Cleaning the sauna chimney

The bath or sauna room should be heated for a short time. The stove is purchased compact, and its main function is to heat up the stones lying on it in a short time. They will serve as a kind of heat accumulators.

The flue gases have a very high temperature, about 800 ° C. In addition, in the sauna and steam bath, it is especially important that there is good traction. Otherwise, a small amount of carbon monoxide in a small room can become fatal. Sauna stoves and pipes must be fenced to prevent injury in the steam room.

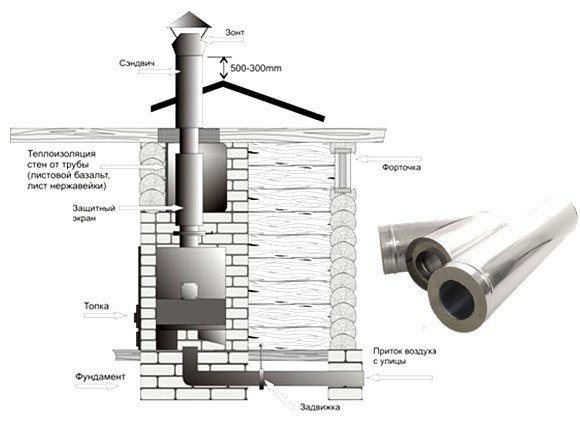

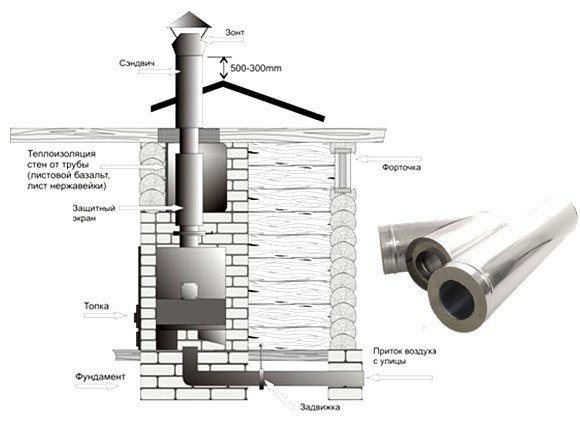

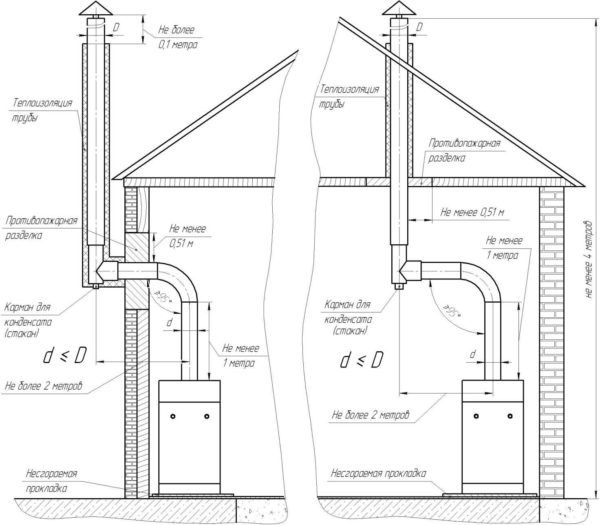

Bath chimney installation diagram

- The pipe for the stove in the bath and the stove itself do not need a massive foundation. Better to insulate it well from wooden structures.

- Make the first chimney element from the sauna stove from thick metal without applying additional thermal insulation to it. After it, it is possible to install a sandwich chimney.

- Remember - the distance between the pipe and the unprotected elements of the bath structure from the fire must be at least 350 mm.

- Cover with your own hands all gaps in the wall, ceiling or roof with galvanized sheet metal with an asbestos backing.

- Be sure to install the asbestos sheet in a place where the tube for the stove in the hot gas bath may come into contact with the wall and ceiling.

To clean the bath pipe from soot, many methods are used, using special brushes and aggressive chemicals. What if an adjustable chimney is installed?

The only option:

- Pour a few liters of hot water directly into the pipe.

- Then heat the stove for a long time so that the pipe does not rust.

You will see how, after kindling, the thickened and long-caked soot will come out of the chimney in a thick cloud. But there will be no smells and residues, they will be destroyed by the high temperature.

Stove and chimney in the bath

Chimney draft problem

If the chimney is designed so that the draft in it is not too high, it will overheat, the chimney must make a turn or half turn, in the manner of a Russian stove before exiting the furnace, so that the combustion products do not fly straight into the chimney, but remain in the stove. If necessary, if the required draft was not provided and the draft is too low, and there is no means to increase it, in order to avoid the formation of smoke, it is necessary to artificially ventilate the chimney using an exhaust hood. That is, it is impossible not to overheat either smoke or afterburning of the fuel in the chimney.

Insulating pipes in a sauna

Today, the best material for insulating bath pipes is foil-insol. It does not emit any harmful substances due to high temperatures.

