Features of the double-deck oven

Structures of this kind are distinguished by their large dimensions and large mass. A stove that will provide heating on two residential floors at the same time requires a strong and reliable support. Accordingly, when laying the foundation, the structure and composition of the soil are taken into account.

The stove is erected with reference to the load-bearing internal walls. Refractory elements should be provided in the places adjacent to the highly heating surfaces of the heating system of the sections of interfloor and ceiling ceilings.

There are two types of two-tier systems: with one and two fireboxes. The first variant of a stove for heating two floors is the simplest and most reliable. On the lower level, there are large elements: a hob and a stove bench. On the second floor, at the request of the owner, for example, a fireplace can be installed. Such structures increase the heat transfer surface and improve the quality of room heating.

Advantages and disadvantages of stove heating

But the stove heating system also has a number of disadvantages. First, the dimensions and weight: a stove installed in the house will look good, but a significant decrease in usable space will still be noticeable. The large weight of the furnace structures necessitates the laying of the foundation. Secondly, a long warm-up time of the system. Of course, this quality acts in both directions, because prolonged heating in the future leads to an equally long cooling. The efficiency of stoves is also their disadvantage, since most of the heat will go either into the pipe or for heating the walls.

The cap of the first tier must be closed, but the holes for cleaning it and cleaning the lower aisles are on the second floor. The furnace and lining are usually made of fireclay bricks, and basalt cardboard must be laid between them. This solution prevents possible cracks in the masonry.

Stove heating video:

Stove on two floors with one firebox

The quality of home heating during the cold period depends on the location and design of the heating system. A single-hearth two-deck oven is less durable than a two-deck one due to higher thermal and other loads. At the same time, it is easier to build and maintain: you do not have to bring firewood and coal to the second floor.

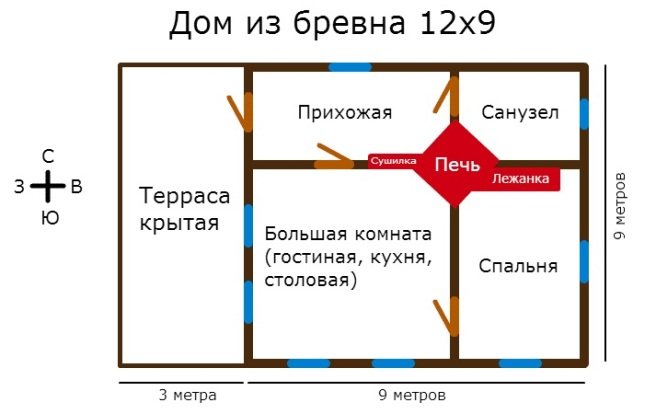

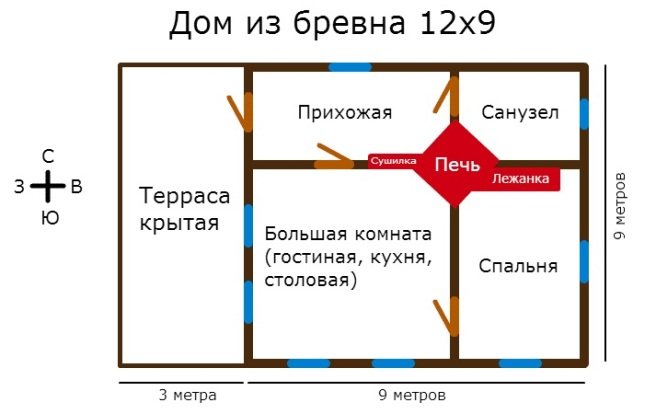

Such structures are installed in the center of the living area and by analogy with stoves for two rooms in a wooden house. This arrangement provides the most stable and even heating of all rooms.

Such heating structures have the following features:

- On the second floor, there will be separate vertical channels equipped with dampers. This allows you to regulate the temperature regime on the floors.

- This system provides delimitation of the paths of movement of combustion products and prevents their rapid cooling with the formation of condensate.

- For normal heating of the house, the size of the projected firebox must accommodate a sufficient amount of firewood, which is laid vertically.

With this arrangement of logs, the combustion area significantly increases, which increases heat transfer. Hot gases rise along the ascending channel and, at the ceiling height of the second floor, are divided into two streams into the corresponding chimneys.

