK" and "Kupper OVK". The Kupper OVK model is additionally equipped with a hob, on which it is convenient to boil water or heat food.

Depending on the size of the heated room, you can choose the modification you need in terms of power: boilers are designed to heat a room from 100 to 300 m². The efficiency level reaches 83-89%, which ensures economical fuel consumption.

Requirements for the boiler room

The PC is mounted in a separate building or an annex to it. With a PC capacity of more than 30 kW, it is placed in a separate building - a furnace.

To organize its work, the owners of the boilers draw up regulatory documents in terms of operation and fire safety.

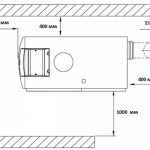

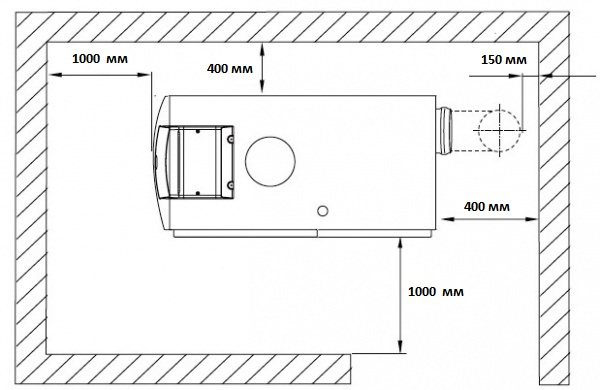

Dimensions to withstand

Basic requirements for placement:

- The floor for the installation must be made of non-combustible materials: concrete or sheet metal.

- The base under the PC should be made of reinforced concrete with a height of 10-20 cm.

- Emergency and operational passages must be provided, between the boiler and the walls of the building - a distance of at least 1 m.

- The room must be dry and heated, with an internal air temperature above + 10 C.

- Supply and exhaust ventilation in the building should be calculated based on the power of the PC, the data can be clarified from the technical and design documentation of the boiler house.

- If the boiler room is installed in a separate room, heating networks to the heating object are laid either underground, with laying below the freezing level of the soil, or by air. In both cases, the heating main must be well insulated from heat loss to the environment.

- The chimney height must be at least 5 m and protrude at least 0.5 m above the roof level; it is recommended to install a draft stabilizer or a conventional rotary damper.

- The chimney diameter is calculated according to the boiler output. For pellet boilers, it must be at least 150 mm.

- The installation of a condensate trap is compulsory.

- The roof is treated with a master flush, the lumen is filled with non-combustible mineral wool.

Specifications

| Model | Kit weight, kg | Dimensions (edit) | Chimney diameter | Room area (up to), m2 |

| Kupper OVK 10 with pellet burner | 132 | 740х340х500 + 920х740х520 | 115 | 100 |

| Kupper OK 15 with pellet burner | 146 | 1660x740x520 | 150 | 150 |

| Kupper OVK 18 with pellet burner | 168 | 1565x740x745 | 150 | 180 |

| Kupper OK 20 with pellet burner | 163 | 1565x740x743 | 150 | 200 |

| Kupper OK 30 with pellet burner | 193 | 1920x740x645 | 150 | 300 |

Equipping solid fuel boilers "Teplodar" with a pellet burner

You can also purchase an automatic pellet burner separately and install it on the Teplodar solid fuel boiler. The APG 25 burner is suitable for any modifications of the Kupper, Uyut, and Kupper PRO 22 and 28 models. Installation of such a burner does not take much time: it can be installed on a boiler that is already connected to the heating system.

The delivery set includes a collapsible pellet hopper, installed on the top of the boiler and equipped with a screw for fuel supply. The bunker is equipped with a built-in control panel.

To start the boiler after installing the burner, it is enough to place the pellets in the hopper and set the required parameters using the control panel. After turning on the burner, the fuel supply and the ignition of the pellets occurs automatically, maintaining the balance of the temperature of the coolant and controlling the combustion also does not require your intervention.

For correct operation, it will be enough to clean the ash pan a couple of times a week and fill the hopper with a new portion of fuel.

Place for installation

The boiler room must comply with fire safety requirements. The PC must stand on a non-combustible podium located above the floor surface so that dangerous situations do not arise during operation or repair:

- ignition of fuel;

- getting burned while servicing a PC;

- carbon monoxide poisoning with low draft and inoperative ventilation.

To increase the reliability of the equipment, the boiler is equipped with a safety automatics equipped with temperature and pressure sensors. For the effective operation of the system as a whole, a storage tank is placed during the installation of the PC. Therefore, it will require additional space at the rate of 50.0 l per 1 kW of boiler power. Optimizing the thermal circuit by using the tank results in 30% fuel savings and protects the PC from overheating.

