How is a boiler that serves two circuits at once

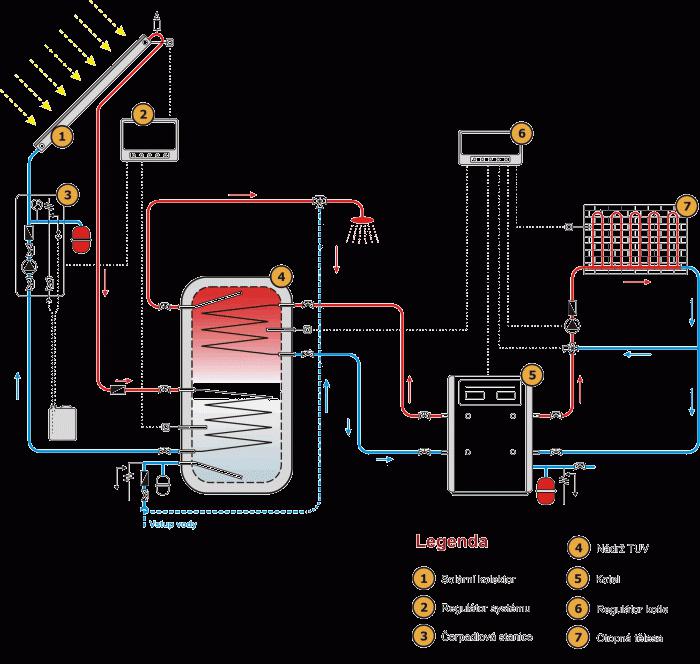

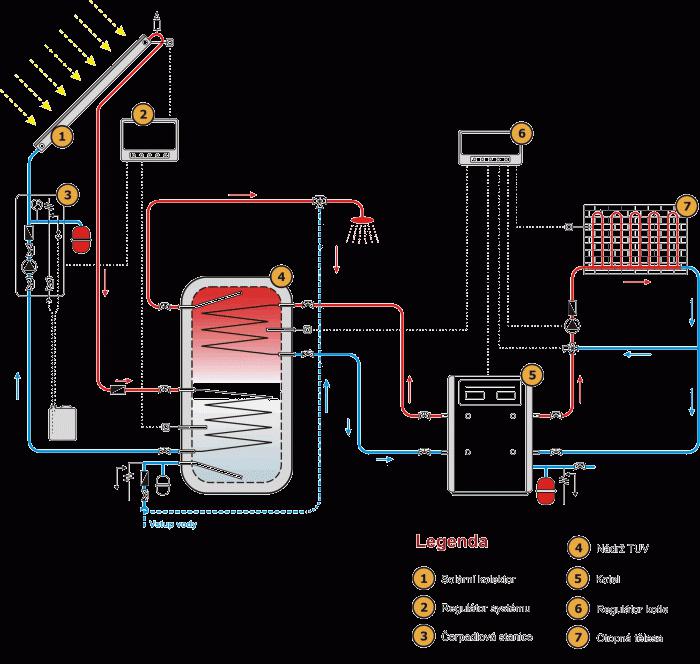

The main difference between a double-circuit boiler and a similar one with one circuit is the ability to simultaneously provide the room with heating and hot water. The primary heat exchanger, due to its location, heats the coolant so that the heating system in the entire room can function fully. The secondary one is responsible for providing the premises with hot water in the required volume.

The stability of the functioning of the principle of operation of a double-circuit boiler can only be ensured by complete serviceability and coordination of operation of each component.

