Heating in the house can be converted to electricity. This transition is justified primarily by the availability of electricity, a high level of automation and a number of simplifications that will affect the design of the heating system. Comparing with gas or solid fuel options, an electric heating boiler with a pump greatly facilitates the operation process. The apartment eliminates the inconstancy of centralized heating and does not require permits. Not subject to prohibitions. For a private home, this is an opportunity to increase comfort without unnecessary hassle.

An electric boiler is strikingly different from its counterparts, which run on gas, wood, coal or even wasteful diesel fuel, but the principle of operation remains the same. There is a reservoir in which the coolant is heated by means of electric heating elements, from one to three. Water enters the heating system through pipes and circulates under the influence of a pump.

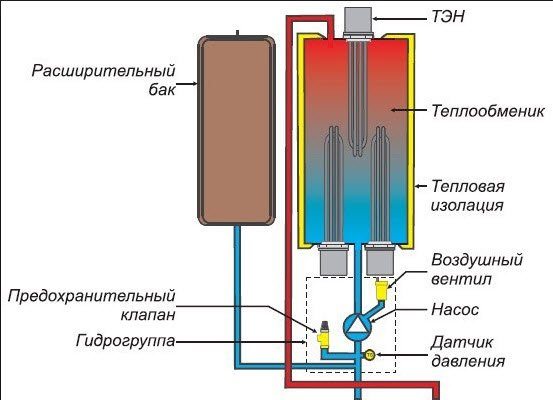

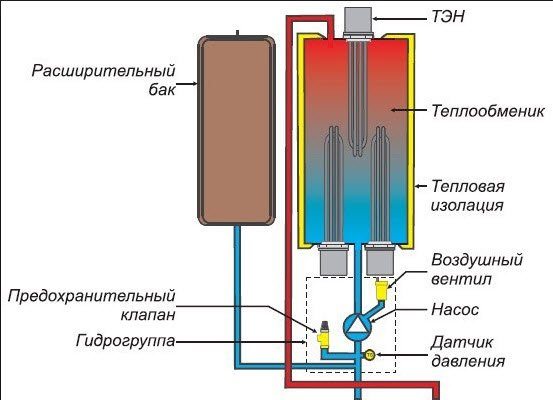

Elements of an electric heating boiler:

- water tank;

- electrical heating elements;

- circulation pump;

- starting relay, thermal relay;

- flow sensor;

- air pressure relief valve;

- water pressure relief valve;

- expansion tank (optional);

- control controller (optional);

Device diagram

Heating elements can be:

- electric heating elements;

- induction heaters.

There are practically no differences for the user between them. Induction heaters, according to the manufacturer, have a longer service life and do not decrease in efficiency over time. However, in practice, to a greater extent, the durability of the boiler is due to the preparation of the coolant. Control of its composition in order to avoid silting or the appearance of salt build-up on the walls of the heating tank.

Most often, induction heaters are used in flow systems, boilers with a minimum volume of coolant in the internal tank.

The boilers are supplied with one or more heating elements. The control activates separately each heating element or all together, which makes it possible to regulate the boiler performance, and at the same time prolongs the life of the heating elements, activating them one by one.

Boilers with heating elements are additionally divided into:

- with storage capacity;

- flowing.

The presence of a volumetric reservoir allows you to increase the heat capacity of the heating system. However, they are significantly heavier and are manufactured in floor-standing design. Flow-through structures are compact and are often mounted on the wall.

The main differences between an electric boiler:

- The small volume of the tank for heating the coolant, for a 3-5 kW boiler is only 1.5-3 liters. Reduction of the total volume of the heating medium in heating.

- The exact power value in accordance with the power supply used (single-phase or three-phase) and the power of the heating elements.

- Smooth regulation of the coolant temperature without surges.

- The boiler does not require the installation of a chimney or the obligatory arrangement of a separate room, only a convenient point of connection to the heating pipes and the supply of the supply network is needed.

The only mandatory requirement is the presence of a powerful electrical input to the apartment or house.

Boilers up to 12 kW can be powered from one phase (220V). For more powerful models and some boilers from 6 kW, a three-phase power supply (380V) will be required.In apartments, especially in old buildings, the input is too weak even for an average power boiler of 4.5-6 kW, and before installation you will have to attend to this issue.

The minimum set of automation is a start relay and a thermal sensor that determines the temperature of the coolant. By adjusting the temperature sensor and setting the level of its response, the maximum permissible temperature of the water in the system is controlled.

Devices with several sensors that measure the temperature of water at the inlet and outlet of the boiler, as well as with a control controller, a programmer, capable of remembering the set boiler operation mode with a weekly schedule, allow to adjust the operating mode more precisely.

Circulation pump

The presence of a circulation pump and an expansion tank in the boiler is a complete solution for heat supply. The pump constantly and evenly pumps the coolant through the pipes to the radiators and back to the boiler. In contrast to the old configuration with natural circulation, three main problems are solved:

- There is no need to increase the cross-section of the pipes and the volume of the system to reduce the hydrodynamic resistance, the diameter of the pipes is selected only to pump the required volume of the coolant without any problems.

- It is unnecessary to part the supply pipes strictly from the top, and the return pipes from the bottom. The optimal variant of two-pipe or one-pipe lower wiring is used. It becomes possible to hide pipes in a screed or sew them into walls.

- The time for the heating to reach the operating mode is reduced. Radiators warm up faster, as does indoor air.

The best option is a glandless pump. In it, the rotor is located directly in the fluid circulation channel. This solves the problem of heat dissipation generated by the pump motor.

The pump is included in boilers designed for heating apartments, cottages and small houses with a capacity of up to 12 kW. Designed primarily for one-pipe connection or two-pipe connection with a small number of branches.

If you plan to use a collector group, then it is preferable to use separate circulation pumps for each of the circuits separately.

Scheme of work

The principle of operation of an electric boiler is simple. Electricity is converted into heat in heating elements with high ohmic resistance. The coolant is heated from them or induction elements and is pumped through the system with the help of a pump. Due to the constant circulation, the water heats up evenly and quickly.

To start water into the system, a special inlet with a check valve and pressure protection is used. The optimum pressure for electric boilers and autonomous heating systems is set at 3 bar. It is monitored by a pressure sensor and displays a pressure gauge. It regulates the pressure of the expansion tank, which can accommodate the excess volume of liquid formed during thermal expansion.

As soon as the water temperature reaches the required value, the thermostat is triggered and the power supply to the heating elements is turned off. As soon as the temperature value drops by a couple of degrees, the relay is triggered again, turning on the heating elements.

To remove air and gases, a special air valve is used, more often located next to the pump. A water pressure sensor should prevent a critical increase in pressure that can harm the heating elements. With an excessive increase in pressure, which the expansion tank cannot cope with, the liquid is discharged through the valve into the sewer.

The choice of equipment for a flow-through heating system

When the owner of the country house has decided on the heating scheme, the question arises, which heating boiler to choose?

