Heading: Fireplaces Published on 31.01.2019 · Comments: · To read: 6 min

This type of heater has been invented for the safe heating of living spaces. It can be used both as a special furnace made of steel or cast iron, which is built into an existing furnace during its modernization or reconstruction, and as an independent independent heating device.

Features of closed cassette foci

Cassette fireplaces, the installation of which does not require significant time expenditure and serious physical effort, has the following distinctive features:

Descriptions and explanations

Installing a cassette fireplace with a closed hearth is the most effective and powerful. Such devices have high efficiency and can act as both the main and additional source of heating at home.

Open models do not differ in high efficiency and sufficient heat capacity. In this case, all the heating goes not into the walls of the structure, but into the air, and thus does not allow high-quality heating. These fireplaces play a decorative role.

The device of cassette fireplaces includes a chimney. This element has a small cross-section and a shortened size. This makes the use and placement of such a heating unit as convenient as possible.

Due to the shortened chimney, the products of combustion and decay are quickly removed to the street and do not linger in the inner part of the hearth.

The fireplace cassette is the main distinguishing feature of this design. This element is responsible for the uniformity and speed of heating and allows you to perform the fastest possible heating of the premises.

For even distribution of air masses, special fans can be used that distribute hot air masses.

Some models with fireplace cassettes are equipped with built-in air ducts that supply air at random. If necessary, such air ducts can be closed at the top with valves.

The price for such models is affordable compared to electric and wood-burning installations. The cost is due to the simple principle of operation and the minimum set of functions.

The most budgetary option will be a cassette fireplace, which is represented by a steel body and a simple door equipped with a horizontal mechanism.

Important: installing

do-it-yourself cassette fireplace, it is necessary to coordinate the installation and conduct of the chimney with special services and organizations. The location of this element in the space of the selected room should be as convenient and correct as possible. Only refractory materials are used as heat-insulating materials and connecting vertical and horizontal elements, and all seams and joints are well sealed.

In order to familiarize yourself with such heating installations in more detail and find out what constitutes a cassette-type fireplace, we also recommend viewing the photos collected in this article.

Formation of value and choice of interior solutions

A cassette-type fireplace can also have doors with a vertical folding mechanism. Such ovens have a higher cost due to their unique design, different shapes and finishes.

The best choice would be a heating unit with shutters equipped with fireproof glass.It can be completely smooth and transparent, as well as matte, refrain and colored, as well as mosaic. Many manufacturers equip their products with useful and important features. For example, due to the constant air circulation inside the structure, the glass can be cleaned on its own and is less prone to the occurrence of various contaminants.

For fire safety purposes, all structural elements

For storing firewood and briquettes, a small firebox is often used, which is provided for by the design of the portal.

Floor surface within

Interesting to know:

fireplace cassetteis responsible for the circulation of air masses around its axis. Thus, the cold air present in the room enters the inside of the oven and heats up, after which it goes back into the room.

Important: in order to

fireplace cassettescould intensively and evenly distribute the heated air over several rooms at once, during installation, it is recommended to install a special metal disk, which, when rotating, will additionally distribute air masses over the ventilation grilles.

Features of the operation of furnaces with heat exchangers

A fireplace insert with a heat exchanger is primarily a special mechanism that exchanges energy flows between two places. In this case, the heat exchanger itself does not have its own medium.

Interesting to know: in this way, thermal energy is transferred by the original source, up to the installed heat carrier. For work and proper functioning,

stove fireplace for summer cottages with heat exchanger, must have a certain internal structure, and the functioning itself occurs due to the laws of physics. When choosing a model, pay attention to what material the heat exchanger is made of. The most qualitative and durable are the hearths made of high-strength, environmentally friendly and refractory materials, when exposed to high temperatures, they do not expand, melt or deform.

Ceramic tiles make the structure more heat-absorbing and protected

The simplest models are affordable

If you wish, you can leave both the factory cladding and replace it yourself.

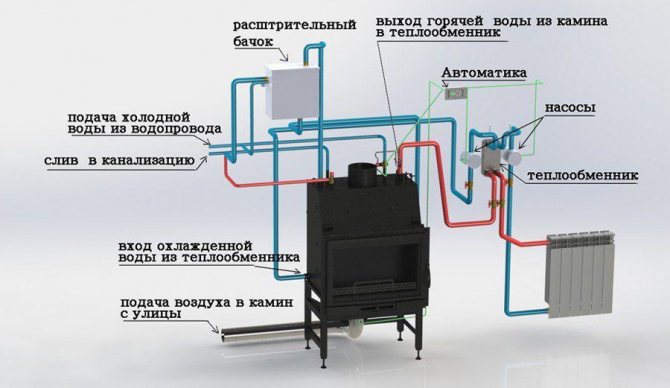

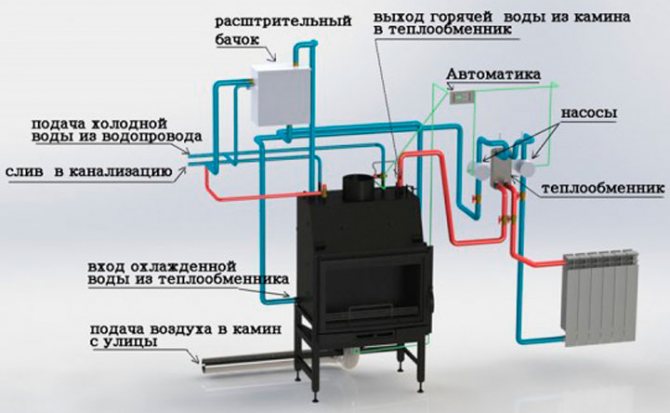

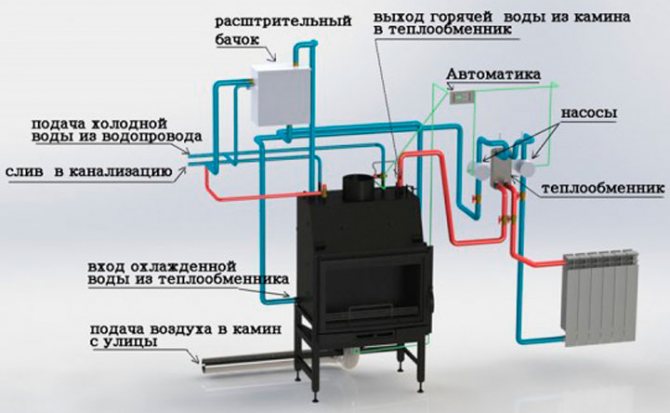

Important: the principle of operation of such furnaces is to fill a special tank with liquid, which heats up and flows through the pipes. In order to prevent oxygen bubbles from forming on the surface in working condition, it is very important to completely fill the tank with water even before heating and turning on the hearth. In this case, heated water flows to the top, while cold water remains at the bottom.

Such temperature drops, their separation of heat fluxes, allows the furnace to receive a higher temperature range at the outlet and efficiently release it into the surrounding space.

Advice: if you want to build this installation

do it yourself, you will definitely need to buy pipes. For these purposes, plastic or metal-plastic elements are categorically unsuitable, since they are not designed to pass hot water through themselves and, when used in such an environment, begin to emit carcinogens that have a negative effect on human health.

What does efficiency depend on?

