Inverter heater

Operating principle

The inverter, which this type of device is equipped with, converts alternating current into direct current, while changing the voltage and frequency. This physical process is called inversion. The inverter looks like a periodic voltage generator. It is similar in shape to a discrete signal. Inverting has a profound effect on the power of the device, and all electrical appliances with it become less noisy and more economical.

Advantages and disadvantages

This type of device has enough advantages:

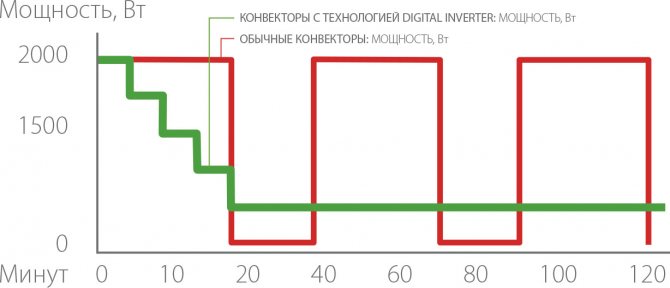

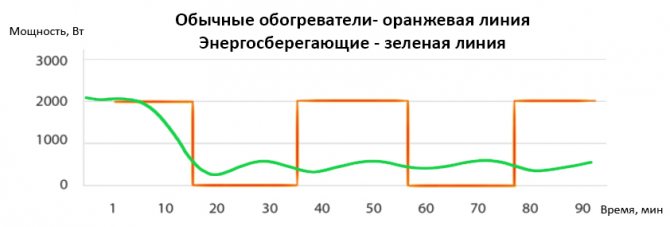

- Economical. When the inverter system of the device reaches the desired temperature level, the mechanism of the device does not turn off, but continues to work at low speeds. This leads to the maintenance of a favorable climate in the room. The heater does not need energy consumption for on and off functions. During the use of the inverter, there is no such thing as "high current" for starting. When the device is started, the current is not more than the rated one, which has a positive effect on the service life of the entire device. The device does not need to be constantly on and off. After all, these cycles significantly reduce the service life of the device. Compared to conventional appliances, energy savings are around 40%.

- Practical and efficient. This device is capable of heating even at very low temperature conditions, while the beneficial effect is expressed by a high coefficient. The heater during operation shows the ratio of the released heat to the consumed energy, denoted as EER. This indicator for the device is equal to four. For example, at a consumption of 250 W, you get more than 1 kW of heat. This is a good indicator.

- During operation, the heater has high safety and environmental characteristics.

- Operation is carried out with a low noise level, this is due to a decrease in rotational speed at partial load. Without a doubt, this indicator has a positive effect on the life of the consumer.

A large number of advantages of the device does not deprive it of its shortcomings, but it is only one. This is a considerable cost of the heater in comparison with other similar devices.

Use in heating systems

Today, the inverter device is successfully used in heating systems, the power source of which is electricity. This innovation has earned a lot of positive reviews. It is installed wherever there is an electrical connection. It is possible to use inverter heating without permits, in particular, you do not need to obtain permission to install a heating system. A pleasant moment for consumers is the cost of equipment, which turned out to be much less than other heating systems.

A conventional gas boiler these days can be easily replaced with an inverter heater. Then the operation of the heating system with the implemented inverter device will be as follows: passing through the heater, electricity enters the boiler. In this case, the inverter boiler constantly produces an induction current. If a power outage occurs, the boiler will continue to operate on battery power. The heater includes a magnetic part and a heat exchanger.

Principle of operation

Inverter heaters operate on a very simple principle, which consists in converting direct current to alternating current, while changing the frequency and voltage. The operation of an inverter is very similar to that of an air conditioner.The main structural element is the pump, which consists of an indoor and outdoor unit. In the inner one there is a heat exchanger, in which freon accumulates under the influence of high pressure. Its temperature can go up to 80 ° C.

