28.06.2018 | admin | Bath accessories, Bath and health

Boilers in a heated water bath

The popularity of the baths as a place of rest and relaxation, hygiene and medical procedures is extremely wide. Almost every owner of a suburban area, be it a summer cottage or a cottage, strives to equip a bathhouse in addition to a house. Most of the amateur builders adhere to traditional canons - the construction of baths, independently heated with solid fuel and using the obtained thermal energy not only to warm up the bathhouse, but also to heat the water for washing. Therefore, the choice of a stove with a water heating tank is very important.

The principle of operation of water heating bath equipment

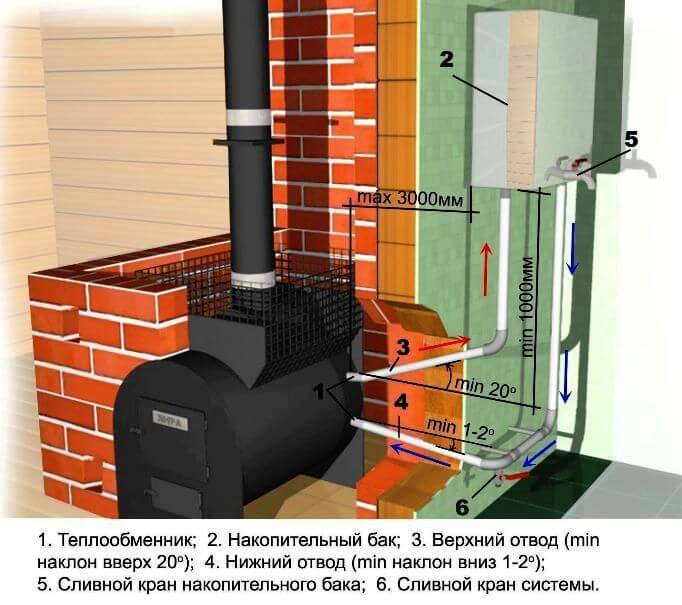

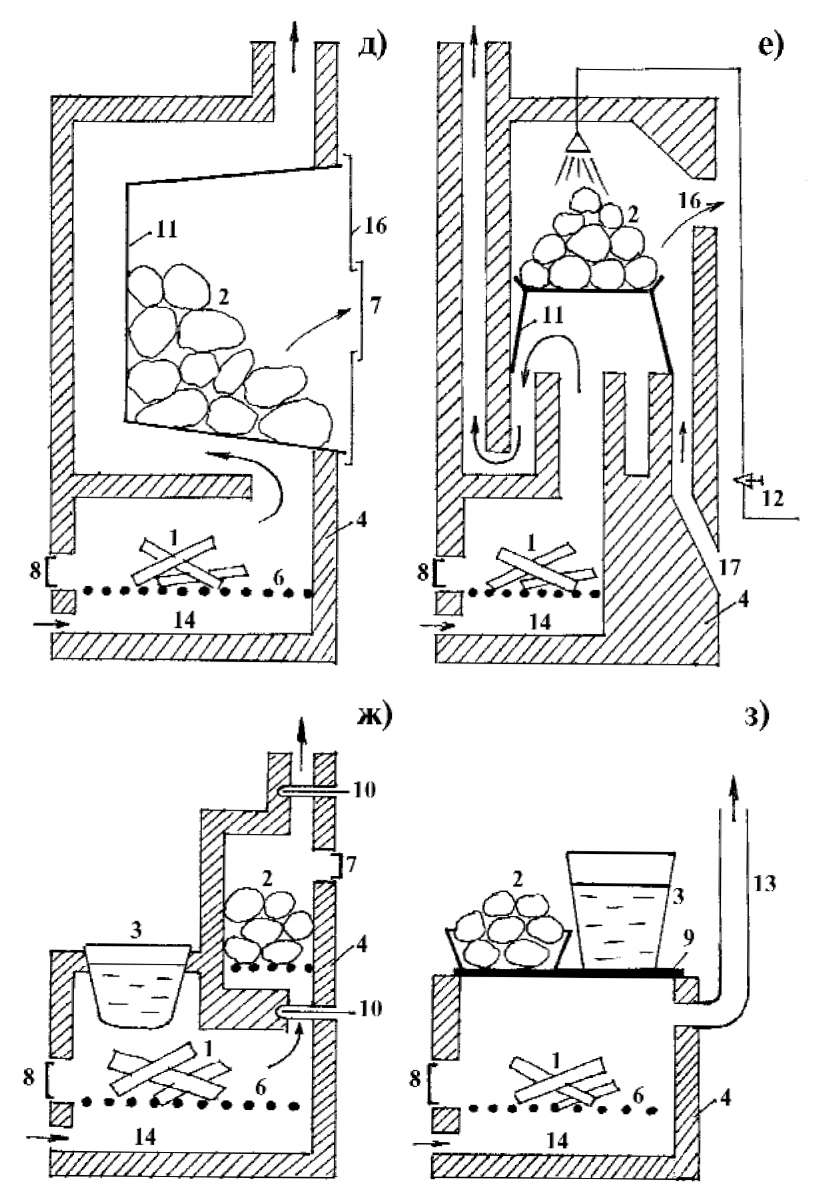

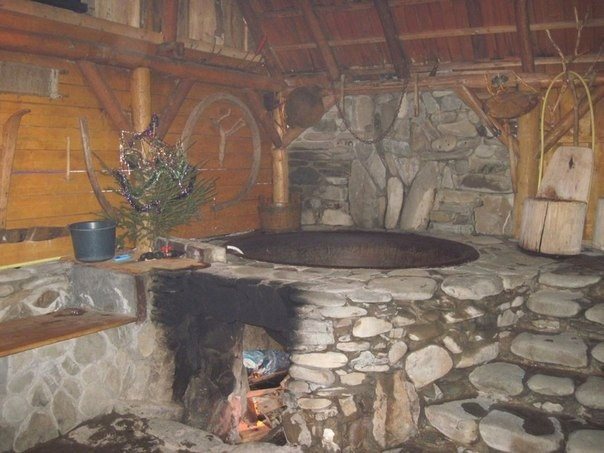

Adherents of traditionalism, who think of the bathhouse as a place of leisurely rest and a rather long stay, prefer the construction of stone / brick stoves, in which a tank / boiler with a capacity of 20-100 liters is built. The location of water heating boilers can vary greatly, depending on the design of the stove. The oldest are constructions in which the boiler is located directly above the combustion chamber, at the upper point of combustion of firewood and the water in it is heated during the heating of the furnace. A more modern design is in which boilers are used in a bath with heated water from sheet metal, usually it is adjacent to one of the walls of the combustion chamber or is located around the chimney. In this case, water heating also occurs only during the heating of the furnace.

