Wilo is a well-known manufacturer of pumping equipment, the entire production and assembly cycle of which is carried out in Germany. He entered the world arena in 1928 with an innovative development at that time - a circulation pump.

For almost a century of history, the range of the company has expanded significantly, which allows you to choose a pump for any task. Only the principles on which the production is based remained unchanged - professionalism, honesty and responsibility to consumers.

Vilo at a glance

The WILO Group is the world's leading manufacturer of pumping equipment used in the domestic, municipal and industrial sectors. The company was founded back in 1872 when its founder Louis Uplander began to manufacture hardware.

WILO is currently the leader in digital innovation. The company compares favorably with competitors with highly efficient and energy-saving solutions, which allows it to produce high-quality equipment according to German standards. Now the enterprises of this company are open all over the world, their number reaches 60.

The division "VILO RUS", founded in 1997, operates on the domestic market. Now it includes 30 branches. In 2016, its own service center was opened, which specializes in the repair of WILO equipment.

Features of WILO brand pumps

The main task of the company is to create such equipment that will make users' lives more comfortable. It is for this reason that all manufactured devices are characterized by reliability. Pumps can be of different designs, scope and functionality. The entire model range has the main advantage - energy efficiency, which saves money on electricity.

Benefits

Natural circulation is most often used in modern heating systems. But there are situations when forced transportation of the coolant is required. To accomplish this task, you need to know how to choose the right pumping equipment. Many factors influence the choice, but the most important is the power indicator, the intensity of the water supply will depend on it.

WILO products are characterized by the following operational advantages:

- Has no heat loss.

- Corrosion-resistant materials are used for the manufacture of equipment components.

- The system is controlled by automation. Typically, the models have a built-in thermostat, and an LCD display is provided to display all functions. If desired, you can switch to manual control, which is necessary to control the shaft speed.

- Even if a high-powered model is selected, it will operate almost silently.

- Compact dimensions. This allows you to easily install the pump in the desired location.

- It is connected by means of spring terminals, which does not take much time and effort.

- The rotor and motor have a multi-stage protection system, which makes the unit immune to power surges.

The only disadvantage of modern pumping units is that electricity is required for their full operation. Therefore, it is not recommended to purchase them for those areas where there are problems with the supply of electric current.

The devices are suitable for both the heating system and the air conditioning of the premises. The lineup includes dozens of different types that differ in characteristics and functionality. Therefore, choosing the right model for a specific task will not be difficult.

Prices for a range of WILO circulation pumps

circulation pumps WILO

Features and areas of operation of pumps "Wilo"

- wear-resistant parts;

- automated assembly and quality control process;

- certification of finished products;

- a developed network of service centers covering the whole of Eurasia;

- energy and resource efficiency;

- the possibility of DIY repair;

- environmental friendliness.

Application of Vilo pumps in:

- heating circuits;

- drinking and municipal water supply;

- wastewater disposal;

- drainage of residential and industrial premises;

- construction industry;

- irrigation purposes.

Classification of pumps "Wilo"

All the variety of pumping units from this brand for their intended purpose is divided into several groups:

- circulation technology - installed in heating circuits, air conditioning systems. Serves to increase heat transfer by accelerating the movement of the coolant;

- borehole units - pumps "Vilo", designed for immersion in underground sources of various depths;

- drainage pumps that work with water of varying degrees of contamination. Drainage of flooded basements, cesspools, etc .;

- fecal aggregates - unlike the previous class, are easily passed through solid and semi-liquid particles, and, depending on the model, are also crushed to a certain fraction. Ideal solution for silted wells, septic tanks, sewer units;

- booster equipment - by increasing the pressure in the water supply circuit (usually for cold water) increases the water pressure.

Let's consider some known modifications of Vilo pumps and their characteristics.

Types of circulation equipment "VILO"

Many owners of suburban housing are faced with the problem of choosing equipment for efficient heating of a large area - up to several hundred square meters. Natural circulation created by a conventional heater is insufficient, because the pressure in such a system rarely exceeds 0.6 MPa.

This problem is solved in two ways:

- A closed system of large-diameter communications is being built. Here you need to take into account that the materials will cost a lot.

- A circulation pump is added to the system.

A more economical option is the second. It will improve the circulation of the coolant in the system, which will increase the heating efficiency. Modern pumping units produced by the WILO brand are of two types, the features of which will be discussed below.