Photo: picspedia.ru

The total weight of the equipment according to this scheme has a large value, which must be taken into account when calculating the load on the boiler room floor.

In addition, the area under the unit must be well insulated, otherwise condensation will constantly occur under the unit.

Required tools and materials

Photo: kievskaya.all.biz

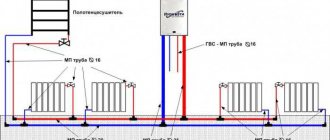

Before carrying out construction and installation work, the following materials and equipment are purchased:

- Pump for circulation of the coolant in the circuit.

- Air valves for removing the air mixture from the expansion tank in schemes with natural circulation of the coolant.

- Collector for distributing the coolant through the heating circuits.

- Sump for removing debris from the network water.

- Heating radiators

- Indirect heating boiler.

- Polypropylene pipes for an apartment heating system.

- Metal pipes for connecting the boiler.

- Safety valve to protect the PC from sudden pressure surges.

- Shut-off and control valves.

- Safety automation on the PC is built-in and consists of the following elements: pressure gauge, sensors, signaling device, boiler control panel.

- Set of tools.

Boiler assembly manual

Pellet boilers have a rather complex design. Instructions for assembling them will also be difficult and multi-stage. For greater convenience, the assembly process for each main unit is considered separately. Buy or manufacture the items you need, and then simply assemble them into a single system.

This element of the pellet boiler is highly recommended to buy ready-made. It is on the burner that you will spend the most money.

Self-fabrication of the burner is almost impossible for the reason that this part of the boiler is not just a container for igniting the loaded pellets, but a complex control and regulation mechanism.

Pellet burners are equipped with special sensors and have several pre-installed programs that allow you to achieve the most rational fuel consumption and ensure the most efficient heating of the house.

Housing and heat exchanger

You can handle the assembly of the case and the manufacture of the heat exchanger yourself. It is best to make the boiler body horizontal - with this arrangement of the unit, the maximum heating efficiency is achieved.

For the manufacture of the case, it is recommended to use fireclay bricks. You simply assemble a kind of box without a top cover and place a heat exchanger with pipes and other elements connected in it. Brick is recommended for the reason that it accumulates heat much more efficiently than cast iron, steel sheets and other popular materials.

The heat exchanger of a pellet boiler is a system of pipes interconnected and connected to the heating pipes of a private house.

First step. Assemble a rectangular heat exchanger from square pipes. To do this, cut the pipes into pieces of the desired length and weld them into a single structure.

Second step. Make holes in the profile serving as a vertical post for connecting round pipes.

Step three. Prepare holes in the remaining front pipes for the water outlet and connection pipes. Hot water will be discharged through the top hole, cold water will be supplied from the bottom.

Use metal pipes with a length of 150 mm or more. Further, it will be possible to use polypropylene pipes. Be sure to install ball valves in the places where pipes are connected to the boiler. Additionally, you can install filters if necessary.

Fourth step. Weld the rear of the unit to the front and weld the side pipes.

At the same stage, choose a convenient place for connecting a chimney with a diameter of 10 cm. At the bottom of the heating unit, provide a small chamber for collecting ash. Also, the design of the pellet boiler necessarily includes a firebox. About him further.

In the firebox, as already noted, pellets are stored and from here they are fed to the burner.

First step. Prepare the necessary materials and fixtures. You will need an auger with a diameter of 7.5 or 10 cm, an electric motor and a metal casing. Connect the engine to the pellet burner control unit.

Any container of suitable volume with sufficiently thick walls can perform the function of a metal casing.

Second step. Install the inlet of your auger into the outlet of the casing. Connect a corrugated plastic pipe to the other part of the auger to supply granular fuel to the burner.

In the end, you just have to collect all the listed elements into a single structure. Do this and proceed to installing the boiler.

Pellet boiler installation

High demands are placed on the installation of PCs. This is due to the fact that according to the technology, the moisture content of the fuel should be minimal, then the coolant is heated to high operating temperatures.

Incorrect installation will lead to a violation of the operating conditions of the boiler and its auxiliary elements, which will create an emergency situation and equipment failure.

In accordance with fire safety requirements, piping of heat and power equipment is carried out only with metal pipelines. Polypropylene structures cannot be used, since the temperature of hot water leaving the PC exceeds the working tolerances of polymers.

To ensure the reliable operation of the boiler room, it is recommended to connect two different phases as power supply. One for the functioning of the PC and auxiliary equipment, and the other for the needs of lighting.

This greatly simplifies the repair work of the main units, so as not to do them in the dark. In addition, independent illumination of the boiler front will help to perform routine maintenance work efficiently.

After checking the equipment according to design specifications, they proceed to direct installation.

Installation algorithm:

- PC installation, connection of the gas-air duct with the chimney.

