In heating systems, air conditioning and ventilation, modern air heating units are used. Water heating is considered the most economical, since the cost of water energy is much lower than electrical energy, and at the same time it is safe. The warm air flow can go both horizontally and vertically, depending on the installation method of the device.

Hot water heaters are used to heat the air in closed rooms of all types. The principle of operation of a water heater for supply ventilation is based on warming up a stream of air supplied by a fan from pipes with hot water or steam, and its further distribution.

The principle of operation and design of a water heater

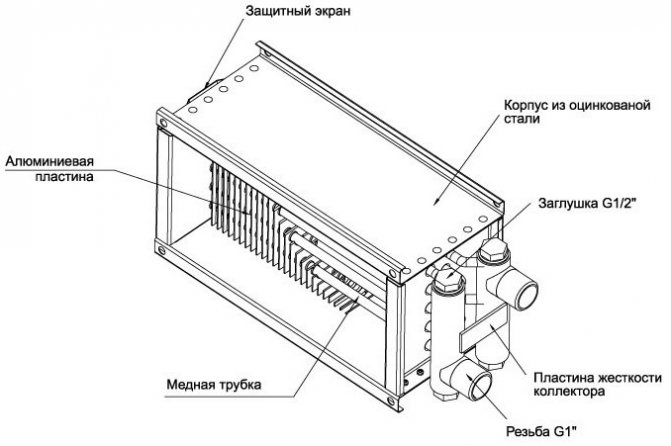

A heater is a device used to heat air. According to the principle of operation, it is a heat exchanger that transfers energy from the coolant to the flow of the supply jet. It consists of a frame, inside which tubes are located in dense rows, connected in one or several lines. A coolant circulates through them - hot water or steam. The air, passing through the cross-section of the frame, receives thermal energy from the hot pipes, due to which it is transported through the ventilation system already heated, which does not create the possibility of condensation or cooling the premises.

Types of heating devices for supply ventilation

All air heaters for supply ventilation can be divided into two main groups:

- Using a coolant.

- Not using a heating medium.

The first group includes water and steam heaters, the second - electric. The fundamental difference between them is that the devices of the first group only organize the transfer of heat energy supplied to them in a finished form, while the devices of the second troupe create heat inside themselves on their own. In addition, water and steam heaters are subdivided into plate heaters, which have greater efficiency, but the worst performance, and spiral-rolled, which are now used almost everywhere.

There are also heating devices, often referred to these groups, for example, a gas heater. The burning gas heats up the air stream passing through the glow zone, preparing it for use in ventilation or air heating systems. The use of such devices is not widespread, since the use of gas in industrial workshops is associated with a lot of dangers and has many restrictions.

There are also waste oil heaters. The heat generated during the burning of the waste is used. For large rooms, such devices do not have sufficient power, but for small auxiliary areas they are quite suitable.

Supply ventilation with heated air: everything you need to know.

We install plastic air ducts for ventilation: advantages and disadvantages.

Ventilation in the bathroom and toilet: selection and installation of an exhaust fan.

Pros and cons of using

The advantages include:

- High efficiency.

- Simplicity of the device, reliability.

- Compactness, possibility of placement in small volumes.

- Low maintenance (water and steam appliances practically do not need it).

The disadvantages include:

- The need for a coolant or connection to the power supply network.

- Independence of work - equipment for air supply is required.

- An interruption in the supply of electricity or heat carrier means a shutdown of the system.

Both the advantages and disadvantages of the devices are due to the design and do not depend on external factors.

Air heater: a device for heating air in different systems

Before proceeding with the choice of a device, it is necessary to understand the very concept of what a heater is, as well as what types are there and what are the typical and functional features of each of them.

Heaters are able to heat both small and fairly spacious rooms.

Heaters are used to heat air in various systems:

- heating;

- air conditioning;

- ventilation.

Heating in heating equipment is carried out due to the reaction between chemically aggressive substances in the middle. That is why the classification of air heaters is based on the type of heat exchanger. The device can be water, steam, freon and electric. A water heater for heating is used as a heat exchanger with an intermediate heat carrier. The steam heater is used to heat the air in heating systems.