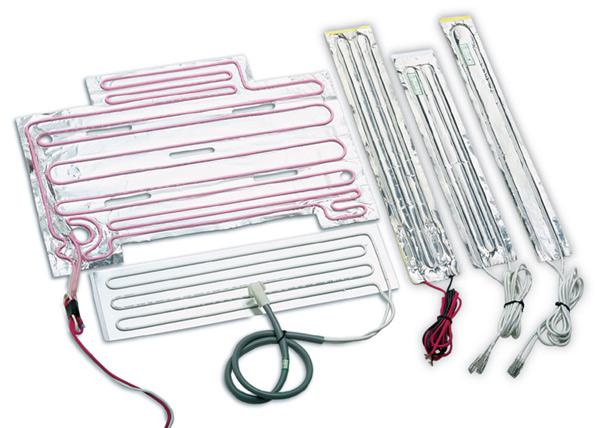

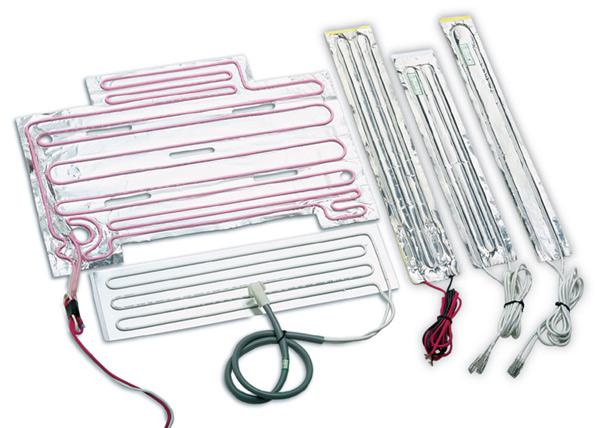

Freon is a liquid substance circulating through a heat exchanger

Then the accumulated substance is directed to the external block, where the pressure is much lower. It is in this place that freon is converted from a liquid state to a gaseous state. As a result, a large amount of heat is generated.

The inverter can automatically control the heating process. This means that if the set room temperature is reached, the system does not turn off, but simply goes to a lower power level. Thanks to this ability, the optimal temperature regime is always maintained in the room. The main feature of such heaters is the minimum energy consumption, as well as the fact that they do not need to be switched on and off all the time.

Frequently asked questions about electric convectors

Which convectors are more efficient - high or low?

The efficiency of the device does not depend on its size, but on the power. All kinds of "form factors" of equipment are created, first of all, for the convenience of its fitting into various interiors.

Is it dangerous to leave the convector unattended?

Definitely not. If your home's electrical wiring is capable of handling the combined wattage of concurrent appliances, you have nothing to worry about.

Can the convector be used as the main source of heating?

As a rule, yes. It all depends on the specific equipment model and manufacturer's recommendations.

Is an electric convector a suitable choice for a children's room?

Quite. Among the products of most popular manufacturers there are units designed specifically for children's rooms - with a solid body, with streamlined shapes, without sharp corners. The holes in them are as small as it is, in principle, possible - all so that the child could not shove anything inside.

Many modern manufacturers of electric heating convectors offer heating equipment models adapted specifically for children's rooms - well-designed and as safe as possible.

How to install the convector correctly

Installation regulations, requirements and restrictions are detailed in the instruction manual. In particular, it states:

- Installation of a gas convector in a wooden house. During operation, the case heats up to 50-55 ° C. It is necessary to insulate wooden surfaces in contact with heating parts of the structure. Installation rules in a wooden house prescribe the manufacture of fireproof roof gaps. If a coaxial pipe is used, insulation is not required at the place of passage through a wooden wall. The surface of the coaxial chimney heats up slightly due to the special design of the burner and pipe.

- Location from the floor. Air heating of a country or residential building has certain features that affect the efficiency of heating. For maximum performance, install the convector as close to the floor as possible. As a result of such a solution, the intensity of circulation of convection flows increases and the efficiency of the equipment increases.

- The gas pipe is supplied to the heater exclusively along the street. A shut-off valve must be installed at the connection point.

A test run is carried out in the presence of a gas service representative. A corresponding note is made in the convector's documentation.

Which is better, a gas convector or a boiler

It all depends on the technical characteristics of the building and the features of its operation. The assembly of the convector requires less time and money.

Air heating is recommended for use in country houses that are not heated during the winter season. During installation, there is no need to use a water circuit, you can heat the building only from time to time. Even at a negative temperature in the room, you can warm up the room in 20-30 minutes.