Fireplaces stoves with a heat exchanger can have different power and efficiency. Much depends on the design features and functionality of the selected model. In general, the speed of heating and the quality of heating depends on:

- How significant is the difference in each temperature regime. The best heating is for those devices, the difference of which is maximum;

- The area of contact of the prior with the space of the house should be as large as possible;

- The materials used, cladding and coatings must not only be durable, environmentally friendly and fireproof, but also have good thermal conductivity and heat transfer.

The advantages of this heating unit are as follows:

- Structures, regardless of the materials of manufacture, have a long service life, even with daily use;

- The metal or cast iron used by the manufacturer does not allow the structure to overheat and give off excessive heat to the premises;

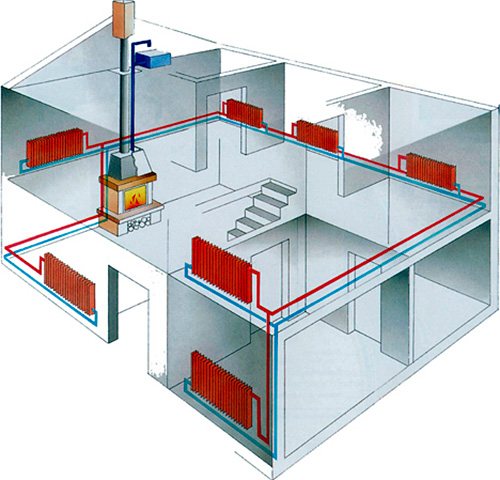

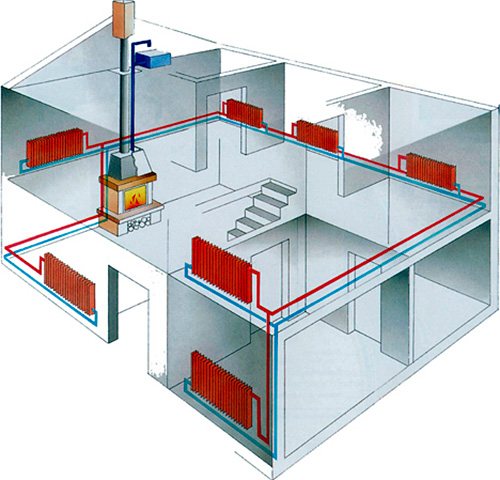

- The well-established heat supply system allows you to evenly and equally heat every room in the house, including rooms located on the second and third floors, if any.

These models are characterized by small dimensions and weight.

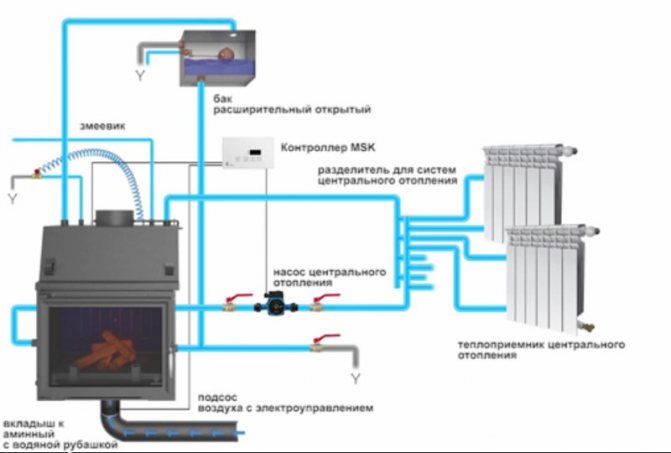

Diagram of the functioning of furnaces with a water circuit

Important: if you decide to use a model with a water heating circuit, it is important to remember that large doors with dimensions exceeding one meter are prohibited for installation and do not allow such a structure to work correctly and fully fulfill its heating function.

Varieties of cassette models

The fireplace cassette can be of a certain variety. The choice of a suitable model is made based on such parameters as power, size and heating footage:

- Cassettes for fireplace stoves can be installed in an open hearth. Such models are characterized by low efficiency and are designed to heat rooms with a small area;

- Heat cassettes for fireplaces are often installed in a closed-type combustion chamber. Such stoves are more efficient, and the cassettes themselves have a higher power and are intended for heating houses with a sufficiently large footage.

The most expensive are multifunctional models.

Corner cassette hearths take up little space.

Interesting to know: the most expensive

heat cassettes for fireplaceequipped with fireclay lining. Finishing with such materials significantly increases power and heat transfer. If necessary, both these and more budget cassettes can be easily replaced with similar ones.

We make a decision

Before making your choice and deciding in favor of such fireplaces, you will need to study not only the device of the cassette fireplace, but also its distinctive features, which include not only advantages, but also disadvantages:

- Manufacturers offer ready-made lines, the models presented in which differ not only in their size and method of placement, but also in style (from baroque to minimalism);

- Such ovens cool down quickly enough and are not able to continue heating when inoperative. In order for the heat to remain as long as possible after the end of the firebox, it is recommended to make a portal from a material such as brick;

- Some types of cassettes can be connected to special pumps and tanks that heat water and distribute it through the general heating system of the house. Such fireplaces are also classified as having a water circuit;

- Also, the adjustable mechanism can be not only water, but also air. In this case, heating the structure must be done after a short period of time, for example, every 4-6 hours;

- Due to the need for a chimney, such heating units can be placed exclusively in private houses or on the last floors of multi-apartment high-rise buildings;

- The flue duct in such models is always equipped with a glass damper. Due to this, the efficiency and speed of heating with such methods is significantly increased.

For finishing the frames, you can use

The closed combustion chamber has a higher heat capacity.

Model complete with support legs without portal

Built-in cassette hearth

Important: the installation of such foci is impossible without a chimney. Accommodation and other requirements are specified in more detail in the PB.

The video in this article will help you learn in more detail about the advantages and disadvantages of such combustion chambers.

We carry out installation

At the first stage, it is necessary to take care of the chimney. Installation of the hearth is carried out on almost any floor, and additional reinforcement is not required. If the mass of the fireplace plays an important role, you can find out from the attached documentation.

Assembly and installation instructions:

- The casing and the main part of the fireplace should have a small gap. To separate the outer box from the pipe itself, the surface must be insulated with refractory materials (mineral or basalt wool is used);

- The diameter of such a chimney has a smaller pipe cross-section than in standard classical furnace units. The number of rotary, horizontal elements and layouts in this case can also be increased;

- To install the hearth at the first stage, you will need to make the floor covering even. This is necessary to give the structure stability. If the floor is made of wood, it should be partially reinforced with concrete;

- The floor and wall surfaces located near the combustion chamber must also have an appropriate finish with heat-resistant materials. As additional protection, it is recommended to cover the floor and walls with a special varnish or refractory impregnation;

- With the initial presence of a chimney with a suitable cross-sectional diameter, it can be used to connect it. Before use, a complete cleaning of the inside is carried out and the tightness of both the entire structure as a whole and each individual joint and section is checked;

- Fixation of each element is carried out by means of cuffs and couplings;

- For fire safety purposes, heating elements should not come into close contact with walls, portal and other elements;

- The walls are additionally insulated, and the framing is made of plasterboard or any other heat-resistant materials.

The advantages of fireplace stoves

Fireplace stoves combine the positive qualities of these heating devices, while they are devoid of their inherent disadvantages. What are the main differences between a traditional stove and a fireplace?

- The oven takes a long time to heat up, but is capable of accumulating heat and for a long time to radiate radiant energy from the walls of the furnace into the surrounding space. The heat from the fireplace immediately spreads throughout the room, in which it is installed, but after stopping the firebox, it quickly cools down, and the temperature in the house decreases.