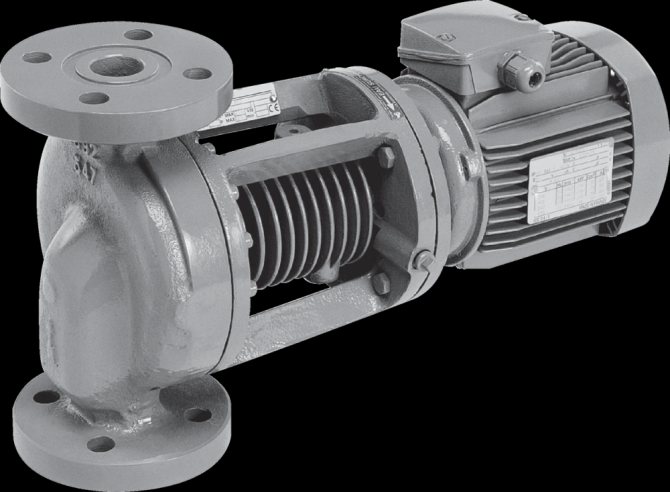

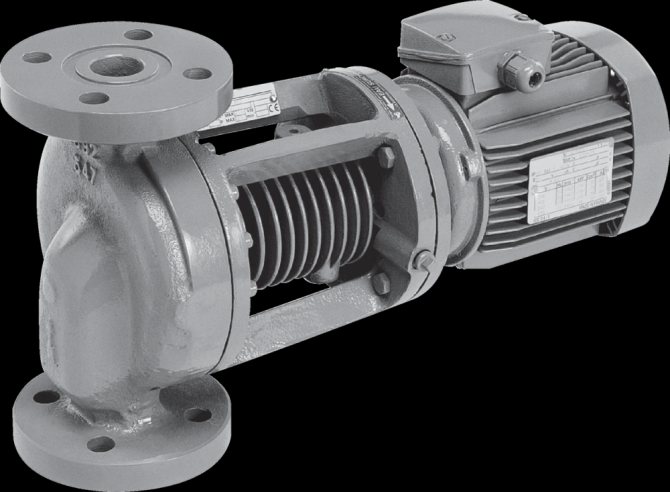

Dry rotor

Such devices are used in long-distance heating systems. O-rings are placed between the pump motor and the rotor, the operation of which is designed for 3 years. During operation, the rotor does not come into contact with the coolant. Thanks to this, the device is reliably protected from corrosion and requires virtually no maintenance. The advantage of pumps with a dry rotor is a high level of efficiency, reaching 80%.

It should be borne in mind that this type of product is quite noisy, so they are installed in a specially designed room. It is important that there are no foreign particles in the fluid that could damage the O-rings.

Wet rotor

With the help of such models, country houses are heated, where heating systems have a short length. A distinctive feature is the presence of a rotor and impeller, which is necessary to accelerate the movement of the coolant. The rotor itself rotates in a liquid, which additionally serves as a cooling mechanism for the mechanism.

When installing such pumps, it is important that their shaft is located in a horizontal plane - only under such conditions water will always remain in the housing.

Glandless pumps have the following advantages:

- almost do not make noise during work;

- have a built-in mechanism for switching the rotor speed;

- are reliable;

- characterized by a long service life;

- do not require additional maintenance;

- easily set up and repaired.

The efficiency index of these installations does not exceed 50%.

How to correctly install a Wilo pump in a heating system

- Only vertical installation is allowed. Do not install a Wilo pump horizontally in the system. The only exceptions are models specially designed for horizontal connection. The installation position of the pump can be found in the operating instructions.

- Connecting underfloor heating - the pump is installed in a special mixing unit. The correct location of the Vilo heating pump is indicated by arrows on the body and on the hydraulic wiring.