It is also used to protect:

- pipelines;

- heating mains;

- air ducts.

If you do everything thoroughly, you need to create a "sandwich" from the pipe:

- the first layer is a stainless steel tube of the sauna stove;

- the second layer is basalt;

- the third layer is the outer contour.

Such a chimney will heat up much less than the traditional one. This will prevent possible condensation.

How to properly insulate a pipe in a sauna

More details

- The fact is that basalt-based insulation:

- withstands high temperatures;

does not ignite under severe heating;

- does not emit unpleasant odors.

- The outer pipe, due to the inner layer of insulation, remains cold, practically not heating up, ensuring complete fire safety of the sauna.

- Such a chimney improves the operation of the furnace, which heats up quickly and immediately goes into operation.

- Traction is improved due to the absence of various obstacles-vortices that brick pipes have.

Therefore, such chimneys are called "warm", since the insulating layer does not allow metal pipes to quickly cool from the outside air. As a result, all water vapor that is necessarily present in the smoke will not cool down and will not appear in the form of condensation along with soot on their inner walls.Because of this, flue gases easily escape to the outside without experiencing resistance.

Bath pipe insulation

Optional: Wrap the pipe with a layer of flexible asbestos where it comes into contact with the combustible elements. Protect the chimney from above with a "fungus" from moisture.

What to look for when choosing a chimney

The maximum temperature of combustion products passing through the exhaust system is 150-160 ° C. This characteristic is relevant for most chimneys.

Most steel grades can easily withstand the temperature, but not all will tolerate the effects of sulfuric acids formed during gas combustion. Chemical compounds corrode the walls of brick, metal, asbestos-cement chimneys. It is recommended to give preference to products made from acid-resistant grades.

The second nuance that you need to know about is the formation of a dew point inside the chimney. As air passes through the pipes, over time, condensation forms on their inner surface. Because of it, it becomes difficult or stops the process of removing flue gases.

Typically, this problem is observed in brick chimneys, the inner walls of which are rough. There is almost no condensation on stainless steel chimneys. It is also rare - on ceramic and asbestos-cement. However, we remember that the latter form harmful substances during combustion, therefore we will not consider them further.

The optimal design of the chimney is "sandwich". The presence of insulation between the pipes evens out the outside and inside temperatures. This results in less condensation.

Before calculating the boiler chimney, you still need to decide on the type of the heating system itself. Let's take a look at the example of gas-powered devices.

External and internal options for the outlet of the chimney of a gas boiler.

Typical mistakes of beginners and self-taught

In the first place among the oversights - the wrong height of the chimney. Too high an option creates excessive draft, which increases the likelihood of tipping over and drawing smoke back into the firebox and the room with the stove. 5-6 meters are considered optimal, but much here depends on the size of the combustion chamber and the configuration of the chimney.

A constant flow of air into the firebox is an obligatory guarantee of good draft in the chimney, which is why it is so important to equip high-quality ventilation in a room with a fireplace or stove.

Overcooling of the chimney and its excessive heating as a result of intensive combustion of fuel in the furnace must not be allowed. Everything should be in moderation, otherwise the pipe may crack. To make it easier for yourself to identify these cracks, the chimney section in the attic should be whitewashed. All soot streaks will be visible on a white background.

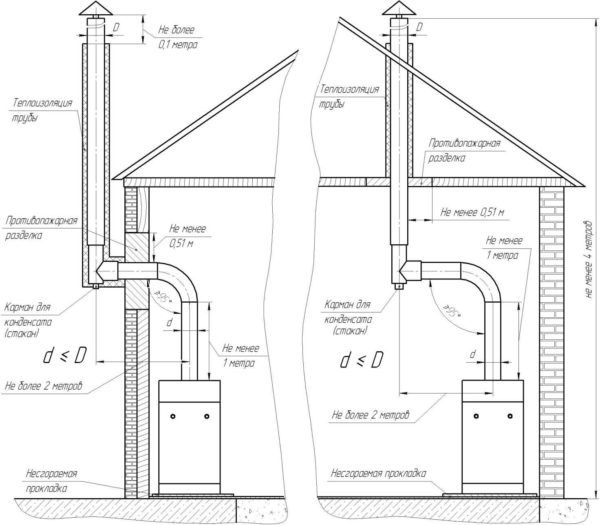

Often, when installing a steel chimney, beginners forget to provide condensate drainage. To do this, you need to make a special collection and insert hatches for inspection into the pipe. Mistakes are also made in the choice of steel grade.

With the usual burning of wood, gas or coal in a fireplace or heating boiler, the chimney heats up to 500-600 ° C. However, the temperature of the fumes, even for a short time, can rise to 1000 ° C. Moreover, after a few meters from the firebox, they cool down to 200-300 degrees and do not pose a threat to the chimney.