- Firebox heating ovens usually performed with blind door small size, this reduces the likelihood of smoke and improves traction. Fireplace insert - open, occupies about half of the area of its facade. With an improperly folded chimney or bad weather conditions, reverse draft and smoke can enter the room, which leads to an unpleasant odor, deposition of soot and soot on household items.

- The smoke exhaust system of the stove has a complex design: the smoke in them passes through numerous channels, giving off most of the heat to the body of the stove. It comes out of the pipe practically cooled down. Chimneyalmost straight in the fireplace, the smoke is retained only under the arch, so its outlet temperature is much higher, and heat removal is worse.

- Efficiency heating ovens on average is 60-80%, near fireplaces - no more than 50%.

- The stove is not too decorative, and you can give it an aesthetic look only with the help of finishing. Fireplace even by itself - interior decoration, and flames decorate it even more.

In the models of industrial production, all the features of these heating devices are taken into account, the most significant disadvantages are eliminated and the advantages are emphasized. As a result, modern fireplace stoves have a number of advantages:

- high efficiency - up to 80%, and when connecting a heating water circuit - up to 92%;

- a sealed firebox with large glass that allows you to observe the flame, but does not allow smoke to enter the room;

- smoke ducts with a smoke circulation and a heat exchanger, which improves heat removal and its transfer to the room;

- aesthetic appearance, there are models decorated with ceramic panels or metal forging;

- light weight - they can be installed even on wooden floors laid on logs, without erecting a foundation;

- small dimensions with high power - fireplace stoves do not take up space, which is very important for small houses;

- the ability to connect a water circuit allows you to heat all the rooms of the house and keep warm for a long time, as well as avoid daily temperature fluctuations;

- low price compared to the cost of materials and work for the construction of brick stoves or fireplaces;

- easy and quick installation that you can do yourself.

In addition, modern fireplace stoves can have a number of other useful features:

- hob;

- a glass cleaning system that does not allow it to darken, as well as a long-term burning mode, which is very popular among consumers.

The reviews of the owners of such stoves are unambiguous: stoves can heat a residential building for a long time and effectively, without causing problems and hassle to the owners.

Features of choice, do-it-yourself installation and operation

The power of the fireplace is selected based on the heating area

A fireplace equipped with a system with a circuit and a boiler is suitable for hot water heating of all rooms in the house. It is connected to the system through pipes in the firebox. When buying equipment, you need to consider:

- Features of safe installation and connection to communications.

- Power. For a house with a total area of 100 m2, models from 7 kW are suitable; in rooms less than 80 m2, low-power equipment is acceptable. It should be borne in mind that 1 kW of power goes to heating 10 m2 of the dwelling.

- Material. Steel units at an inexpensive cost are more prone to corrosion. Cast iron ones accumulate heat for a long time, but their price is more expensive.

- The presence of a long burning mode. Such devices are energy efficient, have an efficiency of 75-90%.

- Complete set. A standard water fireplace is equipped with an ash pan, pipes, chimney, hob, heat-resistant flap.

- Possibility of pouring antifreeze into the system. Glycerine solution, ethylene glycol and propylene glycol do not freeze at -30 degrees.

All technical parameters are in the manufacturer's documentation.

DIY installation

Integrated water circuit inside the fireplace

The compactness and low weight of the fireplace equipment excludes the construction of a massive foundation. It is enough to make a flooring of sheet material, lay out tiles or other fire-resistant coating. Self-installation is done as follows:

- Removing the original packaging and checking the structure for integrity.

- Level control of the finished coating.

- Removal of the branch pipe on the same level with the chimney duct.

- Assembly of gas outlet elements.

- Installation of grate, ash pan, grate and sash.

- Sealing the place where the hearth is connected to the chimney, as well as joints and seams.

Single-circuit pipeline is insulated.

Operating rules

The chimney must be cleaned twice a year to avoid fire

When using fireplaces with a hydraulic heat exchanger, a number of requirements must be adhered to:

- Cleaning smoke ducts from soot 2 times a year.

- Regular, as it accumulates, ash removal from the furnace and ash pan.

- Draining the pipes if the system is not used in summer.

- Preliminary inspection of radiators, tank, pump, fittings and filters before starting heating.

- Cleaning the glass door with special products.

- Filling the heat exchangers with water to prevent burnout.

- Warm water supply in preheated oven mode.

- Using a circulation pump with bypass to improve system efficiency.

In winter, it is allowed to pour antifreeze into communications.

Review of popular models

There are many models of stoves and fireplaces from different manufacturers on the market, and it is easy for a buyer who wants to buy them to get confused in the characteristics and descriptions of these devices. Below is an overview of the most popular, according to the reviews of the Russian consumer, models.