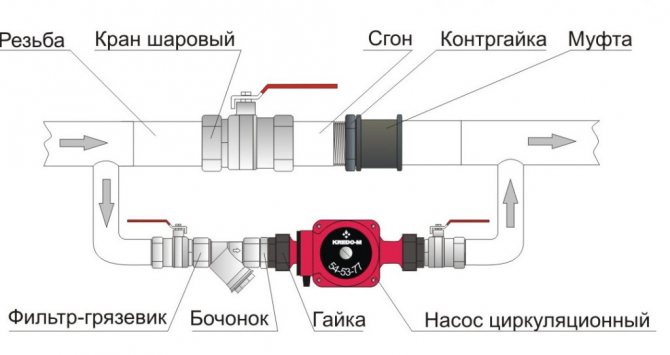

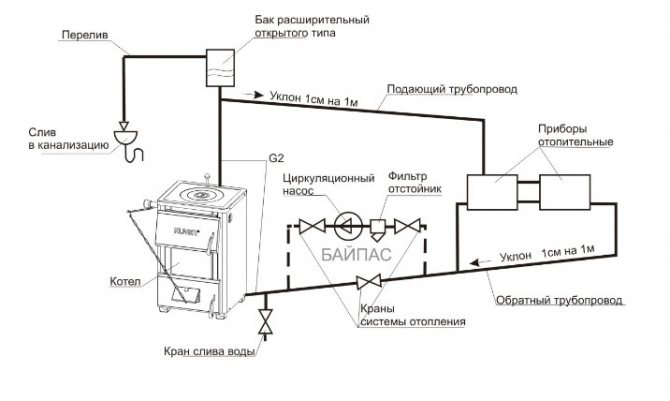

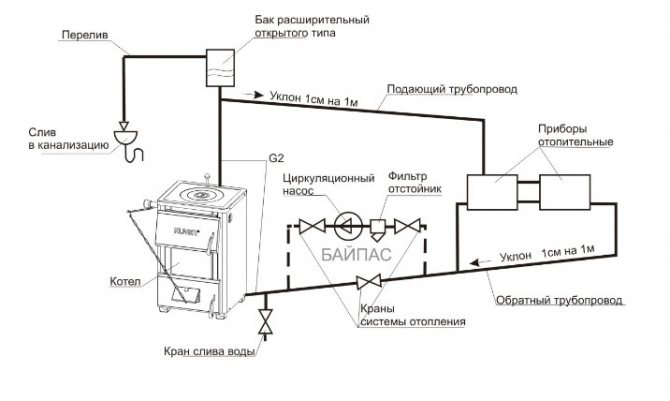

- Connection to a radiator-type heating system - installed in the heating return, directly in front of the boiler. To prevent a complete stop of the circulation of the coolant, they are mounted in a bypass. The rules for installing Vilo pumps allow the use of equipment for heating systems with natural and forced circulation.

- Installation and maintenance - the pump is installed in a vertical position, observing the direction of the coolant indicated by the arrows on the body and mixing unit. It is recommended that the installation be carried out by qualified personnel. The installation methods of the pump depend on the selected model and are described in detail in the technical documentation. Provided that it is correctly connected, no special maintenance of the Wilo pump is required.

- On the bypass frame, it is necessary to install a coarse filter in front of the pump.

- You can leave the pump on at all times. It is recommended to turn on the device for a few minutes after the end of the heating season.

- Hum when the pump is running - indicates several possible malfunctions. The air vent is clogged, as a result of which no air is removed from the system. Another malfunction lies in the incorrectly selected operating mode. Reducing the operating speed usually stops the hum. If not, pump service will be required.

- It is possible to turn on the pumping equipment only when the heating system is full. Wet rotor models use heat transfer fluid for lubrication. When turned on, if there is no lubricant, the bearings burn out quickly.

Only a qualified technician can take into account all the details of the installation of a Wilo circulation heating pump. Equipment installation is completed in just a few hours. When installing a bypass, it will take 3-6 hours.

Pump types by number of speeds

Each pump is designed with a certain number of speeds. The performance of the equipment depends on this parameter. WILO products are available in single and multi-speed, which allows you to select a product for a specific system.

Single speed

Such models are not speed-controlled. If you turn them on, they will only work at maximum power. These products are the simplest from a technical point of view and affordable, since there are no additional elements in the design - regulators. The option is convenient in those situations where the pump must operate at maximum power - as a rule, these are common cases, therefore such products are very popular.

Multi-speed

Due to the presence of several speeds, the user can choose the intensity of the pumping equipment. For example, in some situations it is not necessary for the device to operate at full power, and a reduced speed is set. This leads to energy savings and less wear on the working mechanism.

Modern equipment can have 3 or even 4 speeds, so the user himself decides in which mode the pump will work. More speeds are not found.

We calculate the performance of the pumps: technical characteristics

The pump capacity, denoted by the letter Q in the calculation formula, shows the heat in those quantities that move during one unit of time.

- LiveJournal

- Blogger

The formula should be written like this:

q = 0.86r / tf-tr

- q is the heat consumption per cubic meter per hour;

- r is the heat output for the room;

- tf is the temperature supply to the system;

- tr is the outgoing temperature.

European countries calculate consumer heat based on the following parameters:

- 100 watts per square meter in a small private house;

- 70 watts per square meter in an apartment building.

If you calculate a pump for heating in a house where there is poor heat insulation, then the indicators increase. If it comes to a house with good heat insulation, then e indicators should exceed 45-53 watts per meter.

Marking

On each model of manufactured equipment, in addition to the instructions, a special plate is attached to which all the necessary technical designations are applied. If you can read them, it becomes clear for what purpose the pump is used, its performance and much more.