A gas convector for a house on bottled gas is inferior to a boiler connected to a main pipeline in terms of efficiency, but superior in functionality. The choice of an air heater is justified in the absence of gasification. With a fully filled cylinder, the heater will work for approximately 10 days.

The convector heats the room better and faster and uses less fuel for this, but its efficiency is limited by the properties of convection flows. Heating intensity decreases as obstacles arise: walls, furniture, etc.

For heating a country house or small rooms, a convector-type heater is optimal. But for residential heated houses with large rooms, it is better to install a traditional gas boiler.

Calculation of the power and temperature of a warm water floor

Nuances to consider when installing

Inverter boilers can be used in pressure and gravity heating systems. Since the heating medium heating rate is high, a device should be installed that will dose the water supply to the pipeline system. Consequently, the efficiency of the device will increase and the need for new heated fluid will be reduced.

Before starting the installation of the system, it is necessary to check whether the existing wiring is suitable for connecting new heating equipment. If the wiring does not match, then you need to replace the wires with new ones that have a larger cross section.

In a three-phase power network, it is necessary to carry more cables from the common network. If a sudden voltage drop occurs in the system, then a special protective block will stop the operation of the equipment. Therefore, it must be installed.

Before installing an inverter heating boiler, you should not forget about some points:

- Equipment grounding;

- It is necessary to position the boiler at the required distance from furniture and other objects in the house;

- The heating system must be equipped with a special air release valve;

- If your system is not free-flowing, then an expansion tank must be installed. It is needed to circulate the pump and to compensate for the expansion of the coolant.

When using a GSM module or a special electronic programmer, you can provide a comfortable atmosphere in the house, even with a long absence. This option is great for those who come to a country house only for the weekend.

Heater device and principle of operation

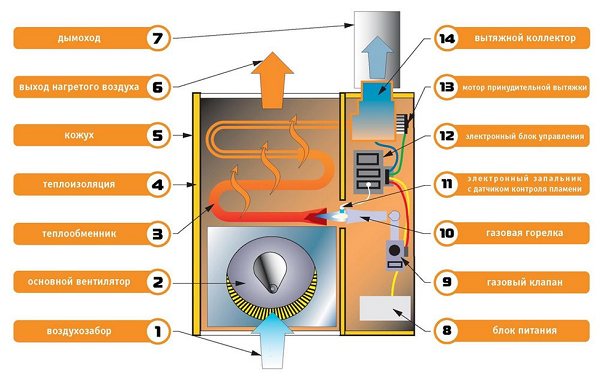

A gas heat convector is a device that is capable of generating heat through the combustion of gas. The design of the unit is quite simple.

- Burner. An igniter is connected to it.

- A heat exchanger, the task of which is to give off heat to the air passing through it. To heat more air, the heat exchanger is made finned (to increase the area).

- System for the removal of combustion products.

- The automation system is installed for safety purposes and shuts down the unit in case of problems in operation.

- The thermostat ensures the maintenance of the set temperature in the room.

- The housing is used to protect the device and is made of metal coated with heat-resistant paint.