The location of the stove in a wooden house

In wooden buildings, the choice of places for installing stoves is limited, due to the observance of fire safety measures. There you have to use packed pipes.It is convenient to place furnaces with shell pipes anywhere, but it should be ensured that the pipe does not fall on the floor beam and rafters. Packing pipes are installed only on massive thick-walled furnaces. For fire safety reasons, thin-walled furnaces are not recommended to be built with packed pipes.

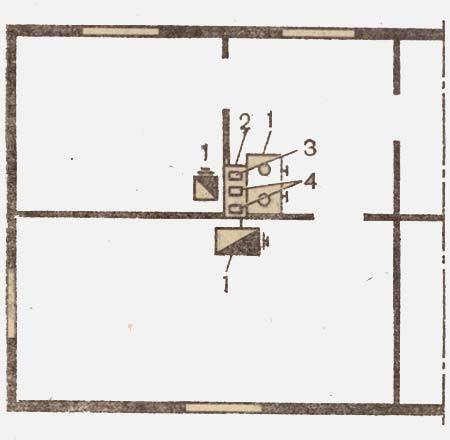

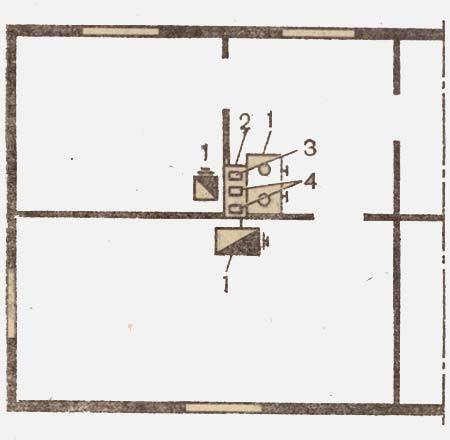

Figure 3. Connecting furnaces to the main pipe

Root pipes are necessary for the removal of flue gases from kitchen fireplaces and, at the same time, flue gases from heating stoves. To do this, the required number of vertical smoke channels, the so-called risers, are made in the root pipe (Fig. 3).

The considered option shows the feasibility of erecting a root pipe in a house with three or four rooms.

If the house has several rooms, each of which is occupied by a separate family, it is advisable to install as many stoves as there are rooms.

When a kitchen-dining room is envisaged, it is more expedient to put combined heating and cooking ovens with a mandatory ventilation device. For the construction of individual houses, there are many standard projects in which all kinds of stoves are carefully designed and selected and their locations are indicated.

Construction of a double-deck oven with a hob

A modern stove on two floors with one firebox, in addition to the main heating function, provides the possibility of preparing simple dishes, heating food and heating water for household needs. For these purposes, it is supplied with a hob with a massive cast iron stove - monolithic or with two round holes. The latter are provided with a composite cover in the form of a set of overlapping rings of decreasing diameter.

When developing a project for a stove designed for heating a two-story house, take into account the following:

- Binding the heating system to the internal capital walls allows not only to reduce the load on the structure of the house, but also to balance the operation of the furnace.

- Furnaces weighing up to 700 kg do not require complex foundations.

- The stove, which is designed as the main source of heat in a two-story house, is a single system that runs through the entire building and is linked to the load-bearing elements.

When laying the stove, both one- and two-tier, a refractory clay mortar should be used. This will greatly increase the resistance of the furnace structure to high temperatures. Vaulted brickwork provides high reliability and durability.

Features of the design of housing with stove heating

Stove heating, which does not have a water circuit, will only be effective if the stove becomes the center of all adjacent rooms. To achieve this, the hearth is installed in the wall between the rooms, and the firebox is taken out into the corridor or into the kitchen.

Some architects offer another option for solving the problem - the installation of two or even three hearths in different rooms. However, a central heating unit is preferable to building several heat sources - this allows you to do with one chimney and significantly saves fuel consumption.

In projects of two-story houses with stove heating, they adhere to the same rules, but they necessarily provide for a reliable overlap between floors that can withstand the mass of a brick building. All heavy parts (stove bench, oven, hob) are placed on the ground floor, and at the top they are limited only by the heating shield.