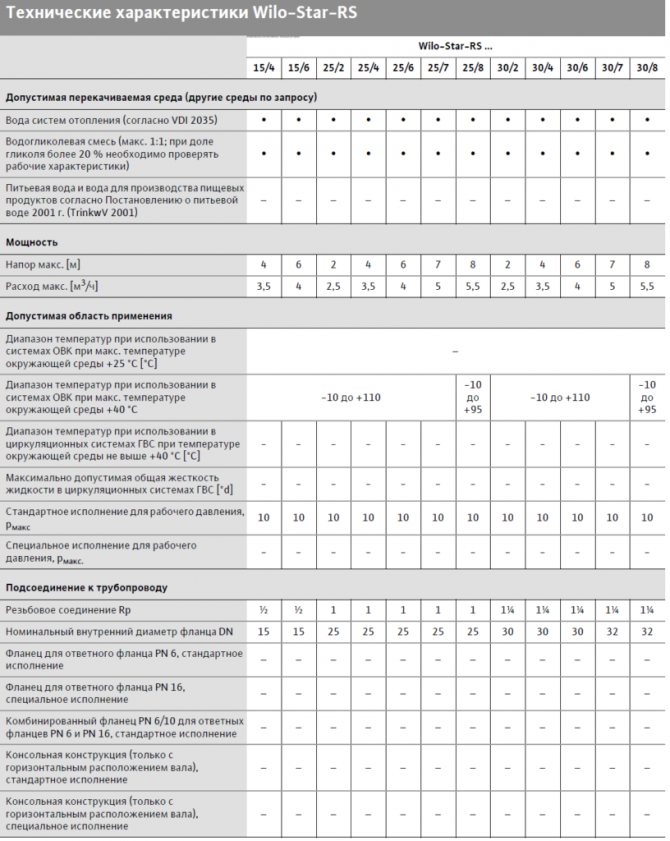

Now several models of WILO pumps are produced:

- Star-RS (RSL, RSD) - heating systems, air conditioning, cooling;

- Star-E - industrial heating models with electronic control;

- Star-AC - refrigeration and air conditioning;

- Star-Z - hot water supply;

- Star-ST - solar thermal systems.

To make it clearer, consider an example.

WILO Star-XX 25 / 1-5 YY:

- Star - equipment type;

- eXX - suitable for which systems;

- 25 - indicator of the inner diameter of the branch pipe;

- 1–5 - possible head measured in meters;

- YY - single or three-phase electric motor.

These are the basic parameters found in the device name.

What else is indicated in the marking:

- brand logo;

- product number and production date;

- model;

- Class F - indicator of resistance to heating of the heat carrier;

- IP - pump protection level;

- PN - permissible working pressure;

- Tmax - maximum operating temperature level;

- SV0 - software availability (if additional functionality is connected, then this parameter is of great importance);

- P1max, P1min - ranges of permissible temperature;

- Imax, Imin - current required for operation;

- 1–230 V - voltage.

These designations are the most common and, starting only from them, you can already make the right choice of equipment. All other characteristics are indicated in the product passport.

Applications

The Wilo brand produces pumps that are designed for different purposes and therefore have different characteristics.

With the help of such a pump, you can water the beds directly from a well, well or the nearest reservoir.

Their area of application is extensive and varied:

- Wilo devices are used in heating systems in closed circuits.

- They are used in the water supply of private houses and in water production wells.

- Such pumps are also suitable for pumping groundwater when creating basements, cellars.

- They are also used at the construction site when working with polluted waters.

- The owners of private suburban areas have found good use for them, in particular, those who are engaged in the cultivation of plants on their personal plot.

The Vilo pump can operate in the most difficult conditions, and it does not matter what temperature the water circulating through the pipes will have and what the pressure will be.

You can connect the device yourself without any problems. For this, it is equipped with special spring terminals. It does not have a fan, so there is practically no noise during operation.

As a rule, choose a pump

Many users do not know which equipment parameters to pay attention to when choosing.

Many factors affecting the operation of the heating system are taken into account:

- The required amount of heat. Many important conditions apply here: the area of the room, the height of the ceilings, the number of storeys, the number of windows and doors, as well as the material of their manufacture. The factor of basement and attic insulation is also taken into account.

- Climatic conditions of the area. When choosing, one should proceed from the minimum air temperature, the frequency of wind loads and other features.

- The construction of the heated building. The thickness and material of manufacture of walls, floors and ceilings are taken into account. Equally important is the presence of a ventilation system in the house.