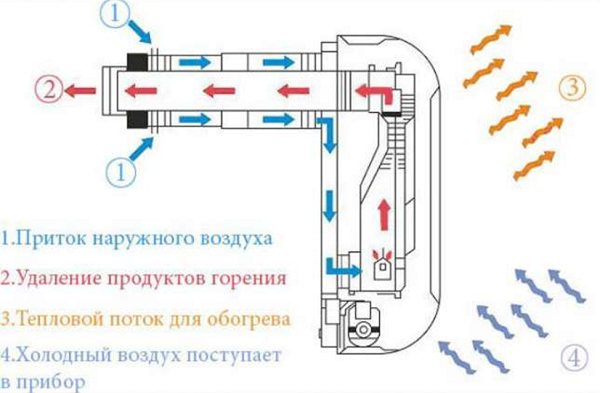

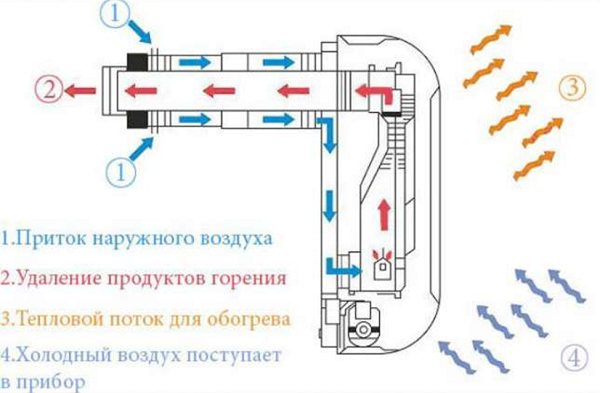

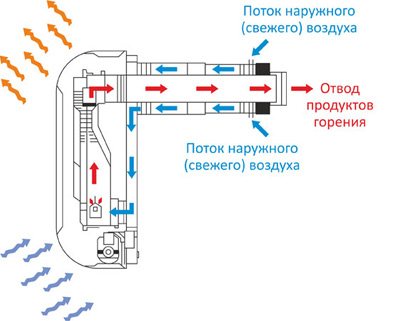

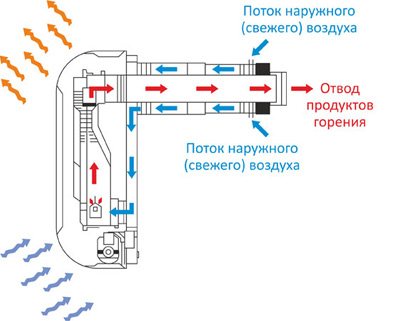

The figure below shows the construction of a gas convector.

The principle of operation of the apparatus is that the gas, when burned in the chamber, heats the heat exchanger.The air flow, passing through the lower openings of the unit, moves through the heat exchanger, takes heat and exits heated into the room through the upper openings. Meanwhile, the combustion products of the gas are removed from the chamber through a double-walled (coaxial) pipe. Through it, fresh air enters the apparatus from the street to maintain the combustion process.

The principle of operation of the convector

Types of electric convectors heating

When choosing climatic technology, it is important to take into account that electric convectors may differ from each other in the following characteristics:

- Mounting type.

- The heating element used.

You should also pay attention to the manufacturer of the product and the cost of electricity.

Types of electric convectors, according to installation features

Air convection heaters can be divided into three categories.

Wall mounted. Wall-mounted convectors are the most efficient. The location on the wall facilitates the convection process and increases the efficiency and heat transfer of the heaters.

Floor-standing version - used as an additional source of heat. Models with a built-in fan differ in performance. The convector with forced air circulation cannot boast of quiet operation, but it warms up the air well. Universal models - can be installed on the floor and mounted on the wall using special mounts. When choosing, you should pay attention to the presence of wheels in the kit. By installing the wheels on the body, you can easily move the heater anywhere in the room.

The main advantage of the convector is the low heating of the device body. This allows you to install a heater for heating a wooden house.

Classification of convectors according to the heating element used

In total, three types of heating elements are used. The design of the heating element affects the operation of the heater.

- Needle heating element - a simple design, is a chromium-nickel heating thread located in a dielectric plate. The top is covered with a special insulating varnish. A heater with a needle heating element is not suitable for wet rooms, since the heating element has absolutely no protection against the ingress of water, steam, condensation and other liquids. As a rule, budget models are equipped with a needle heating element.

- Tubular heating element - manufactured in a waterproof design. The structure consists of a steel tube filled with a heat-conducting backfill, which is also an insulator. To increase heat transfer, heat-distributing fins are fixed on the sides of the heating element, increasing convection. The heaters are equipped with overheating protection. As a disadvantage of the tubular heating element, one can single out the fact that the electric convector heats up for a long time. The operation of the appliance may be accompanied by sounds resembling the crackling of burning wood.

- Monolithic heating element - the most economical electric convectors for heating a private house use a monolithic type heating element. The body of the heating element has no seams, the work does not accompany extraneous noise. If it is planned to make the electric heating of the apartment with convectors the main one, then the models with a monolithic heating element are the best solution. During operation, minimal heat loss is observed. The heater efficiently and quickly heats the room. The only noticed drawback of a monolithic heating element is the high cost of the device.

For space heating using an electric convector, it is better to choose devices that have a tubular or monolithic heating element and are equipped with a built-in electronic or programmable thermostat.