The disadvantage of such structures is that stone, brick ovens with a high heat capacity are heated only once, before going to the bathhouse. The heat accumulated in the stone is enough to maintain a temperature of 60-90 ° C in the bath for several hours. Disadvantage - high consumption of fuel / wood and limited resources of heated water - one-time filling of the boiler. If water is used during the washing process, it is not recommended to add it to the cooling oven. This will rapidly cool the entire bath.

Much more popular are boilers for a bath with heated water of industrial or handicraft production, which are equipped with built-in water heating tanks or have them as attachments. The main advantage of such ovens is:

- Compactness;

- Low weight, which does not require foundation arrangement;

- High speed of heating the bath room;

- The possibility of heating water in the process of taking bath procedures, since the stove requires constant heating, otherwise it cools down quickly.

The location of the water heating tanks in such ovens is more varied:

- In the furnace body on top of the combustion chamber;

Tank in the furnace body

- A tank located around the chimney;

Samovar-type hot water tank

- A tank adjacent to one of the walls of the sauna stove;

Tank for heating water adjacent to the furnace

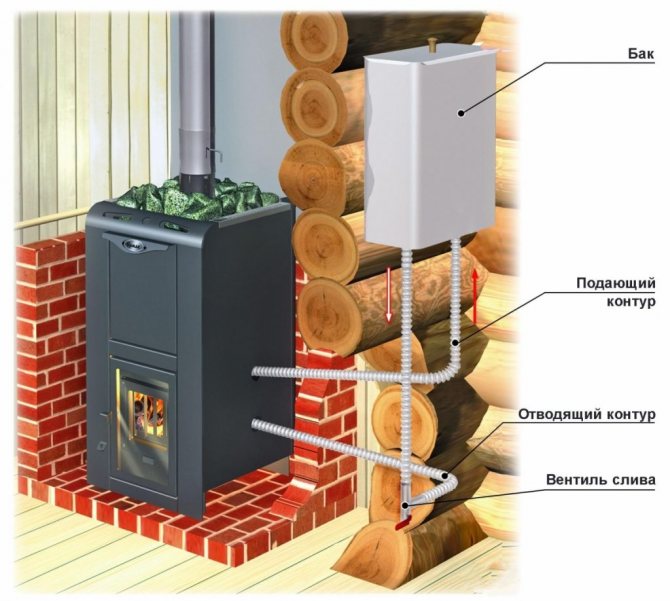

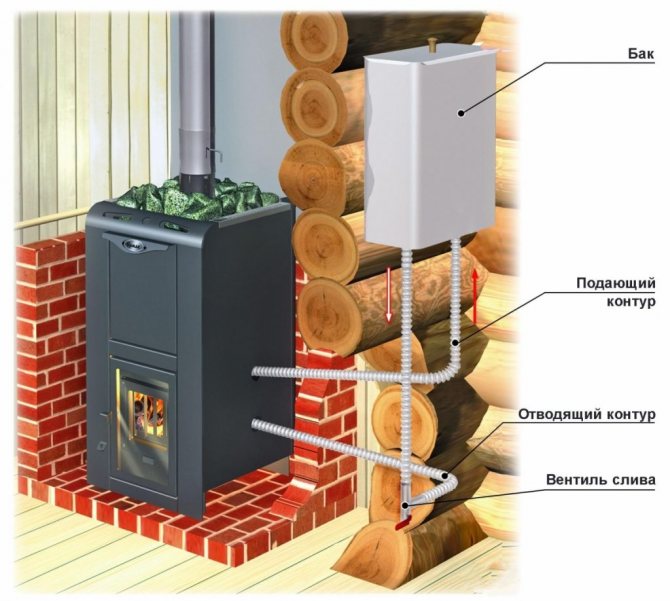

- Separately located tank connected to the furnace by a pipe system.

Freestanding bath boiler

Design

It is good when the planned budget for the construction of a bath is enough for a beautiful interior decoration, and for a spectacular cladding with foreign siding, and for a smart automated heating system. But what if the boiler room is ready, but there were not enough funds for an expensive imported boiler? In this case, you can make a good boiler for a bath with your own hands: from a metal barrel, sheets or pipe. Of course, it will be far from automation, but it will be cheap and cheerful. In Russian, so to speak.

We offer you to familiarize yourself with How to make a well with your own hands: 110 photos of the construction of a real and decorative well

The simplest homemade boiler for a bath is made of a pipe, iron or metal. But you can position it both vertically and horizontally - the first and the second method have their pros and cons.

In general, for work, you will need a welding machine, an angle grinder with discs for metal and a diesel or gasoline generator.

But as soon as you start making your dream come true, it turns out that a homemade stove is not as easy to assemble as it seemed at first glance. To design it requires a solid set of professional skills and a well-stocked workshop with all kinds of tools.

Dear homemade products! Before you start making a sauna stove, really assess your strengths and future costs. Sometimes the cost of material and auxiliary equipment completely destroys all the benefits of the planned event, taking only a lot of time and money from the master.

Let's together analyze the modern market for factory bath boilers and highlight those types of heating equipment that can actually be made independently.

For a long time, the Russian bathhouse was equipped with a massive brick stove, which was built by hand, but with the development of industry, many factories began to specialize in the production of compact metal stoves. "New items" did not supplant the time-tested "classics", but confidently captured the lion's share of the bathing market.