But its initial meter section from the boiler has time to heat up very much. The steel must be heat resistant and capable of withstanding these loads. And the insulation of the steel pipe should be done only a couple of meters from the firebox in order to prevent overheating of this segment of the chimney.

To increase fire safety, passages through ceilings and walls are made through special non-combustible inserts, direct contact of hot pipes and flammable building materials is unacceptable

When laying bricks by an inexperienced master, vertical displacement of their rows relative to each other is often allowed. When building walls, this is allowed, but in the case of a chimney, it is absolutely unacceptable. This greatly reduces the efficiency of the chimney duct, as flow eddies and soot deposits on the walls begin to form in it, which will require cleaning over time. And how to do it correctly, you can read in this material.

The foundation under the brick chimney must be extremely reliable, otherwise the pipe can lead to the side with its subsequent partial or complete destruction. And if smoke removal is done for a gas boiler, then it is better to exclude a brick. It is rapidly degraded by the alkaline environment generated by the combustion of natural gas.

Why are chimneys of stove heating whitewashed?

Stoves are still one of the main sources of heat in both private and residential apartment buildings. Unfortunately, stoves in our homes do not always meet fire safety requirements and cause numerous fires.

To protect your home, apartment or your life, you must follow basic fire safety rules.

Basic principles of safe operation of stoves in homes.

If cracks appear in the stove, over time they become larger, during the heating, sparks begin to break through them, and then the tongues of flame. And if cracks appear in those places where wooden partitions or ceilings are adjacent to the stove, this will inevitably lead to a fire. Any cracks that appear must be wiped up immediately.

To prevent the floor from catching fire from the coals accidentally falling out of the stove, a 70x50 cm metal sheet is nailed in front of the furnace hole of each stove. Having melted the stove, the remaining firewood and debris are removed from this sheet.

The pre-furnace sheet - a metal plate placed under the firebox - must be at least 50 by 70 centimeters.

Particular attention: furniture, curtains and other flammable items must be placed at least half a meter from the firebox. Most fires are caused by violation of this obvious rule.

The outer surfaces of brick and concrete chimneys and channels that cross the roof must be removed from combustible or non-combustible structures (rafters, battens, etc.) at a distance of at least 130 mm.

Smoke ducts in buildings with roofs made of combustible materials should be provided with spark arresters (metal nets) with openings no more than 5 x 5 mm.

The structural elements that protect against fire are the ceiling cut, the pre-furnace plate and the head. The cutting is, as it were, built into the ceiling around the chimney, it is a square made of non-combustible materials - metal, tiles, bricks, clay and mineral wool. It is necessary so that the wood floors do not start from the heat of the stove. The dimensions of the cuttings of the furnaces and smoke channels, taking into account the thickness of the furnace wall, should be taken equal to 500 mm up to the structures of buildings made of combustible materials and 380 mm - up to the structures protected from ignition.

The cap is a "cap" above the pipe, which is designed to extinguish escaping sparks, protect the stove from rain and improve traction. It must be ensured that there are no large deposits of soot on it. However, the same applies to the chimney: if a thick layer of oily soot has formed inside it, this can provoke a fire, especially if the chimney is cracked and there are no protective elements. In addition, the soot contains air. Due to its insulating effect, the furnace does not heat up as much as it could, and it requires much more fuel.The chimney should be cleaned at least once every three months. Soot is formed more intensively if the walls of the chimney are not smooth from the inside, and the fuel is of poor quality - for example, polyethylene and other waste occasionally get into the stove. The safest and most efficient fuel is considered to be birch firewood that has been under a canopy for at least a year. To prevent the accumulation of soot, the stove should be periodically heated with aspen logs - this tree produces long tongues of flame that burn out the unburned substances that make up the soot. Cracks appearing on the chimney due to temperature changes must be erased in a timely manner. It is recommended to regularly whitewash the stove with lime - on a white background, you can immediately see where a dangerous crack is allowing smoke to pass through. The owners need to monitor the condition of the grate - the grate at the bottom of the furnace, through which air enters and ash is removed. Its burnout is also fire hazardous. Gasoline and other flammable liquids must not be used to ignite the stove, and the wood must not be too long and protrude out of the firebox.

Output

Do not be dismissive of pipes for sauna stoves. In fact, they make it possible to create the required temperature in the steam room and remove the burnt gases outside. Their quality and correct installation make it possible to regulate the climate in the steam room, save firewood and provide comfortable conditions in the sauna and steam bath.

Each of the materials is interesting in its own way and can be used. But remember that you must be sure to protect the red-hot elements from flammable ones, which are abundant in wooden steam rooms. In the video presented in this article, you will find additional information on this topic.

Reliable chimney pipes can be made from a variety of building materials. The choice of options is quite extensive. The easiest way is to make a chimney from steel, and cheaper from brick.