Advantages and disadvantages

Consider the advantages of an inverter heater:

- Low energy costs.Compared to other types of heaters, the convector consumes 40% less electricity. This is due to the fact that the device goes into economy mode when the set temperature is reached, and does not turn off.

- Efficiency. The device quickly heats up the room, even under low temperature conditions, it can replace the heating batteries.

- Long service life. The period of trouble-free operation of the equipment reaches 20-25 years.

- Quiet operating mode. During operation, the inverter heater does not emit the characteristic crackles, as, for example, oil heaters do.

- Safety. Modern models are equipped with a temperature sensor and a rollover sensor. If the device is dropped, it will turn off immediately.

In addition, the equipment can be installed directly along the walls or even hung on the walls. Modern models are characterized by stylish and compact design.

The disadvantages of inverter equipment include a higher cost, but it quickly pays off due to savings during operation.

Heat exchanger material

The operation of the convector is based on the combustion of gas in the heat chamber of the unit, while the heat exchanger from the inside is exposed to a powerful thermal effect, its burnout quickly disables the convector. Therefore, it is natural that the material of manufacture should be as strong and stable as possible.

Here the undoubted leader is cast iron. The cast iron heat exchanger is thermally stable, the service life of such convectors is up to 50 years. Another plis of a cast-iron heat exchanger is a more even distribution of heat and slower cooling. The downside is the large mass and high price indicator.

Convectors with a steel heat exchanger are lighter and cheaper than cast iron

When buying, you should pay attention to the quality of the steel, such a gas convector serves for at least 20 years

Heater operating rules

To operate the product for a long time, you need to follow these rules:

- The distance from the heater to any object must be at least 500 mm.

- It is forbidden to install the heater under a window opening.

- Do not leave the device turned on overnight. This rule can be violated when a special thermostat is installed inside the equipment, which automatically controls the operation.

- Do not dry things on the appliance.

Energy efficiency is now considered the most popular factor when purchasing space heaters. Unlike oil radiators and central heating, inverter equipment is capable of heating the area in which a person is located, which is quite profitable and comfortable.

Heating convector, what it is and how it works a detailed overview

A little has already been said about the principle of work, now let's take a closer look. Any electric convector is based on the principle of movement of air masses in a room. We all know that cold masses go down, and warm ones are a little higher. The developers of the heaters took advantage of this by placing openings for cold air in the lower part of the device. The air-type heating element heats up quickly, which is its main feature. The most important thing is that the heated air is lighter and does not have any harmful impurities. Warm masses are discharged through the center and top vents in the enclosure. This solution allows you to increase the room temperature in the shortest possible time. It often takes just a few minutes to heat a small room with a medium-power convector.

Inverter heating device: pros and cons

The owners of inverter heaters during operation clearly indicated the advantages of this technique:

- the speed of transition to the required temperature regime is two times higher than that of other thermal devices;

- the room temperature is maintained at the same level for a long time due to a smooth change in the compressor motor rotation speed;

- low compressor speed minimizes the noise levels of the indoor and outdoor units;

- depending on the manufacturer, such devices can save from 30 to 60% of electricity;

- the technical features of the heater practically do not allow the wires of the power network to heat up;

- no reactive current components without power factor losses;

- absence of combustion products and passive attitude of heating elements to air oxygen.

Among the negative characteristics, the following were identified:

- the complexity of the electrical circuits of the indoor unit increases the sensitivity of the device to voltage drops in the network;

- electronic mechanisms of the device do not allow turning on the compressor at temperatures below -10 ºС and above +42 ºС due to the loss of electricity at the converter in such extreme conditions;

- spare parts for the devices are not standardized, so the repair time can take a rather long period.

How to choose a gas convector

Attention should be paid to the technical characteristics of the heaters. The best option is to choose a convector with a closed-type cast-iron heat exchanger and a programmable control unit.

When choosing equipment, you will need to consider the following:

- Power calculation. Air convection is used to heat the room. Consequently, heaters are only effective in confined spaces. For each room, you will need to install a separate convector. The power is calculated according to the formula 100 W per 1 m².

- Housing type. Heaters with a closed combustion chamber and exhaust of combustion products through a coaxial chimney are suitable for an apartment. You can put any type of equipment in your home. But when installing a heater with a closed chamber, it is necessary to take care of a constant and intensive supply of fresh air.