Experts recommend:

- If the system is gravitational, you can use 3 types of flow-through heating equipment, according to the method of heating the coolant: solid fuel (wood, briquettes) boiler, gas or electric water heater.

- In a forced flow heating system, it is recommended to use a gas or electric boiler. It is necessary choose the right pump for giving, which will circulate the heated water in the system.

How much electricity consumes

With regard to electric heating boilers for a private house, the answer to this question is simple. The efficiency is high and reaches 96-98%. The heat does not go into the pipe, it is not divided between the ambient air and the coolant reservoir, the boiler is located directly in the heated room, and therefore any side heat release is still not wasted.

The only significant waste of electricity is the operation of the pump and the control circuit, however, in comparison with the total consumption of heating elements, these costs are 0.5-1%. The rest of the losses are associated with the costs of expanding the liquid, overcoming the hydraulic resistance and losses in the supply wires.

The conclusion is simple - the consumption of an electric boiler is approximately equal to the power consumption. For a three-fuel flow-through design for 6 kW, consumption can be 2, 4, 6 kW, depending on how many heating elements are currently involved. As a result, all the power goes to the heating radiators to heat the room.

There are differences in induction water heaters and flow-through boilers. There, the power consumption differs from the output by 5-10%, their efficiency is lower than that of heating elements. This is due to the physics of the process. Heating occurs under the influence of an electromagnetic field, and part of it is simply dispersed in space.

Benefits

The popularity of electric boilers with a pump for heating is explained by the following positive characteristics:

- Rich assortment

... Models of various capacities are on sale, which makes it possible to acquire exactly the brand that best suits the operating conditions. Thus, you can choose a heating device for both a country house and an industrial room: there are always options with suitable parameters in stock. - Profitability

... Due to the high energy efficiency of modern electric type heating boilers (their efficiency is close to 99%), their use can save significant finances. An additional economic effect is facilitated by the use of a circulation pump, which is part of the design itself. Having a low energy consumption, it, nevertheless, significantly increases the rate of passage of the coolant through all pipes. As a result, the rooms warm up much faster. - Environmental friendliness

... Such a heating system does not emit combustion products during its operation. Therefore, there is no need to spend money on organizing a chimney and providing additional air flow. For this reason, electric boilers are widely used in city apartments and office buildings. It is important to remember that the absence of smoke does not mean that the ventilation in the house may be poor. - Ease of management

... This is facilitated by the maximum optimization of monitoring and control devices. As a result, even an amateur can monitor the operation of heating equipment. Most of the models on the market are equipped with automatic control units: this allows you to resort to adjusting the operation of the system in very rare cases.

Equipment of this type is able not only to heat the premises, but also to cover the need for hot water. To optimize the water supply system, you will need to install an expansion boiler and a tank with a volume of 80 liters or more.

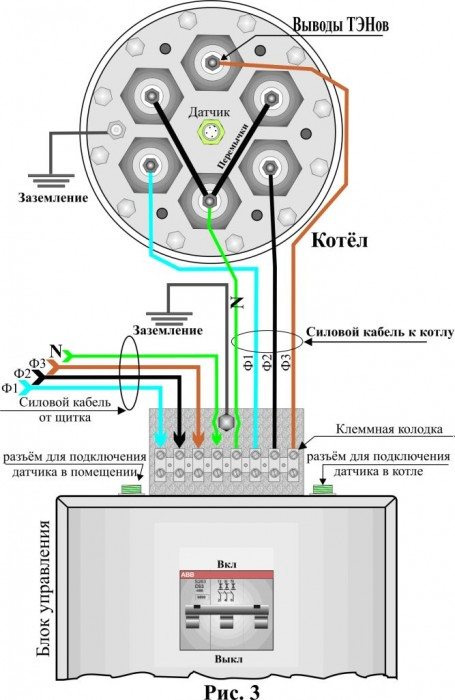

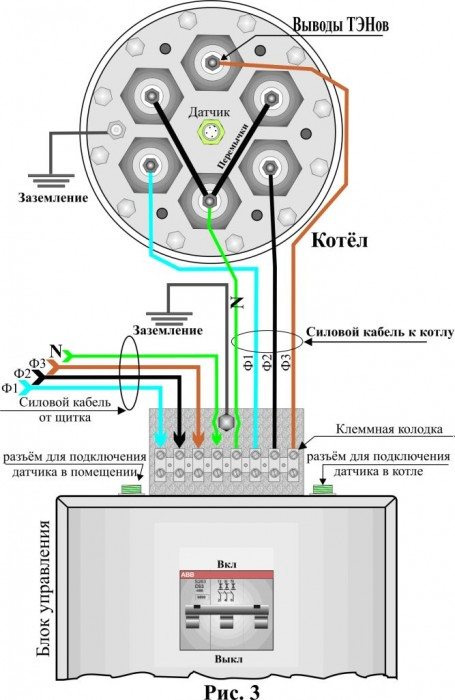

Installation

The main criterion for installing an electric heating boiler is the presence of a powerful input in an apartment or house. Depending on the type of boiler, its power supply can be single-phase or three-phase. The instructions for the boiler indicate what power consumption, current, and what cross-section the supply wires should be.

The cable cross-section is calculated depending on the current strength, while the final selection is made from a number of standard values, always rounded up. The input should naturally be even more powerful to power all other equipment in the house.

The supply cable is laid in a groove or in a box in a protective corrugation, with a separate branch directly from the distribution board. Separate automatic devices for the boiler supply are installed accordingly.

It is better to install a suspended boiler closer to water pipes and sewers. A toilet, bathroom or kitchen is better suited for this than a corridor or any other room. It will be necessary to additionally connect the outputs of the emergency valves for water with the sewage drain, and the valve for replenishing the coolant with the water pipe.

It is better to hang the boiler on a solid supporting wall. For installation on a partition, it must be additionally reinforced. The weight of the structure is quite large, especially in the presence of an expansion tank.

Additionally, manufacturers stipulate minimum distances from all sides of the boiler from enclosing structures and other obstacles. This is necessary for access to functional parts and supply lines.

To connect the pipes, signed and marked branch pipes with the designation of the inlet and outlet are used. For models designed for installation in apartments and houses, the diameter is most often ¾ inch. The pipes are supplied at the bottom of the boiler. On some models, it is possible to correct the direction of the leads in order to optimize the routing routes.

As a full-fledged alternative to gas heating, today many consumers choose electric heating boilers with a pump responsible for the forced circulation of the coolant in the system. These devices have a number of quite tangible operational advantages, and therefore there is a steadily growing demand for this type of product on the market.

In our article, we will describe in detail the design of electric heaters with a circulation pump, as well as analyze the pros and cons of their installation.

Installation procedure

Most often, installation activities are carried out by professional installers, because this requires a special permit. However, knowledge of the sequence of operations will not hurt: at least, this will allow you to control the work being done, making sure that each stage is implemented correctly.