In short, there are many criteria that should be taken into account when selecting effective equipment. If the skills and knowledge are not enough, you should contact a specialist.

The following are also taken into account: the number of installed batteries, the power of the boiler, the features of the water distribution scheme. Another important indicator is pressure. To determine it, they are based on the total hydraulic resistance of the system. As a rule, this parameter is indicated even at the design stage of the house.

If the living area is small (less than 3000 m2), then this makes it easier to choose:

- 200 m2 - WILO Star RS 25 2;

- 350 m2 - Star RS 25 4;

- 520 m2 - Star RS 25 6 or RSD 30 6;

- 700 m2 - Star RS 25 7 or 30 7.

All manufactured equipment operates almost silently and does not require maintenance. In addition, ease of control is achieved through built-in automation.

The lineup

The concern is famous for a fairly wide range of products. The Wilo CAD catalog contains 142 series, among which the most common are:

- Wilo-Economy-CO - multi-pump and single-pump pressure boosting stations. They are assembled on the basis of vertical pumps MVI, Helix V, MVIS, MHI. In the station, 2-4 units are installed in parallel, which increases the reliability of operation and productivity. Supplied with collecting collection tank and solids separation system and control panel. The head varies from 60 to 160 m. The flow rate, depending on the pump, can be 14, 75, 80, 135 cubic meters / h.

- The Wilo-Multivert MVI family is a vertical outdoor centrifugal device. They provide water for irrigation installations, are component parts of boiler rooms, fire extinguishing installations. The design and dimensions of the MVI during installation save space. The MVI 2 series consumes 5 cubic meters / h, the head - 220 m, the fourth series - 8 cubic meters / h, the head - 210 m, the eighth - 14 cubic meters / h with a head of 225 m.

- Star is a line of models with a wet rotor and a threaded connection. There are 3 speed modes. The devices are used for cold water supply, in heating systems. Head - up to 8 m. Flow rate reaches 6 m3 / h.

- TOP are compact circulating pumps with the ability to connect it to a pipe. They work quietly, are ideal for pumping liquids through a pipeline in private houses, they are thermally insulated. Head - 9 m, flow rate - 65 m3 / h.

- The Wilo Helix pump family is multistage equipment belonging to the subtype of non-self-priming pumps with a flow rate of up to 93 m3 / h and a max. head up to 240 m. The units are equipped with a dry rotor, each unit has a frequency converter and air cooling.

- Stratos are highly energy efficient circulation devices. Applicable in heating systems, cooling circuits, air conditioning. The company also creates various control devices. For example, Wilo SK 702 is a device for control, protection and monitoring of pumps against overcurrent, dry running.

- The line of Wilo Comfort Vario pumps has 3 series, differing in design features. The regulator can combine up to 4 products in parallel.

Wilo Comfort Vario pumps

Popular models, their technical characteristics

The most popular models are:

- WJ 203 EM is a self-priming water supply station with a 50-liter tank and a power of 0.75 kW. Max. head - 41 m, flow rate - 5 cubic meters / h;

- Star-RS 25/4 is a circulation model of balanced design used in heating and hot water supply systems. Head - 4 m. Connected to the power supply, the unit operates in one of three stages of rotation. Vit has a 2-sided cable drive, stamps;

- Wilo Hisewlift 3-35 sewage cutter unit with a power consumption of 0.4 kW and a direct start-up type. Rated speed - 2900 rpm. Tank volume - 17 liters;

- Wilo JET HWJ 204 is a horizontal, single-stage, portable self-priming jet device.It pumps water in the supply / suction modes. Delivers water to a depth of 8 m thanks to the hydraulic power of the system. Power consumption - 1.3 kW;

- device HWJ 202 EM Wilo for water supply, irrigation, pumping rainfall, is used mainly in garden areas, a 20-liter membrane tank helps to reduce the frequency of starts. Suction head is 8 m, head is 37 m. Max. the water supply is 4.5 cubic meters / h.

- Wilo Hisewlift 3-15 - automatic installations that drain wastewater from the sink, wastewater with feces from the toilet bowl. The volume of the tank is 17 liters. Power - 0.4 kW. Liquid temperature - from +5 to +35 degrees;

- in the model range of circulating Star RS, a special place is occupied by the Wilo RS 30/6. This is a standard glandless pump with threaded connection. Has 3 stages of rotation frequency, manual control. The head is 6 m, the flow rate is 4 cubic meters / h.

Review of popular models and their cost

The WILO brand produces a wide range of pumping equipment for heating country houses. All models differ in many respects: power, head, coolant temperature and other characteristics.