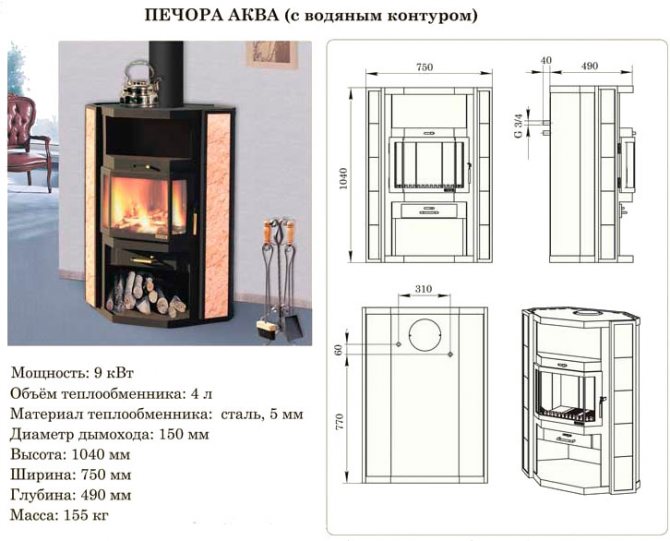

AQUA fireplace stoves

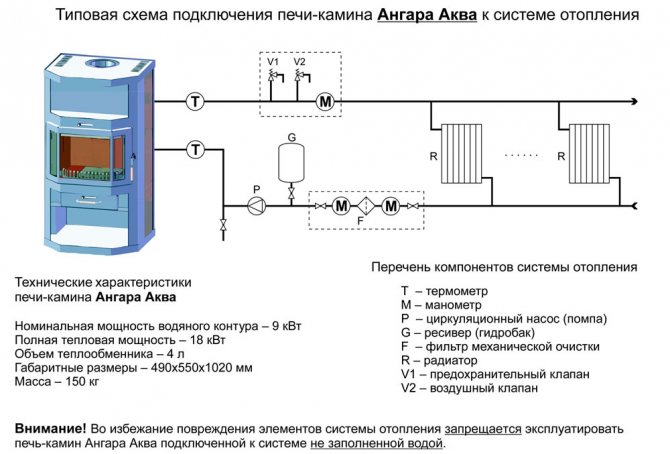

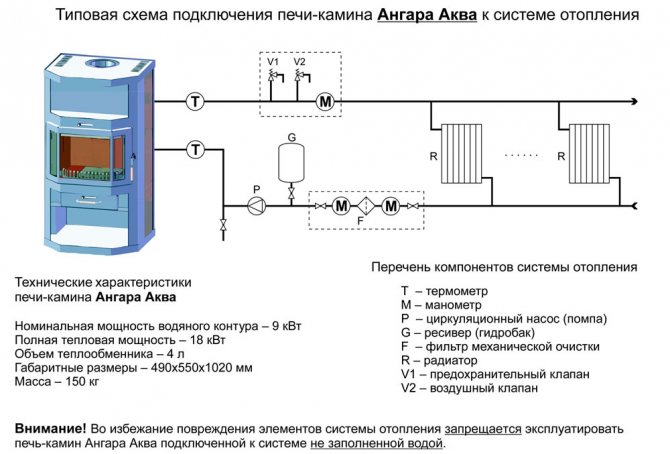

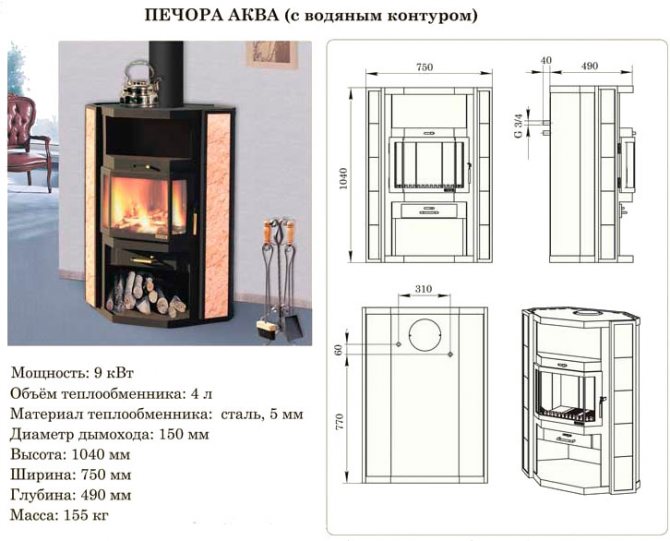

The line of fireplace stoves with a water circuit from the META company is represented by the Angara, Pechora, Varta models, which differ in thermal power, shape and appearance, as well as the installation method.

Hangara AQUA with a water circuit has the following characteristics:

- heating power radiated by the stove during the firebox - 13-16 kW;

- heating power of the connected heating system - 5-7 kW;

- steel heat exchanger;

- wall execution;

- the side walls are lined with ceramics;

- panoramic heat-resistant glass;

- outlet diameter of the flue pipe - 150 mm.

Pechora AQUA differs from Ankara in the shape of the body - it is made compressed prism... Furnace power 13 kW, heating system - up to 5 kW.

Warta AQUA additionally equipped with a hob, a closing lid. Power 13/5 kW, firebox lined with fireclay. The door is straight, equipped with glass and heat-insulated handles, resistant to heat.

A feature of the AQUA fireplace stoves with a water circuit from the META company is the ability to connect only to systems with forced circulation.

Fireplace stoves Bavaria

The Bavaria stoves, which have received recognition from the Russian consumer, are produced in both wall and corner versions, and can also be equipped with a stove for cooking and heating food.

Eco fireplace Bavaria, wall-mounted with a heat output of 12 kW, it is equipped with a 6 kW heat exchanger, which can be connected to a system with any type of circulation. The connection diagram is shown in the figure.

Which heat exchanger for a sauna stove is better

In addition to heating the steam room to the required temperature, a large amount of hot water is needed for a comfortable visit to the bath or sauna. They solve the problem in different ways: by installing a boiler or an instantaneous water heater. Judging by consumer reviews, a heat exchanger for a sauna stove is considered the most economical and heat-efficient solution. The device, depending on the design, provides the needs for hot water supply and allows you to fully heat the adjacent rooms: the washing room and the dressing room.

How does a heat exchanger installed in a sauna stove work?

The device of the furnace with a heat exchanger has proven itself so well that various options for the design of heat removal have appeared, with varying degrees of efficiency. The most common:

- Classic coil.

- Built-in flat heat exchanger (similar to two hollow trays connected to each other).

- Samovar heat exchanger installed on the chimney.

The water jacket surrounding the combustion chamber is used extremely rarely and is found in only 1-2 models of factory-made stoves. Meanwhile, bath stoves with a heat exchanger have become the subject of consumer discussions. Some argue that the application is not practical, others, on the contrary, indicate convenience and comfort during operation. What does a built-in or samovar heat removal device give?

- A heat exchanger in a sauna stove is needed to obtain hot water for washing. This task was the main one in the design of the structure.

- The possibility of heating in a bath from a stove with a water circuit - in fact, a metal stove becomes a kind of heating boiler. During the furnace, enough heat is generated to warm up the coolant and heat the required volume of DHW water.

The principle of operation depends on the device used. Efficiency is determined by several parameters:

- Reliability.

- Sufficient heat dissipation.

- Ability to work without using a heat exchanger.

By its design, it is possible to divide all water heating devices into built-in and built-on ones (samovar type).

Built-in heat exchanger

Stoves for a bath with a water circuit for heating and the needs of hot water supply began to appear after ordinary water heat generators received good reviews. By its design, furnace equipment with an integrated water heating circuit is divided into several classes:

- The coil is the simplest device used in classic solid fuel boilers. A bent metal tube is located inside the structure. The shape is different and depends on the features of the internal design of the furnace. The coil is positioned so that the flame does not directly affect it, but heating is carried out by means of flue gases.

- A flat heat exchanger is a more complex device than the previous one. A flat heat exchanger for a sauna stove looks like two hollow plates connected to each other. In terms of thermal efficiency, the design surpasses the coil used in modern models of furnace equipment.

- Built-in tank - a separate container is made in the furnace, installed on top of the combustion chamber. The built-in horizontal heat exchanger heats up quickly and maintains the temperature as long as the oven remains hot.

- Water jacket - represents a cavity surrounding the entire combustion chamber and smoke channels. The design is often used in the production of solid fuel boilers, but has not been widely used in the manufacture of sauna stoves.

The principle of operation of an integrated heat exchanger in a sauna stove is as follows. The spiral or plate is heated by flue gases, the temperature of which reaches 450-500 ° C. When heated, pressure arises, forcing the coolant to circulate in the heating system. In schemes where an indirect heating boiler is used, the DHW is heated by heating heat.

Samovar type

Installing a heat exchanger on a sauna stove is a budget solution to the problem of hot water supply and heating. The hot water device is made in two ways:

- Coil - a coil made of aluminum or copper is installed on the chimney. For systems with natural circulation, up to a storage tank or water distribution taps, the dimensions of the coil should not exceed 3 m. The optimum dimensions for a heat exchanger with forced circulation are 5 m.

- Samovar-type heat exchanger device - experts agree that it is this design that is optimal for a bath. The hot water for the shower is prepared gradually to prevent the liquid from boiling.

The movement of water in a samovar-type heat exchanger occurs according to natural physical laws. The heated liquid rises upward, pressure is created in the container. The optimal volume of the samovar-type heat exchanger is chosen so that the water reaches the required temperature after 2-3 hours of intense combustion. The design is optimal for providing hot water supply.

Which heat exchanger to choose for a stove in a bath

When choosing a heat exchanger design, the advantages and disadvantages of each type are taken into account. The selection of a suitable device is influenced by the intended purpose and the required performance:

- Sauna stove with built-in heat exchanger - used for simultaneous heating and hot water supply. Long-burning furnaces operating in gas generation mode cannot provide the necessary heat transfer when installing a hinged tank. The reason for this is that the flue gases have a lower heating temperature. If you plan to install a long burning stove, there is no alternative to the built-in coil or plate design. Effective heating in the bath is possible only from a stove with a built-in heat exchanger.