Installation sequence:

- The most difficult thing when connecting an electric heating system is to provide it with the necessary power. If the existing wiring is able to support the power of the appliance, then no modification is required. Otherwise, you have to lay an additional line.

- After resolving the issue with power, the meter, electrical panel and RCD are installed (at least 25 A).

- Boilers are wall-mounted and floor-standing. Usually all the necessary fasteners are included with the system. After the installation of the electric boiler is completed, it is connected to the meter with a cable of the optimal cross-section.

- Temperature sensors are wired separately. Their task is to automatically control the switching on and off of the heating elements.

- A separate sanitary cabinet is used to install the heat accumulator.

- Some models do not have a built-in circulation pump: in this case, it must be installed separately. This will require an additional wire to supply power to the pump motor.

To connect all the elements into a single system, you will need pipes (metal or metal-plastic). When making a test run of the circuit, you need to carefully monitor that there are no coolant leaks anywhere. As you can see from the description, the installation work is quite complicated, so a preliminary study of this process will not be superfluous.

Electric boiler with circulation pump

Design features

The design of devices of this type is not complicated.

By and large, their only feature is the presence of a pumping unit.

- The basis of the design is a heat exchanger, consisting of a container, inside which a heating device is located.

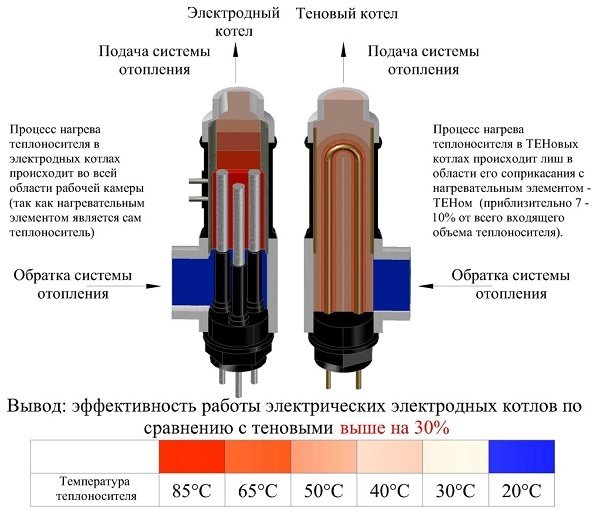

- A heating element (tubular electric heater) most often acts as a heating element, however, recently, electrode-type heaters have also been equipped with pumps to ensure the continuous movement of heated water through pipes.

- In addition to these parts, the kit includes (responsible for the temporary storage of the coolant before it is launched into the pipeline system), a valve that protects against the reverse movement of water, as well as a filter that is responsible for water purification.

- This design works under the control of an electronic unit that regulates the temperature mode of the heater operation, as well as turning on and off the device.

- An integral part of the entire system is the circulation pump for the heating boiler. The main function of this device is to maintain a constant speed of movement of water through the pipes, while ensuring the most efficient heat exchange and heating of the room.

All components are mounted inside the casing with thermal insulation, which reliably protects the boiler from unnecessary heat loss. Due to this, the energy efficiency of the heating system is significantly increased and the consumption of energy carriers is reduced.

Selection criteria

By what criteria will we choose a device for installation in the heating system?

For electric boilers with a pump, these criteria are:

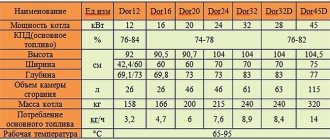

- Power

... It is provided due to the operation of heating elements installed in the heat exchanger. This parameter is indicated in kW, and when we talk about the power of the boiler, we mean exactly the characteristics of the heating elements. As a rule, there are models on the market with a capacity from 2-3 to 60-70 kW.

Note! Low-power devices are most often used for heating small private houses or summer cottages. Models with a power of 50 kW or more are intended for industrial use.

- Heat storage tank volume

... The use of this element allows you to significantly increase the efficiency of the boiler, therefore, you should not neglect its installation. The larger the volume of this container, the more efficient is the distribution of the coolant through the pipes. Experts recommend choosing a heat accumulator at the rate of at least 20 liters per 1 kW of heating element power. - Voltage

... For single-phase networks with a voltage of 220 Volts, it is allowed to install boilers with a power not exceeding 12 kW. If it is necessary to install a device with a higher performance, then a mandatory requirement will be the presence of a three-phase network (380 Volts) in the building. - Cable cross-section for connection

... The more powerful the heating unit, the thicker the electrical cable used to power the system must be. So, for boilers with a capacity of up to 4 kW, a cable with a cross-sectional area of 4 mm 2 will be sufficient, and for a boiler of 12 kW with a single-phase connection, a 16 mm 2 cable will be required. A table showing the dependence of the minimum cross section on power is given below.

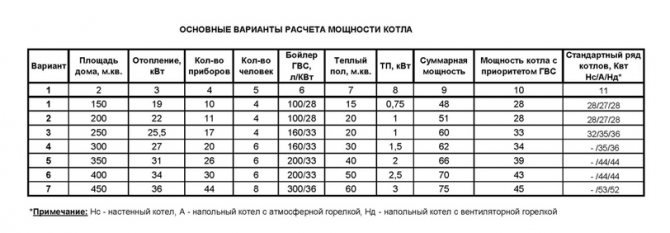

Power calculation

As we noted above, the most important parameter for is its power. It must provide compensation for all heat losses of the heating system, as well as guarantee an uninterrupted supply of hot water to the building.

As a rule, when choosing an installation for heating a house, a complete heat engineering calculation is performed, which takes into account not only the area of the heated rooms, but also the condition of the walls, floor and ceiling, the quality of insulation, installed window and door structures, etc.

But if you plan to heat a private house, then you can calculate the performance according to a simplified scheme. Below is an instruction, following which we can independently find out the minimum required parameters of the device.

The formula for the calculation is as follows:

W = S x W beats / 10m 2, where:

- W is the required heating power (kW).

- S is the total area of all heated rooms (m 2).

- W beats - specific power per 10 square meters.

W ud is different for different regions of our country. In cold regions, this indicator ranges from 1.2 to 2, in central Russia, W beats are taken as 1, and for the southern part, values of 0.7 - 0.8 are used.

Boiler installation

In most cases, the installation of heating systems is carried out with the participation of professional craftsmen with special permits.

Despite this, it is still worth studying the sequence of installation work - at least in order to be able to control the quality of the implementation of each stage.

- The main difficulty when connecting an electric heating installation is to provide it with the required power. If your intra-house network provides this power, it is good, but if not, then you will have to contact the power grid for connecting an additional line.

- When this issue is resolved, it is necessary to install a meter, an electrical panel and a residual current device (at least 25 A).

- We install the boiler itself or hang it on the wall (as a rule, fasteners are supplied in the kit), after which we draw a cable of the appropriate section from the meter to it.

- Separately, we supply wires from temperature sensors to the boiler, which automatically regulate the switching on and off of heating elements.