- Fuel type. It is forbidden to install a gas heating convector on liquefied gas in an apartment of a multi-storey building, due to the high explosion hazard of cylinders.

All convectors are initially manufactured with the ability to connect to the main gas pipeline. If you plan to connect the gas convector to the cylinder in the future, you need to purchase a special reducer (in some modifications it is included in the kit).

Instrument selection criteria

When buying a product, you need to pay attention to the following factors:

- Serial number. A company that produces reliable models puts specialized symbols and numbers on each device.

- Contact quality. This factor can be considered the main one, because the device constantly withstands high voltage.

- Installation of wires in the product. The cable should only be made of non-flammable materials. When ignited, they can smolder for about 10 minutes.

- Availability of certificates. Such documents must be attached to every electrical equipment.

- Conformity marks. They are applied to products that meet all the requirements of the European Union and do not harm human health.

Types of gas convectors

To choose a suitable convector, you should learn about the main differences between existing equipment, the pros and cons of modifications.

What are the criteria for classifying heaters?

- Installation method - there are wall and floor models. The former take up less space, are lightweight and efficient, and are limited in performance (maximum power 10 kW). For heating a garage, rooms with a large area, it is better to choose a floor model. The heaters are heavy due to the enlarged heat exchanger.The performance of floor convectors reaches several mW (industrial versions).

- Exhaust gas removal. An open gas combustion chamber is installed in a conventional convector. The principle of the device is somewhat reminiscent of a simple wood-burning stove. The design has several disadvantages - it burns oxygen, requires good ventilation of the room, as well as the manufacture of a complex smoke exhaust system. New generation convectors use a closed combustion chamber. A coaxial pipe is used instead of a chimney. Air intake is carried out from the street, therefore, during operation, oxygen is not burned in the room. Systems with a closed combustion chamber have only one drawback - the cost is more than that of classic models by 30-50%.

- Heat exchanger material. The principle of operation of the convector is associated with constant thermal exposure. One of the most common reasons for a heater failure is the burnout of the chamber walls. The heat exchanger is made of steel or cast iron. The crystal structure of the latter metal provides a long service life (about 50 years) and high heat transfer. The steel chamber will work for about 10-15 years.

- Fan. High power convectors are equipped with a forced air circulation system. Budget household models may not have a fan.

- Gas type. The models are designed to operate on any kind of "blue" fuel. The natural gas convector can also be operated with propane. A special adapter kit is required for conversion.

- Control automation. Budget models are equipped with conventional thermostats. The programmable control unit allows you to control the room temperature and set the required heating mode.

The cost of a gas convector depends on the material of the heat exchanger, the availability of an adapter kit, and the characteristics of the control unit.

Appointment

A natural gas-fired convector is intended for heating premises for various purposes. In this case, combustion occurs in a closed chamber, air is supplied from the street and combustion products are discharged there. The heat released during fuel combustion is transferred to the combustion chamber housing and heat exchanger, and then to the indoor air. Due to the rapid heating, the air rises up, making room for a colder one, maintaining an active convection process throughout the room.

A gas convector warms up the air faster and more actively than its electric counterparts or, even more so, converter-type radiators for a water heating system. This is due to the higher surface temperature of the heat exchanger and the increased rate of heat transfer from the combustion chamber.

The gas convector is an excellent solution in the following situations:

- Primary heating of a small room or a house with one or two adjoining rooms.

- As a replacement for the solid fuel stove, which was previously used to heat the house.

- For quick warming up and maintaining a comfortable temperature in a garage, utility room, small country house.

- As a supplement to the central heating system in rooms where the installation of a water radiator is difficult (basement and basement, attic, veranda, etc.).

- For heating greenhouse facilities.

As a replacement for the main heating, a gas convector is suitable only for small houses or individual rooms. The efficiently heated area is easily calculated based on the models of gas convectors available in terms of power. On sale, devices with a power of 2.5-6 kW are more common, less often up to 12 kW. In the first case, the convector is enough to heat a room up to 50 m2. The most powerful models are in demand only for industrial and public premises up to 100 m2.