Star

The equipment of this line is used in domestic conditions and is suitable for organizing a heating system in a small house.

There are two series:

- Star Rs. This includes 12 models labeled from 15-4 to 30-8. Heat-resistant cast iron is used for the manufacture of the body. Parts that come into contact with the coolant during operation are made of stainless steel. The Star RS is manually regulated, and these pumps are capable of generating pressures up to 10 bar. The maximum throughput rate is 6 m3 per hour.

- Star RSD. These are more functional devices. With their help, you can increase the pressure in the system. Devices connected to such a pump can last longer. In addition, the module can be simultaneously connected to two circuits at once. The device is completed with a special switch required to adjust the electric motors. The weight of the device is only 5 kg, but it is able to provide the necessary pressure for a house of 750 m2.

We should also highlight the 15 WILO Star Z Nova model, which is used for recirculation in hot water supply systems. The head and performance of each model is different. The price of these devices starts at 3600 rubles.

Top

This category of pumps is used in heating systems for large cottages and apartment buildings. Due to their high performance, they can be connected to systems where the heating area does not exceed 1400 m2.

A distinctive feature is the presence of thermal insulation, so the device is suitable for outdoor installation. The maximum working pressure is 10 bar.

The following models are produced:

- RL and S. These are the most efficient wet rotor units available with one or two motors. They are connected to a one- or three-phase network. The three-speed pump is equipped with a mechanical switch.

- Z. By purchasing this unit, you do not have to worry about the quality of the coolant. Often the Z 15 TT 1 model is chosen, which is not afraid of calcium or magnesium precipitation. There are no strict requirements for the installation site.

- TOP. These are basic devices, the number of which is more than 50. They differ in flange size and performance.

In short, if you need a device for a large house, you should pay attention to the Top series, where you will definitely find a suitable model. You can buy a circulation pump for heating WILO at a price of 15 150 rubles.

Stratos

This is a relatively new invention in the field of pumping equipment. The key feature is the built-in LCD display for control. The screen displays the necessary information about the operation of the device. The line was created with the pumps in mind to be installed in large heating systems. Connection to a boiler with a capacity of 25 kW or more is possible.

Key Features:

- power adjustment from 2 to 48 W;

- the presence of a night mode, during which a minimum of electricity is consumed;

- automatic adjustment of performance indicators, for which the controller must be connected to a room thermostat.

Among the list of models, there are 2 interesting ones: one with a bronze case and an increased productivity (16 bar). Best of all, this line shows itself in energy-saving systems. The cost starts at 10,485 rubles.

Yonos

These are models equipped with an electronic control unit and air protection. An additional function is the removal of solid attachments from the liquid. Mode switching is mechanical. If it is necessary to achieve economy, the device is switched to automatic mode. Operating information is displayed on the indicator panel: what is the pressure in the system, how much electricity the pump consumes, and so on.

This series is one of the last released by the company, therefore it has absorbed all the positive qualities of its predecessors. The price of these modern devices is from 8900 rubles.

The most popular models of Vilo drainage pumps

- Wilo-DrainTMT 32H102 / 7,5Ci pump Submersible unit for vertical installation. It can be used for pumping hot water and aggressive liquid media.

- Drainage pump Wilo-Drain TMW 32/11. Used for pumping waste water. Prevents the accumulation of precipitated substances, destroys them together with the pumped out liquid. The temperature environment is not more than 35 degrees.

- DrinVC model. The vertical positioner can handle contaminated environments that contain a 5mm particle. The VC30 / 10 type pumps water at a speed of 7m³ per hour with a head of ten meters.

- The EMU KS unit is used for pumping wastewater from flooded basements or pits, ingress of grains with a diameter of 5-45 millimeters is allowed.

Wilo manufactures versatile equipment that can be used in different areas of life. Each drainage pump of this brand will delight you with excellent quality and optimal technical characteristics.

Installation features

Installation can take place in different ways.

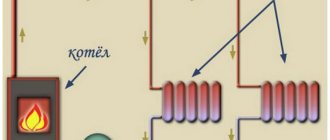

There are 2 schemes:

- One-pipe. The coolant is constantly consumed, while the temperature drops are insignificant.

- Two-pipe. With high drops and variable flow.

Before starting installation work, the instructions for the product are studied in detail. It is also important to choose the place of installation, namely, there must be access to the device for maintenance. Most often, this type of equipment is installed in front of the boiler. Installation on the supply is not relevant, since there is a possibility of creating a vacuum.

Installation steps:

- The remaining liquid is drained from the system.

- The pipeline is being cleaned.

- The pump itself and auxiliary fittings are being installed.