If the house is planned according to the studio principle and consists of one large room, the Russian stove is made the central link, at the same time entrusting it with the tasks of separating the space. Thus, the hearth can separate the kitchen and living room, sleeping area and common room.

Materials and tools used to build a stove on two floors

The construction of such a complex structure requires specific knowledge, skills and experience. To build a functional and efficient stove on 2 floors in a private house, you will need the following materials:

- refractory brick and ordinary solid (red);

- fire-resistant fireclay clay;

- quarry sand, sifted and washed;

- cement grade not less than 500;

- cast-iron doors: large - for the firebox, small - for the blower;

- grate bars from 4 to 10 pieces, depending on the size of the firebox;

- cast iron plate, solid or with holes;

- views and dampers for blocking flows in chimneys.

- equal metal corner with a side of 50-60 mm;

- tin cover for installation above the chimney on the roof;

- steel wire;

- asbestos sheets.

To build a stove that will heat both floors of a private house at the same time, you will need the following tools and devices:

- concrete mixer or containers for the preparation of solutions - large and small;

- inventory: bayonet and shovels, buckets for water and mortar;

- tools: a mason's hammer, a trowel, an electric drill with a nozzle for mixing solutions, a level and a plumb line.

The calculation of the required amount of materials is carried out based on the design dimensions of the furnace with a small margin of 5-10%. So, part of the brick, even with an experienced master, becomes unusable as a result of splitting during the masonry process, part turns out to be defective initially.

Foundation device

The substructure must be strong enough to support the weight of the double-deck heating system. A large oven on two floors creates a significant load on the foundation, during the construction of which the following requirements are taken into account:

- Loose sandy and sandy loam soils must be compacted before laying the foundation. The deepening of the foundation is at least 1 m, the sand-crushed stone pillow is necessarily poured and waterproofing is done.

- In width and length, the base should be at least 50 mm larger than the stove, the height should be flush with the floor of the first floor or 50-70 mm above it.

- The distance from the foundation of the house to the foundation of the furnace should be at least 500 mm, the gap between them is filled with sand and carefully compacted.

Pouring the base for the furnace cannot be carried out simultaneously with the laying of the supporting structure of the house, this can lead to uneven shrinkage. After completion of work on the construction of the foundation, it is necessary to leave it alone for a month and a half until the cement is completely mineralized. The side walls of the base are insulated with roofing felt to protect it from the destructive action of moisture.

Choosing the best place

First of all, the principle of operation of the heater will help to determine the optimal location of the stove in the house. The location may vary depending on whether it is possible to build a chimney on a particular site and equip the correct operating area.

If you definitely want the stove to be located exactly in this place, then before its construction you need to calculate such an indicator as fire breaks: how far are constantly heating surfaces from walls covered with flammable materials.

You can more accurately determine the place of the stove in the house, based on the recommendations below:

- If the owner of the house has at his disposal hot-air heating devices, for example. "Potbelly stove" or "Buleryana", then they should be placed so that air flows can penetrate unhindered. This will create a convection system, thanks to which you can heat two adjacent rooms without doors.

- If the heating device has a built-in heat exchanger, then the placement of the stove can be any, subject to fire safety rules. However, it should be borne in mind that the furnace circuit must act as the lower boundary of the heating system.