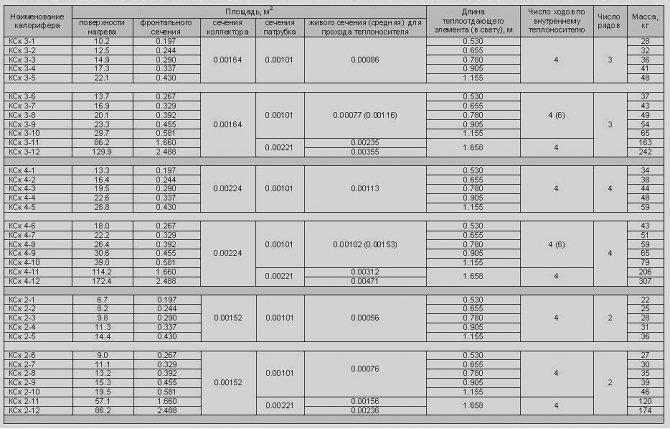

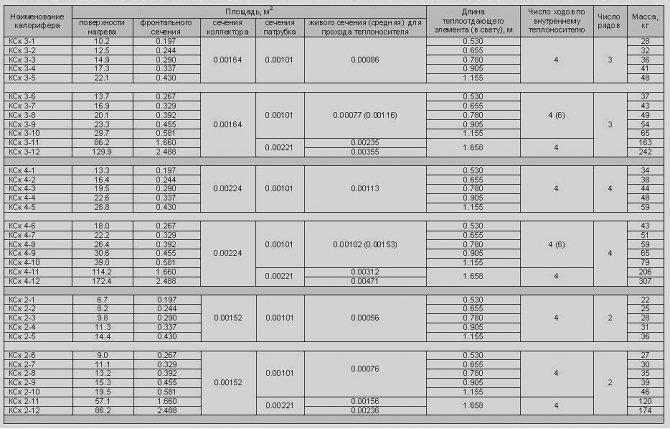

If air heaters are classified according to thermal and aerodynamic characteristics, then the types of air heaters are divided into three-row and four-row. According to the number of connecting dimensions, the heaters of individual models are divided into 7 numbers.

Steel pipes, which have a ribbed surface on the outside, serve as a carrier of the coolant in the middle of the heater. Due to this design, the area increases and, as a result, such a piping of the heater increases the efficiency of heat transfer. In the middle of the ribbed tubes, a heating or cooling element is transported in the form of water, steam or freon. Outside, air currents flow, which are heated or cooled during contact with the pipes.

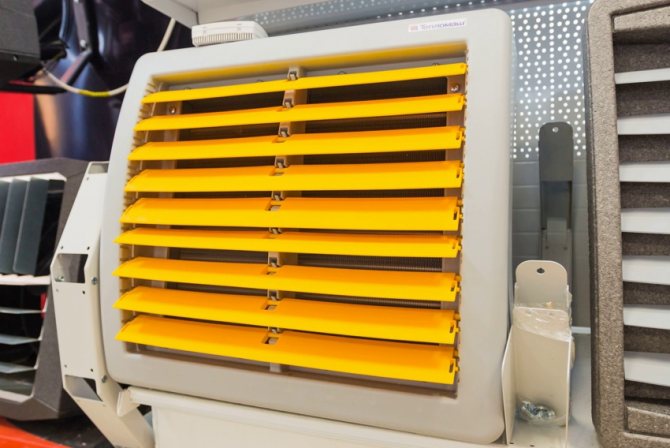

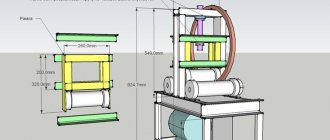

Volcano air heater structure: 1 - movable adjustable blades, 2 - built-in diffuser with a fan, 3 - heating elements, 4 - warm air supply

The general scheme is based on this principle of action: the coolant has a high heat transfer coefficient when interacting with air flows. The ribs on the device are metal plates that are simply pushed onto tubes or wound like ribbons or wire.

Types of heaters

There are several types of heaters used in different locations and conditions.

Let's take a closer look at them:

Aquatic

The most common group of devices, characterized by high efficiency, safety and ease of operation. They use hot water as a heat carrier, coming from the central heating network, hot water supply or from their own boiler. A water heater for supply ventilation is the most convenient and economical solution that allows you to perform the assigned tasks with minimal maintenance or repair costs. The only drawback of the device is the need to connect to the coolant supply system, which creates certain difficulties at the installation stage and prevents rapid transfer to another place.