- If you plan to use a reservoir for heat storage, we install them in separate sanitary cabinets.

- If the circulation pump is not included in the housing of the device itself, then the pumps for heating boilers are connected separately. In this case, a wire must be provided to provide power to the pump motor.

All elements are interconnected using pipes (metal or metal-plastic). After a test run of the system, there should be no undercutting of the coolant anywhere.

As you can see, the work is going to be quite difficult, so you should still carefully study the video instructions and documentation for your pump. The time that you spend on acquiring new knowledge will definitely pay off during the installation!

Choosing a flow-through heating boiler

Having decided on the type of system, you need to choose the right flow heating boiler. It is on its parameters that the efficiency and efficiency indicator will depend. The main difference for them is the type of fuel used. Manufacturers currently offer solid fuel models that run on gas or liquid fuels. Electric boilers are no less popular.

In addition, there are general recommendations for choosing a flow-through boiler for heating:

- Rated power. This parameter can be calculated in two ways - depending on the quadrature of the room or the total volume of the coolant. In the first case, the power of an instantaneous heater for heating a house must correspond to the ratio per 1 kW of energy - 15 liters of water. With normal thermal insulation of the outer walls of the house, it can also be taken into account that to maintain a comfortable temperature by 10 sq. 1 kW of power is required;

- The presence of a second circuit.It serves for hot water supply and is more than relevant when organizing heating in a private house;

- Dimensions and requirements for the room where flow-through heating boilers will be installed. For solid fuel, it is necessary to make a separate boiler room that meets the standards of DBN V.2.5-20-200. Gas and electric models can be installed in the kitchen, but only if their power does not exceed 200 kW;

- Possibility of connection to external temperature sensors for automatic regulation of the degree of water heating. This is necessary to optimize energy consumption, which directly depends on the temperature in the room and outside;

- The presence of a heating flow pump and an expansion tank in the housing.

These are just general recommendations for choosing a flow-through boiler for heating. Despite the popularity of gas and solid fuel models, attention is paid to electric ones. Although they have a number of unique qualities.

Along with foreign manufacturers, there are currently a number of Russian companies producing reliable boilers for flow-through heating systems: Romstar, Galan and Evan. Their products are significantly lower in price, and their functional qualities and performance are more than acceptable.

Electric boiler for instantaneous heating

Comparative cost of various heat carriers

First you need to find out the relevance of installing this type of heating equipment. The advantages of flow-through electric boilers for heating are their small size. Unlike solid fuel or gas types, electric ones do not have a combustion chamber as such. This affects their size and weight. The reliability of the equipment should also be noted. Average service life can range from 20 to 40 years. But this is taking into account the observance of the operating rules.

The main disadvantage of an electric flow-through heating boiler is the high cost of the energy carrier. Therefore, it is installed only in the absence of a gas main and as an alternative to solid fuel models. To select electric flow heating boilers, their types should be considered. The design specifics depend on the type of heaters.

Heating element

The design of a flow-through electric heater with heating elements

The heating element is used as the main heating element. Inside the sealed tube is a coiled wire made of high resistance metal. When electrical energy is supplied, heat energy is released, as a result of which the heater for heating of the eastern type begins to increase the temperature of the water.

The design consists of the following blocks:

- Heating unit... It houses the heating element, which is washed by the coolant of the heating system;

- Control block... Designed for manual or automatic power adjustment of the heating element;

- Air vent... Not all manufacturers install this security feature. But in case of overheating of the coolant in the flow-through boiler during heating operation, the air vent will promptly remove the airlock;

- Additional accessories - circulation pump, pressure gauge, automatic shutdown system in the absence of water.

Also, when choosing, you need to pay attention to the manufacturers of a flow heater designed for heating a house. The most popular brands are considered to be products from Bosch, Protherm and Dakon.

| Model | power, kWt | Cost, rub. |

| Bosch Tronic 5000 H | 18 | 63800 |

| Bosch Tronic 5000 H | 36 | 90500 |

| DAKON DALINE PTE 10 | 10 | 53560 |

| DAKON DALINE PTE 24 | 24 | 62000 |

| PROTHERM SKAT 12K | 12 | 46410 |

| PROTHERM SKAT 24K | 24 | 57450 |

An important factor is the manufacturer's warranty and the availability of service centers for the prompt repair of a flow heater for heating. It is recommended to find out this information before purchasing.

Advantages and disadvantages

Advantages of operating boilers with a circulation pump

The growing popularity of this equipment is due to the quite obvious advantages provided by the use of electric heating systems in heating private houses:

- A wide range of models in terms of power allows you to choose exactly the brand that suits your conditions. Regardless of what you need to heat - a country house or an industrial workshop - you always have the opportunity to purchase an installation with suitable parameters.

- The economic effect of the use of electric heating systems is also quite obvious. The energy efficiency of modern models is very high (the efficiency is 97-99%), therefore the installation of such a boiler opens up opportunities for very significant savings.

- The use of a circulation pump integrated into the design itself also contributes to increased efficiency. Possessing a fairly low energy consumption, the pump contributes to the fastest possible passage of the coolant through all circuits, ensuring rapid heating of the air in the premises.

- Since during the operation of such a heating system, combustion products are not formed, it can be considered absolutely environmentally friendly. An additional plus is that there is no need to spend money on the construction of a chimney, as well as to ensure an enhanced air flow.

Note! Despite the absence of combustion products during the operation of the boiler, high-quality ventilation of the room in which it is installed is still necessary!

- Management of such devices is optimized as much as possible. Thanks to this, even a layman can control the temperature regime of the room. In addition, for most of the models on the market, the control unit includes components that automate the operation of the heating element, so adjustment is extremely rare.

In addition to these advantages, it should also be mentioned that the boiler of this design can be used as a source of hot water. At the same time, to optimize the water supply system, it is necessary to install an expansion boiler with a tank with a capacity of at least 80 liters.

Disadvantages and features requiring special attention

Despite the impressive list of advantages that an electric boiler with a built-in pump provides to its owner, this design also has quite obvious disadvantages:

- First, the cost of operating such a plant directly depends on the cost of electricity. For this reason, in most countries, electric heating systems are recognized as less efficient than gas or solid fuel boilers.

Advice! To reduce financial costs, experts recommend installing heat storage tanks. This allows you to reduce heat loss and reduce energy consumption for water heating.

- Secondly, the operation of the boiler itself and the circulation pump built into it depend on the presence of voltage in the network. Therefore, you should take into account the peculiarities of your region: if power outages are common for you, then it is better to opt for a different design of the heating system.

- Also, a way out of the situation can be the installation of an alternative heat source in case of an "emergency" situation, for example, a solid fuel stove or fireplace. Of course, they will not provide full heating, but in case of failure of the main system, they will protect the house from cooling down.

- It should also be taken into account that efficient operation of the "heater + pump" system is impossible without high-quality electrical wiring. That is why, when installing such heating with your own hands, you may have to completely change all the wires. This can also lead to additional costs.

