Laminate flooring is in great demand due to its installation and operational advantages. Proper insulation of floors in a private house is important when laying laminate flooring, as this affects the service life of the material.

In case of poor quality insulation, condensable moisture may appear, which will lead to damage to the floor covering. In addition, energy costs for heating a house or apartment increase by 20%.

Insulation types

The base for laying the laminate can be wood or concrete. Depending on this, insulation for the floor under the laminate is chosen. Expanded clay is used as a heater for a wooden floor. For better insulation, its layer should be at least 10 cm.

Other types of insulation are produced that can be laid on wooden and concrete floors:

- Styrofoam - insulation with a grainy texture, which is filled with air. It is very lightweight, practical, has excellent thermal and sound insulation qualities.

- Expanded polystyrene - evens out the base for laying the topcoat.

- Polyurethane foam... There are two types: jellied and sprayed. Slightly absorbs moisture, retains heat. Work on insulation with such material requires special equipment, in this case it is better to hire craftsmen.

- Mineral wool Is an inexpensive and long-lasting material. After installation, this insulation must be covered with foil or metallized film.

- Ecowool in its structure and qualities it is similar to mineral wool, but it is made from cellulose fibers, therefore it does not harm human health.

- Foil available in two forms: in slabs and in rolls. Lay with reflective side down.

- Bung - the most expensive insulation, however, environmentally friendly, reliable and durable.

- Plywood underlay, oriented strand board (OSB), gypsum fiber sheet (gypsum fiber board - in more detail: "How is the laying of gypsum fiber board on the floor - examples from practice"), fibreboard (fiberboard), chipboard (chipboard) - will allow in a short time and with this qualitatively make the floor even and warm.

What material to choose

Today on the market there is a large selection of modern materials that are used for floor insulation. When choosing a thermal insulation material, it is worth considering some factors.

First of all, this concerns the type of flooring, as well as the temperature regime in this room. As for the choice, you can use to insulate the floor under the laminate:

- Substrate;

- Expanded clay;

- Foil;

- Glass wool;

- Styrofoam;

- Warm floor and others.

To make the right choice, you need to carefully consider each of the above materials. This is especially true of their merits and demerits.

General technology of floor insulation

First, the base is prepared. All existing irregularities on the floor should be eliminated: comb off protrusions, pits and cracks, seal up with mortar and putty. The next stage is the implementation of waterproofing. The surface is covered with plastic wrap so that the edges overlap. Scotch tape is glued to the seams. The waterproofing layer is very important: it protects the wooden elements from moisture.

If a wooden floor is insulated, then logs are laid, and heat-insulating material (expanded clay, mineral wool, polystyrene) is placed in the space between them. Then, to level the surface, boards and substrates from materials produced in sheets, for example, plywood, are used.

If the floor is uneven, then it can be leveled with a concrete screed or self-leveling mixture. Prepare such a flooring mixture according to the instructions in a container of a suitable size. Then it must be spread over the surface with a spatula.

Also, insulation under the laminate on the concrete floor can be laid between the beams, and a dry screed can be made on top and a substrate can be laid. To prevent the floor level from rising very high, you can lay a thin thermal insulation film with a foil layer. This material is glued to flat floors with a special compound.

Styling process

When laying the laminate with your own hands, do not forget about the backing. It cannot be laid under linoleum, under laminated boards it is necessary. Here are some of the functions that a backing does:

- soundproofing;

- thermal insulation;

- leveling minor surface flaws.

It also helps preserve the flooring itself. You cannot save on the substrate. Forget about the cheap roll-up liner that usually sells by foot. For several years of operation, the laminate boards will simply be destroyed, after which they themselves will become unusable.

Choose only a high-quality substrate: cork, expanded polystyrene, coniferous. At the same time, please note that it is not required to fix it either to the walls or to the floor. However, like the coating itself. You can only grab it with masking tape at the junction. And then, it is not necessary.