Steam

Steam devices are complete analogs of water ones and in practice differ from them only in the type of coolant. The only difference between steam appliances is the large wall thickness of the tubes - 2 mm versus 1.5 for water ones. This is due to the high pressure in the system, requiring reinforced channels for circulation. The rest of the devices are identical, have the same operating rules and requirements.

Electrical

An electric air heater for supply ventilation does not need a heating medium supply, since the heating source is an electric current. Connecting such devices is much easier, which makes them mobile and easy to use, but high energy costs limit the use of this group.Most often they are installed for local heating when performing one-time work, they are used as emergency or temporary heat sources.

Electric heater: features of operation

Electric heaters are now successfully used to heat various premises, both residential and economic and industrial. Given that the source of energy is electricity, there are certain safety measures during their operation. First of all, the presence of vapors from explosive objects, as well as conductive dust, should be excluded.

Basically, electric heaters are installed in spacious warehouses, workshops, halls, garages and drying chambers. Their vertical and horizontal installation is provided. An important condition for safe operation is the availability of access to the system reset panel in manual mode. Particularly popular are air heaters, which are successfully used on construction sites.

Electric heaters significantly speed up the drying process of various building materials, in particular plaster and paint. They are often used to form a thermal curtain at gates or door structures.

A wide temperature range of operational capabilities allows it to be used in the temperature range from -30 to 50 ° C. In order to avoid overheating of the unit, care should be taken to ensure sufficient air flow, therefore, a corresponding calculation must first be carried out. The heater, if used correctly and carefully, can serve for a long time.

The heater can be used in the temperature range from -30 to 50 ° С

Helpful advice! When choosing an electric industrial heater, you must be extremely careful and take into account the size of the serviced area. It is also necessary to take into account that wall-mounted units are most often used, therefore, for safety reasons, it is necessary to take care of their reliable fixation using special brackets.

Calculation of the power of the heater

Calorifier calculation produced in several stages. Sequentially determined:

- Thermal power.

- Determination of the size of the frontal section, selection of the finished device.

- Calculation of media consumption.

Since the air flow is known from the characteristics of the ventilation system, it does not need to be calculated. The formula for determining the thermal power of the device:

Qt = L • Pw • Cw • (tvn - tout)

Where Qt - heat output of the heater.

L - air consumption (value of the supply flow).

Pv - air density, tabular value, is in SNiP.

Cv - specific heat capacity of air, available in the SNiP tables.

(tвн - tнр) - the difference between internal and external temperatures.

The internal temperature is a sanitary standard for a given room, the outside temperature is determined by the average value of the coldest five-day period of the year for a given region.

Determine the frontal section:

F = (L • P) / V,

Where F - frontal section.

L - air consumption.

P - air density.

V - mass flow rate, taken about 3-5 kg / m2 • s.

Then we find the flow rate of the coolant:

G = (3.6 • Qt) / Cv • (tin - tout),

Where G - coolant consumption.

3,6 - correction factor for obtaining the required units of measurement.

Qt - thermal power of the device.

Cv - specific heat capacity of the medium.

(tin - tout) - the difference between the temperatures of the coolant at the inlet and outlet of the device.

Knowing the flow rate of the carrier, you can determine the diameter of the piping pipes and select the necessary equipment.

Calculation example

Determine the heat output at a temperature difference from -25 ° to + 23 °, with a fan capacity of 17000 m3 / h:

Qt = L • Pw • Cw • (tvn - tout) = 17000 • 1.3 • 1009 • (23 - (- 25)) = 297319 W = 297.3 kW

Frontal section:

F = (L • P) / V = (17000 * 1.3) / 4 = 5525 = 0.55 m2.

Determine the flow rate of the coolant:

G = (3.6 • Qt) / Cv • (tin - tout) = (3.6 • 297.3) / 1009 • (95-50) = 1.58 kg / sec.

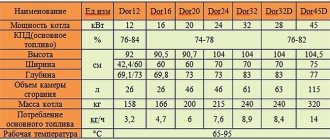

Based on the data obtained from the heaters table, we select the most suitable model.