Metal stoves run on all conventional fuels:

- Firewood

- Coal

- Electricity

- Gas

Unlike a brick stove, metal heaters heat up in just 30-60 minutes, do not take up much space and do not require careful maintenance. With their appearance, the bathing industry made a huge step forward towards its popularization, because it became possible to arrange tiny individual steam rooms in private houses and apartments, mobile baths and camp baths-tents. Light and miniature angular, wall-mounted and collapsible models of units are installed in them.

According to its technical characteristics, a standard factory heater is, of course, inferior to the brick “queen” because of the uneven and short-term heating of the room. But even here a compromise was found: in family baths, steel boilers are placed in brick boxes, which soften the unevenness of their thermal radiation.

Metal stoves have become the subject of heated discussions by home-made people who want to construct a solid model on their own, which will in no way be inferior to their own. But not all units are so easy to clone: it is better to buy gas and electric types of heaters from a reliable manufacturer due to the high risk of emergencies.

Advice from the master!

This prohibition is especially strict for gas equipment, as the correct installation is checked by the appropriate regulatory authorities. It is much more accessible and realistic to make a boiler for a bath with your own hands, running on the most affordable fuel - wood.

It is easy to find a suitable scheme on the net, the main thing is to be able to implement it. And for this, the future designer must have some compulsory practical skills.

In this article we will try to answer these questions.

Homemade constructions are often used as a heat source in baths.

Terminology

First of all, let's understand the definitions. Of course, you can put a homemade boiler in a bathhouse, but ... this is not practiced. The respected reader will probably be surprised to list the many owners of DIY equipment, right?

You see, do not confuse boilers with stoves. These are fundamentally different types of equipment.The first are designed to heat the coolant; the latter transfer heat directly to the air in the room.

Homemade boilers for a bath (as, indeed, and factory products) imply the presence of heating devices. However, the use of convectors, radiators or registers is not that impossible - impractical. Why?

Yes, simply because to heat the air at least up to 80 degrees with radiators with a temperature of about 90 C, the maximum for autonomous heating equipment, the steam room would have to be completely hung with them. At the same time, a furnace, whose surface is heated to 400-800 C, can be quite compact.

Please note: the compact size of the steam room and the dressing room does not require the transportation of heat from its source. The entire volume of the premises will be heated by a single stove.

Both the steam room and the dressing room are evenly warmed up by the only source of heat.

Materials (edit)

So, we figured out the misconceptions. We have to make a furnace. How can this be done?

Actually, the choice of options is small.

- Brick is the most traditional material. Solid red brick is used for masonry walls, fireclay - for lining the furnace. Since cement does not like high temperatures, the kiln is placed on clay mortar.

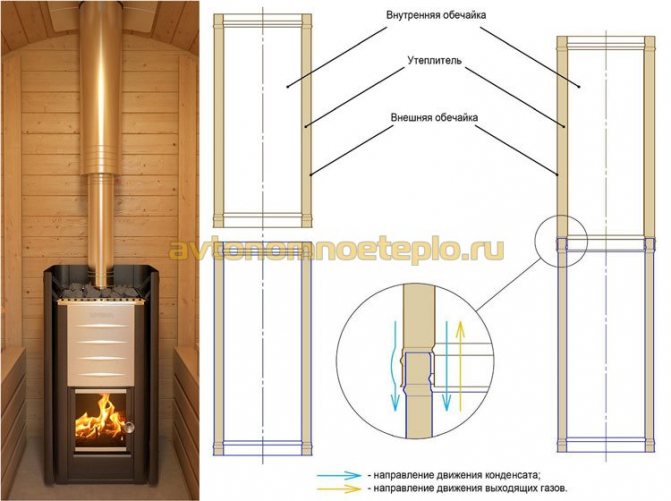

- Steel allows you to save money and time compared to brick; in addition, the design will be much more compact. However, it is much easier to burn yourself on a steel stove, and the service life of the product will be shorter. To connect steel parts, electric welding is used, for cutting - a grinder or an acetylene cutter.

The instructions for building a stove, of course, depend on the material you choose.

Brick oven construction.

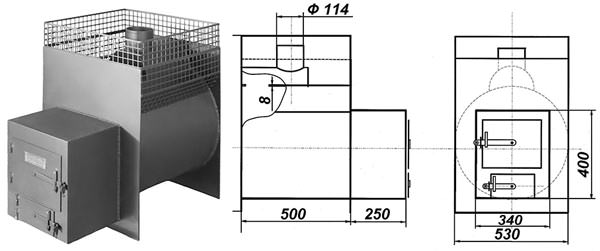

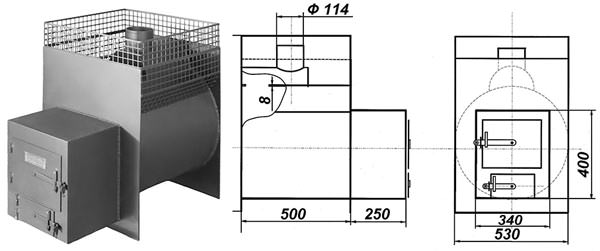

Drawing of a homemade boiler in a bath

Sauna stoves operate under different conditions than wood-fired heating boilers, hence the differences in design:

- Any home-made boiler in the bath is devoid of a water jacket, the walls of the firebox give off heat directly to the air in the room.

- The firebox body is made of steel, since it is unrealistic to make iron casting at home.

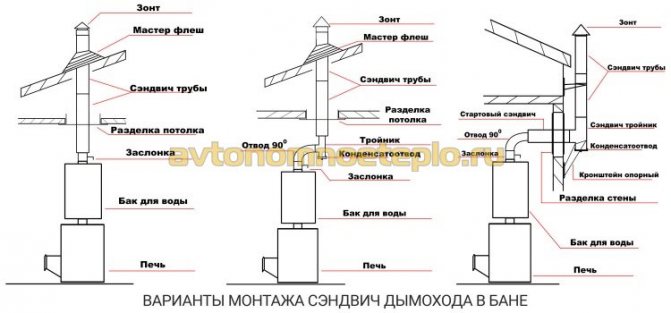

- There are no internal channels for flue gases, and the chimney has a minimum number of turns, since the temperature of the gases at the outlet is high. The result is that the metal burns out at the place of turning or connection.

