Waterproofing of pipelines is a necessary measure that is performed to protect the pipeline from moisture. Today, there are communications that are different in material and purpose, and in order to increase their operational life, it is necessary to organize a suitable waterproofer. The choice of a waterproofing composite depends on many factors: pipe material, area of use, environmental characteristics, etc.

Waterproofing of pipes and pipeline joints is a mandatory measure to protect networks from moisture

Types of waterproofing materials for pipes

To organize waterproofing of various communications, many options for waterproofing are used. Let's consider the most popular ones:

- polyvinyl chloride (PVC) tape;

- heat shrink tape;

- rubber cloth;

- gluing waterproofing Izol;

- polyurethane foam (PPU);

- heat-shrinkable couplings.

All of the above materials are distinguished by high technical characteristics, the main of which is water resistance. DWaterproofing of various pipes is necessary in order to protect the pipeline from the harmful effects of corrosion, as well as to extend the operational life of the system as a whole.

Polyvinyl chloride (PVC) tape

Polyvinyl chloride (PVC) tape is very popular when organizing waterproofing of various communications. It has excellent characteristics and is mainly used to protect the outer surface of pipes from the harmful effects of corrosion.

Note! The most popular tape is made of polyvinyl chloride for the protection of gas and oil pipelines, which are trunk lines.

Most pipes can be waterproofed with PVC tape

In addition, nowadays, polyvinyl chloride tape is used in the repair of heat pipes, namely, during the replacement of an old waterproofer with communications transporting hot water or gas. In some cases, PVC tape is used for waterproofing utility lines.

One side of the PVC tape is supplied at the production stage with a special adhesive composition, which allows its installation as convenient as possible. Before using this tape, it is recommended to carefully check it for cracks and other defects.

Such waterproofing is stored, transported and sold in special rolls that are wound on spools. To protect against moisture, such coils are wrapped in polyethylene.

Cement-based waterproofing coating type is a reliable hydro-barrier.

Performing waterproofing works is a crucial stage, especially when it comes to complex objects: underground, high-rise and hydraulic engineering facilities.

A well-chosen technical solution for the object will solve the problem of the durability of the structure and the operational period. A comprehensive solution for waterproofing an object includes: the correct method of construction, technology and the materials themselves. Operational requirements often dictate the choice of materials. There are many factors affecting the destruction of structures. The most common cause of damage is water.

At one time, waterproofing based on bitumen was popular in everyday life, it was called "black bath", but nowadays, polymer waterproofing and waterproofing on cement has a number of advantages over bitumen waterproofing, since the latter is carcinogenic, hot (requires special conditions for application / operation ), with a limited service life, impermeable, during subsequent finishing requires the implementation of thick-layer plaster layers with the obligatory use of a metal mesh on vertical bases, which violates the integrity of the waterproofing material itself.Cement-based waterproofing is fireproof when performing work, unlike bituminous.

Modern industry offers the following types of cementitious waterproofing:

- Coating waterproofing.

It is divided into two types: rigid and elastic. Elastic allows bridging small cracks (up to 0.5 mm). Example: hydro-barrier protection of the hard coating type

GLIMS WaterStop

with a cement base. Applied in three layers (4–6 mm), it can withstand direct water pressure up to 7 atm. Before applying this material, the surface is pre-prepared. If you compare

GLIMS WaterStop

with bituminous waterproofing, significant advantages can be noted, it is very easy to work with it, it is enough just to dilute in a bucket and apply to the base with a brush.

GLIMS WaterStop

has established itself from a reliable side among builders, therefore it is used for significant objects. Using

GLIMS WaterStop

at the household level (bathroom) it will be enough to apply it in two layers. The only drawback of this type of waterproofing is the tendency to cracking together with the treated base material, but this problem can be easily solved using a two-component polymer-cement waterproofing

GLIMSPRO WP FLEX 2 K

... Due to its characteristics, such a composition increases tensile strength, which means that it copes well with mechanical stress. Flexible coating waterproofing is used on complex surfaces that need reliable protection, such as: pools, water tanks, treatment facilities, sedimentation tanks, canals, offshore structures (piers), transport construction (concrete supports, beams, tunnels, bridges, road and railway viaducts), cooling towers, shafts, retaining walls and foundations.

- Penetrating waterproofing.