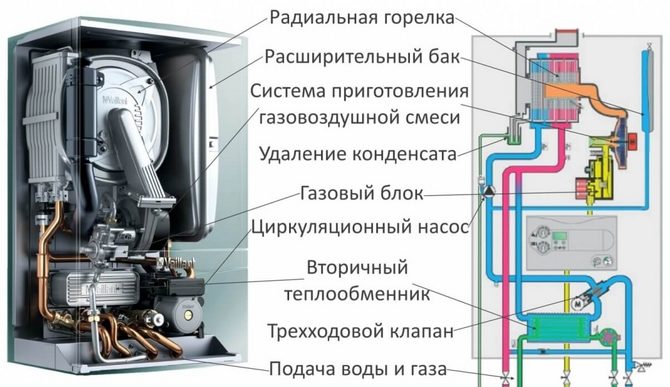

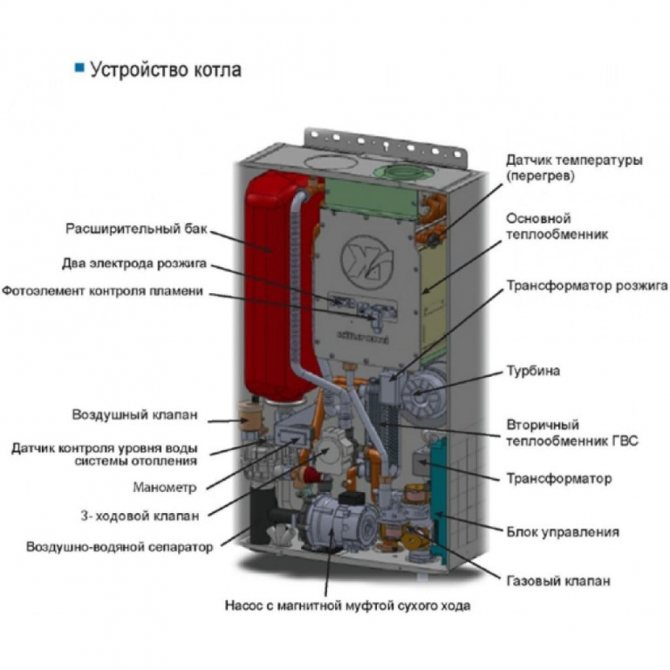

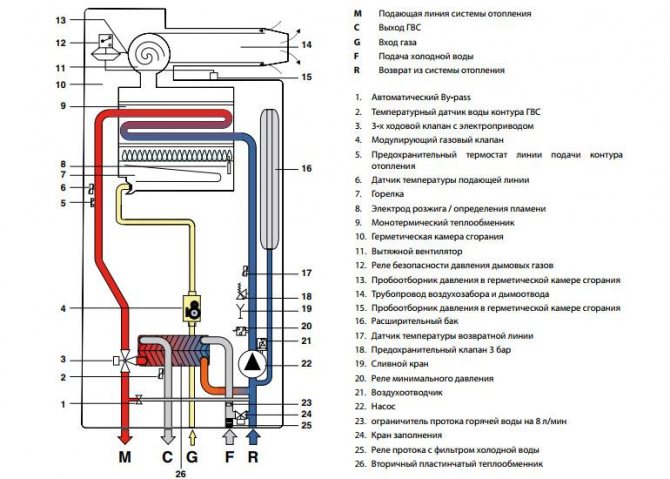

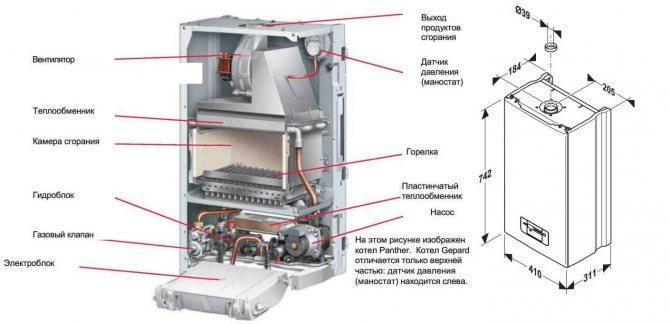

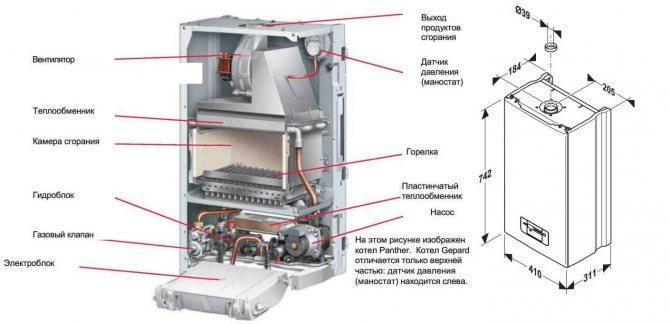

Structurally, any double-circuit boiler includes such elements as:

- heat exchangers in the amount of two;

- combustion chamber, to which the burner block is mandatory;

- protective equipment;

- control system.

To understand exactly how a gas boiler of a double-circuit type is arranged and its principle of operation, each significant component of such a design should be considered in more detail separately.

Let's talk about the shortcomings

- Such a boiler cannot simultaneously perform two functions: "supply" hot water to the heating system and provide hot water.