But if you need the most durable and safe system for removing stove fumes, then ceramics is the undisputed leader. It is expensive, but it will last for decades. The main thing when installing all options is to comply with construction and fire safety rules.

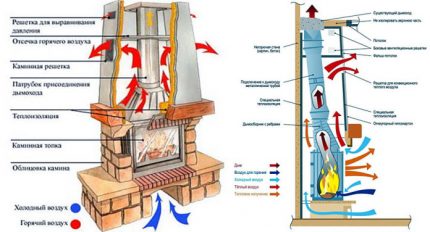

The principles of the chimney of the stove and household boilers

For the normal functioning of heating devices that generate heat when burning fuel, a chimney is required.

The flue-gas design provides oxygen supply, without which neither gas nor solid or liquid fuel can burn. In addition, smoke containing combustion products is removed through the chimney, which is a guarantee of the safety of the heating system - after all, smoke in the premises is deadly for humans. This gas exchange is called thrust.

Internal combustion boilers are equipped with coaxial chimneys, which create draft forcibly, removing smoke through one pipe and sucking fresh air through another. Wood-burning stoves and most household boilers operate on natural draft, which is formed due to the temperature and pressure difference in the heating device and at the outlet of the chimney.

The principle of the chimney is simple:

- the gases released during the combustion of fuel have a high temperature, low density and high pressure, and they become cramped inside the heater;

- smoke is directed to where there are no obstacles for it, that is, it moves in the direction where the pressure is lower, trying to fill a relatively free space, in addition, due to the low density, gases tend upward;

- if the chimney is arranged correctly, then at the exit from the chimney the cold air has a low pressure and is not an obstacle to the exit of hot smoke;

- since the low pressure area is located above the boiler, the smoke goes along the most convenient path - up the chimney to the street.

With open burners.

Quite bulky boilers, comparable in size to a fireplace and installed on the floor. The operating device consumes oxygen from the room. For stable operation, constant high-quality air exchange is needed.If not enough air enters the room, carbon dioxide escapes from the boiler inside the house, released during the combustion process.

For boilers with an open burner, it is recommended to use a vertical flue. Such a system is brought out at a right angle to the roof section, under which the boiler room is located.

With closed burners.

Such devices are installed on compact low-power boilers (up to 40 kW). Fuel combustion takes place in a sealed chamber. For such a boiler, a coaxial type chimney is optimal. The chimney is mounted in a horizontal plane.

Now it's time to study the requirements of GOSTs and SNiPs regarding heating equipment. With them, the algorithm for calculating chimneys for solid fuel boilers, as well as for gas boilers, will become a little more understandable.

When installing chimney systems, a dozen formulas are used, which take into account:

- physical processes of fuel combustion (movement of carbon dioxide, temperature outside and inside the pipe);

- the geometric characteristics of the house and the boiler (ceiling height, cross-sectional shape of the outlet pipe, channel area);

- constant values (for example, the acceleration of gravity when calculating the speed of gas movement or the coefficient of smoothness of pipes, depending on the material).

Accurate calculations for all cannot be done independently. It is better to turn to specialists, however, some conclusions can be obtained by going a cheaper and shorter way.

So, there are three ways of installing a chimney, depending on its distance from the ridge of the roof:

- The chimney is more than 3 m away from the ridge. In this case, its highest point can be installed below the ridge level by an angle not exceeding 10 °. An actual requirement if you want to save money on chimney elements.

- The chimney is at a distance of 1.5-3 m from the ridge. The height of the channel is equal to the height of the house, that is, the ridge and the upper point of the flue system are located at the same level.

- Between the chimney and the ridge - less than 1.5 m. The highest point of the chimney is at least 50 cm above the ridge.

We suggest that you familiarize yourself with: How to process the walls in the bath inside

We decided on the length of the chimney, it remains to calculate the sufficient cross-section for the pipe. This is done most accurately by the formula F = (AxB) / 4.19xC, where:

- F - section (sq. M);

- A - tabular coefficient from 0.02 to 0.03;

- B - boiler power (kW);

- С - chimney height (m).

The resulting value is compared with the tabulated value according to SNiP 2.04.05-91 and, if necessary, corrected upwards.

If we take the average characteristics from the aforementioned document, we get the recommended rounded section with a diameter of 200 mm for a 7 m high pipe that removes gas from a 16 kW boiler, or a diameter of 150 mm for a 32 kW boiler and a 20 m long outlet.

You can calculate the chimney for a gas boiler online on the website. If the design of the diverting system and the approximate scheme of its implementation are known, the calculations will take less than a minute.

Our experts are always ready to make the necessary calculations, give recommendations on the choice of chimney elements and voice their exact cost.

The design and installation of a smoke evacuation system can be delegated to professionals, but you will have to think about caring for it. Do not overheat gas and solid fuel boilers, do not use them at maximum power and clean them at least once a year. Then the selected chimney will last more than one decade.