- A stove for a bath with a samovar-type water heater is distinguished by high performance of hot water, but for heating, a tank worn on the chimney is not very suitable in terms of technical characteristics.

When choosing what to install, a built-in heat exchanger or a samovar type, take into account the peculiarities of their operation. For simultaneous heating and hot water supply, a coil, plate heat sink or water jacket is better suited. Exclusively for hot water supply, it is better to install a samovar-type water heating tank.

How to install a heat exchanger in an oven

Built-in heat exchanger - mounted at the factory, drum type - installed on the chimney. Tanks are made of different internal diameters, therefore, installation does not require much effort and is carried out simultaneously with the output of the chimney. Factory containers are supplied with a capacity of 20 to 80 L. The difficulty lies in connecting the batteries from the oven. On the body there are special outlets for the supply and return of the coolant, to which the pipes of the heating system are connected. The work is performed in compliance with the following recommendations:

- Pipes for connection to the heat exchanger. The coolant temperature often exceeds 85-100 ° C. Plastic, with such heating, can deform, so it is not used. For the heat exchanger, steel pipes must be used, copper is suitable.

- Connecting batteries - with natural circulation, the length of the pipe from the furnace body should not exceed 10 m.

- Installation of circulation equipment - forced circulation heating systems are installed for large heated rooms, often used in industrial baths.

- The diameter of the heat exchanger pipe - manufacturers clearly prescribe in the technical documentation the size and pitch of the thread, which facilitates the selection of the pipe for installation. The diameter of the pipeline in the heating system, if necessary, can be increased, but not reduced.

It is forbidden to use a stove with a built-in heat exchanger without water. The liquid serves as a heat-dissipating element that cools the circuit. Without a coolant, after just a few furnaces, deformation and burning of the metal is observed, after which the furnace becomes unusable.

Which sauna stoves are better - with or without a circuit

Traditional sauna stoves did not use a heat exchanger in the usual sense of the word. A built-in tank with a bottom or top connection was installed in the stoves, designed to heat water. Later, a removable heat exchanger appeared, installed on the chimney. Over a certain period of operation, consumers were able to highlight the strengths and weaknesses of a stove with a water heating circuit. You can find out about them by carefully studying the reviews about heat exchangers.

- Noise in the heat exchanger - a few months after installation, there is a hum during the kindling of the furnace. This happens due to the overgrowth of the coil. The narrowing of the pipe diameter leads to rapid heating and boiling of the coolant, which causes noise.

- Installation requirements - with natural circulation of the coolant, for normal operation of the furnace, it will be necessary that the pipes in the heating system be installed with strict observance of the slopes. It is quite difficult to remove the airlock from the pipes; you will have to heat the stove for several hours at maximum heating.

- Regular maintenance requirement. Heating water through a heat exchanger is associated with the need to clean and flush the internal cavity of the coil at least once every heating season.

In winter, after each visit and kindling of the stove, it will be necessary to remove water from the internal heat exchanger, which also causes inconvenience. Bath stoves with a water circuit are widely used for industrial purposes.Household models are not widespread, with the exception of samovar-type water heaters installed on a pipe.

The popularity of models with an integrated circuit is limited by the fact that they cannot work without a coolant. The domestic buyer prefers traditional stoves and modifications with a chimney-mounted water heating tank.

avtonomnoeteplo.ru

Features of the selection, installation and operation of fireplaces

In order for home heating to be effective and safe, when buying, installing and using industrial stoves with a fireplace effect, you need to take into account some of the nuances:

- selection of power;

- body and heat exchanger material;

- conditions for safe installation;

- rules for connecting to the heating system;

- requirements for the arrangement of the chimney;

- selection of firewood and other types of fuel;

- proper firebox, cleaning and do-it-yourself maintenance.

You should also follow the manufacturer's recommendations specified in the documentation for the oven. Only in this case will the operation of the furnace be safe and the service life will be long.

Choice of oven power

The most important parameter, which must be considered before buying a certain model - heat output of the heating unit... It is measured in kilowatts, and it is generally accepted that 1 kW of stove power can heat 10 m² of house area.

However, it should be borne in mind that the manufacturer tests the stove in conditions close to ideal, and when using insufficiently dried wood, its power may decrease by a third. Therefore, to use a stove with a heating circuit as the only source of heating, it is better to buy a model with a small power reserve.

Steel or cast iron?

Heating stoves-fireplaces are steel and cast iron. Steel furnaces are cheaper, lighter, but more susceptible to corrosion. Models made entirely of cast iron have increased durability, corrosion resistance, but at the same time they are much heavier, they are afraid of sudden changes in temperature, from which they can crack.

The best option is combined models, in which the body and slightly heated elements are made of steel, and the elements of the furnace, grates and doors that are exposed to strong overheating are made of forged cast iron. They are not afraid of prolonged exposure to high temperatures and are suitable for constant use, and with intermittent heating, the condensate formed in the pipes does not cause corrosion.

Installing a fireplace stove

Due to their low weight, industrial models do not have special requirements for floor preparation, they do not need a separate foundation. The only requirement is the finishing of wooden floors with non-combustible materials.: sheet metal, ceramic tiles or fire-resistant types of coating, which can be done by hand at a minimum cost.

Video: installing a fireplace stove Bavaria

Heating connection

Most industrial fireplace stoves can be operated with or without a connected water circuit. Moreover, their service life does not differ significantly.

If the fireplace stove is connected to a water circuit, under no circumstances should it be operated with the heating medium drained! This will lead to damage to the heat exchanger and the system itself! Furnaces with a water circuit can be used in systems with both natural circulation (gravitational) and forced (using a pump). At the same time, the connection diagrams to the heating system do not differ from traditional ones.

Features of connecting a furnace with your own hands to a gravitational heating system:

- Immediately after leaving the heat exchanger, a booster manifold is performed, which raises the coolant to the upper point of the system.

- An open or membrane-type expansion tank is installed at the top point.

- For the main pipe, a minimum diameter of 32 mm is required; with a smaller pipe section, the hydraulic resistance of the system increases, which leads to a deterioration in circulation.

- The slope of the main pipe should be at least 5 cm / 1 m, otherwise the movement of the coolant will slow down, the temperature in the system will be uneven, and heating will be ineffective.

- The pipe bends to the radiators should have a diameter of 16-20 mm. Radiators cut parallel to the line in a lower or diagonal pattern.

When using a forced system, the requirements for its installation are much less:

- The expansion tank can be installed in any convenient place, usually it is placed on the return pipe, after the circulation pump.

- The radiator connection diagram can be any.

- It is not necessary to withstand a significant slope of the main pipe.

- With the help of automation, you can set the speed of movement of the coolant, as well as the return temperature, which will avoid the appearance of condensate in the firebox.

The choice of a heat carrier is an equally important step, which depends on the operating mode of the furnace.... For houses with permanent residence, it is more convenient to use purified water - it is cheaper, practically does not cause corrosion in a closed heating system, it can be easily topped up from the water supply if necessary.

If the house is used intermittently, the use of water during the winter can cause the system to freeze. In this case, the water expands and damages the elements of the system: pipes, radiators, fittings, which will subsequently lead to leaks.

In this case, you can use special antifreezes, or install an electric boiler parallel to the oven, operating in the mode of automatically maintaining a plus temperature at the level of 5-10 ° C.