- A double-circuit gas heating boiler was originally designed for the normal supply of hot water to only one point, for example, a kitchen or a bath. The water consumption is determined by the power of the boiler and is indicated in its passport. Dispensing hot water, you are unlikely to get more than the specified value. Opening the hot water tap in the kitchen while someone is showering can cause the temperature of the bathroom water to drop dramatically. But this is half the trouble ... The trouble may be if the shower was turned on at a time when the hot water tap in the kitchen was already open. When the kitchen tap is suddenly closed, the bather can get a sharp stream of hot water from the "rain". A more "smoother" uniform supply of hot water can be ensured by installing an additional indirect heating boiler or using a double-circuit boiler with a built-in boiler.

- Instant "dispensing" of hot water from the tap when it is opened will not work. The features of the device of a double-circuit gas heating boiler do not allow it to immediately switch to water heating mode. In addition, cold water in the main pipe will initially flow out of the "hot" tap. Now think about whether the water meter in your apartment will "understand" such intricacies ...

- When heated water comes into contact with the heat exchanger, the latter fail over time. And the harder the water and the lower the inlet water pressure, the shorter the life of the heat exchanger.

Gas burners as part of a double-circuit boiler

The burner of a gas boiler is responsible for obtaining the required amount of heat, which can ensure the correct operation of the heating system in each room of the heated object. Also, the water is heated to the required temperature and is supplied hot in the proper volume. Thermal energy can be obtained by burning appropriate volumes of fuel. For this, the burner is placed in the combustion chamber, where, in addition to gas, air is also injected, which helps to maintain the flame.

Depending on the selected mode, the burners can be conditionally divided into single-level, multi-level and simulated. In the first version, the equipment operates only in two modes - "start" and "stop", is highly efficient, inexpensive and has a simple design.Double-deck burners can operate at full or partial power. Its advantages can be fully appreciated, starting in spring, when there is no need for heating, and therefore it makes no sense to operate the device at full capacity. The modulating burner is considered the most expensive, with its help you can adjust and regulate the power of the boiler. The latter is economical and lasts quite a long time.

Structurally, burners are open and closed. In the first case, the air, without which full combustion of fuel is impossible, is supplied from the room where the boiler is located. Such a system is equipped with a chimney, with its help natural draft is provided.

Atmospheric heating boilers are equipped with a conventional metal pipe, while turbocharged models are equipped with a coaxial chimney. They can be installed vertically, but often they are located at an angle - this option is connected to a common shaft, through which smoke and combustion products are fully removed.

Special attention should be paid to turbocharged models of gas boilers, in which closed-type combustion chambers are installed. Oxygen enters them forcibly, and therefore they are considered more reliable and do not pose any danger in the process of work, which makes them in demand in residential premises. In addition to the chimney, they need a special channel - it is through it that oxygen will be supplied to the chamber.

For turbo boilers, coaxial pipes are required in order to remove smoke and draw in fresh air from the street. In some models, there are two such elements, in addition they are equipped with a pipe for air supply.

All of the above models are necessarily equipped with fans that promote smoke, as well as automation and a multi-level protection system.

Positive and negative aspects of installing double-circuit floor-standing gas heating boilers

All heating systems, in spite of what kind of fuel is the basis of their functioning, and what kind of device design, have advantages and disadvantages. The positive aspects of purchasing floor-standing gas boilers with two circuits include:

- there is no need for constant monitoring of the heating system by a person;

- high efficiency of the unit, with minimal fuel consumption;

- maintaining an optimal temperature regime, both in small and large buildings;

- reliability and safety of equipment during operation.

As for the negative aspects of using the installation, here you should take into account:

- requires a huge amount of documentation for permission to mount equipment;

- additional installation of a chimney is required to remove waste carbon dioxide from the room;

- the room must have an appropriate ventilation system for continuous circulation of air flows;

- the high cost of the equipment itself and the complexity of its installation.

Despite the above disadvantages, the installation of a floor-standing unit is still a profitable investment in a high-quality heating system in your home.

What are the heat exchangers of gas boilers

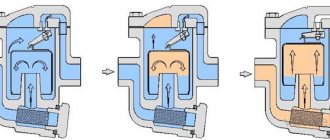

A heat exchanger in a gas boiler is responsible for receiving heat in order to transfer it to water later. If we are talking about a double-circuit boiler and its principle of operation, then there is a primary and secondary heat exchanger. The first is located above the burner and is represented by a tube with ribs, a curved snake. The water heated to the required temperature in the heat exchanger moves into the three-way valve, after which it enters the heating system. The secondary heat exchanger is represented by a whole system of plates curved by waves, all of them are combined in a single block, on which 4 holes are also located.Through 2 of them, the flow of water is carried out, 2 more are responsible for the movement of the coolant, which is supplied to the heating circuit.