- The loading door is located in the remote channel. The combustion chamber is located in the steam room, and you need to load it with firewood from the dressing room, so such a channel is made to pass through the wall.

As a rule, homemade boilers for baths are made of two types: cylindrical and rectangular. The design of the former is more accessible in materials and easy to manufacture. The manufacture of a rectangular furnace will require more financial and labor costs, but such boilers are better and more popular in operation.

Diagram of a boiler for a bath To begin with, you should stock up on everything you need to assemble such a boiler with equipment and tools. From the tool you will need a welding machine and a "grinder", and as an initial workpiece you can use a metal barrel with a volume of 200 liters (horizontal version).

We offer you to familiarize yourself with Polypropylene pool: do-it-yourself installation

Let's consider this option in more detail.

The entire pipe is divided into three parts, each of which represents a specific functional unit of the furnace, used for its intended purpose. The lowest and above it part of the pipe space is used for the firebox and stone. They provide the required mode of operation of the boiler and create conditions for its normal operation.

The lowest sections of the chimney (blower, firebox and stove) are equipped with partitions on which special grates are hung - grates, which are freely sold in specialized stores of furnace casting.The heater compartment is filled with small oval stones, the structure of which allows it to “keep” warm for a long time.

In a vertical stove, a compartment that serves as a container for hot water is installed directly above the stove. For this, another partition is mounted directly above it, which is the bottom of this compartment.

Furnace selection and calculation of heat transfer from furnace equipment

The choice of stove depends on many factors:

- Bath foundation;

- The material from which the walls are made;

- Bath area, dressing room, other premises;

- Steam room ceiling thickness;

- The type of fuel on which the furnace will operate;

- The climatic zone and the time of the year in which the bathhouse will be mainly operated.

Few can afford the construction of large baths from thick coniferous forests, due to the significant cost and labor intensity. In addition, such a bath requires prolonged heating of the stove and, therefore, a large amount of fuel. Arrangement of the foundation for a stone oven in terms of labor intensity and time is no different from work on arranging it for a house.

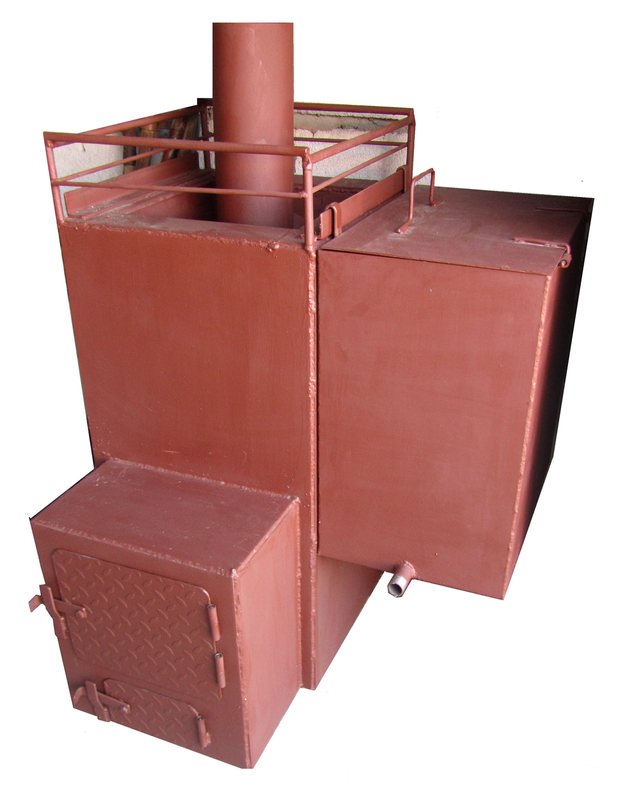

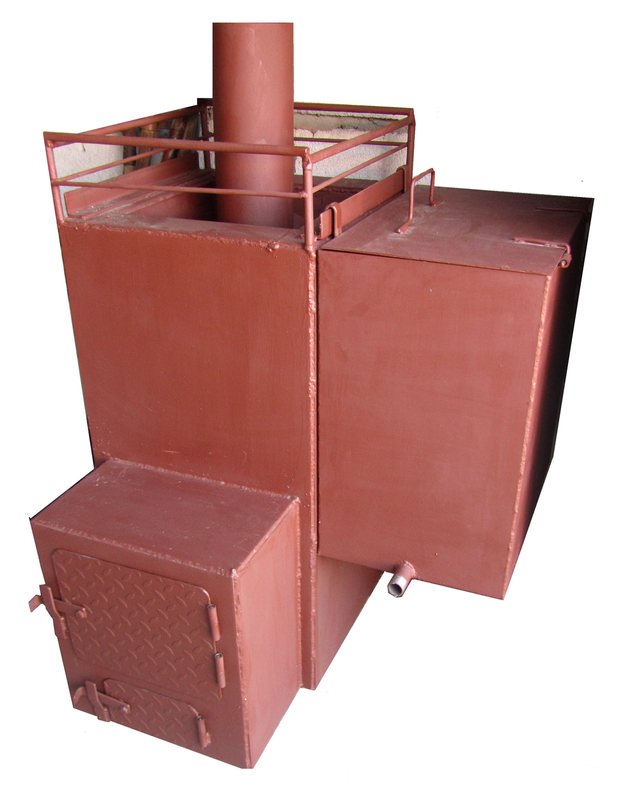

Metal boiler

A sauna boiler can be made of steel sheets - the result should be an open stove, which is lined with bricks for safety.