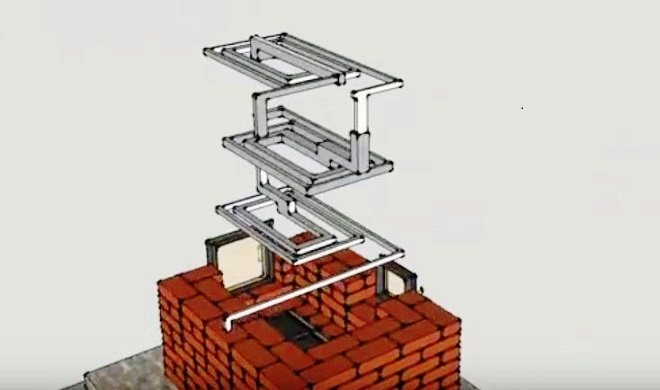

Chimney requirements

For safe operation, fireplace stoves require strict adherence to the rules for installing a chimney... For these heating devices, experienced stove-makers advise to install chimneys made of ceramics or stainless steel of the "sandwich" type.

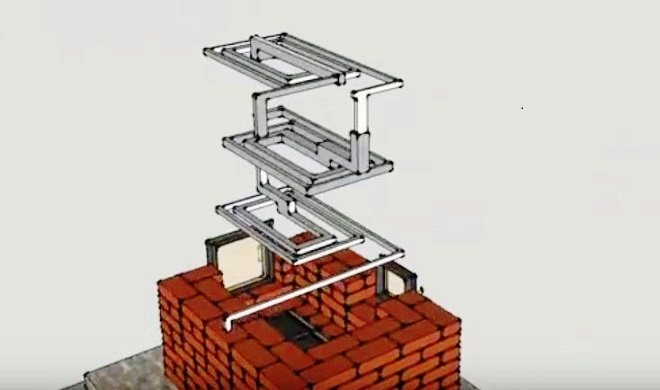

Ceramic chimneys are a prefabricated structure of ready-made blocks for various purposes. The flue gas duct consists of glazed ceramics, which eliminates the swirling of smoke and the deposition of solid sediment. It is placed in a hollow foam concrete block and insulated with basalt mats, heat-resistant at temperatures up to 1000 ° C. The elements are connected to special glue (blocks) and sealant (ceramics).

Metal sandwich chimneys look like two pipes of different diameters, inserted into one another and insulated with basalt. The inner tube is made of stainless steel, the outer one can be made of galvanized iron. The blocks are assembled with a heat resistant sealant.

Features of ceramic chimneys:

- long service life - at least 25 years;

- the smooth inner surface practically does not allow soot to settle;

- high fire safety and resistance to burnout;

- heavy weight, which requires installation on a separate foundation;

- high price.

Features of stainless steel chimneys:

- quickly assembles with his own hands;

- the price is much lower than ceramic;

- does not require installation on a foundation;

- with constant overheating, they can burn out, therefore regular revision is necessary.

Video: comparison of different chimneys

The choice of the type of chimney is a matter of preferences and financial capabilities, however, when installing it, several prerequisites must be observed.

- The diameter of the chimney should ideally be equal to the diameter of the flue outlet, or pipe. You can't narrow it down! It is possible to expand the diameter of the chimney, but not more than 30%, while it is necessary to use special elements of the chimney.

- The chimney must be equipped with a gate or valve that blocks the flow of cold air into the furnace and regulates the draft.

- The total length of the horizontal sections should not exceed 1 meter, otherwise the thrust will be much worse.

- The total height of the chimney and chimney must not be less than that indicated in the passport for the stove. Usually this value ranges from 5 to 8 meters.

- All passages through walls and ceilings are made with the help of special elements that ensure their thermal insulation from combustible structures.

- It is necessary to equip the chimney with cleaners that provide access to any part of it, as well as a condensate collector.

Heating system device

In order to qualitatively consider the principle of energy conversion, the entire heating system should be divided into two conditional blocks: the heat exchanger and the line itself.

The heat exchanger for the fireplace can be made in the form of a pipe through which water flows. To increase the efficiency of heat transfer, it is necessary to increase the area of the heat exchanger located in the core (furnace zone), therefore, the pipe is made in the form of a coil, radiator or other version of the labyrinth. This unit, even in brick fireplaces, is made of cast iron or steel. The cast iron coil is capable of perfectly transferring heat to the circulating fluid and withstands exposure to temperatures. But casting from cast iron significantly increases the cost of making a fireplace, so a steel structure is an alternative.

The constant temperature drop and the effect of an open flame on a steel heat exchanger leads to a rapid failure of the latter. Considering all the nuances, two different schemes for transferring heat from flame to water are used.

- The first circuit is called single-circuit. The cast iron coil is located in the firebox and is heated by direct contact from the flame. Water enters the heating and water supply system, and cold water is constantly supplied to replace it.

- The second scheme is double-circuit. It excludes direct contact of the coil with an open flame. In the body of the fireplace, a cavity is made throughout the entire volume, which is called a jacket. It is filled with water. During the operation of the fireplace, the water in the jacket constantly maintains a high temperature, and already in this jacket there is a coil made in a form convenient for the design. Energy is transferred first to the water in the jacket and then to the water in the circuit. This method implies an extra intermediate link, which leads to a longer heating of the system, but this increases the life of the fireplace.

Option for placing the system in a country house

The fireplace circuit can be included in the heating system, as an addition to the main one, and as the main one. According to the device, the system is divided into two types: open (with natural circulation) and closed (with forced).

- In an open heating system, the fluid flow is ensured by the initial potential energy that it receives during convection. The heated water rises up the riser and flows along the entire line, made at a slope. This system uses only metal pipes. Its installation is carried out by experienced workers, since any mistake will lead to stagnation of the liquid in one specific place.

In order for the water to expand when heated, a branch is constructed at the very top of the system in the form of an expansion tank. Such a heating system could be called less expensive, but today the cost of metal pipes is so high that it makes this statement false.

- The closed system is assembled from plastic pipes and requires the installation of a pump for forced circulation of water. The idea behind such a system is that as the fluid expands, pressure increases. This leads to an increase in the boiling point. Such water can be heated by more than 100 ° C degrees.

Good to know: Fireplace complex, which includes a barbecue, brazier, smokehouse, cauldron and oven

Of course, in practice, such indicators are not allowed, however, it has been noticed that the system under pressure is more effective. The expansion tank is also present, only it is closed, and there is a rubber baffle inside it. It zones the tank into two parts: the first compartment is for water, and the other part contains pressurized air.

A small but very useful device in the household

In order not to be distracted from the question of the fireplace, it should be noted that fireplaces with a heat exchanger can be included in an open and closed system.

Fireplaces with water heating

Heating of premises is probably the main characteristic that gives a sense of convenience to the residents. Different heating systems are designed to heat the home in the most comfortable and harmless way, while maintaining the comfort and beauty of the interior. One of the popular options is a water fireplace.

Wood-fired water fireplaces can be used as the main or backup heating equipment. In the case when the fireplace is considered the main heater, a special heating system is being developed, which can, in addition to heating buildings with an area of 400 square meters, supply it with hot water for traditional needs or a floor heating system. A water fireplace can also act as an additional source of heat in an already installed heating system. In this case, if the fireplace is melted, the automatics will turn off the remaining heat sources, which is achieved by monitoring the temperature of the coolant in the system with special sensors. In the warm season, when the need for heating disappears, the water fireplace can be used exclusively for obtaining hot water. A water fireplace can significantly increase the efficiency of using the heat generated during fuel combustion. At the same time, a water fireplace remains a fireplace and allows you to enjoy the view of an open flame. A considerable advantage of such devices is that it does not require the combustion of special fuel, but allows the use of traditional firewood.