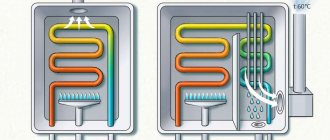

The system of two heat exchangers is called double. There are heating devices on the market that use a bithermal heat exchanger. It is characterized by a complicated configuration. For its manufacture, copper is used, the element itself is represented by tubes located in each other: the heat carrier moves along the outer one, the inner one serves for the movement of water, with the help of which the supply of hot water is ensured.

Gas boilers equipped with such heat exchangers are difficult to operate, the latter being difficult to descale. However, such heating devices are in demand, since they are small in size and heat water very quickly.

Construction and circuit diagram

The device is similar in structure to its single-circuit counterpart.

The main units are located in the building:

- Main burner.

- Igniter. Not available on all models.

- Ignition device. It is based on a piezoelectric element. In boilers with an igniter, the device is activated by pressing a button, in models without it, it is triggered automatically when gas is supplied to the main burner. The source of energy is batteries or the mains.

- Primary heat exchanger. Located above the main burner, it is connected to the heating circuit.

- Secondary heat exchanger. Located away from the gas burner. Having a plate or coaxial design, it is conventionally divided into 2 parts: one is connected to the DHW line, the other to the primary heat exchanger.

- Three-way valve. Installed at the outlet of the primary heat exchanger. Switches between 2 positions: in the first, the substance is directed to the heating pipes, in the second - to the DHW circuit.

- Automatic system. Performs 2 functions. First: control of the boiler operation in order to maintain a user-specified temperature of the coolant or air in the room (if a sensor is installed in the house). Second: blocking the gas supply when the burner goes out or when the draft is broken.

The inner space where the first 4 components are located is called the combustion chamber, or firebox. In its upper part there is a branch pipe for connection to the chimney.

In most models, in addition to the main nodes, additional ones are located:

- Circulation pump.

- A safety group that includes a pressure gauge, a safety valve that relieves pressure when the coolant boils, and an air vent.

- Expansion tank.

A boiler arranged in this way fully ensures the operation of the heating system, eliminating the need for the user to purchase additional equipment. It remains only to connect pipes to it.

With bithermic heat exchanger

There are models with a slightly different design. Instead of 2 separate heat exchangers, 1 combined, called bithermal, is installed. It is located above the main burner and has a plate or coaxial design. One part is connected to the heating system, the other to the hot water supply line.

Advantages of boilers with bithermic heat exchanger:

- Compactness.

- Simplicity of design. There is no three-way valve, which positively affects the cost of the device and its reliability.

- High speed of heating water. The stream becomes hot almost immediately after the tap is opened.

There are also significant disadvantages:

- High price.

- Expensive renovation. Since the primary and secondary heat exchangers are combined, when the latter is overgrown with scale, both must be replaced.

- Small channel cross-section. Because of this, a bithermic heat exchanger clogs up with scale faster than a separate one.

With high water hardness, it is not recommended to purchase this boiler. Use the DHW circuit carefully so as not to burn yourself.

How the boiler is controlled

In order to ensure the stable and safe operation of such heating equipment, it is better to choose automation. It controls the temperature of the water in individual components, maintains the temperature of the coolant at the proper level and is responsible for the competent principle of operation of the double-circuit boiler. In the event of potentially dangerous situations, the boiler automatically turns off - a similar manifestation is shown if:

- decrease in pressure in the gas system;

- maximum heating of the coolant;

- lack of traction.

In those gas boilers that are on the market today, mainly "smart" control is used, the software of which allows you to select one of the available operating modes.

Classification

Let's start with the model line, which is based on the method of installing the heating unit. Here, as in all other forms, there are only two positions:

- Outdoor.

- Wall mounted.

The first option is gas boilers with high power. They are most often used in large houses (multi-storey is also taken into account). They themselves have large dimensions and rather high weight. A reliable foundation is necessarily poured under them, but there are a number of requirements for their installation. If there is a need to heat a house with an area of more than 200 m² and the need for hot water is at least 14 l / min, then a floor-standing gas boiler is the best solution. In other cases, wall structures are used.

Wall option

Wall-hung boilers are compact devices with low product weight. Accordingly, they have low power. But it is these devices that can be called mini boiler rooms. Why? Manufacturers immediately include both a circulation pump and an expansion tank in their package. That is, all devices are located inside the boiler drum. On the one hand, it is convenient, because the manufacturer himself has already qualified and accurately calculated the necessary parameters of additional devices. And this is a very important point. But on the other hand, such gas boilers are volatile, so you will have to pay additional electricity bills. In addition, the service life of a gas boiler in this category is shorter.