Calculation of the heating surface

The heating surface area determines the efficiency of the device. The larger it is, the higher the heat transfer coefficient, the more the device heats up the air flow. Determined by the formula:

Fk = Q / k • (tav.t - tav.w)

Where Q - thermal power.

k - coefficient.

tav.t - the average temperature of the coolant (between the values at the inlet and outlet from the device).

tav.in - average air temperature (outside and inside).

The obtained data are compared with the passport characteristics of the selected device. Ideally, the discrepancy between the real and calculated values should be 10-20% more than the real ones.

Features of calculating steam heaters

The method for calculating steam heaters is almost identical to the one considered. The only difference is the formula for calculating the coolant:

G = Q / r

Where r - specific heat arising from steam condensation.

Self-calculation of heating installations is quite complicated and fraught with the appearance of many errors. If you need to calculate the device, the best solution would be to contact a specialist or use an online calculator, of which there are many on the Internet. The solution is quite simple, you just need to substitute your own data in the program windows and get the desired values, on the basis of which you can select ready-made devices.

Design features of the device

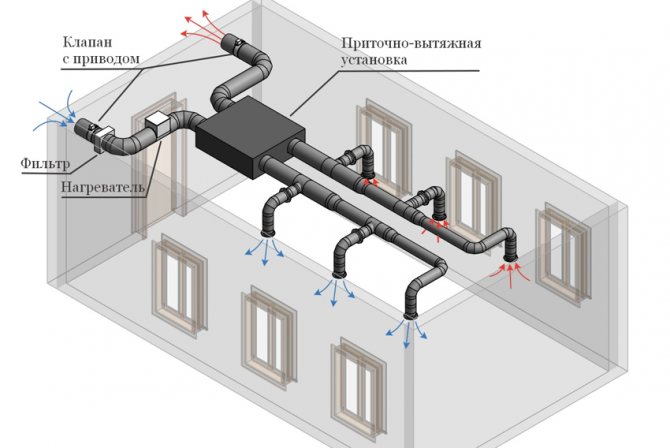

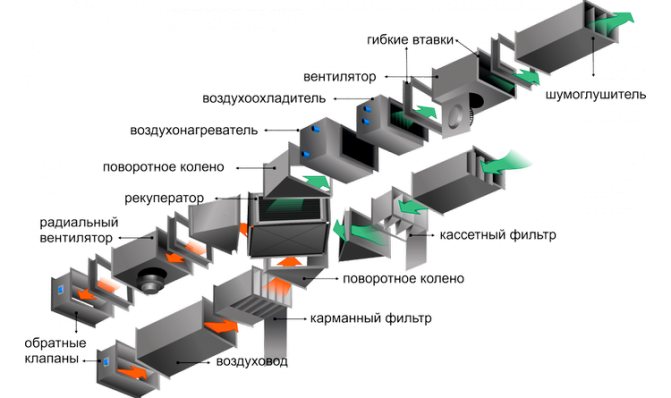

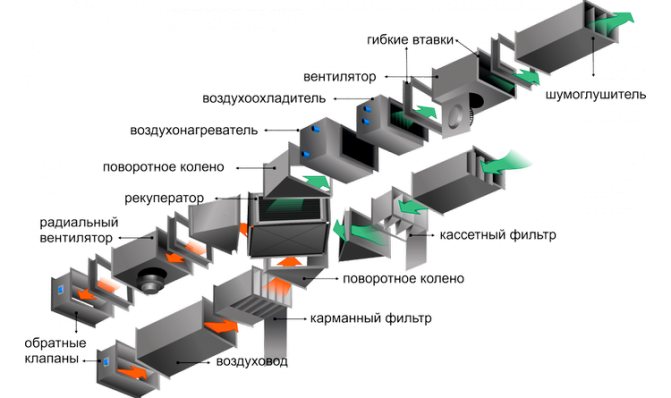

The main elements of supply ventilation

- Air intake grille. It acts as an aesthetic design and a barrier that protects debris in the supply air masses.

- Supply ventilation valve. Its purpose is to block the passage of cold air from outside in winter and hot air in summer. You can make it work automatically using an electric drive.

- Filters. Their purpose is to clean the incoming air. I need to be replaced every 6 months.

- Water heater, electric heating elements - designed to heat incoming air masses.