There is a metal firebox in the fireplace device, in which fuel is burned. Flue gases wash around heat exchange tubes, inside of which water circulates. This water is heated by hot gases, which in turn are cooled. To ensure the normal circulation of the coolant in the heating system, the necessary piping elements are connected to the heat exchange tubes of the fireplace to supply hot water to the heating system. The appearance of the fireplace is complemented by a special portal, the external decoration of which is selected so that the fireplace becomes a worthy element of the interior of the room in which it will be installed. The power control of the fireplace is carried out by adjusting the air flow through the fireplace blower.

Oven location

If the stove is in a rest room, then when it burns in the cold season, heat will be transferred in the room naturally. If the heat from the stove is not enough, then a radiator is installed in the room. The system is equipped with a distribution manifold from which 2 pipes emerge. One leads to the steam room, the other to the relaxation room.

Heat begins to be supplied immediately when the oven heats up. On the 2nd pipe, a tap is provided that can turn off the steam heating. This is necessary so that in the summer it is comfortable to relax in the room. For the summer they equip a veranda near the bathhouse. An intense heat is emitted from the oven. After the steam room, you can go out into the fresh air.

If the bath is used in the summer, but the steam line does not have an additional branch, then it is recommended to slightly alter the stove. If it is brick, then 3 tiers are provided in the firebox. The distance between the tiers is up to 40 cm. In winter, firewood is placed on the lower grate. The heat from the stove will go to the dressing room.

In the fall, firewood is placed on the second tier. In the summertime, firewood is placed on the upper tier. In this case, all the heat will enter the heat exchanger and further into the main line. Heat will not enter the lounge. Doors to the firebox are made double. This additionally isolates the dressing room from the firebox.

If the oven is in the house. It was built to heat living quarters, then a separate circuit is displayed for the bath. A crane must be installed on it.When it is opened, steam will enter the bath and heat the steam room and the rest of the rooms.

If the tap is closed, then the heating in the bath is turned off. It is necessary to provide for a separate disconnection of the circuit that runs through the living rooms of the house. In this case, the sauna can be heated in the summer as well. Otherwise, the steam will go along the highway, which is located in the house.

We recommend: Which wood stoves are suitable for steam heating?

In order not to make an additional circuit for obtaining hot water, a separate circuit is brought out in the condensate storage tank. There will be enough water for the needs of vacationers. You should always make sure that there is water in the container. The minimum level is 10 cm. In this case, the system will not stop working, the coolant will circulate normally.

When installing the stove, consider the material and source of heating. A wood-fired brick oven takes a long time to burn, but it also cools down for a long time. A unit with a metal body heats up in a short time, but also cools down quickly.

Fuel varies. The sauna will have a pleasant smell if you use firewood as fuel. They purchase gas-fired furnaces. Gas and firewood will make the heating in the bath autonomous. If the oven is powered by electricity, then it is convenient to use.

With the help of program control, the heating mode is set: you can not interrupt the rest in the bath, but the heating in this case will not depend on the electricity supply. Network outages can ruin spa treatments.

YouTube responded with an error: Access Not Configured. YouTube Data API has not been used in project 268921522881 before or it is disabled. Enable it by visiting https://console.developers.google.com/apis/api/youtube.googleapis.com/overview?project=268921522881 then retry. If you enabled this API recently, wait a few minutes for the action to propagate to our systems and retry.

- Similar posts

- Pros and cons of steam heating without a pump

- Which wood stoves are suitable for steam heating?

- What are the features of steam heating "Leningradka"?

- How is a steam-heated stove arranged?

- How to make steam heating in the country?

- How does a low pressure steam heating system work?

Water fireplace and its benefits

1. A water fireplace is a more affordable device than traditional heating boilers;

2. Installation of a water fireplace will not require alteration of the existing heating system;

3. The fuels used in the fireplace are cheap and readily available;

4. The power of the fireplace is enough to heat a large area, but at the same time it will have an attractive appearance;

5. A cast iron water fireplace can be installed in rooms where only the most elementary fire safety rules will be observed;

6. Convective circulation of hot water in the heating system eliminates the consumption of electricity or other types of energy by the fireplace;

7. The water fireplace is a stand-alone device with the simplest operating algorithm.

Do not forget about the auxiliary elements that a water fireplace can be equipped with, which will significantly expand its capabilities. So one of the main auxiliary elements in the delivery of the boiler is the grill, thanks to which the fireplace not only becomes an element of the heating system, but also an item on which you can cook delicious food. And for those who like to admire the flames, but at the same time are very worried about safety, the fireplace can be equipped with special transparent screens that allow you to admire the fire and at the same time greatly reduce the likelihood of fires.

Heating circuit

Steam heating in a bath from a stove is recommended to be made of a forced type, with 2 circuits. The circulation pump is designed for condensate. With liquid heating, a pump is installed at the outlet of the boiler, increasing the flow of hot water into the system. What does the heating scheme for a bath look like?

- Furnace with heat exchanger. In the heat exchanger, an outlet for the water supply is made in order to fill the coil.

- Outlet pipe.

- If necessary, install an expansion tank. Steam can accumulate in it to prevent too high a load on the line.

- Steam supply pipe.

- If necessary, equip radiators. In the sauna, most often, pipes are located.A loop is made, a platform for stones is equipped. Batteries are installed in the break room. The washing compartment is heated by a stove that gives off heat, a pipe that comes out of the firebox or an expansion tank. A small room is allocated for the shower room. No special heating is done for it.

- Condensate line.

- Storage tank.

- A vertical pipe emerges from the tank. It is recommended to provide an air outlet in it. It is necessary so that an air lock does not form in the line.

- Water filter or sump.

- A circulation pump that pumps liquid from the storage tank to the boiler.

For the line, choose galvanized pipes with a diameter of up to 40 mm, a wall thickness of 5.5 mm. Radiators are also chosen from the same material. It is recommended to install a temperature and pressure regulator on the devices. In the steam room, the steam line is laid under the sun loungers. This will protect vacationers from burns when touching hot pipes. The sun loungers will not interfere with the heating of the sauna. The temperature of the pipes is over 100 ° C.

We recommend: How is a steam-heated stove arranged?

Cons of fireplaces with a water circuit

But with all the advantages of water fireplaces, these devices are not without some disadvantages. In particular, the efficiency in them is not high enough to provide a decent level of heating for premises in the far north. However, using a water fireplace in conjunction with other heating methods can reduce fuel consumption by 40%. The flue gas recovery system is designed to increase the efficiency of the fireplace, which can be equipped with fireplaces at the request of the customer. In this case, due to the heat of the exhaust flue gases, the combustion air is heated.

An additional disadvantage of a water fireplace is completely manual control. This aspect severely limits the use of water fireplaces as the main sources of heat, but allows them to be widely disclosed as backup sources of heating.

Traditionally, the choice of a fireplace should be carried out taking into account the required power, which will be supplied for heating. It is believed that to heat 10 square meters of a room with a height of 2.5 m, it is necessary to spend 1 kW of energy. Knowing this and the area of the room, it is easy to set the required power of the fireplace. Moreover, this value should coincide with the rated power of the heating device. In addition to the nominal power, the passport of the fireplace also indicates the maximum and minimum power that the fireplace is capable of delivering for a short time in case of a strong cold snap or thaw, but in order for the resource of the fireplace to be as large as possible, these operating modes should be avoided.