As for such a parameter as the price of the device itself, here the total amount largely depends on the model you choose (and by and large - on the power needed to heat your home). You can find quite inexpensive boilers, but a really powerful device, by definition, cannot be cheap.

Electric heating systems with integrated circulation pumps, shown in the photo in our article, will provide efficient heating in your home. And although these devices are not without drawbacks, but, nevertheless, in some cases the choice of such boilers will be not only justified, but also the only correct one!

Electric boilers with a pump are used as an efficient, environmentally friendly source of heat and are suitable for heating any premises: from residential buildings and apartments to public institutions and industrial enterprises. The devices are equipped with a pump that performs the function of regulation and forced circulation of the medium in the system.

Features of flow-through heating

The specificity of the flow-through heating system is in the correct arrangement of all its elements. She is reacts to incorrect placement of heating devices, they should be located in series, the coolant (hot water) gives off heat, passing through the system also sequentially. Naturally, the first battery heats up more than the last one in sequential order.

Features of the sequential circuit:

- Flow-through boilers for heating water in this scheme must have sufficient power. The accepted expression for the ratio of a heating area of 10 square meters per 1 kW of energy power is not entirely correct. Based on the length of the line of the connected radiators, it is necessary to add from 15% or more, maximum 30% of the obtained value. Experts recommend, when choosing a flow-through boiler, to take into account the need to provide it with water, to complete the system with a pump for its supply, and also to take into account the properties of the cottage's heat-insulating materials.

- In a flow-through system, you cannot adjust the heating of each battery. Heating devices are heated consistently and evenly.

- The circuit has a high hydrodynamic resistance, therefore, a flow pump is used for heating, which provides movement in the coolant systemwhen there are a lot of batteries in the country. This type of heating system requires an accurate calculation.

Some owners of summer cottages attribute the features of the flow system to its disadvantages, but it also has positive parameters: low financial costswhen the cottage is completed according to this heating scheme, it is not necessary to build an additional heating circuit.

When calculating the flow system, it is necessary to take into account the diameter of the main pipes. This affects the choice of the pump, the larger the pipe, the lower the hydrodynamic resistance.

First you need to choose the type of flow-through heating system, it can be:

- gravitational, when a heated liquid (heat carrier) moves by gravity through pipes;

- forced circuit, with the use of a pump for the movement of the coolant through the equipment of the system.

Advantages of electric boilers with a pump

- Efficiency. Electric heating boilers with a pump are highly energy efficient. The efficiency of electric boilers is up to 97-99%. The pump increases the speed of movement of the coolant along the contours of the system and ensures the fastest possible warming up of the room.

- Saving. Boilers with a pump are characterized by low energy consumption, which can significantly save money spent on heating.

- Convenient management. The design of the products is optimized as much as possible, so everyone can cope with the control. Automated elements and thermostats included in the structure of the boiler control unit will provide the most comfortable control of the device.

- Environmental friendliness.When using electric boilers for heating with a pump, no harmful combustion products are formed, therefore, the device is environmentally friendly for human health. At the same time, there is no need for a chimney or additional installations to increase the air flow.

Gravity heating

It is considered the simplest one-tube gravity system. To equip a dacha or a residential building with this system, you need to buy the following equipment:

- Flow-through heating boiler.

- Expansion tank, it can be open type or membrane type.

- The main pipeline that delivers the heated coolant (water) to the heating devices and back to the heating boiler.

- Heating radiators.

In this system the main element is the heating boiler, which should optimally maintain the temperature regime in heated rooms. The speed of movement of the coolant through the main pipeline depends on its performance, according to this heating scheme.

This happens as follows: the water in the boiler heats up and expands, begins to move along the pipe, in the process of movement, the coolant cools down, through the return pipe, it returns to the heating boiler for heating.

Consider the features of this heating system:

- For a summer residence, the length of the main pipeline will not be more than 30 meters, since the pressure in it is low and there is no way to warm it up for a long length.

- In this scheme more often a solid fuel heating boiler is used, which is economical on fuel.

- Increased inertness of the coolant, which is in direct proportion to the temperature of its heating in the boiler tank, how many turns of the pipeline in the circuit. For this reason, in the distant rooms of the cottage, heating devices heat up more slowly.

- The low cost of this heating scheme allows it to be used in summer cottages, in small private buildings. For its operation, you can buy a small flow heater.

The circulating movement of the coolant is provided by the created pressure using a vertical riser; it is made at the outlet of the heated coolant from the boiler. Its height should not be more than 5 meters.

How to choose an electric heating boiler with a pump

The online store presents various options for electric boilers with a pump. When choosing a product, you should take into account the main criteria, which include:

- Power. The power indicator of the heating elements is measured in kW and is indicated in the technical data sheet for each product. For large industrial premises, boilers with a capacity of more than 50 kW are suitable.

- Contouring. The catalog contains single-circuit and double-circuit electric boilers with a pump. Devices with one circuit are only suitable for space heating. The double-circuit boiler additionally performs the function of hot water supply.

- Supply voltage. To install a boiler with a capacity not exceeding 12 kW in rooms with a single-phase electrical network, a standard voltage of 220 V is suitable. Products with higher energy efficiency require a three-phase network with a power supply of 380 V.

In our time of high technologies in the field of heating equipment, new technical solutions are constantly being introduced, aimed at improving the efficiency of work, safety and comfort during the operation of equipment. The result of one of these implementations is an electric boiler with a pump, built-in expansion tank and a circuit for providing hot water. In fact, a whole micro-boiler house is assembled within the framework of one high-tech product.

Forced heating system

Forced heating system diagram provides for the use of additional equipment Is a circulation pump that qualitatively improves the heating characteristics of a summer house or a country house.

With the help of a flow pump, the speed of movement in the main pipeline of the coolant increases, and the inertness of the system is significantly reduced. A pressure of about 3 atmospheres is created in the pipeline, the value of the boiling point of water increases, and the permissible possibilities for the formation of air locks in the system become less.

In this heating scheme, two types of boilers are used: electric or gas. If there is no centralized gas supply in the country house, it is recommended to install an electric instantaneous heating boiler. There are two types of such boilers: single-circuit and double-circuit. Single-circuit heating boilers work only for space heating country house or cottage, and a double-circuit flow heater can, in addition to heating, supply residents of the summer cottage with hot water.

What is a built-in pump for?

Electric heating boiler device with circulation pump

In electric boilers, there are no dimensional or massive elements that are an integral part of the design of other heat sources. Therefore, heating electrical installations are made, as a rule, in a wall-mounted version. At the same time, they are maximally completed with additional elements in order to simplify installation and piping of the boiler on site. One of the most important piping elements built into the heater design is a circulation pump. Its presence in an electric boiler is more than appropriate, especially if the latter provides a secondary circuit for hot water supply. Circulation pumps for boilers solve two problems:

- Forcing the coolant to flow through the pipelines of the heating system at a certain speed.