To begin with, we will install the spacers, since the cover can only be properly laid by maintaining the release gap. What it is? We have already said that in the process of changing humidity and temperature, a tree can expand and contract. So, this is, roughly speaking, the gap between the wall and the floor covering, which is needed in order for the material to have room to "grow". Otherwise, the joints may acquire a Λ-shape, which is highly undesirable.

Now we lay the backing, after which we start the laminate flooring. Here is the algorithm to use when styling:

start at the corner farthest from the door. Take four boards. For those that will be laid against the wall (the first and third in a row), it is necessary to cut off the ridge with a sharp knife. But you do not need to touch the groove. When stacking, it must always face the stacker;

By the way, it is recommended to lay the boards perpendicular to the old floorboards;

- panels of adjacent rows must be offset. Therefore, measure this distance in advance. It must be at least 30 cm;

- snap in the first and third panels. The latching method depends on the type of lock - Click or Lock;

- place the resulting fragment of the floor in its place;

- lay the second row in the same way as the first. Do not forget that the panels are displaced by at least 30 cm, and a gap must remain between the coating and the wall, which will subsequently be hidden by the plinth;

- when laying the last row in a room, the laminated boards must be sawn to length according to precisely measured dimensions.

You can lay the laminate in any convenient way. You can dock ready-made rows of boards or lay them using the additional method, that is, one board at a time. If you are new to this business (and most likely you are), then the second method will be more convenient for you.

After the last board is in place, you can remove the spacers and proceed with the installation of the skirting board. With its lower edge, it should fit snugly against the floor, and with its upper edge against the wall. Installation is carried out using dowels and self-tapping screws.

Of course, in those rooms where cleaning with soapy water will often be carried out, it is better to lay linoleum. Constant exposure to moisture can even lead to delamination of the board, and then there is practically nothing to "help" it.

In places where the laminate meets other flooring (tiles, carpet), use a padded sill.It should be mounted, like the skirting board, with self-tapping screws, which are most often sold in a set.

The sills with hidden fastening look more aesthetically pleasing, where the caps of the screws are driven into a hidden groove, so they are not visible. The threshold without hidden fastening is fixed with self-tapping screws from above. Thanks to this, if necessary, it can be unscrewed and reused. But the profile with hidden fastening is not screwed on, but hammered into pre-prepared holes. If necessary, you can dismantle it with a mount, but it is not a fact that it will "survive" this procedure.

Now you know what it is like to mount a laminate on a wood base. In order for the flooring to serve you faithfully, you should not save on materials or try to invest in the shortest possible time. Be prepared that a good backing and quality laminate will not come cheap. The miser, as everyone knows, pays at least twice.

https://youtube.com/watch?v=aoHoHHzqbRY

Laminate underlays

Laminate flooring should not be laid directly on concrete, even if it is perfectly leveled and insulated. Otherwise, the laminate floor will make unpleasant squeaky sounds when walking.

Where an uneven laminate floor will bend, as a result, the locks will loosen and break, and gaps will appear between the panels. All instructions for laying laminate flooring indicate that it should be laid on a substrate with a thickness of at least 3 mm, otherwise the claims arising about the quality of the coating will not be accepted.

The underlayment under the laminate prevents condensation and constant evaporation of moisture under the coating due to temperature changes. Regardless of the fact that the substrate is thin, only a few millimeters, it has high heat-shielding characteristics, attenuates resonance during sound and shock noise, there is no need to perform additional waterproofing, as it provides natural ventilation.