Advantages and types of wood-burning stoves

There are several heating systems for country houses, saunas, and other premises. Wood stoves, despite the emergence of modern, technologically advanced ways to maintain a comfortable microclimate, and now not only have not become a rarity, but successfully compete with other options for maintaining the "weather in the house". What, if not a real wood-burning stove with smoke, the smell of logs, dancing tongues of fire, will give you a living, real warmth?

A bit of history

It is probably difficult to say for sure when, by whom and where the wood-burning stove was invented. For a long time in Russia, smoke-fired smoking stoves were used. Classical Russian, which was used not only as a means of heating a hut, but also as a place for rest, sleep, serving for cooking, and even as an alternative to a bathhouse, has existed for several centuries.

Modern wood-burning stove in the interior

This "sauna" was very popular. An interesting fact: the children were placed in the oven for washing, sitting on a wooden shovel. Didn't it come from this that in Russian fairy tales the main character, having visited Baba Yaga, did not perceive it unusual to use this household item as a means of transporting it to the oven?

In ancient Rome, wood-fired ovens were used to prepare traditional pizza several thousand years ago. They are also found in Ancient Egypt, Europe, wherever the making of bread was known, and it was possible to use firewood as fuel.

About Scandinavian wood stoves

Scope and advantages

In a modern house, the main task of such a stove is heating, and it copes with it well, quite doing well with a small amount of firewood. First of all, given the design, the use of such a stove is justified in small rooms. The application determines the material from which it is made, as well as how often it is used. A small metal stove can quickly and effectively warm up a room, but it cannot keep warm for a long time. Made of brick, it heats up more slowly, but also cools down more slowly.

Serial production wood-burning metal stove

Any wood-burning stove has the following advantages:

- fast heating of the room;

- the simplicity of the design, both of the furnace itself and the heating system of the house as a whole. It is quite possible to do without installing radiators, installing pipes;

- economic benefit in the absence of connection to the gas main or to other sources of heating. Harvesting and using firewood can cost less than using electricity for space heating;

- combustion of the furnace requires the provision of traction, and therefore the supply of fresh air. This improves heat transfer between the street and the room, regulates the humidity in it;

- some options for stoves allow you to cook food, and even arrange a semblance of beds for relaxation, although both nowadays are rather exotic;

- kindling is done as needed.

The latter is also a disadvantage. A stove, wood-fired or fired with coal, peat, etc., is not an autonomous device and requires constant attention. It needs to be cleaned, kindled, maintained and regulated from time to time, and firewood must be prepared and a special place for storing it.

Metal ovens

Wood stoves made of metal are often compact, simple in design, and allow you to perform installation yourself, with your own hands, without the cost of specialists. It is only necessary to place it in a prepared place and install the pipe.

Note: Install the oven on a non-combustible base, the area of which is 1.5-2 times the area of the oven. This will prevent charcoal from falling out of the firebox from falling onto the floor, carpet, etc. The fire should be inside the oven, not outside it.

New format metal wood stove

A wood-burning stove can be made using different metals, which may affect its characteristics.

About Milano II

Manufacturing materials

The materials for the manufacture of the heating furnace are:

- heat-resistant austenitic high-alloy steel. A low percentage of carbon and a large amount of alloying additions make such steel resistant to corrosion, and the presence of a small amount of silicon in it ensures the formation of a strong oxide film covering the metal upon heating. This protects it from the effects of combustion gases and prevents destruction. Steel furnaces are not afraid of thermal shock, mechanical stress;

Steel wood burning stove

- black boiler steel. Due to its characteristics, the thickness of the steel used is greater; fireclay bricks are often used to protect the walls. Most often, wood-burning stoves are made from this metal, intended for installation in baths or saunas;

Furnaces made of black boiler steel

- cast iron. It expands less when heated, and, unlike steel, can last a long time. The wood-burning cast-iron stove, due to the lower thermal conductivity of the material, heats up more slowly, but also retains heat longer. Unlike steel, it weighs more, tolerates mechanical shock worse, but does not corrode.

Cast iron wood stove

Furnace types

By the type of heating, the following types can be distinguished:

- single chamber. The simplest option, best suited for quick heating of a small room. Such a stove, wood-burning or allowing the use of other fuels, is distinguished by its low cost and small size. Perfect for a sauna;

Single chamber wood burning stove

- two-chamber (hydrolysis). For heating, not only the energy of combustion of wood is used, but also hydrolysis gas. Combustion of wood in the lower chamber with oxygen deficiency contributes to the release of this gas. When it enters the upper chamber through the grate, where there is enough oxygen, its active combustion begins. Among the advantages that a wood-burning stove has, it can be noted that the hydrolysis gas reacts with carbon dioxide, reducing its emission. The combustion process is longer, firewood is economically consumed, which increases autonomy, and in general the heating system has a higher efficiency;

Two-chamber wood-burning stove

- convection. The body has air ducts in which cold air, passing from the bottom up, heats up. Convection heat radiation accounts for about 2/3 of the entire heating efficiency of the oven. Among the disadvantages is rapid cooling.

Wood-fired convection oven

Oven with a water circuit

A wood-fired stove can have a heat exchanger installed, which is a tube through which liquid circulates. The coolant can be ordinary water, but it is better to use antifreeze, which will avoid freezing of the liquid in the pipes. With the help of nozzles, it is connected to the heating system of the house, which will make it possible to heat several rooms. The circulation of the liquid can be made forced by turning on a pump in the circuit, or it can be limited to the natural transfer of heat.

Wood burning stove with water heating circuit

Natural circulation will allow you not to be afraid of power outages and, accordingly, stopping the circulation pump. In this case, it is necessary to provide for a reliable movement of the coolant through the system in order to avoid boiling of the liquid in the heat exchanger and its possible destruction.

Note: Locate the heating system lines with the greatest possible slope, and install the expansion tank above the furnace level by installing a vertical riser that will act as a boost manifold.

Given the design, wood-burning stoves with a water heat exchanger require less attention than heating boilers. At the same time, unlike the latter, not only the coolant is involved in heating the room, but also the entire surface. When choosing, you can be guided by this approximate formula: 1 kW of oven power per 10 m2 of room area with a standard ceiling height of 2.5 m.To calculate more accurately, you need to take into account the outside temperature, the presence of windows, the quality of wall insulation, etc.

Brick

Brick wood stoves are capital structures that can become the center of a home. A wood-fired brick oven can be of different shapes, designs, sizes. The most famous species are Russian, Swedish and Dutch. A water circuit can be installed in it. By designation, a wood-burning brick stove can be heating, heating and cooking, or mainly intended for cooking. To build it yourself, you need more skills and knowledge than in the case of installing a metal analogue. They are most often used in homes rather than saunas.

Wood-fired brick oven

Among the advantages is that it can be used to heat several rooms. Almost the entire surface is involved in heating, therefore, it can be built in such a way that part of it will be in one room, and part in another. For example, place the firebox, the hob on the side of the kitchen, and the back part will be in the living room.At the same time, a wood-burning stove can be combined with a wood-burning fireplace, which will create coziness and the opportunity to spend time near the fire.

Conclusion

Probably, wood stoves will never cease to be an effective heating tool in a country house, they will never go out of fashion, and their live fire will become a source of warmth, aromas and mood for a sauna. In our digital time, only a stove, wood-burning, coal or any other, will warm you with real, living, "analog" heat, cheer you up with reflections of a flame, and envelop you in the smoke of burning logs.

About the wood-burning stove Tomera Supra

opechi.com