- In double-circuit electrical installations, they drive the coolant through a flow-through heat exchanger to prepare water for hot water supply.

In single-circuit boilers, the pump only solves the problem of forced circulation of water throughout the entire heating system. Here one nuance arises: the manufacturer supplies its product with a pump, the parameters of which approximately correspond to the power of the electrical installation - the average value of the hydraulic resistance, which the system of a given thermal power should have, is taken.

Wilo circulation pump for heating systems

But there are an infinite number of options for heating schemes, some of them have greater hydraulic resistance than a standard pumping device of a heat generator can overcome. Then an electric boiler with a pump will not be able to supply the coolant to all branches of the system.

A simple example: a standard pumping unit WILO-STAR-RS is able to provide a capacity of 6 m3 / h of heating medium, developing a pressure of 0.8 bar or 8 m wc. If the heat source is located in the basement of a three-storey cottage, then only to overcome the lifting height will require a pressure of about 0.6 bar. And you also need to deliver the coolant along the horizontal branches, the resistance of which is taken in aggregate according to this ratio: 10 m of the length of the horizontal pipe is considered as 1 m of the riser. And as a result of the calculation, it turns out that an electric boiler with a built-in circulation pump will not cope with its task, the circuit will not function.

Advice.

If we are talking about heating buildings with a branched system, long branches or large differences in height, then it is better to perform an enlarged calculation and check its result with the parameters of the pumping device, after consulting with a sales representative of the manufacturer of heat generators. This will save you from buying unnecessary equipment later.

A situation is possible when an electric boiler with a circulation pump has already been purchased, installed, and after that it turned out that the pressure of the standard blower is not enough.In this case, additional costs are inevitable, and the problem can be solved as follows:

- Perform an enlarged calculation of the hydraulic resistance of the system independently or with the assistance of a specialist.

- According to the calculation results, purchase a separate circulation pump.

- Introduce a hydraulic separator (hydraulic arrow) into the circuit, then the heater blower will operate in a small circuit.

- Install a separate pump on a large heating circuit, as shown in the diagram:

Heating system with low loss header

How to choose the right expansion tank model

When choosing an electric heating boiler with a pump for your home, it is recommended to pay attention to the following criteria:

- Power... Affects the performance of heating elements in the heat exchanger (it is indicated in kW). It is the heating elements that characterize the boiler power. In most cases, models on the modern market have a power from 2-3 to 60-70 kW per TEN. Appliances with low power are usually used to heat small private houses and summer cottages. Boilers with indicators over 50 kW are used in the industrial sector.

- Heat accumulator capacity... Thanks to this capacity, a significant increase in the efficiency of the boiler operation is achieved, therefore it must be installed. The volume of the heat accumulator directly affects the efficiency of the distribution of the coolant in the pipeline. As experts advise, when choosing a tank, you need to focus on the ratio of 20 l / 1 kW of boiler power.

- Voltage... In houses with 220 V single-phase networks, boilers up to 12 kW can be used. If you need to install a more powerful device, then in this case you will have to lay a three-phase network (380 V).

- Cross-section of commutation wires... As the capacity of the heating equipment increases, thicker cabling must be used to supply electricity to the system. Appliances up to 4 kW can be equipped with 4 mm2 cables, and 12 kW single-phase boilers are connected with 16 mm2 cables.

In addition to heating elements, electric boilers also include electrode and induction boilers. In the latter case, we are talking about a small dielectric tube and a ferromagnetic rod. The coolant moves inside the tube, heating up due to the passing electric current. The advantages of these models are durability, compactness and efficiency (the "soft start" function saves almost 50% of electricity). The disadvantage of induction devices is the complex control unit.

As for the electrode assemblies, they are also called "direct action" devices (due to the absence of a heating element). Heating of the coolant occurs while moving through it an alternating electric current with a frequency of 50 Hz. Such equipment is distinguished by safety, since it is equipped with an automatic security system. The disadvantages of electrode boilers include the need for enhanced preparation of the coolant, which must have the required resistance. Regular replacement of the electrodes will also be required, due to their gradual dissolution.

Circulation in double-circuit hot water boilers

The operation of double-circuit electric boilers with a pump is complicated by the need to periodically supply a heat exchanger with a coolant that heats water for hot water supply. Here, the blower alternately operates in the heating and hot water supply circuits, switching is carried out by a two-way valve with an electric drive at the command of the controller. This happens at the moment the hot water tap is opened in the house, this fact is recorded by the flow sensor and transmits a signal to the controller. After switching the flows, the circulation pump pumps the coolant into the flow-through heat exchanger until the tap in the house is closed and the two-way valve directs the flow into the heating supply pipeline.The device of a double-circuit boiler with a circulation pump is shown in the figure.

Installation diagram

1 - a flask with heating elements and an automatic air vent; 2 - unit body with mounting holes; 3 - controller; 4 - membrane expansion tank; 5 - pumping group with a two-way valve and a flow-through heat exchanger

.

The flow-through heater has rather narrow channels; accordingly, the blower is selected in such a way as to overcome the hydraulic resistance of the heat exchanger, taking into account its increase as scale appears.

For reference:

the automation of most electrical installations is programmed to periodically turn on the circulation pump in the summer, so that its rotor does not get stuck during idle time.

Electric boiler application and equipment installation

An electric boiler with a flow-through pump in the country will make living in a house much more comfortable. In cold weather, when there is no central heating, this type of heating is irreplaceable. Such equipment is not prohibited for installation and does not require additional permits.

With all the differences from a solid fuel and gas boiler, an electric heater works according to the same principles as other heating boilers.

Constructive elements of an electric heater:

- Coolant (water) tank.

- Heating element - heating element.

- Flow-through circulation pump.

- Start relay and temperature relay.

- Water flow sensor.

- Air and water relief valves.

- Expansion tank.

Induction heaters or heating elements can be used as heating elements. There are no fundamental differences, except for a longer operation of induction heaters without a decrease in operating efficiency. Experts recommend paying special attention to the preparation of the coolant for use, it is because of it that boilers fail. Salt deposits and siltation on the walls of the reservoir.

Installation of a flow-through boiler for heating the premises of the summer cottage can be carried out in two versions: floor-standing and wall-mounted. Since it is relatively light in weight, it is more often mounted on the wall.

Summarizing

Electric boilers with pumps are an excellent choice for heating a house in areas where there is no centralized gas supply, and there is no desire to use solid fuel counterparts. Even at the production stage, the manufacturer supplements the boiler with such elements as an expansion tank and a circulation pump, due to this, the installation process of the heating system is somewhat simplified.

The video shows an example of connecting a 6 kW electric boiler.