Types of double-circuit gas boilers

This classification takes into account a purely design feature of the combustion chamber. Therefore, double-circuit boilers are divided in this case into two groups:

- With an open combustion chamber.

- Closed.

How do they differ from each other? In the first case, this is complete non-volatility. This is not a bad indicator, because, to be honest, domestic electric networks in suburban settlements cannot boast of a constant supply of electricity, and the voltage jumps all the time, especially in winter. If we talk about wall-mounted appliances, then this is the cheapest product available today. But in the case of a wall-mounted sample, and with an outdoor one, you will have to adhere to fairly strict requirements regarding the rules and regulations of fire safety and the organization of the ventilation system.

Floor option

With gas boilers with a closed combustion chamber, the requirements are not so stringent. But they have one big drawback - they are dependent on electricity, because the boilers of this group are the owners of the most modern automation, which does not work without electricity. But there is also a rather big plus - there is no need to organize a separate boiler room or furnace for them. Such boilers can be installed, for example, in the kitchen, in the bathroom, in the pantry. In addition, their presentable appearance will perfectly fit into any room interior.

The specifics of the operation of boilers with two circuits

Those who think that both circuits in such a system heat up immediately at the same time are mistaken, in fact, everything works completely differently. In normal operation, such equipment operates on an ongoing basis only in order to heat the coolant circulating in the system. How often it will turn on and how intense the flame seems during the operation depends on the temperature sensor that monitors these processes. Together with the burner, the pump starts, but only if the circulation of the coolant naturally does not have any effect on the operation of the heating system. After the temperature of the latter reaches the desired level, a signal is sent from the sensor that the activity of the burner should be reduced. After that, the boiler works only in passive mode until the temperature indicator reaches the programmed level. Next, the sensor sends a signal to the automation, which, in turn, starts the valve, which is responsible for supplying fuel.

It is enough to first familiarize yourself with certain subtleties of the functioning of gas boilers equipped with two circuits in order to understand what advantages can be obtained from their operation. Moreover, the purchase of such heating systems allows you not to purchase additional equipment, which may be required in any other case in order to provide the house with hot water. Even if one circuit fails, the second can be operated further, replacing one circuit will still be much cheaper than repairing an entire heating installation.

A double-circuit boiler may well be operated in the summer, when there is no need for heating and it is only necessary to provide heating of water intended for domestic needs. In this way, you can really save money, since buying two units at the same time, each of which functions autonomously, will cost much more.

The principle of operation of the heater

The design of a double-circuit device consists of the following components: a heat exchanger and a pair of circuits. When the heating circuit is operating, the heat carrier does not enter the hot water circuit. To prevent the coolant from entering the second circuit, a special valve is installed.

When the hot water tap is turned on, hot water supply is preferred and the valve blocks access already to the heating circuit. When the tap is closed, the system is reset to normal operation.

The principle of operation of each model of the device depends on its design features. There are convection and condensing variants of heating double-circuit gas boilers.

Convection units remove waste products and water vapor through the chimney. As for the condensation types, they use the additionally released heat and convert it into energy. The latter installation option is more rational and economical, but the cost of purchasing the unit itself is quite high.

Floor-standing equipment requires a lot of space and is not as compact as wall-mounted models, but has more powerful characteristics, is reliable in use and will last a long time.

The best known manufacturers and models: characteristics and prices

All the models below are the most famous and widespread, one of the most problem-free and proven, optimal in terms of price-quality ratio, double-circuit wall-mounted boilers. It is rather difficult to sort them into a rating by reliability or quality, since most of them are the most successful models in the competitive market, practically the same when evaluated by a set of parameters, but clearly having their own characteristics.

BAXI ECO-4s 24F

The most widespread and “beloved” in Russia is an Italian double-circuit boiler with a closed combustion chamber (prefix F in the name). Differs in high efficiency and economy, its efficiency is one of the highest in the price segment - 92.9%, the maximum gas consumption - 2.73 m³ / hour. At the same time, the boiler is perfectly adapted to domestic conditions: unstable gas and water pressure, as a rule, is not the cleanest coolant, automation and the pump tolerate minor voltage drops.