After filling the concrete structure, it forms an internal waterproof barrier. Scope: basements, foundations, basements. The main advantage of penetrating waterproofing is the acceleration of the construction process, since there is no need to dry the concrete. This type of waterproofing is most often used on an already finished structure, since it eliminates the need to excavate its base. Penetrating waterproofing is not without its drawbacks, the main disadvantage is the need to use it in combination with other waterproofing agents. Another disadvantage is the high cost and inability to use it for masonry surfaces. - Cement repair waterproofing compounds.

Despite the fact that concrete is particularly strong, reliable and durable, over time it also collapses. After the cement repair mortars hit the market of building mixtures, the builders no longer needed to completely replace the deformed areas. Due to the characteristics of the repair mixtures, the surface regains its attractive appearance and regains its original properties. In order not to worry about the updated system for a long time, it is necessary to choose high-quality cement repair mortars from a reliable manufacturer. GLIMS has developed a complete line of cementitious repair mortars. When choosing a composition, pay attention to the curing time and finishing strength, material consumption, degree of protection against UV, frost, chemical exposure, etc.

- Hydraulic seal.

It is similar in properties to the repair compound, but differs in accelerated setting time and increased efficiency. A hydraulic seal can eliminate leaks, even if setting water oozes during the work (1.5 - 3 minutes)

GLIMS Hydro-seal

- the material has a cement base and is able to eliminate "live leaks". This material is effective for sealing cracks and fixing embedded parts.

The constantly progressing market for waterproofing mixtures imposes a number of requirements, where cement-based waterproofing materials are preferred.

High-quality cementitious waterproofing includes: aggregate, cement and specialized polymer additives that improve adhesion (adhesion), penetrating and crystallizing in the concrete monolith. Polymer additives give the mixture elasticity and enhance the hydrophobic characteristics.

Criteria for choosing a high-quality waterproofing:

1. The level of exposure to moisture. Internal or external (ground, melt water, condensation of water vapor) contact with water 2. Possibility of intermediate repair work. The choice of material is carried out at the design stage, taking into account the geological conclusions, which avoids additional expenses in the future. 3. The level of deformation effect on structures.

The main advantages of cement-based waterproofing:

- Wide range of applications. Cement waterproofing is used in both civil and industrial construction (facades, foundations, plinths, bathrooms, kitchens, balconies, pools, basements, ponds, terraces, wells, etc.)

- High level of protection against the damaging effects of moisture. Can be used for complex objects.

- Convenience and ease of use.

- Cement-based waterproofing can be applied to a damp surface and the adhesion (adhesion) will only increase.

- Absence of any chemical reactions in contact with aggressive media.

- Frost resistance

- Vapor permeability

- Environmental Safety

Application method:

Before using waterproofing, we recommend that you read the instructions for the work from the manufacturer. General technology for applying cement-based waterproofing:

- Cleaning the surface from dust, debris, dirt, grease, etc.

- Treat the base with a primer using a roller, brush the joints with a brush.

- At the joints, lay a specialized tape for additional protection and sealing. If there are cracks and seams, use an appropriate repair compound.

Waterproofing tape GLIMS Corner

- material with a high elasticity index (144%). The main purpose of the tape is to reliably seal the areas that are most exposed to deformation loads.

GLIMS Corner

used in conjunction with cement waterproofing

GLIMS WaterStop

or flexible waterproofing

GLIMS GreenResin

.

How to avoid errors in calculating the amount of the mixture.

Estimating errors can be very expensive, so the calculation must be entrusted to professionals. GLIMS technical specialists will help you, free of charge, to determine which waterproofing mixtures, in what quantity and on which surfaces you need to apply. In addition, we will help you find the necessary accompanying building mixtures for high-quality repairs.