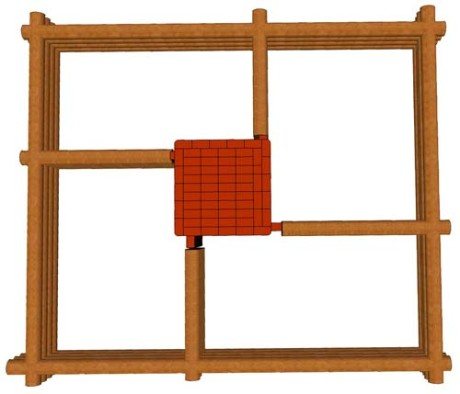

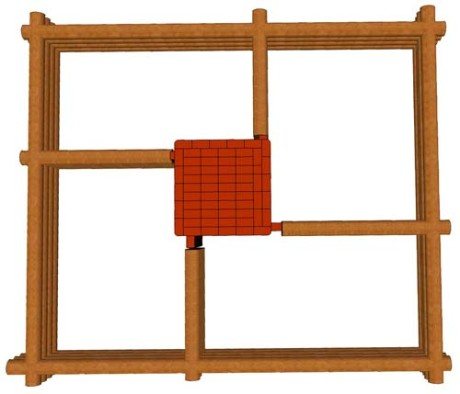

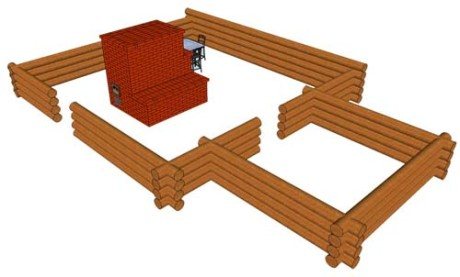

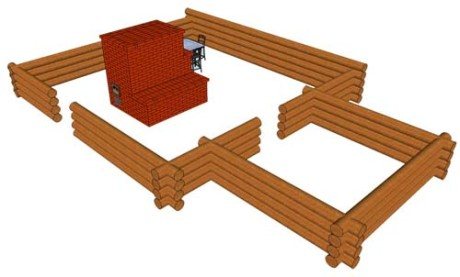

Drawing of a standard log house

- It is impossible to install the stove, and at the same time avoid the construction of the chimney part and the pipe inside the house. In this case, the location directly depends on how it will be easier to connect the heater itself with the smoke extraction system.

- An important point is taking into account the free space when opening the door of the combustion chamber. If there is a lack of it, then there will be difficulties in order to clean and heat the stove in a wooden house.

- Buildings that are supposed to be heated by stoves must have a sufficient area so that fire breaks from heated surfaces to flammable elements can be observed, which corresponds to 1.1-1.25 meters. Also, the rule states that the distance to the opening door of the combustion chamber should not be less than 1 m 25 cm.

Good to know: What should be the height of the furnace in the furnace, we study the dependence on the type of fuel

Bunk oven masonry and its main elements

A waterproofing layer is laid on the upper surface of the matured foundation. When building any stove - a fireplace for two adjacent rooms or a two-tier one - the first row of single bricks is laid without mortar. Accuracy is ensured by applying the marking directly on the roofing felt.

The construction of a heating structure is carried out according to a pre-drawn scheme, which provides for all its main elements:

- blew;

- a firebox capable of accommodating a sufficient number of logs;

- hob for cooking;

- chimney channels;

- views and dampers;

- inspection hatches;

- bed;

- chimney.

When laying the furnace, a solution of refractory clay and sand is used in consistency corresponding to thick sour cream. After drying, it does not crack or spill out. The prepared masonry mixture is used within an hour and a half, when thickening, the addition of water is not allowed.