- For rooms with a small area, it is recommended to use ventilation systems with electric heating elements, for large spaces - a water heater.

Supply and exhaust ventilation elements

Additional elements

- Fans.

- Diffusers (help distribute air flow masses).

- Noise muffler.

- Recuperator.

The ventilation design directly depends on the type and method of fixing the system. They are passive and active.

Passive ventilation systems.

Such a device is a supply ventilation valve. The scooping up of street air masses occurs due to the pressure drop. In the cold season, the discharge is facilitated by the temperature difference, in the warm season - by the exhaust fan. The regulation of such ventilation can be automatic or manual.

Automated regulation directly depends on:

- the flow rate of air masses passing through the ventilation;

- humidity in the space of the room.

The disadvantage of the system is that in the winter season such ventilation is not effective for heating the house, since a large temperature difference is created.

On the wall

Refers to a passive type of supply ventilation. This installation has a compact box that can be wall-mounted. For heating control it is equipped with an LCD display and a control panel. The principle of operation is to recuperate internal and external air masses. To heat the room, this device is placed near the heating radiator.

Active ventilation systems

Since in such systems it is possible to regulate the intensity of the fresh air supply, such ventilation for heating and heating the room is more in demand.

According to the heating principle, such a supply heater can be water or electric.

Water heater

Powered by a heating system. The principle of operation of this ventilation system is to circulate air through a system of channels and pipes, inside which there is hot water or a special liquid. In this case, heating takes place in a heat exchanger built into the centralized heating system.

Electric heater.

The principle of operation of the system is to convert electrical energy into heat using an electric heating element.

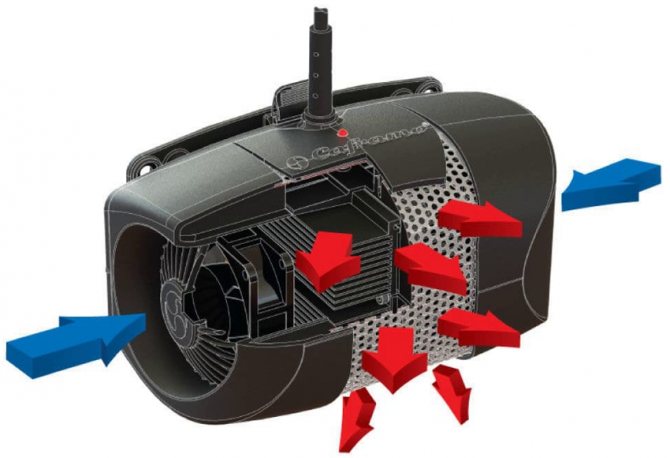

Breezer

This is a compact device, small in size for supply ventilation, with heating. To supply fresh air, this device is attached to the wall of the room.

Breezer Tion o2

Breather design o2:

- A duct consisting of an air intake and an air duct. This is a sealed and insulated tube, due to which the device draws air from the outside.

- Air delay valve. This element is an air gap. It is designed to prevent the outflow of warm air while the device is turned off.

- Filtration system. It consists of three filters that are installed in a specific sequence. The first two filters remove visible contaminants from the air stream. The third filter - deep cleaning - from bacteria and allergens. It cleans the incoming air from various odors and exhaust gases.

- Outdoor fan.

- Ceramic heater that is equipped with climate control. Responsible for heating the air flow and automatic temperature control.

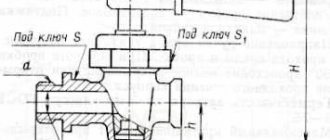

Strapping methods

Heater piping is a set of devices and elements for regulating the supply of coolant to the device. It includes the following elements:

- Pump.

- Two- or three-way valve.

- Measuring instruments.

- Shut-off valves.

- Filter.

- Bypass.

Depending on the operating conditions, these elements can be located in the immediate vicinity of the device, or at a decent distance from it. Based on the connection conditions, they are distinguished:

- Flexible strapping. It is mounted on control units located next to the device. The installation of such straps is considered easier, since it makes it possible to carry out all work on threaded connections, practically without the need for welding.

- Rigid strapping. It is used on devices remote from control units and requiring strong communications.

With a difference in the installation technique, both types perform the same function - they provide setting and adjustment of the heater's operating mode.