The primary heat exchanger is made of copper, there are almost all protection systems available today: from overheating and freezing, blocking of the circulation pump, autodiagnostics. A water filter is also preinstalled. The quality of assembly and layout is excellent, for more than 6 years of operation, the boiler is known for its trouble-free operation. Also, the owners note the almost silent operation. Of the shortcomings, only a slight instability of the temperature of the heated water can be noted.

Cost: RUB 31,200-35,500

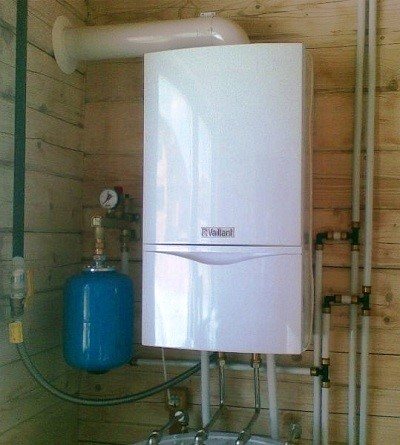

Vaillant turboFIT VUW 242 / 5-2

Despite the lesser popularity, in our opinion, this is one of the best wall-mounted double-circuit gas boilers for heating a private house. TurboFIT VUW 242 / 5-2 is one of the German reference models with a closed combustion chamber. Differs in excellent efficiency, efficiency - 93.5%, and maximum gas consumption - 2.66 m³ / hour. The heat exchangers are separate, the primary one is copper. The capacity between the circuits is carried out using a three-way valve, which allows you to maintain the temperature of the coolant with open points of hot water consumption. At the same time, DHW performance is at the level of analogues

The model has been on the market for only a few years (from 2020) and so far no cases of service failures are known. However, the manufacturer has long been known for its high reliability and durability. Judging by the layout, this model is no exception: all the pipes are copper, not rubber, the connections are threaded, and the build quality is excellent. All the necessary protection systems are present. The turbine, servo drive and ignition are virtually silent.

Its only drawback is its higher price, in fact it is a budget model of a well-known premium manufacturer. It is also worth considering that it is advisable to connect the boiler through a voltage stabilizer to prevent the failure of the electronic control board.

Cost: RUB 35,000-43,200

Viessmann Vitopend 100-W A1JB010 24

Another reference German boiler with a closed combustion chamber, slightly inferior in performance to Vaillant turboFIT. Efficiency - 91% at maximum gas consumption - 2.77 m³ / hour. The heat exchangers are separate, the primary one is steel, albeit with thick walls, designed for an operating pressure of up to 3 bar; no problems with burnout or leakage are known during operation in Russia. The distribution of capacity between the circuits in it is also through a three-way valve, there are all protection systems.

A special difference is the presence of a programmer that allows you to set the boiler operation settings for a day or a week, which, with proper operation, can significantly reduce the consumption. The built-in programmer is a rarity in boilers of this price category.

The disadvantages are standard for most Viessmann models: vulnerability to voltage surges (the protective mechanism is designed for 170-253 V, which is not always enough), again, we recommend connecting the boiler through a voltage stabilizer. Also, in rare cases, clogging of the flame sensor and the burner module as a whole can occur, as a result of which the automation knocks out the F4 error. It is imperative to clean the boiler regularly (at least once every 3-4 years) and monitor the condition of the gas filter.

Cost: 34,000-41,000 rubles.

Bosch Gaz 6000 W WBN 6000-24 С

A budget model from a well-known manufacturer, not the most outstanding in terms of performance, but proven in operation. The maximum gas consumption is 2.8 m³ / hour, the heat exchangers are separate, the primary one is copper, the distribution of productivity between them is carried out by means of a three-way valve. It works almost silently, at the level of the reference Vaillant, in particular thanks to the technology of smooth ignition, without the characteristic pop.

The device and the materials used are not particularly different from previous analogs, but some connections are not threaded, but with the use of rubber. In general, there are no serious complaints about technical reliability, however, the boiler is very picky about the presence of grounding, preferably dedicated, specifically for the boiler, otherwise it will constantly give an EA error.

Also, owners often note less convenient control; to change the temperature of the DHW circuit and some other settings, several actions must be taken, unlike individual buttons or "knobs" in previous models.

Cost: RUB 29,800-32,000

Buderus Logamax U072-24K

The German model with a closed-type combustion chamber, however, with Russian localization (assembly is carried out at a Russian plant), which significantly influenced the cost of the boiler and made it possible to distinguish it from others. Efficiency - 92%, maximum gas consumption - 2.8 m³ / hour, primary heat exchanger - copper. In terms of layout, the boiler is not much different from previous German counterparts, the connections are threaded, however, the quality of the Russian assembly is sometimes inferior to the European one.