- Installation of a pellet hopper.

- Fuel auger connection.

- Assembling and configuring the PC control panel: pressure gauge, safety valve and air vent.

- Piping with pressure gauges and thermometers of the circulation pump.

- Installation of automatic equipment for controlling heating of the return heat carrier.

- Placement of backup power supply and voltage stabilizer.

Before starting up, commissioning works are performed:

- verification of the compliance of the assembled boiler house circuit with the project;

- checking the tightness of the gas path;

- pressure testing of PC and heating system;

- checking the operability of safety automation;

- test start-up, measurement of operating parameters and performance of a set of commissioning works.

After the completion of the installation and construction work, adjustments are carried out otherwise the equipment will operate with low efficiency, cost overruns in fuel and electricity.

Principle of operation

The main principle of operation of a pellet boiler is the implementation of a metered supply of fuel to the combustion chamber. How much the user loads the pellets, so much heat he will receive. They are fed into the combustion chamber in certain portions, which makes the boiler different from other competitors. Then they go to the burner mechanism. It can be flare, retort and flow. For example, in forced-feed boilers, the fuel is supplied by a screw. The serving size directly depends on the required temperature. A fan located at the burner supplies air, the amount of which is calculated by the controller. The heat from the combustion of the pellets is removed by a heat exchanger.

Boiler switching on for the first time

- Fill the pellet hopper.

- Check the water pressure in the heating network and, if necessary, recharge to the standard value.

- I open the smoke flap.

- The burner is ignited - through the operating panel of the boiler or manually.

- Check the compliance of the operating parameters with the design parameters.

- A complete stop of the PC is performed after all the fuel has burned out. The process is monitored through a viewing window.

- In order to prevent the formation of condensation, the temperature of the inlet heat carrier of the water heater is monitored. It should not be cold, otherwise this will lead to abundant formation of condensate, an increase in soot in the gas path, both on the walls of the heat exchanger and in the chimney, which sharply reduces the efficiency of the installation.

Common mistakes in piping a pellet heating boiler:

- There is no control over the temperature of the return water entering the boiler.

- Poor sealing of the gas path, leakage of pyrolysis gas and drop in efficiency.

- There is no thermal insulation of the base under the boiler, as a result of condensation with the release of harmful substances.

- The inconsistency of the dimensions of the premises with the fire safety requirements leads to the impossibility of servicing the auger with pellets and the bunker.

Pellet boilers are efficient and easy to operate, since they have the possibility of long-term autonomous operation. The cost of heat energy of such an installation is not high, and it is much more convenient to use it than other heating equipment in a wooden house. However, all this will depend on how correctly the choice of equipment is made, its installation and commissioning.

The advantages of pellet equipment

Today, the advantages of pellet boilers are significant, which makes them in demand. One of the most important advantages is high efficiency, it reaches 80-97%. It is comparable to the most recognized heating equipment - gas boilers.

It is important that efficiency is provided by cheap fuel - pellets are made from wood processing waste (shavings, pressed sawdust of various deciduous or coniferous species), due to which their cost is second only to gas.

Moderate fuel prices coupled with high efficiency ensure the equipment is economical. In Russia, this is the cheapest form of heating after gas, in a number of post-Soviet countries (for example, Ukraine) it is the most affordable.

For example, using a pellet boiler will cost 1.5 times less than similar equipment using coal. Heating a building with an electric boiler is 2-3 times more expensive.

A pellet boiler differs from any other solid fuel boiler only by the presence of a special burner

An important advantage is autonomy in work - it is achieved by a high level of automation. For example, the boiler itself is able to supply the required amount of pellets to the furnace, control the temperature regime set by the owner, stop and start work. Often, equipment is even able to clean itself of ash.

Autonomy is within 2-15 days, and if the automated boiler is provided with an uninterrupted supply of fuel, then it is able to work without human intervention for the entire cold season. Also, these units are independent of the presence of centralized heating, main gas pipeline.

We must not forget about environmental friendliness - pellets are compressed sawdust, they do not contain glue or other binders. This guarantees the absence of harmful substances (for example, sulfur) in the granules, their ash content is ten times lower than that of firewood, as well as the release of carbon dioxide.

Another important advantage is safety. To ensure it, a multi-level fire-fighting system is used, which includes control sensors, electronics that interrupt the supply of pellets, automatic shutdown, a number of boilers are equipped with alarm systems.

The cheap service will also please - this is a guaranteed fact, due to the fact that there are few jobs and any person who does not have special skills can handle them.

An important plus is the simple installation - the owner of the boiler does not need to obtain any permission or draw up a project. The current rules allow such equipment to be mounted in utility rooms, basements, corridors, kitchens. In addition, the piping of the pellet boiler can be done independently.