You should know

- Using a long and straight pipe creates good traction. However, this will reduce the efficiency of the furnace, since the combustion products will not have time to give up all the heat.

- Install a deflector on the sauna stove pipe with your own hands, which will not only protect the chimney from snow and rain, but also help create the necessary draft. It is made of galvanized steel, preferably titanium or stainless steel. The opposite effect may also occur if the various “caps” and “umbrellas” are of the wrong configuration.In this case, smoke will begin to flow into the room in a strong wind.

- Make sure that the oven tube does not take all the heat from the oven gases. Otherwise, when the temperature of the combustion products drops to 150 ° C, condensation will begin to form in it.

- If you need to join together sandwich pipe or ceramic pipe elements, use a high temperature silicone sealant.

- Use the valve on the pipe carefully to keep carbon monoxide out of the room. Better to dismantle it altogether.

Chimney diameter table

To find the correct element, let's turn to the formula.

For the construction of a smoke exhaust structure, it is imperative to carry out calculations:

- total height and height relative to the roof,

- chimney inner diameter,

- generated thrust.

All these parameters are interrelated. The geometric dimensions of the chimney must be calculated in order to draw up its project, and the magnitude of the draft - to determine the efficiency of the chimney in the usual weather conditions for the area.

The main regulatory requirement for the size of the chimney is its compliance with the outlet of the heating device.

For a wood-burning stove or a domestic boiler that does not have a factory branch pipe, it is necessary to calculate the parameters of the internal section of the chimney, at which the chimney will have the required throughput.

To calculate the diameter of a round pipe or the width and length of a rectangular pipe, you need to find the area of its internal section. The calculation is carried out in several stages.

Vg = Mt * Vt * (tg 273) ÷ 273,

- where Mt is the fuel consumption per unit of time indicated in the accompanying documentation of the heater,

- Vт - the coefficient of smoke emission of the fuel used,

- and tg is the temperature of flue gases at the inlet to the chimney, usually indicated in the documentation for the heating device and equal to 120-150 ° C.

| Fuel | Smoke emission coefficient, m3 / kg |

| dry firewood, peat | 10 |

| brown coal in briquettes | 12 |

| natural gas | 12,5 |

| anthracite, coal | 17 |

S = Vg ÷ v.

The optimal speed is considered to be 1–2 m / s. At such a speed, soot and condensate do not have time to settle on the pipe walls, but the heat also remains in the room, and is not drawn out into the street.

For example, if the standard consumption for a wood-burning stove is 8 kg / h, then during conversion it is necessary to divide this value by 3600. Thus, the consumption will be 0.0022 kg / s.

D = 2√S ÷ 3.14.

S≥a * b.

To create a sufficient difference in pressure and temperature in the boiler and outside, the minimum required chimney height must be 5 meters. But in addition to the minimum value, it is necessary to calculate the height of the outlet above the roof.

These calculations take into account the type of roof, the location of the chimney in relation to the ridge of the roof, and the presence of closely spaced buildings or other tall objects.

| Features of the location of the chimney | height | |

| on a flat roof | without parapets and other roofing elements | 0.5 m above the roof |

| with parapets and other roofing elements | 1.2-1.3 m above the parapet | |

| on a pitched roof, with a horizontal distance between the chimney and the ridge | up to 1.5 m | 0.5 m above the ridge |

| 1.5-3 m | at the level of the ridge | |

| more than 3 m | 10º below the ridge | |

| relative to nearby buildings, structures, trees and other objects | 1.2-1.5 m higher than the highest | |

We suggest that you familiarize yourself with: Gray clay for the oven

Traction calculation

To check the operability of the chimney, which will be erected in accordance with the performed calculations of the height and internal section of the pipe, the draft is additionally calculated.

ΔP = hd * (ρw-ρg),

where hд is the height of the chimney above the heating device,

в– air density outside,

d - smoke density.

The chimney height has already been calculated, but the density of air and flue gases will need to be calculated. Depending on weather conditions, the air density indicator changes.

ρv = ρn * 273 ÷ tv,

where n = 1.29 kg / cubic meter - air density under normal conditions,

and tv is the ambient temperature.

ρg = ρn * 273 ÷ tg.

Δtg = (tg td),

where tg is the temperature of gases at the outlet of the heater, indicated in the accompanying documentation,

and td is the temperature of the smoke at the exit from the chimney.

td = tg-hd * V * √1000 ÷ Q,

where B is the heat transfer coefficient of the chimney, which depends on the material from which the chimney is made and the level of its thermal insulation.

| Chimney features | Heat transfer coefficient |

| uninsulated metal or asbestos-cement pipe | 0,85 |

| brick shaft with wall thickness up to 0.5 m | 0,17 |

| sandwich pipes | 0,34 |

If, after all the calculations, the draft level turned out to be in the range of 10-20 Pa, then the designed chimney will cope with its task and ensure uninterrupted operation of the heating unit. Otherwise, it will be necessary to increase the height of the chimney or equip the headrest with a deflector or a smoke exhauster to create an artificial draft.