In general, this is an extremely budgetary, efficient, reliable and stylish model, but at the same time it has a few more drawbacks. First, in addition to the lower build quality, it is a plastic make-up valve that can be easily broken over time. Secondly, the electronic board is vulnerable to voltage surges. Nevertheless, the price of the boiler makes it competitive and worthy of attention.

Cost: RUB 28,500-32,500

Ariston ALTEAS X 24 FF NG

An extremely stylish, efficient and high-tech boiler with a closed combustion chamber. Efficiency - 93.7%, maximum gas consumption - 2.73 m³ / hour, separate heat exchangers, distribution by means of a three-way valve. In addition to design and build quality, the main difference from previous analogs is the presence of a programmer and the ability to control from an application on a smartphone via Wi-Fi. Also, the owners note a large number of fine settings (limiting the temperature of the coolant, the effect on the on / off frequency, etc.).

The only drawbacks are the interface, which is somewhat difficult to master, the not practical glass coating on which fingerprints are noticeable and the rather high price, which, however, can hardly be considered overpriced.

Cost: RUB 49,200-52,000

Undoubtedly, there are other excellent models of the same or other manufacturers, in some moments inferior to those listed, and in some superior, it is impossible to list all of them within the framework of the article.

If you wish, you can also pay attention to the models of such companies as Protherm, Lamborghini, MORA-TOP, De Dietrich, Wolf. Due to the increased problematic nature and quality, we do not recommend choosing Korean models, Russian-made boilers and similar ones that are attractive by their cost: Navien, Kiturami, Lemax, Ferroli (assembled in China).

Double-circuit turbocharged gas boiler: advantages and disadvantages

The essence of the work of turbocharged models is that there is forced ventilation. Air supply for the gas combustion process, as well as the removal of combustion products, is carried out using a built-in fan. In this case, there is a pair of small diameter air ducts. The process takes place simultaneously. The combustion products are released into the environment, and the oxygen necessary to maintain combustion, on the contrary, is supplied to the boiler.The fans are mounted inside the boiler. But it is worth paying your attention to the fact that the forced discharge is suitable for units with a capacity of not more than 30 kW. As for the advantages, they are obvious, there is no need to build a chimney. Two pipes are brought out to the street, one of a large diameter, the other of a small one. The first is used to supply oxygen, the second is used to remove combustion products. But there are also disadvantages here, the fact is that double-circuit gas heating boilers have a more complex design, and it is far from always possible to make a hole in the wall. Let's take a look at another important point.

Manufacturers

The range of double-circuit gas boilers on the market offers customers products in three price segments - expensive, medium and cheap. The most popular are the following models.

Italian

- Beretta - this boiler is equipped with a closed combustion chamber, an improved heat exchanger model and a three-speed pump.

- Ferroli (Ferroli) - the protection system, self-diagnostics and electronic control explain the popularity of this equipment. And the bimetallic heat exchanger, resistant to many breakdowns, can significantly extend the service life of this boiler.

In addition, popular Italian boiler manufacturers are companies such as Baxi and Aristonwhose products are not inferior in quality to the above.

German

- Vaillant - these two-circuit boilers can have an open or closed combustion chamber. The main advantages of the boilers of this company are protection against freezing, jamming of the pump and the switching directional valve. The model also provides electronic ignition, a mode with partial power setting, technical condition monitoring and a convenient display.

- Viessmann - The efficiency of boilers from this manufacturer reaches 93%. The settings of this boiler can be adjusted depending on the temperature change in the room. The advantage of Viessmann boilers are quick-release couplings that simplify installation.

Note! It differs in good quality and Korean equipment, however, it is worth knowing that for the normal operation of double-circuit gas boilers of any manufacturer, there must be certain conditions:

- stable power supply;

- a certain gas pressure - as a rule, not less than 2 atm.

Device, structure and characteristics of equipment

A double-circuit gas boiler is a device in which heat energy is generated as a result of the combustion of gas. The received energy is directed to heating the water consumed for heating the house, and is also supplied to the hot water supply system.

What such a unit consists of:

- gas-burner;

- heat exchanger;

- igniter;

- heating circuit;

- hot water supply;

- expansion tank;

- liquid circulation pump;

- chimney required to remove combustion products;

- automation - allows you to control the boiler, as well as control the temperature.

When choosing a gas unit of a double-circuit type, it is important to know exactly what you need to pay attention to in the first place. That is why it is worthwhile to familiarize yourself with its device in more detail.