Did you like the article? Subscribe to our channel Yandex.Zen

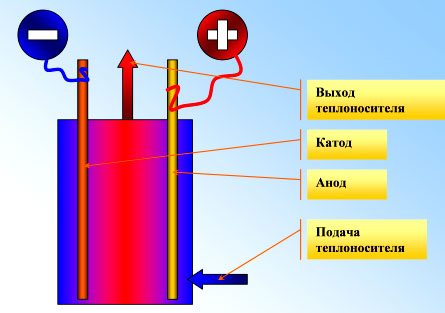

How the electrode boiler works

In the event of a coolant leak, the electrode boiler is automatically turned off, since the electrical circuit is closed by the liquid that circulates in the pipes and the heating device.

A simple mock-up demonstrating its work is 2 wires with metal blades, fastened with wood chips 4.5 cm apart and connected to the network.

Photo source: kamburg.ru

Under the influence of alternating current, a chaotic movement of ions begins with the release of a large amount of heat. A similar home-made device was in demand by students and soldiers during the Soviet Union as a boiler.

The device of the electrode or ion boiler has a similar design. The body is made in the form of a cylinder with electrodes inside.

Their number depends on the provided power supply system. 1 or 2 electrodes are typical for single-phase current. For three-phase current, 3-electrode designs are used. At a voltage of 220V, the body can play the role of the zero phase, and in this case there is only 1 electrode.

The inlet pipe for the coolant is located on the side, closer to the place where the electrodes are attached.

Technical characteristics of electric heating boilers

Electric boilers have a variety of heating elements for a private house. It is important to highlight the devices depending on their technical features. Many residents of private houses cannot decide on the choice of an economical, powerful and efficient electric boiler. Therefore, we will consider the main technical characteristics of such equipment.

First of all, you should pay attention to the source that heats the water. This results in the cost of equipment, economy and productivity. The smallest efficiency factor of a tubular electric heater, that is, heating elements. They work like a conventional boiler.

If we single out the most efficient economical option for heating a house with electricity, then these are induction models. But such equipment is not very popular, since only some manufacturers make such devices. If you highlight an option with high quality and reasonable cost, then this is an ionic electric energy-saving boiler that works on the principle of electronic heating.

Another important point is the way of connecting to the network, as well as the requirements for the power supply. You need to know these nuances before buying an electric boiler. You should find out in advance whether it will be possible to draw a line with a capacity of 380 V. If this is not possible, then you need to choose an economical electric boiler that works from a conventional network.

When choosing a boiler, it is important to know about the efficiency of the equipment. Depending on the model, you can choose an economical unit with the required power. A standard electric boiler can have a power of 6-12 kW, but there are also more powerful options with a capacity of up to 300 kW.

If you need water heating in small quantities, then you should choose a double-circuit unit. If you require large volumes of hot water, then it is better to purchase a single-circuit boiler and a separate indirect heating boiler. Most of the models are equipped with automation that allows you to control the operation of the boiler from a distance.

Before buying a boiler, you need to check that the device meets the requirements and can be used in your home. You can study photos of samples that are available from consultants selling heating equipment.

Types of electric boilers

Boilers can be classified according to the method of water heating, and the pump for the heating boiler can be installed in any type of device.

I distinguish such boiler classes as:

- devices in which water heating is carried out using a heating element... Such electric heating boilers are rather bulky and if the water is hard, then the scale will quickly cover the heating element. They are considered the simplest in design;

Boiler device with heating elements

- induction - they use the phenomenon of electromagnetic induction... The heating element is a conventional induction coil - a wire is wound on a steel core (which is located in a dielectric tube), through which an electric current passes. When the boiler is turned on, the current passing through the winding provokes the occurrence of a current in the core, this leads to the heating of the steel rod;

The induction boiler is small in size

- electrode boilers - can work exclusively with water, since the composition of the coolant is important... Water is, in principle, an ordinary conductor with a fairly high resistance. 2 conductors are lowered into it, through which an alternating current is then passed, the water, like any conductor, heats up. Devices of this type are usually not equipped with circulation pumps.

Electrode boiler circuit

As for the circulation pump and expansion tank for the heating system, the following options for the location of these elements are possible:

- both the pump and the tank are located in the boiler body - such models are usually preferred if the boiler is located in the house, and not in a separate room;

Heat exchanger and pump are located in one housing

- the pump can be removed outside the housing, this does not affect the efficiency of its operation.

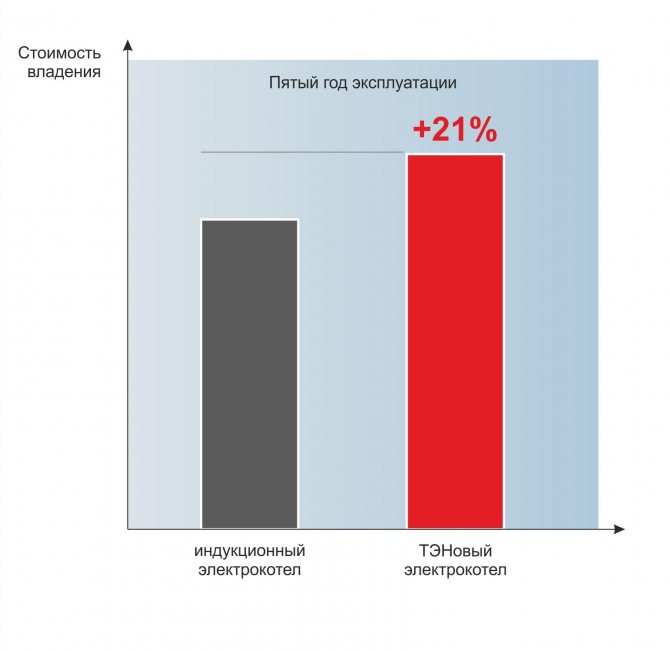

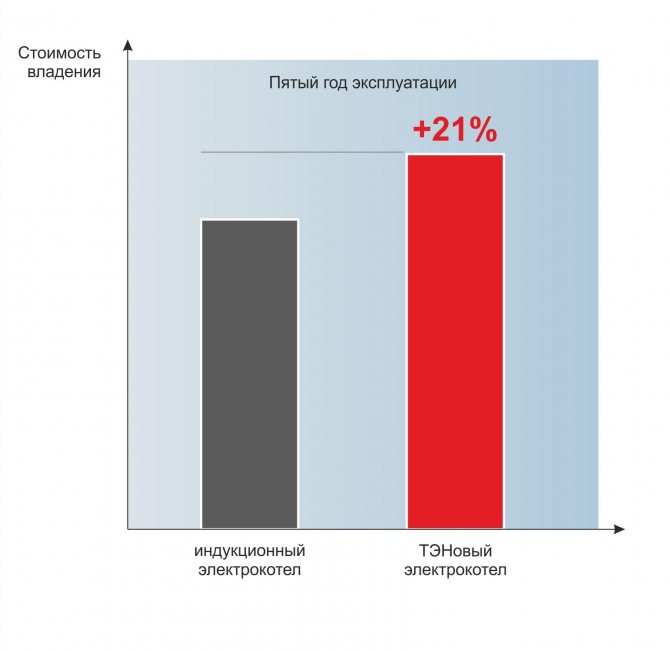

Costs in the fifth year of operation

It seems, at last, we entered the operating mode with the heating element boiler: everything became more rhythmic and mundane. Yes, you have to pay more for electricity, yes, you have to buy heating elements, yes, recently replaced elements start to fail (the quality is falling?) And there was an unpleasant case when a low-quality heating element broke through and the voltage "went" into the system. It is good that the heater was grounded at the very beginning, otherwise there will be trouble ...