Supply ventilation types

These indoor air movement systems are classified according to a number of characteristics. According to the design of the ventilation network, the system is:

- National team

... When individual elements are connected using air ducts. - Monoblock supply ventilation

... In this embodiment, most of the elements are combined in one body.

According to the ventilation method, the supply system is divided into: local, complex and emergency. According to the presence or absence of an air duct, the classification is:

- Channelless

... When fresh air enters the room through the air inlet. - Duct

... The intake takes place through the air duct system.

Channelless ventilation

The device provides for the injection of clean air in the room due to the operation of the supply device, due to which the effect of an air curtain or an oasis is formed in the intended area of the room. Channelless supply ventilation ensures the removal of contaminated air through a special opening or slot in the door and window. If there is a powerful fan that makes a lot of noise, it must be supplemented with a noise suppressor. Depending on the degree of complexity, supply ventilation is a device that is divided into three types:

- window valve

; - supply fan

; - Supply unit

.

In installations for filtering impurities, a filter is installed, and an air intake grill to protect against debris. Supply and exhaust ventilation for an apartment can be equipped with a system for heating the incoming air, for this a special element is used that does not allow the room temperature to fall below a predetermined level. Each owner chooses one or another type for himself, depending on the ultimate purpose of the acquisition and financial capabilities.

Duct ventilation

These devices are a complex of air ducts that unite all rooms. Their difference is the need for periodic maintenance to maintain the quality of functioning. Ducted supply ventilation has one drawback - a large network of air ducts that must be hidden by the ceiling. This must be taken into account and engaged in installation at the stage of repair in the room. The principle of operation of the system is simple - fresh air enters the room through the channels and displaces the exhaust through the air intakes with its flow.

Often such forced ventilation is installed at large facilities, where heating requires high energy consumption. In order to lower them, you can set:

- recuperator;

- water heater;

- VAV system.

Adjusting the heating process

There are two ways to adjust the operating mode:

- Quantitative. The adjustment is made by changing the volume of the coolant entering the device. With this method, there are sharp jumps in temperature, instability of the regime, therefore, the second type has been more common recently.

- Qualitative. This method allows you to ensure a constant flow rate of the coolant, which makes the operation of the device more stable and smooth. At a constant flow rate, only the temperature of the carrier changes. This is done by mixing some of the colder return flow into the direct flow, which is controlled by a three-way valve. This system protects the structure from freezing.

Arrangement of ventilation in a private house with your own hands: choosing a scheme and drawing up a project.

Combined boilers for wood and electricity: the optimal solution for heating a country house.

Features of installation and connection

Installation work, connection, launching the system, setting up work - all this must be done by a team of specialists. Do-it-yourself installation of a heater is possible only in private houses, where there is no such high responsibility as in industrial premises. The main operations include installing the device and control elements, connecting them in the required order, connecting to the coolant supply and removal system, pressure testing, and test run. If all units of the complex demonstrate high-quality work, then the system is put into permanent operation.

Installation tips

Heaters with sensors in the greenhouse maintain the desired temperature

The water air heater is installed in rooms connected to the central heating main. When self-installation, it is worth following the recommendations of specialists:

- The diagonal of the heater depends on the peculiarities of the channel bends, the type of damper and structural elements.

- To protect the heater from freezing, the installation is carried out in rooms with a temperature of at least 0 degrees.

- Before starting the installation, it is necessary to inspect the plates and tubes for integrity.

- Welding flanges are most easily butt welded.

- Direct-flow valves of air outlets are located at the top of the outlet and supply manifolds.

- The joints of the device and the ventilation system are sealed.

- Wall-mounted models are installed by attaching the console with two self-tapping screws.

In the absence of experience in connecting and strapping the work system, it is better to entrust it to specialists.

Operating rules and the possibility of repair

The main requirements for the operation and safety of the device are set out in the passport.They are aimed at eliminating emergencies caused by exceeding the permissible temperature or pressure of the coolant, avoiding a sharp increase in the temperature of the complex at the first start-up in the cold season. Particular attention should be paid to the danger of freezing of the tubes of the device in winter, threatening the failure of the device. For the repair of devices, specialized organizations should be involved, independent intervention most often only increases the degree of the problem.