At the first stage, they acquire everything necessary for the manufacture of such a structure:

- Sheet steel with a minimum thickness of 5 mm - it will go for the construction of the boiler walls;

- 10mm steel for making the bottom. Here the material is taken thicker, because it heats up more under the influence of high temperatures;

- Various fittings for heating devices;

- Armature no more than 4-5 mm thickfrom which the mesh for stones will be welded;

- Channel bars;

- Galvanized sheet for the removal of combustion products - its thickness should be about 2 mm;

- Asbestos for top elements chimney.

Before starting work on the manufacture of a heating boiler, they develop a drawing of it, where the structure should be depicted from above, from the side, in section. All dimensions are strictly in millimeters. When this is done, the drawing is transferred on a one-to-one scale to the purchased materials.

The boiler body is assembled from steel sheets. Welding should be approached very responsibly and carefully boil the metal to its full thickness, otherwise fistulas will gradually form in these areas under the influence of high temperature.

A hole is cut in the upper part of the boiler for the subsequent installation of the chimney. Weld the tin pipe immediately. It should be noted that in this case it will be necessary to use special electrodes.

When constructing such a structure, it will also be necessary to make the foundation of the furnace, otherwise the floor simply will not support the weight of the product. The foundation must be made using the same technology as for a boiler made of a metal pipe.

Metal boiler drawing

Calculation of the heat transfer of the furnace

For these reasons, most builders of baths on personal plots are trying to build the lightest possible structure from a thin bar or brick, insulating and sheathing the interior with clapboard. For such baths, the correct calculation of the heat transfer of the stove is of particular relevance. In most cases, if it is not made by handicraft, the technical specifications (product passport) indicate the volume of the room (or area) that can be heated by such a stove. In this case, there are no problems with the choice. It is enough to use the calculator, entering the required values, to determine which oven is best suited.

It is much more difficult to comply with all the conditions when making a stove with your own hands. In this case, it is necessary to take into account:

- A combustion door will be located inside the steam room or outside;

- What material is the door made of and is it sufficiently insulated;

- The type of fuel with which the stove will be heated;

- The thickness of the attic floor and floors.

IMPORTANT! An important aspect will be the shape of the steam room and the location of the stove. In the event of its incorrect location, it is possible that unheated zones may form, especially under the shelves, in which cold air will accumulate. Free-standing water tanks should not be placed in such blind spots. Otherwise, a large amount of fuel will be spent on heating, and the water in them will quickly cool down.

Installation work

How to install the boiler correctly so that it evenly heats the steam room and possibly adjacent rooms? Installing a boiler is a difficult task. When installing, take into account:

- The path of the chimney and piping of the heat exchange system. When deciding how to install the boiler, you need to remember that the chimney, like the pipes of the heat exchange system, should not be very long. In the first case, the stove will have a weak draft, in the second, a large volume of water in the system will not be completely heated. At the same time, they should not be too short. This is fraught with "heat escape into the pipe" and rapid boiling of the system. Thus, when deciding how to make a boiler, you need to correctly calculate the dimensions of the accompanying structures.

- Distance to flammable structures such as log walls. If the boiler has a brick screen, then this problem is not relevant. Otherwise, the distance to the walls must be at least one meter, or they must be finished with heat-insulating non-combustible materials.

- Distance from shops. It is very easy to get burned in a steam room with a metal stove. Such a structure is very dangerous, therefore it should be installed at a considerable distance from the shelves.

It is necessary to strictly follow the installation rules. How the stove is installed determines not only the efficiency of its operation, but also the safety of visitors to the steam room. A diagram of the correct installation of heating equipment is attached.

So which one to choose: a self-made oven or a ready-made version from a store? You don't even have to install it. Companies selling such products do their own delivery and installation.

When choosing an acceptable option, one should take into account the expended forces and funds. People weld homemade products, spending money only on electricity and electrodes, everything else can be found in every subsidiary farm. Thus, a boiler for a bath costs "three kopecks".

Making a device from iron sheets can take more than one day. Not the fact that everything will work out the first time. If you want to save money and have free time, then you can safely start assembling. Otherwise, we recommend choosing an option that is acceptable in terms of power in the store.

The choice of material for the tank

The most common are sheet metal tanks:

- Cast iron;

- Stainless steel;

- Enameled.

Each of these materials has certain advantages and disadvantages.

Cast iron tanks - a classic of the Russian bath!

They are durable, not subject to corrosion, have a high heat capacity and do not cool down for a long time, are easy to clean from dirt, and are resistant to shock and mechanical damage.

They can be built into the furnace body. The only drawback is the large weight, which creates a load on the oven and requires a frame or hanging from chains.

Cast iron boiler

The boiler for a bath with heated stainless steel water is the most popular at the present time. Suitable for the device of a water tank of any shape and volume. It can be located both inside the oven and outside. Ideal for freestanding containers. The durability of the built-in tank depends only on the thickness of the metal. The only drawback is the rather high cost of material and manufacturing.

Stainless steel tank

Enamelled tanks are used only as hinged or freestanding. On contact with fire, the enamel quickly cracks and crumbles.Not resistant to mechanical damage, although it has the most aesthetic appearance among other similar products.

Enamelled boiler-titanium

Technical indicators and additional functions of metal boilers

The main tasks of boilers for a bath are: to warm up the room to the set temperature as quickly as possible, to maintain it in the required parameters for a long time and to make it possible to change it as quickly as possible. What can you say about metal boilers in this regard?

Warming up the premises can be done in the shortest possible time. The boiler has a small furnace mass, it heats up very quickly to a high temperature and effectively heats the steam room. This is one of the main advantages of such boilers over brick stoves. Not everyone has the opportunity to heat the steam room for half a day to wash for an hour. Sometimes they come to the dacha for only a few hours and wish to complete all their affairs in this short time.

Unfortunately, after the cessation of combustion, the fuel cools down just as quickly. There are so-called long-burning boilers on sale. At a price they are more expensive than ordinary ones, but is it worth paying that kind of money for them? Let's figure it out.