Factory-made heating devices usually do not require serious chimney calculations - the main parameters are indicated in the accompanying documentation. A distinctive feature of calculations for household boilers is their simplicity.

- The height is determined according to general rules, taking into account the peculiarities of the location of the smoke exhaust structure relative to the roof of the house and nearby buildings.

- The diameter of the inner section of the chimney is selected in accordance with the capacity of the heat generating unit, without taking into account either the type of fuel or the volume of gases emitted. Since factory devices are manufactured according to manufacturing standards, all parameters have long been calculated and collected in a table.

| Maximum power of the device, kW | Required pipe diameter, mm |

| up to 3.5 | 140-150 |

| 3,5-5,0 | 140-200 |

| 5,0-7,0 | 200-270 |

| 7,0-10,0 | 250-300 |

When designing a chimney, you must choose the material to use. And the material largely depends on what kind of fuel will be used for heating. After all, the chimney is designed to remove the combustion residues of one fuel, and will not work with another. For example, a brick chimney works great with wood, but is not suitable for gas-fired heaters.

In addition, a correct calculation of the diameter of the chimney is required. If the flue gas vent is used for a single heater, the problem can be solved by reviewing the technical documents provided by the manufacturer of the appliance. And if several different systems are connected to one pipe, then to calculate the chimney, you need knowledge of the laws of thermodynamics, professional calculation, especially the diameter of the pipe. It is wrong to assume that a larger diameter is needed.

Swedish method

Among the different methods for calculating the diameter, an optimally suitable scheme is important, especially if the devices are low-temperature and long-burning.

Where f is the area of the chimney cut, and F is the area of the furnace.

Suppose, for example, the cross-sectional area of the furnace F is 70 * 45 = 3150 sq. cm, and the cross-section of the chimney f is 26 * 15 = 390. The ratio between the above parameters is (390/3150) * 100% = 12.3%. Having compared the obtained result with the graph, we see that the height of the chimney is approximately 5 m.

Important! This method of calculation is more suitable for fireplaces, because it does not take into account the volume of air inside the firebox.

Important! In the case of installing a chimney for complex heating systems, it is important to calculate the parameters of the chimney.

Exact calculation

To calculate the required section of the chimney, be sure to take into account all its characteristics. For example, you can perform a standard calculation of the dimensions of a chimney connected to a wood-burning stove. They take the following data for calculations:

- the temperature of the combustion waste in the pipe is equal to t = 150 ° С;

- the speed of passage through the waste pipeline is 2 m / s;

- the burning rate of wood B is 10 kg / h.

Here V is equal to the amount of air required for fuel combustion at a rate of v = 10 kg / h. It is equal to 10 m³ / kg.

Nowadays, the tables of diameters compiled for various chimneys are relevant, since many prefer to install ready-made pipe elements from various materials. In order to easily understand these various materials and learn how to choose the correct parameters, documents with regulatory data entered into special tables have been developed. The relevant parameters are listed here. To calculate the required dimensions, you can use these tables.

Attention! It should be remembered that the cross-section of the flue pipe must be greater than or equal to the cross-section of the internal channel of the heater.

The exact tables of the calculated diameters of the flue pipe for its correct operation are calculated in accordance with the technical parameters of all elements, in accordance with the recommendations of specialists, the materials of the flue duct, or using the diameter - power tables.

What is the combustion process

An isothermal reaction in which a certain amount of thermal energy is released is called combustion. This reaction goes through several successive stages.

In the first stage, the wood is heated by an external fire source to the point of ignition. As it heats up to 120-150 ℃, the wood turns into charcoal, which is capable of spontaneous combustion. Upon reaching a temperature of 250-350 ℃, flammable gases begin to evolve - this process is called pyrolysis. At the same time, the top layer of wood smolders, which is accompanied by white or brown smoke - these are mixed pyrolysis gases with water vapor.

At the second stage, as a result of heating, the pyrolysis gases light up with a light yellow flame. It gradually spreads to the entire area of the wood, continuing to heat the wood.

The next stage is characterized by the ignition of the wood. As a rule, for this, it must warm up to 450-620 ℃. In order for the wood to ignite, an external source of heat is needed, which will be intense enough to rapidly heat the wood and accelerate the reaction.

In addition, factors such as:

- traction;

- moisture content of wood;

- section and shape of firewood, as well as their number in one tab;

- wood structure - loose firewood ignites faster than dense wood;

- placement of the tree relative to the air flow - horizontally or vertically.

Let's clarify some points. Since damp wood, when burning, first of all evaporates excess liquid, it ignites and burns much worse than dry wood. Shape also matters - ribbed and serrated logs ignite more easily and faster than smooth and round ones.

The draft in the chimney must be sufficient to ensure the flow of oxygen and dissipate thermal energy inside the firebox to all objects in it, but not blow out the fire.