In general, it's good that we only have a 50-kilowatt heater. What if there were 350? 7 times 50! How many heating elements are there, and how much would all our worries and expenses increase?

The induction heater hums slowly. Still, the "brother" of the transformer. It seems to have begun to hum a little harder. Although, this, perhaps, only seems - there is simply nothing to find fault with.

| Fifth year | Induction heater | Heating element boiler |

| Heating period, days | 200 | 200 |

| Time of continuous work, hour / day | 10 | 15,18 |

| Energy tariff | 2,8 | 2,8 |

| Electricity costs, rub / season | 50×200×10×2,8=280 000 | 50×200×15,18×2,8=425 040 |

| Risk of accident | 0 | 50 |

| Consumables costs, rub. | 0 | 10,000 (replacement of 5 heating elements) |

| Labor costs for operation * | 0 | 950 |

| Current expenses for the period | 280 000 | 425 040+10 000+950=435 990 |

| Cumulative total costs | 1 265 000+280 000=1 545 000 | 994 960+435 990=1 430 950 |

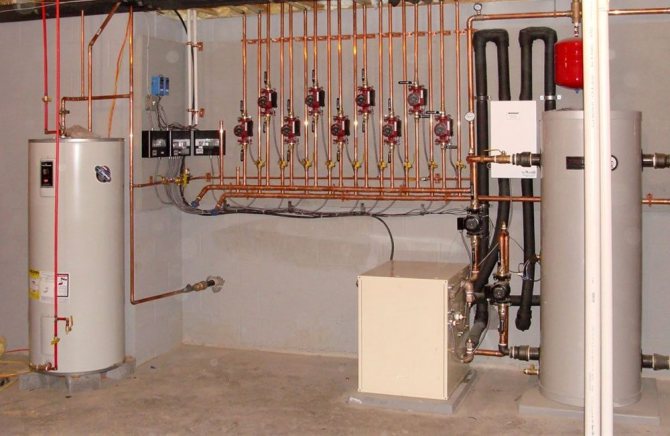

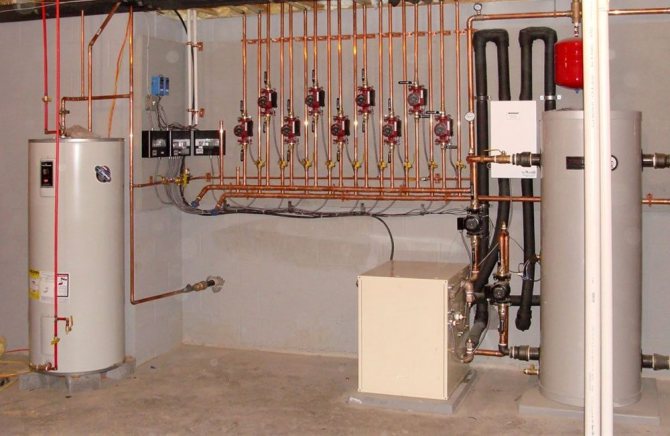

Electric boiler piping

The piping is understood as the whole process of connecting from A to Z, that is, not only supplying power to the boiler, but also installing all elements of the heating system (expansion tank, circulation pump, filters, protection group, etc.).

In the photo - the connection of the electric boiler is completed

For added flexibility in heating control, a mixer circuit can be used. Due to this, the temperature regime can be regulated not only by changing the power of the boiler, but also by means of a mixer with a servo drive.

When installing the boiler, you should adhere to the following recommendations:

- it is advisable to remove it from the water supply as much as possible, the electric boiler is placed only in a dry place, this is done to avoid a short circuit;

- the compact boiler can be placed on the wall, in which case dowels or anchor bolts are used. Floor-standing models are also popular, for them you can limit yourself to a simple dielectric stand, of course, the base should be flat;

Floor standing boiler mounted on a small plinth

- after that, proceed directly to connecting it to the heating system. Naturally, the water supply is stopped during installation. The connection itself is simple, detachable connections are used, so if necessary, it will not be difficult to dismantle the boiler. Pumps for heating boilers are installed closer to the boiler on the return line;

- then comes the turn of the electrical part. We figured out the calculation in the previous sections, the only thing that needs to be noted is that it is better to place the wires in cable channels. Of course, all cables are well insulated, but additional protection will not be superfluous. A corrugated flexible conduit can be used as a cable channel.

The diagram shows an example of connecting a heating element boiler

Note! If power surges are not uncommon, then the connection must be made through a stabilizer.

- after that, it remains only to fill the system with water and check the tightness.

Advantages of electric boilers

Electric boiler works silently, easy to install and maintain

In comparison with gas or other types of heating boilers, electric boilers have advantages:

- Quiet operation as the heating elements turn on imperceptibly.

- Can be left unattended, just like gas. The boiler can turn off on its own only in the event of a power outage.The equipment is fully automated.

- Low cost of equipment, as well as installation and maintenance.

- Fewer installation problems, as the electric boiler does not require installation documents.

- The small size of the unit, but at the same time, the power develops high.

- Environmentally friendly - no chimneys or residues to be drained or disposed of. Can be connected in any room.

In regions where the cost of electricity is high, it is unprofitable to install electrical equipment for heating a private house. Gas in this case will be cheaper for utility bills.

Energy savings

The operation of an electric boiler will consume energy, which must be paid for and the prices of which are constantly increasing. In order not to throw away finances, it is recommended to carry out work to reduce heat loss that can occur through cracks in wooden windows, single-glazed windows in metal-plastic structures, an uninsulated ceiling or floors between floors, a roof that is not sealed with insulation, as well as the floor.

For insulation, you can use inexpensive materials - mineral wool, foamed polyethylene, polyurethane foam.

Popular models of energy-saving electric boilers

If you choose budget models of electric boilers for heating a country house, then you should give preference to the Polish manufacturer Kospel EKCO. Heat losses are reduced to a minimum, and the efficiency reaches 98%. Three-phase units have a multi-stage system. The equipment can operate in automatic or manual mode.

Among Russian manufacturers, you can find them, which are popular among buyers. The boilers have 3 capacities. The equipment can be used not only from a three-phase network, but also from a single-phase one. Buyers often choose a domestic manufacturer.

Another well-known company in Russia is SAV. The cost of such units varies between 30-150 thousand rubles. The efficiency of SAV boilers is 99%.

When choosing heating, you should remember about heat losses. Therefore, it is important to properly insulate the house and reduce heat losses.