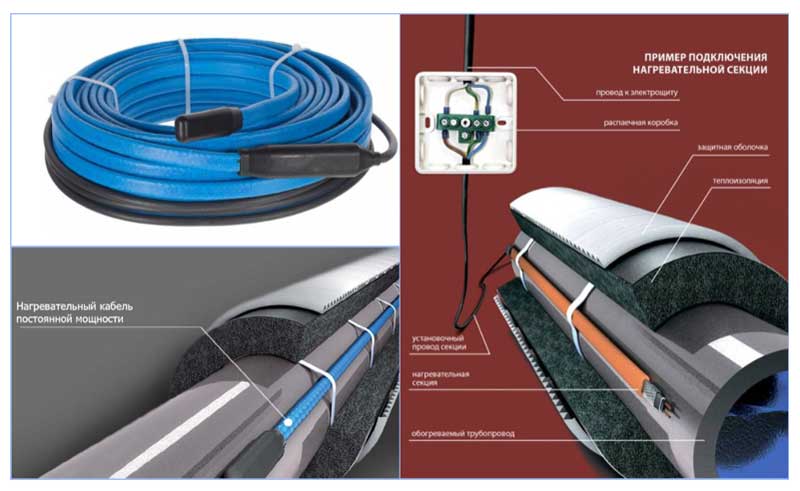

Heat shrinkable tape

Such a tape is used in cases where it is necessary to protect the welded joint. The place of the weld joint is the most vulnerable to destructive corrosive effects, therefore, the use of heat-shrinkable waterproofing tape is a necessity. However, in some cases it is used to protect the surface of the entire communication, but such cases are extremely rare.

Heat shrinkable tape is used to protect welded joints

It is important to remember that it is strictly forbidden to use such a tape for installation on a pipeline if the operating temperature exceeds 60 ° C. Heat-shrinkable tape provides reliable protection of welded joints and consists of two layers:

- hot melt layer;

- a layer that is a polyethylene film (PE film is the base).

In combination with this tape, you can also use a special fixing agent - a primer. In this case, such waterproofing is allowed to be used even for pipes that have a coating consisting of three layers.

Let's consider the main advantages of using a heat-shrinkable waterproofing tape:

- high elasticity, allowing you to mount such a tape on a pipe with virtually no restrictions;

- the material of the tape is highly fire-resistant;

- Heat-shrinkable tape does not allow moisture to pass through.

Before installing such a tape on a pipe, it is imperative to warm up the pipe to a temperature of 80–100 ° C. To date, there are quite a few varieties of such a tape and you can purchase it without much difficulty.

This tape has little resistance to UV rays, so it must be stored in a dark place. Otherwise, it will lose its properties and be useless. For waterproofing one welded joint of the pipeline, an amount of tape equal to 3.5 indicators of the pipe cross-section is required.

Preheated pipe is wrapped with polyethylene tape

Where to order?

If you need to carry out work on waterproofing the chimney or places of passage of engineering communications, please contact. We have a powerful material and technical base that allows us to implement projects of any complexity and any scale. All work is carried out by experienced professionals who are highly qualified and comply with all technological processes. Along with the use of innovative technologies and the use of quality materials, this always guarantees excellent results!

Rubber cloth

Waterproofing pipes in the ground provides protection from moisture and groundwater for steel pipes and other underground materials. Such insulation is usually carried out by means of a special rubber sheet.

Such a sheet provides reliable protection of the pipeline structure mounted underground from destructive corrosive effects, and also effectively insulates the joints between the pipes.

Typically, rubber sheets are used to waterproof oil pipelines. In addition to the main function - isolation from groundwater, the rubber sheet is used to protect gas and oil pipelines, brick and reinforced concrete pipelines that transport wastewater.

Note! For waterproofing utility lines, such an insulator is practically not used. This is due to the fact that its transportation is impossible without special equipment.

Consider the main advantages of this waterproofer:

- the main advantage of this waterproofer is resistance to temperature extremes;

- the rubber sheet is resistant to corrosion, as well as to aggressive chemical compounds;

- it is resistant to electric fields in the soil;

- has a high strength factor;

- has high elasticity;

- and also has a long service life.

Rubber sheet is the simplest but most reliable material for protecting pipes from moisture

Waterproofing of pipelines in the ground against corrosion

Waterproofing pipelines in the ground with mastic

Sewerage systems, cold and hot water supply systems, heating systems, as well as ventilation and air conditioning systems are subject to mandatory treatment with mastic against moisture in the ground.

Do-it-yourself high-quality waterproofing will significantly prolong the operation of the system with a minimum probability of breakdowns, prevent the development of pathogenic bacteria, and protect the walls and ceilings of the building from condensation and smudges.

Insulation waterproofing Isol

The glued waterproofing material Izol is resistant to very high temperature indicators.In addition, this material is waterproof and has a high strength factor.

Such material adheres perfectly to the outer wall of the metal pipe and thereby provides high sealing performance. Due to its thermal stability, Izol is widely used as a waterproofing agent for steel pipes transporting hot water and steam.

However, it should be noted that piping waterproofing is weakly resistant to aggressive chemicals, which consist of organic connectors and solvents.... This material is classified into several main types, depending on the components used in its production.

It is stored, transported and sold waterproofing coating in special rolls. In addition to waterproofing metal communications, this material is widely used for waterproofing bridges and other metal structures.