The fourth stage of the thermochemical reaction is a stable combustion process, which, after the outbreak of pyrolysis gases, covers all the fuel in the furnace. Combustion takes place in two phases - smoldering and burning with a flame.

In the process of smoldering, the coal formed as a result of pyrolysis burns, while the gases are released rather slowly and cannot ignite due to their low concentration. Condensing gases produce white smoke as they cool. When the wood smolders, fresh oxygen gradually penetrates inside, which leads to a further spread of the reaction to all other fuels. The flame arises from the combustion of pyrolysis gases, which move vertically towards the exit.

As long as the required temperature is maintained inside the furnace, oxygen is supplied and there is unburned fuel, the combustion process continues.

If these conditions are not maintained, then the thermochemical reaction passes into the final stage - attenuation.

How to clean the chimney?

It is considered that the pipe should be cleaned if the soot layer on its inner surface is thicker than 2 mm.If the soot deposits are very dense, a scraper should be used for cleaning in the first step. Then comes the hard brush with a long multi-link handle. The length of the latter is changed in accordance with the course of cleaning - from the top of the chimney to the bottom. So that as little soot gets into the room as possible, the furnace hole is covered with plastic wrap or a thick sheet during cleaning. Additionally, we advise you to prevent drafts and cover the furniture. Chemicals are also used for cleaning. Most often these are powders or "miracle logs". Burning in the furnace, such substances emit non-toxic gas, under the influence of which the soot lags behind the walls of the chimney. It should be borne in mind that it is very difficult to clean a heavily polluted chimney with "chemistry"; it is best to combine chemical and mechanical cleaning. The people recommend once a year to heat the stove or fireplace well with aspen wood. When aspen burns, the flame reaches a great height and burns out soot from the chimney. However, this advice is only suitable if there is not too much of it accumulated in the chimney. Otherwise, a fire is possible. In addition, you can burn potato peelings in the furnace: the steam generated during this effectively fights off soot deposits.

Ventilation ducts

The thickness of the walls of the channels in the outer walls of buildings is taken taking into account the design temperature of the outside air. The height of the exhaust ventilation ducts located next to the chimneys should be taken equal to the height of these pipes.

The dimensions of the indentation (cutting) at the stoves and smoke channels.

An indent (cutting) is an air space between the outer surface of a stove, chimney or chimney, on the one hand, and a combustible wall, partition or other building structure, on the other. Leave an air gap (indentation) for the entire height of the stove or chimney.

When arranging grooves in ceilings, an independent upsetting of furnaces and pipes should be ensured. The bearing of the grooves on the structural elements of the floor is not allowed. The groove height should be greater than the floor thickness by the amount of possible building settlement and 70 mm above the layer of the combustible backfill.

Horizontal cuts in the overlap plane should be performed simultaneously with the main masonry.

The gaps between the overlap and the groove should be filled with asbestos-doped clay mortar.

For walls or partitions made of combustible and hardly combustible materials, a deviation should be taken in accordance with Table 1 (see below), and for prefabricated furnaces, it should be taken according to the manufacturer's documentation.

The dimensions of the indentation (cuts) of the furnaces and channels, taking into account the thickness of the furnace wall, should be taken equal to:

a) 500 mm - up to building structures made of combustible materials; b) 380 mm - to a wall or partition made of non-combustible materials adjacent at an angle to the front of the furnace and protected from fire from the floor to a level 250 mm above the top of the furnace door:

- plaster on a metal mesh - 25 mm thick

- or a metal sheet on asbestos cardboard - 8 mm thick.

The dimensions of the sections should be taken in accordance with the mandatory requirements for "deviations" given in table 1:

Table 1. Dimensions of sections according to SNiP 2.01.01-82

| Furnace wall thickness, mm | Distance from the outer surface of the furnace or smoke channel (pipe) to the wall or partition, mm | ||

| Retreat | not protected from fire | protected from fire | |

| 120 | Open | 260 | 200 |

| 120 | Closed | 320 | 260 |

| 65 | Open | 320 | 260 |

| 65 | Closed | 500 | 380 |

| Notes: 1. For walls with a fire resistance limit of 1 hour. and more and with a flame spread limit of 0 cm, the distance from the outer surface of the furnace or smoke channel (pipe) to the partition wall is not standardized. 2. In the buildings of children's institutions, hostels and public catering establishments, the fire resistance of the wall (partition) within the retreat should be provided for at least 1 hour. 3. Protection of ceilings, floors, walls and partitions - should be performed at a distance, not less than | |||

The groove should be 70 mm more than the thickness of the ceiling (ceiling). Do not support or rigidly connect the oven cut to the building structure. In the walls covering the indentation, openings should be provided above the floor and at the top with gratings with a free area each of at least 150 cm2.

The floor in a closed indentation should be made of non-combustible materials and placed 70 mm above the floor of the room.