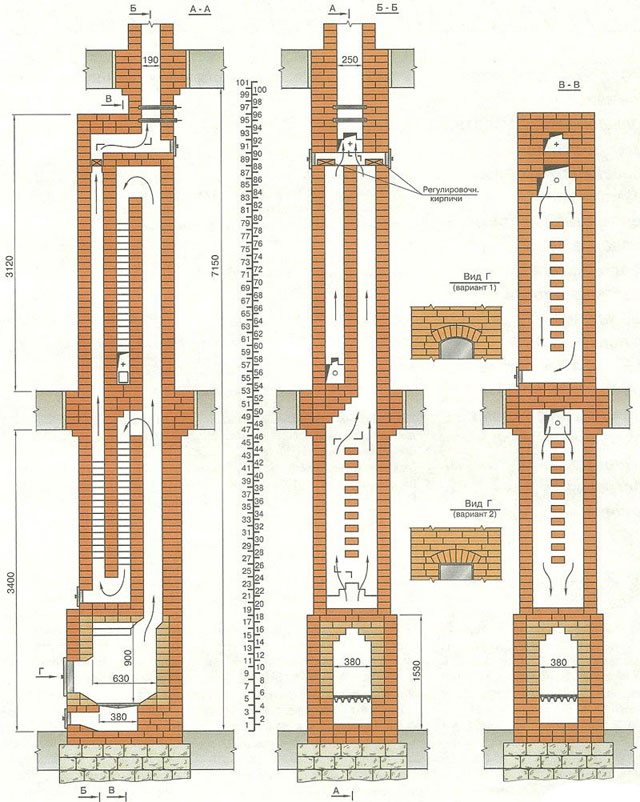

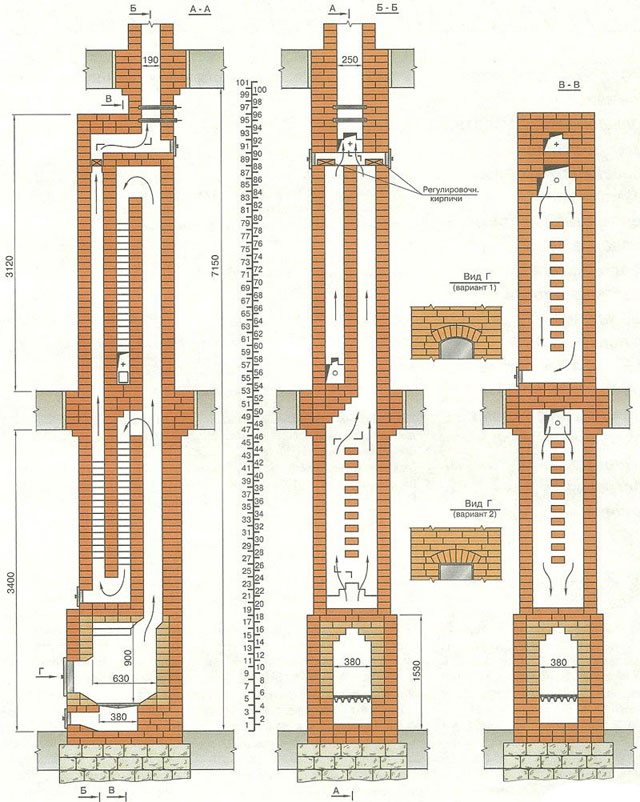

Step-by-step instructions for building a two-story oven

The laying of a two-tier heating system in a cottage or a private house is carried out at positive temperatures. Experienced stove-makers prefer to work when it is warm and dry outside, but not hot. This avoids uneven setting and drying of the mortar.

The construction of a bunk oven is carried out in the following order:

- On top of the first row laid dry (without mortar), the second row is laid with a solution. On the front side, a blower door is installed and temporarily secured with wire.

- When forming the blower part, the latter is made smaller than the furnace, and grooves are provided in the brick for laying the grates.

- In the fourth row, the firebox door is mounted in the same way as the blower door.

- The walls of the combustion chamber are created by rows of fireclay bricks, starting from the 4th to the 8th inclusive.

- Above, the stove narrows - in this part are the chimney ducts, which make up the rows of bricks from the 16th to the 20th.

- Over this structure, starting from the 21st row, the expansion is carried out up to the ceiling.

On the second floor, the masonry levels are numbered from the beginning. Up to the 26th row, inclusive, construction is carried out in accordance with the classic scheme "stove-chimney".

During the construction process, a kind of "labyrinth" is created, consisting of long horizontal channels. They are connected to each other by short vertical ones. Above them, starting from the 31st row, a chimney pipe is formed, which passes through the ceiling, the attic and goes to the roof.

Bunk stove for main and additional heating of the house

The presence of a two-tier heating structure provides your cottage with the highest level of autonomy. Such a stove for two rooms, located one above the other, is able to create comfortable conditions in the whole country house.Its rear walls also warm up well, which contributes to maintaining the necessary microclimate in two or even four adjacent rooms.

Depending on the layout of the house, a two-storey heating stove can be used as the main system. However, recently, due to the widespread laying of gas mains and the allocation of sufficient electrical power, this structure is increasingly becoming additional.

The brick bunk stove, decorated with tiles or special ceramic tiles, becomes the central decorative element of many designer interiors.

With one firebox

A special feature of the double-deck oven is its high heat capacity. She has good heat dissipation. It reaches 5.5 thousand kcal / hour. At the same time, for constant heat, the stove can be heated once a day for 2-2.5 hours, while the bricks heat up well and the air in the room will be warm for a long time. Firewood consumption is no more than 60 kg.

Firewood for one furnace

Description of construction and materials

The design of a single-furnace stove is thought out in such a way that its operating period is much shorter than that of stoves with two fireboxes.

The internal structure consists of chimney ducts. On the second floor, the chimney is laid out vertically. To separate the interfloor heating system, metal dampers are installed. They prevent the free passage of combustion products in the form of gases.