Consider the main advantages of Izol glued waterproofing:

- good adhesion to metal material and concrete products;

- resistance to high temperatures (up to 150 ° C);

- high strength characteristics;

- high waterproofing performance;

- long service life (up to 50 years).

A shell made of polyurethane foam can serve as both moisture protection and thermal insulation

Chimney waterproofing

When planning a stove heating system in a private house, waterproofing of the pipe on the roof should be provided, in which condensation can accumulate, which adversely affects traction.

Various materials are used for these works: roll filters, asbestos plates, cotton wool. High-quality waterproofing will ensure uniform heating of the entire smoke passage, while evaporating moisture and preventing condensation from accumulating.

First you need to glue the diffusion membrane to the chimney. The surface is pre-primed. The membrane is fixed with bitumen mastic. Then it is folded up along the edge and sealed with mastic again. After that, the lower and upper ties are attached using the corners. Sheets must be laid with an overlap, all joints are processed with bitumen mastic.

Waterproofing the roof chimney will prevent moisture from entering the chimney.

Shell made of polyurethane foam (PPU)

Such a waterproofer is very popular due to its ease of installation. The polyurethane foam shell protects the pipe from corrosive effects, as well as from unwanted heat loss. Therefore, such a material can be considered not only a waterproofing agent, but also a heat insulator.

Note! It should be noted that even pipes made of modern polymeric materials need protection. This is due to the fact that condensate forms and accumulates on the surface of plastic pipes during operation, which leads to the development of mold and mildew in the main communications.

Thermo - and waterproofing shell made of polyurethane foam excludes the possibility of condensation on the surface of metal and plastic pipes. Such an insulator is distinguished by its efficiency and reliability, and no special construction knowledge and skills are required for its installation.

Waterproofing of pipelines in the ground. SNiP

Compliance with SNP will increase the service life

When building new pipelines, expanding and reconstructing existing water supply and sewerage facilities in residential and industrial buildings, the requirements of SNiP 3.01.01-85 (Organization of construction production), SNiP III-4-80 (Safety in construction) and other rules and departmental regulatory documents approved by the State Construction Committee in accordance with SNiP 1.01.01-83.

Excavation work on the arrangement of foundations during the construction of water supply and sewerage pipelines must be carried out in accordance with the requirements of SNiP 3.02.01-87. Completed pipelines, water supply and sewerage communications in private houses should be taken into operation in accordance with the provisions of SNiP 3.01.04-87 (Acceptance of completed construction projects into operation), approved by the State Construction Committee.

Heat shrinkable sleeves

First of all, it is worth noting that heat-shrinkable waterproofing couplings are put on the pipe before the start of welding, and after that they are "shrinked" in place of the pipe weld.

Consider the positive aspects of using such a clutch:

- high tightness rates;

- efficiency and reliability;

- resistance to aggressive chemicals;

- ease of installation;

- long operational life.

Heat-shrinkable couplings are used to insulate pipe joints of heating and hot water systems.

The choice of the most suitable waterproofing material depends on the specific conditions, therefore, for each case, it is necessary to select the most suitable waterproofing material. For the insulation of welded seams in communications that transport hot water, the most suitable option is a waterproofing heat-shrinkable sleeve. Such a sleeve is usually made of polyethylene.

Waterproofing of underground tanks

Tanks in the ground are attacked by moisture and chemicals that alter the structure of the metal. This is especially true for structures located in loamy soils with a high level of groundwater. With a larger tank volume, it can practically stay in water for a long time.

In this case, the waterproofing material must also be very resistant to mechanical stress.

For "heavy" waterproofing of such surfaces, a two-component mastic is used based on a bituminous primer and rubber additives, and a bituminous material with polymer additives "Petroflex".

Waterproofing an underground metal barrel

When protecting a new metal layer, it is first primed with a bitumen-polymer primer in several layers. Working with the next layer begins after the previous one has dried. Then the surface is coated with a bitumen coating.

When working with old coatings, you must first clean them from traces of previous insulation to a metal surface, remove surface traces of corrosion. Then a primer and mastic coating is done.

The number of layers of primer and coating is calculated based on the assessment of the moisture saturation level of the soil where the reservoir will be located.

If the soil is moderately moist without the threat of flooding by upstream waters, the following scheme can be applied:

- the first material is a rubber-containing bitumen mastic, applied in one layer with a thickness of at least two millimeters. Can be applied in two layers, one millimeter thick.

- the second material - "petroflex" roll waterproofing and roofing, melted on a bitumen-polymer basis. Fits in one layer.