The distance between the top of the furnace ceiling, made of three rows of bricks, should be taken:

with a ceiling made of combustible or hardly combustible materials, protected by plaster on a steel mesh or steel sheet on asbestos cardboard 10 mm thick:

- 250 mm - for furnaces with intermittent fire

- 700 mm - for long burning ovens

and with an unprotected ceiling:

- 350 mm - for furnaces with intermittent fire

- 1000 mm - for long burning ovens

For ovens with an overlap of two rows of bricks, the indicated distances should be increased by 1.5 times. The distance between the top of the metal furnace and the ceiling should be taken:

- with heat-insulated ceiling and protected ceiling - 800 mm

- with non-insulated ceiling and unprotected ceiling - 1200 mm

Vertical cuts of furnaces and pipes installed in the openings of combustible partitions are performed to the entire height of the furnace or pipe.

| p / p | Furnace devices | Combustible structures | |

| Not protected from fire | Fire protected | ||

| 1 | 2 | 3 | 4 |

| Intermittent heating furnaces with the duration of the combustion: | |||

| 1 | - up to 3 hours | 380 | 250 |

| 2 | - more than 3 hours | 510 | 380 |

| 3 | Gas fired furnaces with a flow rate of more than 2 m3 / hour | 380 | 250 |

| 4 | Long burning heating stoves. Solid fuel kitchen stoves. Apartment type gas water heaters | 250 | 250 |

| 5 | Combined cookers with built-in boilers and separate apartment-type boilers | 380 | 250 |

| Note: Metal chimneys lay through combustible ceilings | |||

In the walls of the enclosed space above the furnace, two openings with gratings should be provided at different levels, each having a free area of at least 150 cm2. The indentation is left open or sealed on both sides with bricks or other non-combustible materials.

It is not allowed to tie the side walls of the closed retreat chamber with the main masonry of the furnace. The floor in the air gap is lined with bricks one row above the floor level of the room. The width of the indentation and the method of insulation of walls and partitions in the indentations are taken in accordance with the data given in table 3:

Table 3. Types and sizes of indentations

| p / p | Heating stoves | Types of indentation | Distances between stoves and combustible walls or partitions, mm | Methods for protecting combustible structures |

| 1 | 2 | 3 | 4 | 5 |

| 1 | Furnaces of apartment type with walls 1/2 brick thick with a furnace duration of up to 3 hours. | Open or closed on one side | 130 | Lime or lime-cement plaster 25 mm thick; asbestos cardboard |

| 2 | Also | Closed on both sides | 130 | Brick cladding with a thickness of 1/4 of a brick on clay mortar or asbestos-vermiculite boards with a thickness of 40 mm |

| 3 | The same with walls 1/4 brick thick | Open on both sides | 320 | Lime-gypsum plaster 25 mm thick; asbestos-vermiculite boards 40 mm thick |

| 4 | Heating stoves for long burning | Open | 260 | Also |

| 5 | Stoves and cookers with 1/2 brick walls with a heating duration of over 3 hours. | Open | 260 | The same, or cladding 1/4 thick brick on clay mortar |

| 6 | Also | Closed | 260 | Brick cladding 1/2 brick thickness |

| Metal ovens: | ||||

| 7 | - without lining | Open | 1000 | Plaster 25 mm thick |

| 8 | - with lining | Open | 700 | Also |

The distances from the upper planes of the stove floors to the combustible (or protected from fire) ceilings of the premises must be at least as indicated in Table 4:

Table 4.Distances from the top of stove floors to burned ceilings, mm

| p / p | Ovens | Ceilings | |

| Not protected from fire | Fire protected | ||

| 1 | 2 | 3 | 4 |

| 1 | Heat-consuming | 350 | 250 |

| 2 | Non-heat consuming | 1000 | 700 |

| Note: 1. The thickness of the upper floors of the furnaces should be at least three rows of bricks. With a smaller thickness, the distances between the top of the ovens and the ceilings increase accordingly. 2. Ceilings can be protected from fire | |||

The gap between the top of the thick-walled furnace and the ceiling can be closed on all sides with brick walls. In this case, the thickness of the upper ceiling of the furnace must be at least 4 rows of brickwork, and the combustion ceiling must be protected from fire.

Heat transfer when burning wood in a stove

There is a direct relationship between the temperature of burning wood in the stove and heat transfer - the hotter the flame, the more heat it emits into the room. The amount of generated heat energy is influenced by various characteristics of the tree. The calculated values can be found in the reference literature.

It should be noted that all standard indicators were calculated under ideal conditions:

- the wood is well dried;

- the furnace is closed;

- oxygen is supplied in precisely metered portions to maintain the combustion process.

Naturally, it is impossible to create such conditions in a home stove, so less heat will be released than the calculations show. Therefore, the standards will be useful only for determining the overall dynamics and comparison of characteristics.