In a single room, different types of substrates are not used, but in different rooms of a house or apartment it is possible. For example, in the bedroom and living room, substrates from natural materials are used, in the kitchen and bathroom - from artificial ones. You should not lay the underlay on the entire floor surface at once, just put one strip, which is enough for 2-3 rows of laminate flooring, then the material will remain even and clean (about

Characteristics of extruded polystyrene foam

How to lay laminate flooring correctly

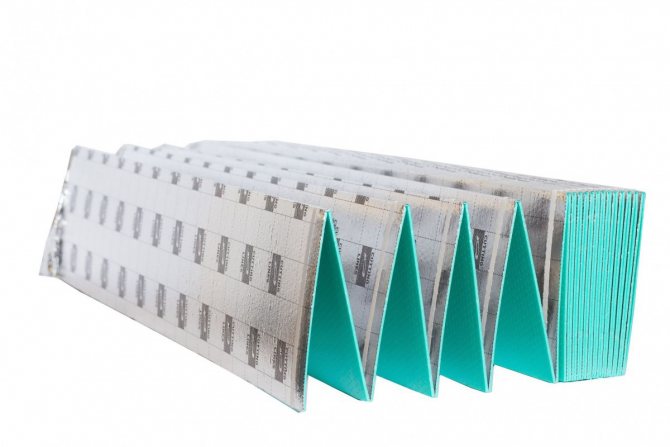

Most often, substrates made of this particular material are used under the laminate. The peculiarity of its structure lies in evenly spaced closed cells, which ensures the moisture resistance of the material. The production of the substrate takes place using an extrusion molding machine, where polystyrene, together with a blowing agent, is fed through a narrow nozzle under high pressure and high temperatures. The result is a material with a low density (30-40 kg / m³).

Expanded polystyrene backing

The grooves on one side of the substrate are necessary for natural air circulation

The material does not rot and does not absorb moisture. When wet, water does not penetrate beyond the open lateral combs on the cut. It is distinguished from analogues by its great strength and thermal insulation properties. Substrates from this material are produced in rolls and in the form of sheets, 1000 x 500 x 3 mm in size.

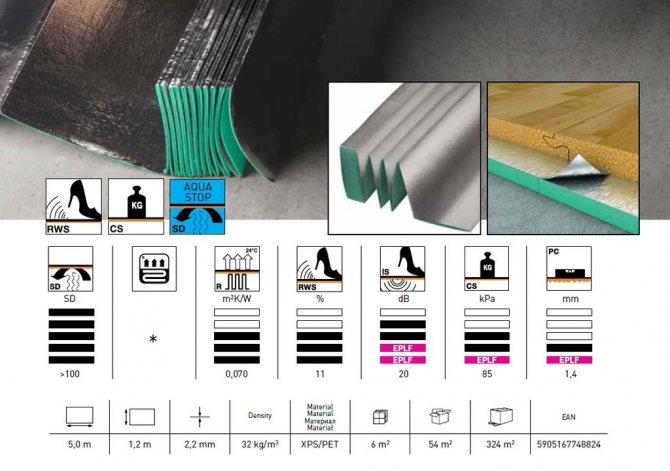

Table 2. Characteristics of expanded polystyrene

| Technical properties | unit of measurement | Value |

| Moisture absorption | % | 0.08 |

| Working temperature range | ° C | from -50 to +75 |

| Density | kg / m³ | 35 |

| Soundproofing | dB | 5.5 to 22 |

| Thermal conductivity | W / (m * ° C) | 0.035 |

Polystyrene foam substrates combine high quality and affordable price

Recommended posts

Recently viewed by 0 users

No registered user is viewing this page.

The best articles on the IVD website

Are you a professional architect or designer?

IVD.Renovation and finishing

Are you a professional architect or designer?

The IVD.ru website is a leading Internet project dedicated to the reconstruction and interior design of residential premises. The main content of the site is the archive of the Ideas for Your Home magazine - exclusive author's articles, high-quality illustrations, practical advice and lessons. A team of professionals is working on the project in close cooperation with renowned designers, architects and leading experts of the publishing house.

On our site you can find complex design solutions; view detailed reviews of the market for building and finishing materials, furniture, machinery and equipment; compare your own ideas with the design projects of leading architects; communicate directly with other readers and editors on the forum.