Tank size depending on furnace performance

Bath builders, striving to save on material and price, do not always take into account the real need for water for washing. This is especially true for young families with children. The water consumption for washing each next family member is equal to that for an adult. Therefore, already during the design, it is necessary to lay down the volume of the tank, especially for stoves that do not provide for constant fuel filling and continuous heating of water, which would be enough to wash all those who were washed in the bath + 25-50% of the minimum requirement.

IMPORTANT! The volume of the built-in tanks is especially critical. For ovens with an internal arrangement of the container, its volume should not exceed ½ of the oven volume. Otherwise, the water in the tank will heat up for a long time. In furnaces with high heat transfer, there is a high probability of constant boiling of water, its evaporation and the creation of excess moisture.

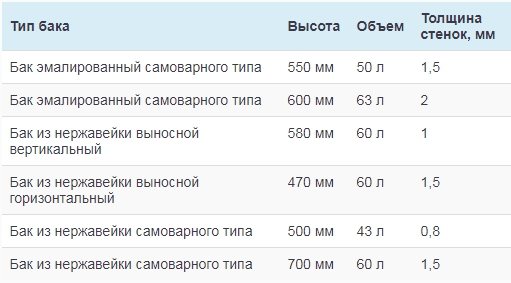

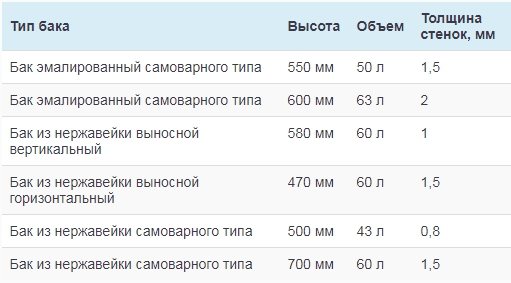

Tank wall thickness depending on volume

Metal and cast iron stoves for a bath

A wide range of high quality products.

For many centuries, for a Russian person, a village house is inseparably associated with another building. This, of course, is a bathhouse, which is an important attribute of suburban and suburban life. In the design and construction of this building, the choice of such structures as sauna stoves plays an important role.

It is on their characteristics and quality that the full functioning of the entire room depends. Nowadays, bath stoves can be easily purchased ready-made, this will significantly save time and effort, especially since modern high-tech models are distinguished by impeccable performance and ease of installation.

Our store specializes in the sale of this particular equipment. We offer to buy a sauna stove for everyone who wants to purchase reliable, safe, high-quality products from the best manufacturers. Our catalog clearly presents a wide range of different models for every taste and for any room, which differ from each other in design solutions and characteristics. You can find descriptions of each model on our website. Compact and stylish - we present at a very affordable price.

We offer products from a variety of materials. In recent years, metal stoves for baths have become most popular, which are a serious competitor for their brick counterpart. Their small size allows them to be placed even in the smallest room. One of the advantages of the oven is that it heats up very quickly to the desired temperature in a short period of time, while it heats the space well, both in the steam room itself and in adjacent rooms.

We also offer cast iron modifications, which also have a number of advantages.Such products retain heat for a long time, have a fair amount of power, do not rust and do not require coating with special paint. These options are very versatile and are equally well suited for both a regular bath and a sauna.

We suggest that you familiarize yourself with: Primer for a brick oven

Tank location

The water tank located in the furnace body or on the chimney (samovar type) is suitable only for single-volume rooms of Russian baths with high humidity, in which high humidity is maintained at a relatively low temperature and in which they are simultaneously steamed and washed. For baths of the Finnish type - saunas, the tank must be separately located, in the washing department adjacent to the steam room. Otherwise, each trip for hot water will require opening the doors, which will negate the effect of a dry room heated to a temperature of 90-110 ° C.

Do not neglect security measures. The tank should be located in such a place that there is no risk of burns when touching its surface. A high-located tap is also a source of increased risk of burns when drawing water.

We lay out the brick oven

If you have some practical experience in building brick stoves, try folding a capital sauna heater yourself. We offer a variant of a stove-heater with dimensions of 102 x 129 cm, equipped with a tank of 170 liters and designed to heat a bath with an area of 12 m².

To build the stove shown in the drawing, prepare a set of materials:

- corpulent clay brick (red) - 580 pcs.;

- fireclay stone brand ША-8 - 80 pcs .;

- cast iron grates measuring 30 x 25 cm - 2 lattices;

- the main door for loading firewood - 210 x 250 mm;

- ash chamber door - 14 x 25 cm;

- smoke damper - 320 x 450 mm;

- heater door - 51 x 42 cm;

- steel pipe with a diameter of 57 x 4 mm - 6.3 m;

- iron strip with a cross section of 40 x 5 mm - 2 m;

- the same, 80 x 10 mm in size - 2.5 m;

- basalt cardboard, roofing material.

Note. The list did not include the brick required for the construction of the chimney, cement, clay and sand for mixing the mortar.

Also, before construction, you need to weld a tank - a boiler with dimensions of 102 x 77 x 25 cm from sheet steel grade St20 with a thickness of at least 3 mm. We will not describe the technology for constructing a reinforced concrete foundation, preparing mortar and stove masonry - it is described in detail in the instructions for building a fireplace.

Let's move on to the construction of the furnace according to the presented orders:

- The zero and first rows fit into a solid one. Tiers 2 and 3 form an ash pan, a blower door is installed.

- Row No. 4, covering the door, is the bottom of the fuel chamber, partially lined with refractory stones with a 5 mm gap from the red bricks. Trimming is done, the grate and loading door are inserted.

- When tiers 5-9 are laid, the walls of the firebox are built. On the 10th row, cells for pipes are prepared, cut into blanks with a length of 1050 mm. The elements are placed in the nests and sealed with basalt cardboard, a water tank is installed.

- From the 11th to the 20th tier, the walls of the furnace are erected around the tank. On the 20th row, the end of the boiler is overlapped by two steel strips L = 35 cm.

- On the 21st row, the heater door is installed, the laying of the outer walls continues according to the scheme up to the 26th tier. On top of the door are placed 2 strips 650 mm long.