- Liquid is poured into the system, from which excess air is removed.

For proper installation, preparation of the bypass is required. Thanks to him, the device will be able to continue its work, even if the power is cut off. The diameter of the main pipe and the bypass must be different.

Adhering to these recommendations, even a beginner wizard will cope with the installation:

- For maximum performance, the instrument shaft must be horizontal.

- The terminal box is installed from the top.

- There must be a ball valve on each side of the pump for subsequent servicing.

- The system must have a filter that removes small particles from the coolant.

- A vent valve should be placed on top of the bypass line.

- The presence of shut-off valves is necessary so that water does not leak.

- An expansion tank is provided for an open heating system.

- To increase the performance, the joints of the device must be properly sealed.

Competent installation in compliance with all rules and recommendations is the key to effective operation of pumping equipment.

Selection and installation

Before choosing any device, you need to know all its technical characteristics. First of all, they pay attention to the power of the device. It directly depends on the area that needs to be heated. For example:

- Let's say the area for heating is 130 m2. In order for the heating system to work efficiently, a wilo heating pump with a capacity of 0.4 m3 / hour is required.

- If the area increases to 170 m2, a device with a capacity of 0.6 m3 / h is required.

- And for an area of 300 m2, the required capacity is 0.9 m3 / hour.

These are rough estimates. For a more accurate calculation, the value of the speed of the coolant inside the system and special coefficients are required.

Installation of devices

The Vilo manufacturer provides a large selection of devices for the heating system. Due to the huge variety, you can choose any size of threaded and flange connections that are suitable for installation in any heating system.

Installation of devices is not difficult. You can install the circulation pump wilo on the pipeline. For small areas up to 750 m2, the Wilo-Star-RS model is preferable. This series of devices is equipped with a three-step switch. The required voltage in the network is 230 V. The temperature of the working fluid is from -10 to +110 degrees. But the ambient temperature should not be more than +40 degrees.

The unit is placed on the shaft horizontally or vertically. Installation with any angles of deviation from the horizontal or vertical is strictly prohibited. Most often, the installation is carried out on the return flow pipe, near the entrance to the boiler. However, the installation can be carried out at any point in the heating system, both on the supply pipes and on the return pipes.

Vilo circulation pumps in the heating system

To simplify the installation, repair and replacement of the pump in the heating system, a bypass is usually welded into the pipe, and the pump is already mounted on it. A bypass is a section of pipe with outlet flanges. A tap is installed on the bypass pipe, which is welded into the main heating circuit. On the branch arc, valves are also installed on both sides of the pump and a filter at the inlet to it. This allows, in case of need for repair or replacement of the pump, to carry out all work without draining the system and cooling the room. It will only be necessary to turn off the taps on both sides of the pump and open the direct circulation tap.

The terminal box has two cable outlets. Therefore, the pump is connected to the mains from either side. The terminals are spring-loaded, making the cable easy to connect.

After installing the pump, at the first start-up, it is necessary to bleed all the air from its housing. For this, there is a screw on the front of the pump. After starting the pump, the screw must be completely unscrewed and wait until water runs from the opened hole. Then screw the screw back tightly.

So, connecting a circulation pump is not a complicated process that you can do yourself. You just need to choose the right device and familiarize yourself with the installation features.

Exploitation

It is better to repair wilo circulation pumps, like any other imported devices, at a service center. Therefore, you should pay attention to the prevention of breakdowns.

- It is not allowed to operate the apparatus with zero feed.

- Do not operate the device without liquid.

- With a long idle time, the unit is turned on once a month for 10-15 minutes. Otherwise, there is a possibility that it will oxidize and block the shaft.

- It is necessary to ensure that the device operates only within the permissible limits of the set parameter values.

Testing the electrical box of the pump

Maintenance of the devices is carried out periodically.

- First, make sure that there is no vibration and noise.

- They check the operation of the pump according to the pressure-flow parameters.

- Check if the engine is overheating.

- Lubricate the threads of the flange bolts.

- Check the grounding on the case.

- Check if the pipeline is leaking at the attachment points.

- Check the quality of the cable connections in the terminal box.

Operation and maintenance recommendations

During the operation of the circulation pump, various problems can arise. The design of WILO products is so simple that you can service them yourself without the help of professionals.

Frequently encountered problems and solutions:

- The shaft stopped rotating. These pumps run so quietly that it is impossible to immediately determine the cause of the breakdown. A special shaft rotation tester is used to identify the malfunction. If the scale shows no movement, the device must be disconnected from the power supply. This situation sometimes occurs during long periods of inactivity or when a foreign object gets inside the camera. In any case, you will have to disassemble the pump and unscrew the shaft, and then remove foreign particles from it.