Timberk TEC.E0 M 2000 - sustainability and safety

The main task of the TEC.E0 M 2000 convector is to heat rooms up to 15-20 sq. m. Such equipment is worth buying both for use in an apartment and for a summer residence or office. Operational safety is ensured by the presence of a protective sensor.

In addition, the design of the device allows both wall mounting and floor mounting. The kit includes parts for two options - brackets and support legs. You can choose the optimal mode using the convenient regulator. The first stage provides a power of 1.2 kW, the second - 2 kW.

The technology used, Heating Energy Balance, is one of the technical features. It increases the environmental friendliness of using the device and provides instant heating. The permissible microclimatic conditions will be obtained in just 30-60 minutes after turning on the device.

Other reasons for buying include the resistance of the device to voltage surges, low weight, no noise during operation or shutdown. The latter feature allows the device to be used to heat living rooms, including a bedroom or a nursery.

Technique advantages:

- noiselessness of work;

- floor installation and wall mounting;

- lightness - the device weighs only 5 kg;

- compactness - the heater does not take up much space;

- the presence of power control;

- fall protection reliability;

- heating rate.

Cons of the device:

- air drying during work;

- the length of the cord, because of which the equipment will have to be placed close to the outlet;

- lack of wheels on legs for moving the device.

| Space heating rate | 9 |

| Safety | 9,6 |

| Build quality | 9,2 |

| Design | 9 |

| Efficiency | 9 |

Gas convector

A wide variety of devices and heat sources are now used to heat premises for any purpose. All possible versions and operating principles are involved, from electric heaters, gas boilers to the use of geothermal energy. Among this variety, there is also a heating gas convector. This device outwardly resembles a conventional radiator, only slightly larger and runs on mainline natural or liquefied gas. Water is not heated in it, followed by distribution through the radiators, the heat from the combustion of gas through the heat exchanger immediately enters the room.

It is interesting to understand the features of this type of heaters and determine the scope of its application based on the advantages and disadvantages of a gas convector.

About the advantages of electric convectors

It is impossible not to highlight this aspect, since it is necessary to clearly understand what the pros and cons of such equipment. The main advantage is that the efficiency reaches 95%. This means that the consumed electricity is almost completely converted into heat. Quiet operation is another important point. For many, this factor is decisive, for obvious reasons. If you come from work to a cold apartment, then you need to heat it up as quickly as possible. The convector will best of all cope with the solution of this issue. The device does not need to waste time heating the media. It is enough to wait just one minute, and the unit will operate at the set temperature. One cannot but mention the cost of equipment, which is much less than that of gas boilers, oil heaters, etc.

Some general information about the device

In Europe, many have been using electric heating for quite some time. In our country, due to high electricity prices, this is problematic. Nevertheless, you need to somehow warm up, and therefore buying a convector is one of the best solutions. The principle of operation of the device is quite simple. The essence lies in the natural convection of air passing through the heating element. Heating equipment of this type has a small shape, which allows it to be placed where it is convenient. Today there are both floor-standing and wall-mounted options.In most cases, the shape is rectangular, although there are also squares, etc. So what are convectors, you ask? This is a device that has many holes in its body. Cold air enters the side and bottom, then it heats up and exits through the holes on the front side.

How the convector works

The principle of operation of a gas convector is based on the change in the properties of the gas with an increase in its temperature.

Pre-assembled gas convector

Passing through the convector's heat exchanger, the air heats up, becomes lighter and rises higher, and new portions of cold air come in its place. This movement of air layers is called convection, hence the name of the device.

Internally, the device and the principle of operation of this heater uniquely determine the way of its placement: it is best to install the convector as low as possible, then its efficiency will be greatest.

The fact is that the coldest air, due to its density and greater weight, is always at the bottom, and it will heat up in this configuration in the first place. In practice, a gas heating unit is most often tried to be mounted under a window, where heat loss is usually maximum.

The principle of operation of a gas convector

Gas heaters are often equipped with a tangential fan. Its installation helps to increase the rate of supply of heated air and significantly speed up the process of warming up the room. In addition, some expensive models have an increased thickness of the walls of the case and, therefore, are able to accumulate significant amounts of heat, and then transfer it to the surrounding space using thermal radiation. Such devices combine the advantages of conventional radiators and convectors and provide the highest heating quality.