- On the 27th row, the stove overlap begins to form. Cutouts are made for laying large strips 120 cm long. Bricks of the 28th tier cover the cavity of the heater, leaving a chimney opening.

- The flue valve is placed on the 28th row, tiers 29-32 finally form the furnace roof and the transition to the chimney.

Six bridges in the form of pipes Ø57 mm serve as supports for the future massif of stones and at the same time are convective air heaters in the sauna. After 2-3 days, when the solution dries well, it is necessary to eliminate the defects, load the stove and start a test kindling.For a detailed description of the masonry in rows, see the next video:

How to choose a boiler for a bath?

IMPORTANT! It is not an easy task to take into account all the nuances of choosing a boiler with a water heating tank, its location and optimal volume. When faced with its decision for the first time, inexperienced organizers of a bath are often mistaken. Therefore, the best way out is to resort to the services of a designer specializing in the arrangement of baths. This guarantees against the need to redo the internal heating system of the bath due to its low efficiency or inconvenience of use.

About the Author

Electric heating in the bath

If there is a need to heat only a steam room, then a solid fuel stove is the ideal solution. Otherwise, when you need to heat the dressing room, shower room and other rooms available in the bath building, this option can be safely dismissed.

For heating a large area, it is better to use an electric boiler. Its manufacture and installation do not have any technical difficulties. All that is needed is to weld the water heating heating elements into a container with water and correctly equip the heat exchange system.

The advantages of electric boilers are obvious:

- there is no need to equip the chimney system;

- ease of installation, operation and maintenance;

- high efficiency.

Along with the advantages, there is a significant disadvantage: significant power consumption.

Features of the device heaters on metal boilers

Some manufacturers claim that only their boilers are capable of producing high-quality steam, this is one of the important advantages of the advertised products. What is quality steam? Such a characteristic does not exist, we can only talk about the comfortable conditions of stay in the steam room, and they are individual for everyone.

The conditions in the steam room depend on the temperature and the relative humidity of the air. The more the boiler is heated, the higher the temperature, and the more water is poured onto the stove, the higher the humidity. This means that quality steam is made by people, not boilers. Infusions of medicinal plants can be added to the water and a therapeutic effect can be obtained. There is a desire - add aromatic substances to the water - the air will smell good. By the way, if you splash a little natural beer on the stove, then a very pleasant smell of freshly baked bread will appear in the steam room.

We got acquainted with the characteristics of steam, it's time to move on to the heaters. What characteristics should you pay attention to when choosing a boiler?

- Volume. The larger the heater, the better the boiler. A large number of stones allows the accumulation of thermal energy; a stable temperature will be maintained in the steam room for a long time.

- Location. The heater can be located on the upper surface of the boiler, surround it around the perimeter, be installed in the chimney, etc. We recommend buying those boilers in which the arrangement of stones allows them to heat up to maximum values (upper position). The fact is that each portion of water poured out to generate steam cools the stones. If they are not warmed up enough, then after a few buckets of water the temperature of the stones will drop significantly and steam will not form.

There are variants of boilers in which the stove is attached along all the groans of the stove. This is a pretty good option, a lot of heat accumulates, the stones are heated to a high temperature.

Practical advice. A circular heater has one drawback - the likelihood of strong heating of the metal increases, which causes the boiler to fail prematurely. Buy those devices that have a small gap between the stones and the walls of the boiler, due to air convection, they are not allowed to overheat excessively.

Weight and overall dimensions of boilers

According to these indicators, the selection is as individual as possible.A large number of metal boilers for a bath have a relatively low weight, which allows them to be installed directly on the floor covering of a steam room or other room. But you need to take into account the dimensions of the floor beams or logs and check their bearing capabilities with the parameters of the boiler.

If the boiler is rather large and heavy, then its installation must be provided even during the construction work: prepare a concrete foundation or use reinforced beams and a floor covering at the installation site. The dimensions are taken into account taking into account the dimensions of the steam room and the specific location of the boiler.

Important. During installation, pay attention to the location of the ceiling and rafter system, they should not interfere with the installation of the chimney. If problems arise, then it is necessary to purchase various elbows to change the location of the exit of the chimney on the roof or take it outside through a special hole in the wall.