Are you a professional architect or designer?

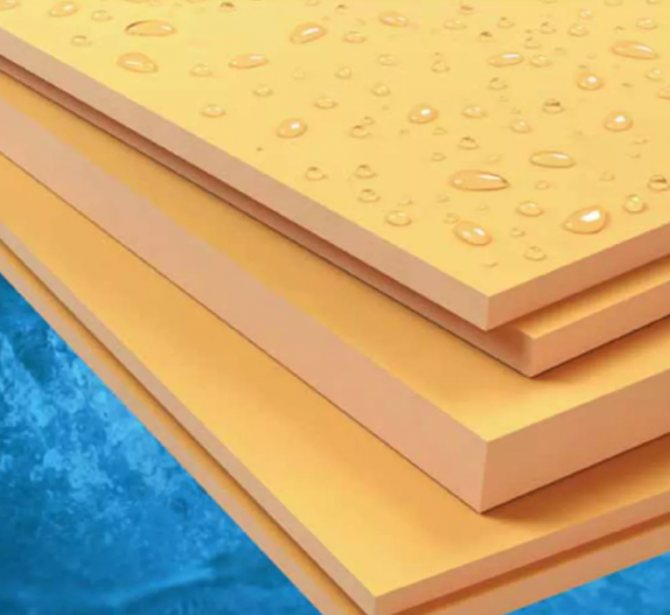

It is common to insulate the floor with penoplex today. offer the heat insulator is chosen because of the low thermal conductivity, to dispense with the possibility of a small thickness, as well as high compression strength, which makes it possible to dispense with additional reinforcement when installing floors. They insulate floors on the ground, floors above basement floors, rooms on floors, balconies and loggias. The material is also popular because the price of floor foam and screed is relatively affordable. As a finishing coating, tiles are mounted, veneered tiles are arranged, a screed board with a "warm floor" system, penoplex is placed under the laminate and linoleum.

Penoplex - warm floor base

There are many technologies for floor insulation. This is expanded clay, mineral wool, and penoplex, of course. The latter is one of the best modern heat insulators, although, it should be noted, not the most For. cheap floor insulation is sufficient for 20-30 mm first (on slab floors it can be up to 50 mm), while the thickness of the mineral wool is increased, for example two times more is recommended.

- The advantages of foam insulation for the floor are as follows:

- Excellent moisture insulation Good

- thermal insulation properties

- Mechanical strength

- Durability

- installation Simple

Before installing the penoplex on the laminate, you need to lay the insulation itself. This is easy enough to do. It all depends on what kind of leveling screed will be - a cement sheet made of either material (plywood, OSB boards, For). GVL one will need as smooth a rough surface as possible, for the other one will have to lay down wooden logs as the basis of the coating for.

underlay and Penoplex under the laminate

As you know, when laying when covering, a substrate is used - polyethylene foam cork or. Can laminate flooring be laid on a foam backing? without Many "craftsmen", as it shows, the practice is such a temptation, how to put penoplex on the laminate without any screeds. It seems that this material is durable, why be smart with a screed? gender This will only bring problems.

Penoplex is not point-to-point for the calculated load, its strength makes itself felt under static pressure. The heat insulator, according to the rules under the screed, can withstand a huge amount of time, and at the same weight it is easy to make a hole in it with a pencil though. And most of the pieces of furniture are the same point load.

An unsuccessfully placed cabinet, caught with its foot on the lock of the laminate board, can simply fall into the floor. Penoplex under the laminate will not save from destruction - there will be little in it, it is intended to protect it from noise and moisture, and not to reinforce the base. In addition, such a coating will creak terribly.

Carrying out insulation and flooring, it is still better to abandon "folk inventions" and existing technologies to rely on. And they argue that the laminate cannot be mounted directly on the penoplex. It is better to follow the instructions and end up with a warm and beautiful floor than starting a new renovation six months later, correcting your own mistakes.