- A creak appeared. This most often happens when the system heats up. A squeak is heard if the engine pulley starts to come into contact with the start plug. To eliminate this problem, it is enough to install a gasket on the plug. If this does not help, then the part of the pulley that rubs against the bushing can be sawed off, but not more than 3 mm.

- The pump stalls. Usually, the reason lies in the formed scale, which must be cleaned with a brush. If the system has a coarse filter, this problem practically does not arise.

- Pump vibration. This indicates that the bearings need to be replaced. The appearance of vibration can also indicate a drop in pressure, which should be increased. Sometimes it helps to reduce the viscosity of the coolant.

- Low water pressure. The problem indicates that the device is not connected correctly. This can happen if the filter is dirty, water pipes are faulty, or there is a large amount of glycol in the coolant.

These emergencies are extremely rare and most often due to improper connection of equipment. In any case, they can be fixed simply and without the use of special tools.

Advantages of devices

Thanks to the special properties of the Wilo pump, the efficiency of the heating system is significantly increased. In this case, thin pipes can be used, which, in turn, helps to reduce material and fuel costs. Also, when using a pump, the volume of carbon dioxide that is emitted into the atmosphere decreases, and the daily consumption of electrical energy is no more than 250 watts.

Of course, such a device is not cheap. You will have to pay a large amount for its purchase, but the cost will surely pay off later when used due to energy savings and durability. The device will not need repair for a long time.

Vilo pumps have many positive properties.

During operation, the working part of the pump is constantly washed by the pumped liquid, so there is no need for regular maintenance of the unit

The most important ones are as follows:

- There is no heat loss after the water has evaporated.

- The system can be controlled automatically. The device has an LCD screen, built-in thermostat, and other elements that allow for control. You can also manually switch the speed of rotation of the working shaft.

- Compared to many circulation pumps from other brands, Wilo devices are quite compact and therefore do not take up much space.

- The motor and rotor have a multi-stage protection system that helps prevent damage due to sudden power surges.

- The motor runs silently, making it possible to install the device in residential buildings.

Wilo pumps are used in small rooms with an area of several hundred square meters. The selection is carried out according to parameters such as power, volume of circulated water, area of the room and head height.The last parameter is the most important.

How to distinguish an original pump from a fake, you can see in the following video:

How to recognize a fake

WILO is a popular piece of equipment, so now you can often stumble upon a fake. If the product is original, it is covered by the warranty. A separate category is the Chinese WILO pumps, the service life of which is only 2-3 years, while the original is capable of serving up to 15 years.

How to visually identify a fake:

- The original packaging has a cube shape with high-quality glossy paint. Counterfeits are packed in a rectangular box.

- A sticker is attached to the original device; for fakes, the article, serial number and other data are printed.

- The serial number is not punched on the body of the counterfeit device.

- On the original, the arrow showing the direction of water movement is large, on Chinese products it is small.

In addition to visual qualities, attention should be paid to the internal structure.

Differences:

- The rotor and stator are marked on their housings with the serial number and date of manufacture.

- On original models, the top of the unit is detached from the rotor, making the unit repairable.

- The electronics must also be labeled.

These are the key points by which you can distinguish the original from the Chinese counterfeit.

Household circulation pump WILO Device

The modern household Wilo circulating pump is a single design. The hydraulic volute is made of high quality cast iron alloy. The pump casing, which accommodates the induction motor, is made of cast, ribbed aluminum. The rotor is made in the form of a cartridge, fixed on front sliding bearings made of metal graphite, made of stainless steel in a sealed casing, it is not repairable and in case of breakdown, it changes entirely.

The polypropylene impeller is mounted on a stainless steel shaft. The stator is reliably separated from the rotor. This design is called a "wet rotor" and differs from a conventional pump in the absence of air cooling. Cooling of the electric motor is carried out by the pumped liquid. The two parts of the pump are fastened together with just two bolts through a gasket. The pump forks includes threaded connections and two gaskets. The temperature regime of the pumped-over heat carrier can reach + 110 degrees Celsius.

It remains to add that the Wilo pump has a three-speed control, with switching on the terminal box. The Wilo pump is equipped with an internal motor protection, so there is no need to install additional overload protection. A starting capacitor is located inside the terminal box.

A built-in thermostat is included with electronic devices. The maximum pressure provided by the pump reaches 7.5 bar, and the flow rate reaches up to 12 m3 / h. Such parameters make it possible to equip a heating system with room sizes from 150 to 2300 square meters.