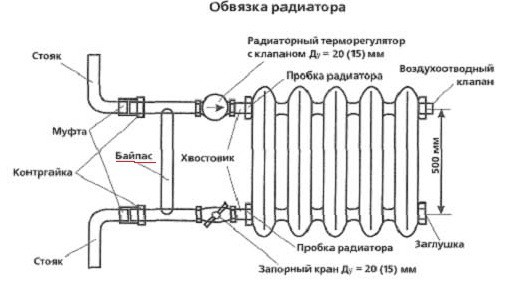

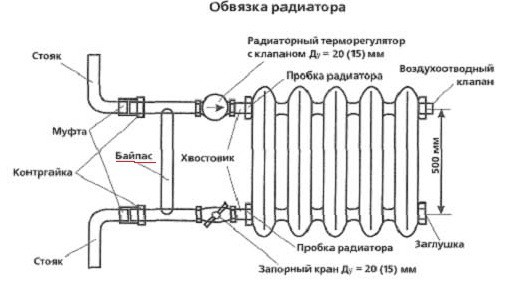

How to connect radiators

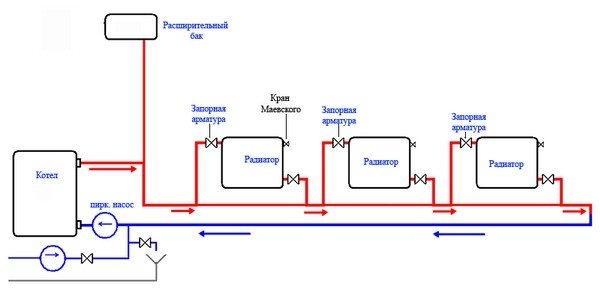

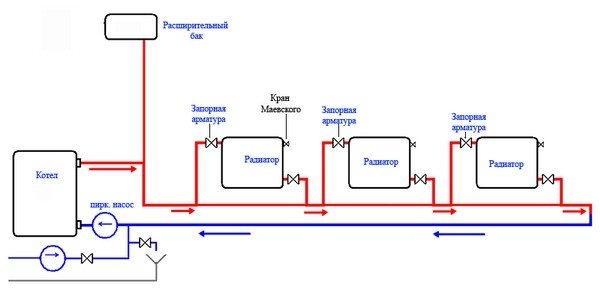

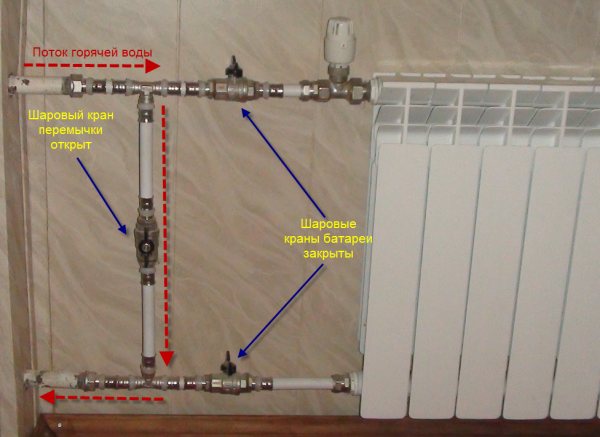

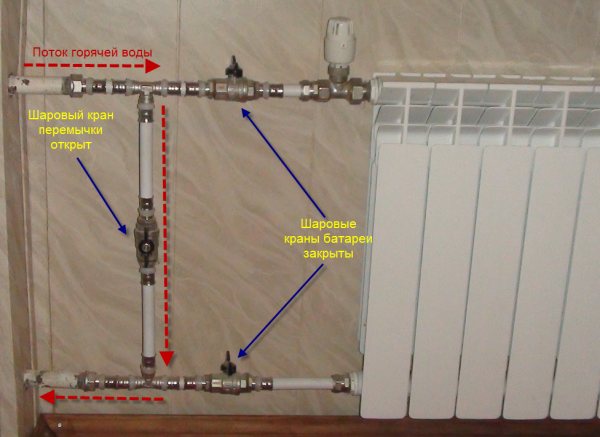

In the bath, you need to heat a maximum of two rooms: a relaxation room and a shower room. We advise you to use a one-pipe bypass system, it fully meets the technical conditions, is easy to install and effective in use, requires little materials and time.

One-pipe bypass heating system

Heating bypass

The diagram shows the diagonal connection of radiators, but you can also connect them in the lower version: the entrance and exit are located at the same level near the floor.

Each radiator has shut-off valves, which makes it possible to regulate the temperature of its heating. If one of the batteries is completely disconnected, then the coolant is supplied to the second through the bypass. Practice shows that one battery is enough for a shower, and it is advisable to install two in the rest room. It's cold in the shower - and put two radiators there.

Heating radiator bypass

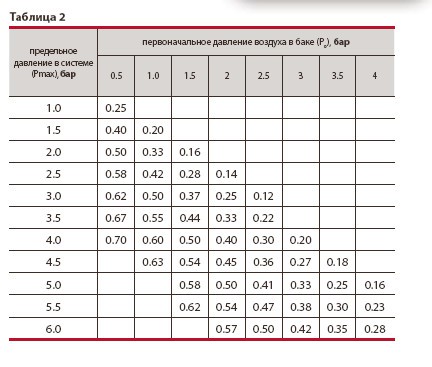

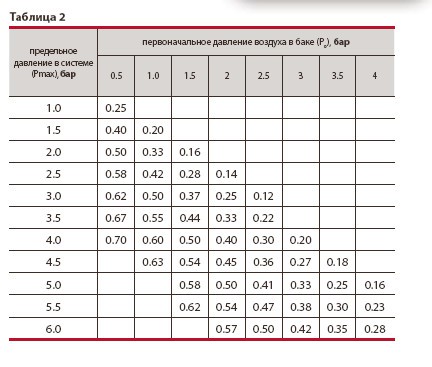

Important. Be sure to use a closed expansion tank, this will exclude the evaporation of the coolant.

Closed expansion tanks

The volume of the expansion tank should be selected taking into account the volume of the coolant. One hundred liters of coolant requires a three-liter tank. Using this data, you can choose the best option for your particular case.

This table will help you calculate the required volume of the tank.

Closed expansion tank

In order to facilitate the replacement of heating batteries, we recommend installing shut-off valves at the inlet and outlet. By closing two taps, you completely disconnect the radiator from the system and you can repair it, all the rest will work as usual. Air is removed from the system using Mayevsky taps or ordinary drain valves.

Mayevsky crane

Expansion tank prices

expansion tank

Long burning boilers

They appeared quite a long time ago, they have their own advantages and disadvantages. Manufacturers claim that one load of wood will burn for a long time, and this will ensure fuel economy and a stable room temperature. To understand where is the truth and what is a publicity stunt, you need to remember school physics lessons. Heat energy is needed to heat the room. For example, one pile of firewood during combustion can release 1 Gcal of heat. If firewood burns out in an ordinary boiler within an hour, then 1 Gcal of heat is released during this time. In the boiler, the same firewood will burn for 10 hours and during this time 1 Gcal of heat will also be released. Note, not more, but exactly the same. This amount of heat in an hour can raise the temperature in the steam room by 100 ° C or by 10 ° C in ten hours. For clarity, we used conventional numbers, it’s easier to understand the meaning. Do you need a long-burning boiler in a steam room to keep it slightly warm?

One more nuance you should know. The burning time is regulated by the amount of air supplied to the furnace. Less oxygen - slower burning of wood, more - wood burns faster and gives off heat energy.The combustion process can be controlled much more easily. Buy boilers that have adjustable holes on the door of the blower or firebox (or make them yourself), increase / decrease the amount of air as needed and you will have a long-burning boiler without large financial costs.

Factory long-burning boilers have quite a lot of different additional equipment, it costs a lot of money. And the efficiency from its use is approaching zero.