Heat exchanger types

The main difference between a two-circuit device is that it is capable of heating water for heating a room, as well as for hot water supply.

Attention! Both functions cannot work at the same time.

That is why the device contains special heat exchangers, which are of the following types.

Doubled

It includes 2 modules, each of which is presented separately - primary and plate. In the primary, the water required for heating the house is heated, and in the secondary, the water intended for household needs is heated.

If you look at the structure of a double heat exchanger, then the first type of module is comparable to a tube with fins, and the secondary one looks like a set of plates. Both of these modules are connected to each other, so they represent a single part, however, structures are located in two different boiler parts - primary on top, and plate-like below.

Bithermal

In appearance, it looks like 2 tubes made of metal, which are inserted into one another. In the inner part of the 1st tube, the water used for household needs is heated, and the 2nd tube (external) is needed for heating.

Dual heat exchanger system considered the highest quality and most durable... The fact is that when heating water for domestic use, running water is taken, which leads to a large amount of scale in the pipes.

This situation contributes to the frequent repair of the unit or requires its complete replacement, which is not always easy to do.

And if only some parts of the hot water supply can be replaced in a double heat exchanger, then in the case of bithermic separation, a new device will need to be installed, which will cost the owner twice as much.

It is also worth considering the fact that if the DHW system fails in a double-circuit gas boiler, the double heat exchanger will continue to successfully heat the room, while the bithermic one will have to be repaired, since it will be completely unusable.

Heat exchanger material

When choosing a gas boiler of a double-circuit type, it is worth paying special attention to the material for the manufacture of the heat exchanger:

- Cink Steel - the cheapest and fastest "out of order" material;

- stainless steel - it is a more durable material, which is distinguished by a considerable price, however, the efficiency of such a boiler is rather low;

- copper - this durable material is characterized by good efficiency, so the high cost of a device with a copper heat exchanger does not scare many people who prefer to pay less for gas in the future.

We recommend: Types of gas boilers. How to choose a reliable one for heating and water supply of a private house?

Copper is considered the best option, therefore most modern and high-quality boilers have heat exchangers made of this material.

The boiler automation helps to prevent overheating, and it is possible to reduce excessive chemical activity by using chemically neutral materials such as polymer pipes.

Burner types

Depending on the type of flame control, burners can be divided into the following types:

- Single stage - there are no intermediate positions, the burner is either operating or in a switched off state. This is not the best mode of operation, since the unit is turned on / off.

- Two-stage - there are 2 modes of operation of the device - 50-60% and 100% power. The required power is maintained automatically. Based on the decrease in the number of on / off switching, these types of burners operate in a more economical mode and maintain the required temperature well.

- Modulated - these are the most expensive, but also the most economical types of burners. They are controlled by automation, and they have the ability to set exactly the power that is required at a certain time - from 10 to 100%. Since the double-circuit boiler, equipped with a modulating burner, has a minimum number of on / off cycles during operation, it has increased durability. On the positive side, such boilers have significantly lower fuel consumption than other models.

The most economical choice is a boiler equipped with a modulating burner.It allows you to set the required room temperature, as well as heat the water to the required values.

Automation

To ensure the safe operation of the boiler and to facilitate its performance, gas boilers must must be equipped with automation... Parameters that are tracked using it:

- flame control;

- gas pressure;

- the presence of draft in the chimney.

If one or more of the above parameters does not correspond to the norm, the boiler will not turn on.

But in order to increase comfortable living conditions, as well as to simplify operation, it is worth choosing models that have extensive customization optionsand. Additional functions of gas boilers include:

- Opportunity setting a stable temperature for space heating and water heating. This function can be achieved thanks to two types of automation. In one case, the water temperature is controlled, and in the second, the air temperature.

- Opportunity heating liquid for the heating system with different temperature conditions... This may be required, for example, if heated floors are made. In pipes laid under the floor, a higher temperature can be given, while in radiators it can be reduced.

- Combustion control - flame modulation, electronic ignition, soft start.

- On timer hot water supply at a given time. This function will allow you to set the heating of the water for a certain time, so that in the morning, before going to work, it was possible to take a shower and not wait for the boiler to heat up.

- Post-circulation pump - after the liquid reaches the set temperature and the burner turns off, the pump continues to work for a certain time, which will allow the circulating water to “remove” energy from the cooling down heat exchangers.

Also, do not forget about automatic security systems that will prevent the occurrence of various emergencies and notify when equipment fails.