Lingering, the gases begin to cool down, forming condensation on the inner walls of the chimney. As a result of exposure to moisture, the masonry begins to collapse. Two-furnace models are better because they provide quick heating of the furnace, and condensation does not form.

Description of a single-deck structure:

- There is one main firebox on the ground floor.

- In terms of dimensions, the building has the following dimensions: 89x115 cm.

- Height - 715 cm.

- Heating panel on the ground floor 77x102.

- The second floor is supplied with a panel with a smaller size - 77x95.

In order to start laying the stove, you need to stock up on the following tools and building materials:

- You will need red ceramic bricks for lining the stove.

- The inner part is laid out of refractory fireclay bricks.

- Red clay is useful for working with facing material.

- Use refractory clay to lay out the interior of the furnace structure.

- When mixing clay mortar, you cannot do without sand.

- Grizzly grate for the equipment of the furnace (laying firewood in the stove).

- To prevent accidentally flying out coals from falling to the floor and spoiling the coating, a steel sheet is spread in front of the firebox.

- Firebox door.

- A blower door for regulating the air supply, which is necessary for good combustion of the flame.

- Cleaning doors for installation in the chimney in order to have access to the ducts (the number depends on the length of the chimney and the design features).

- Chimney valves to regulate the outlet of warm gases.

Construction sections and masonry scheme

Having carefully examined the drawing of a two-story oven in section, you can see the device of the flue ducts and how the gases should move along them.

Internal organization

In the section, it is easy to distinguish between refractory bricks and facing bricks - they differ in color from each other.

It is unacceptable to use ceramic bricks for bonding with a refractory row. The same applies to the binding of the facing row with refractory bricks.

The structure is completed by a packing tube, which is erected above the furnace.

If you use the presented diagram, then the structure shown in the drawing is erected with ceilings with a height of 3 m 40 cm. If necessary, the height of the furnace structure can be easily changed. To do this, you need to make the appropriate adjustments during construction in rows 26 to 46, as well as from 60 to 82.

Attention! Changing the data that was entered into the project will entail a deterioration in the operation of the finished furnace.

Erection of the foundation

A two-story structure weighs much more than a brick oven for a one-story house. For this reason, the base on which the structure will be erected must be more massive, capable of withstanding significant loads.

Stove foundation

In size, such a foundation exceeds the base of the stove. For example, if the base is 1000x1000, then the pillow will be 1100x1100 mm.

Before pouring the foundation, you need to prepare the following building materials:

- For concrete mortar, sand, cement and crushed stone.

- Before the concrete is poured, the formwork is built. To do this, you will need boards (old, but necessarily strong, capable of withstanding the load from concrete expansion will do).

- The bond is reinforced with reinforcement or mesh reinforcement.

- To protect the concrete from moisture, waterproofing is laid on the surface of the soil. It can be roofing material.

The foundation area can be higher than the base of the floor or at the same level with it. To do this, you need to follow these steps:

- Cover up with a sand pillow.

- Assemble the formwork from solid planks.

- Reinforce the site.

- Fill with concrete.

The foundation must be dried. The drying period lasts at least a month. Then several sheets of roofing material are laid on the base for reliable waterproofing. The construction of the stove begins on them. The base must be level, without slopes.

Furnace erection

The construction of the stove is impossible without additional elements such as grates, doors and other details. The most important thing is to prepare a high-quality clay solution. The quality of the entire structure depends on this.

Due to the violation of the proportions of clay, sand and cement, the stove will crack, carbon monoxide gases will penetrate into the room, and this is dangerous to human health.

The number of components in the solution depends on the fat content of the clay: the kneading is done either 1: 1 or 1: 2, but there is a very oily clay, which requires a 1: 3 ratio.

To test, you need to make several different solutions and roll them into balls, leaving them to dry. After drying, the material is selected, the balls from which did not crack.

External finishing

The outer side of the object can be laid out with refractory bricks and, after plastering, painted or other refractory finishes can be applied.

Finishing option

Some people prefer simple ceramic brick cladding. There are several color options for this finishing method.

You can recommend ceramic tiles, but a stove of this size will require a lot of this material.

More information about laying the stove on two floors can be found in this video: