Dangerous temperature

For comparison, consider a number of studies conducted by scientists in the twentieth century, observing the effects of the effects of regular visits to a steam room heated to extreme values of 110-130 ° C.

Professor H. Teir in the 80s of the last century put forward an assumption about the connection of high temperature in Finnish saunas with the occurrence of cancer, which was later confirmed by the results of a large study. After considering a significant number of cases of lung cancer among those who like to steam at 110-130 ° C, it was found that staying in a steam room heated to such temperatures contributes to the formation of this disease.

https://www.youtube.com/watch?v=

The fact is that in such conditions it is possible to be only when the air in the room is very dry, and this excludes the hydrostatic effect of steam on the body. As a result, the blood does not supply the lungs well enough and they get burned due to the inability to adapt to high temperatures to the required extent.

A number of other studies have also found that exposure to dry, highly overheated sauna air negatively affects sperm production and also leads to digestive problems in babies born to mothers who frequent such baths during pregnancy.

There are a lot of discussions "what is the temperature of the stove in the bathhouse" or the temperature around the stove in the steam room. Unfortunately, all of them are conducted on an intuitive level, and only a few experts devote whole research to this issue using pyrometers, thermometers and other equipment. How does the temperature of the sauna oven and the steam room really differ from the one that the thermometer shows us?

Bath lovers are not builders and for the most part they coordinate the oven modes with their feelings. The other half of the vapers are looking at the thermometer. I decided to find out what is the difference between our perceptions, between the data of the arrows of a universal thermometer and what a remote-action digital temperature meter will show us.

Some temperature measurement data puzzled me, which I wrote about in the conclusions after the video.

By and large, we are not interested in the temperature of the stove, but in the conditions in the steam room. Your own skin is more expensive than the cover of a piece of iron. Therefore, I measured everything where the laser pointer of the device was fired. I wanted to make the temperature measurements with a diagram, but decided to shoot a video with remarks

Attention! I used a device with a maximum measurement threshold of 330 degrees (frames in the furnace firebox)

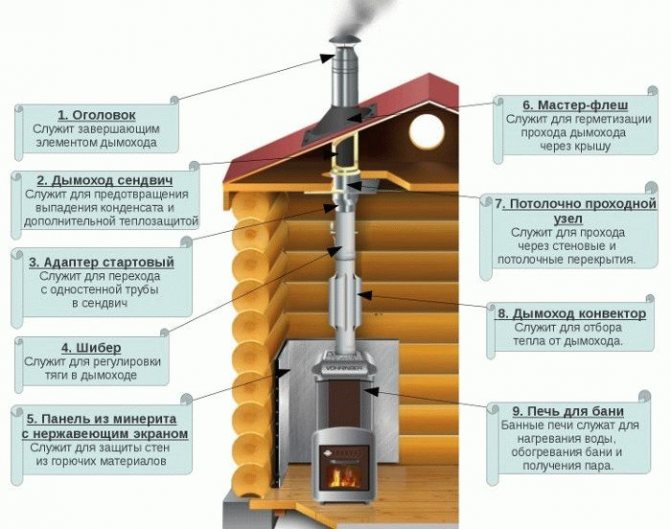

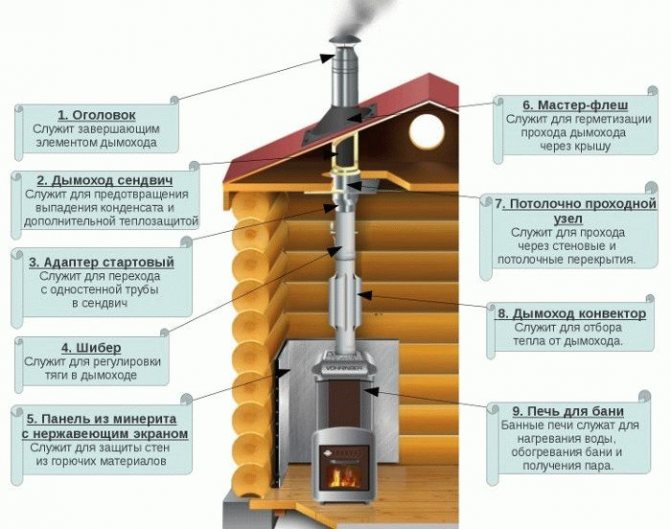

The technology of manufacturing a sauna stove makes special demands on the equipment of all its departments, including the chimney. Its device is slightly different from the chimney system of a home stove. It must ensure long-term heat conservation and the safety of the steam room visitors. Before organizing a chimney in a bath, it is worth learning a few important nuances.

The design of sauna stoves includes 2 types of chimneys:

- Indigenous. They are organized next to the stove, using a special pipe for connection, through which the smoke goes into the main channel. One chimney can be used for 2-3 stoves. The main thing is that its inner diameter has the appropriate parameters, and the pipes from each heating device are located at different heights;

- Packed tube systems are mounted directly on the chimney and led out through the roof. This chimney option is the most common for sauna stoves.

The classification of chimneys at the place of installation includes 2 types:

- Outdoor. Most of them are located outdoors and fixed on the wall with a bracket. Not too recommended for a bath, as they cool down quickly, losing precious heat.

- Internal. These are vertical structures with good traction, located inside the building.

According to the material used, chimneys are:

- Brick. A traditional look, characterized by the laboriousness of masonry and high requirements for compliance with all parameters. They have a lot of advantages: durability, fire safety, strength, good thermal insulation and heat accumulation. The disadvantages include the roughness and angularity of the inner surface, on which soot deposits accumulate;

- A metal chimney is installed faster and costs less. It has a perfectly smooth surface, but weaker heat-retaining characteristics;

- Combined version, including 2 parts: the lower one is made of bricks, the upper one is made of a modern sandwich pipe. Allows you to organize neat, small passages that are easier to cover with heat-resistant material.

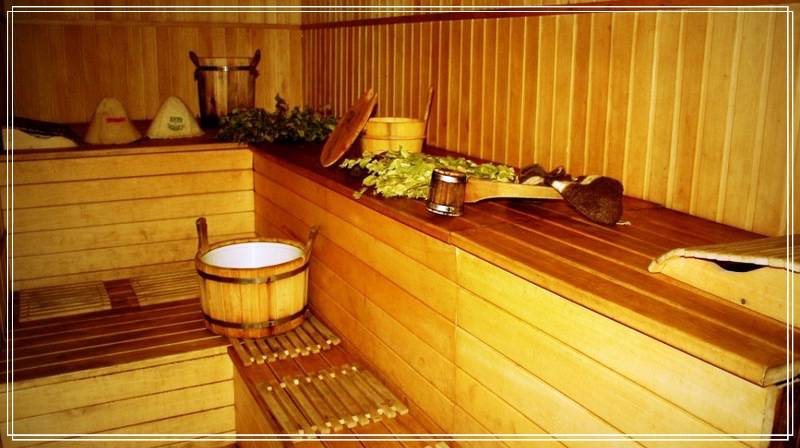

What brand of steel is better for a sauna stove

The heating temperature of flue gases inside the furnace reaches 450-550 ° C. When heated at such an intensity, deformation of the metal is observed.

Direct exposure to fire causes the steel to burn out. Of course, you can simply use metal with a thickness of 10 mm or more, but then you will have to heat the steam room for a long time, spend a lot of fuel to warm it up. Due to the use of thick-walled steel sheets, a durable furnace will become economically disadvantageous.

The task facing the master is to make the structure strong enough to prevent deformation, burnout and at the same time having good thermal conductivity. At the factory, metal with a high degree of heat resistance is used for the manufacture of sauna stoves.

Most manufacturers use the grade of chromium corrosion-resistant stainless steel AISI 430. In budget models, iron for bath stoves is changed to structural steel GOST 1050-88. Each metal has its own pros and cons.

Alloy steel differs from structural steel in the following characteristics:

Chromium-containing heat-resistant steels are expensive and not all components experience the same thermal and corrosive stress. For this reason, the construction of a sauna stove is made of several metals:

- Firebox - for the combustion chamber use AISI 430 or an analogue of 08X17T. For self-production, steel 10 GOST 1050-88 is used.

- Screen - convection channels do not experience the same load as the firebox, therefore, 08PS or 08YU GOST 19904-90 are taken for their production.

- The body of the sauna stove is made of structural steel sheet.

- Combustion chamber door - practice shows that this part of the device experiences maximum thermal stress. For this reason, using even highly alloyed stainless steel is not enough. After several fireboxes, deformation of the doors is observed. The best solution is to hang a cast iron door.

As a rule, in the independent manufacture of a sauna stove, metal is used, which is easier to machine and weld.

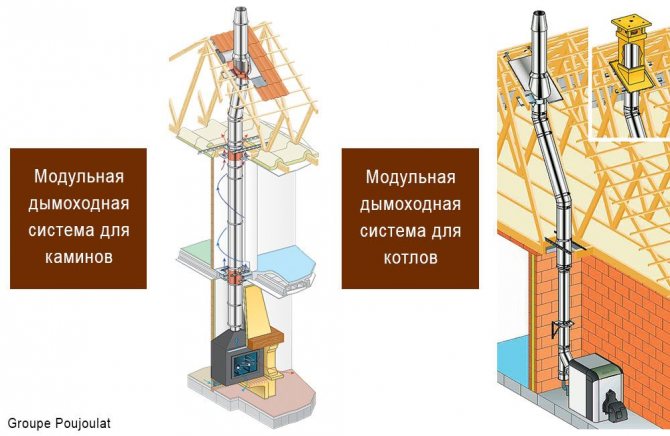

The correct temperature in the steam room

A lot can be said about the rules of classical health-improving bath procedures, but in this article we will dwell on temperature in detail. If we talk about the temperature in the steam room that is most suitable for health in all respects, then this indicator lies between 50 ° C and 70 ° C. In the classic Russian bath, the stoves were always built of bricks and, as a rule, they were with closed stoves.

A ladle of water was poured onto the stones heated to red from a direct flame, which instantly turned into a light hot, finely dispersed steam, most comfortable for both the respiratory tract and the skin. A cloud of steam rose under the ceiling and a person lying on a shelf was gradually doused with this steam with the help of brooms in small portions.

When designing your own bath, it is important to understand that in addition to the correct temperature to obtain the full range of positive effects of vaping on the body, the bath must also have a certain humidity. The optimal indicator is within 60%

It is this combination of temperature and humidity that provides ideal conditions for the healing of the whole body.

It is only possible to achieve the specified temperature and the correct humidity in the steam room only if the stove is in it with a closed heater.

We suggest that you familiarize yourself with What you can eat in the bath

It is very important to obtain high-quality fine-dispersed steam that the stones in the furnace are heated to at least 300 ° C. And if the stove is open, then when the stones are heated in it to such an extent, the stove itself will be so hot that the temperature of the steam room will go beyond 70 ° C.

ANSWER

This problem exists for everyone who uses a heat-insulated stove in a bath. The solution to the problem is to replace the oven. Naturally, for this you will have to shell out a certain amount of money, but on the other hand, the inconveniences will disappear. Other options can only be called a half-measure.

If, nevertheless, it is not possible to change the stove, then you will have to heat it, adhering to certain rules. Namely: after heating the oven to 100 degrees, try not to increase the temperature anymore, but keep the one that is. For this purpose, the fuel is placed in the furnace to a minimum, the ash pan is closed. In this way, ensure high efficiency for the furnace, a comfortable temperature in the room, and all this while saving fuel. The air temperature in about 40 minutes will reach the minimum when you can start steaming.

Protective materials for wooden structures

Due to the fact that the chimney and the stove quickly heat up, a fire may occur. Moreover, according to tradition, wood is the material for the bath. Even in the old days, it was customary to insulate walls, a ceiling, a stove, a chimney with an asbestos layer, clay and other available materials that are quite poorly conductive of thermal energy and resistant to high temperatures.

So how to lay the pipe from the stove today? Insulation of the chimney structure is necessary both for the purpose of fire safety and protection against condensation, so that cooling takes place more slowly and the flue system lasts longer.

A red brick is not always needed for lining a pipe, although it is endowed with excellent thermal insulation properties. The reason is that such a design is not combined for every bath in design.

Before purchasing materials, it is necessary to determine the structural features of the chimney.

Brick system

The structure is made of heat-resistant bricks using a special dry mix or kiln clay. In addition, you may need material to create a fungus above the pipe.

Before purchasing material for making a metal chimney in a bath, it is necessary to draw up its exact diagram with a detailed location of all corners and turns of the pipe.

You will also need 2 iron sheets with holes corresponding to the diameter of the pipe. They are fixed on the ceiling of the bathhouse and on the floor of the attic. You will also need heat-resistant material, which will be fixed around the pipe at its exit to the wooden attic.

To create waterproofing around the chimney on the roof, it is necessary to prepare a sealant or a special rubber seal.

The choice of pipes: what to look for

When buying iron chimneys, you need to decide on their cross section.Basically, it depends on the power of the stove, but for most sauna options this parameter is 15-20 cm.Do not take too large a diameter, as it will retain heat poorly. And too small - will not create the necessary draft for the extraction of smoke. Whatever it was, the cross-section of the pipe should not be less than the diameter of the outlet pipe of the heating structure.

There are a number of other requirements for the elements of the chimney in the bath:

- The minimum pipe height is 5 m. Neglect of this requirement threatens to deteriorate traction. The exact value is calculated depending on the location of the pipe on the roof. In any case, it should rise at least half a meter above the ridge. The ideal height from the ridge is considered to be 1.5 m, but this is not necessary;

- The minimum thickness of the metal used to create the pipe is 1 mm;

- If it is planned that the chimney system will be equipped with a hot water tank, then it must be reflected in a previously drawn up diagram. It is better if the tank is made of stainless steel.

What chimneys to install?

The table below contains data from laboratory studies of the Petrozavodsk Kami Center. They test different chimneys in their laboratory, relentlessly driving them in the most aggressive modes *. And we, sellers and installers, based on these tests, have a complete picture of the behavior of chimneys in operation **.

This table is my professional tool and I am sharing it with you.

* You can see an example of such tests here: https://yadi.sk/i/AnJ6J21z3MzhKA

** Ask the chimney seller: does he have any test data for these chimneys? There will be two options for the development of events: 1) he will smile and get the test data - exactly on the chimney that he recommends; 2) make round eyes and try to prove your complete incompetence in this matter. And then - your choice, to whom you entrust the safety of your home and loved ones.

How to make sure yourself?

- Conduct an experiment: when it snows, flood the bathhouse and in an hour and a half or two look at the roof. If the snow melted near the chimney, or even completely melted and icicles hang down, your roof heats up. What to do: Insulate the roof passage with materials that keep high temperatures.

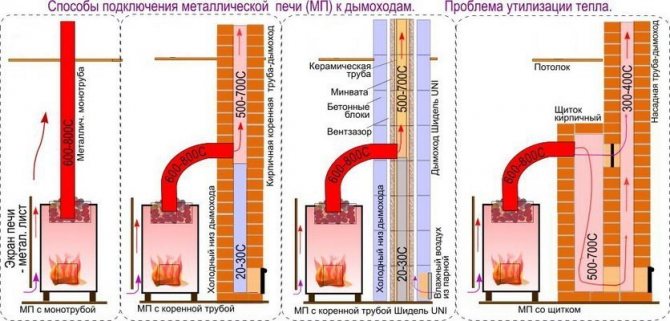

- Laboratory studies at one of the factories producing sandwich pipes showed that at the exit from a metal bath furnace, the flow of combustion products can have a temperature of 800 ° C, and after 1.5-2 meters - 850 ° C. The temperature rises already in the chimney, probably due to the afterburning of volatile gases. In this stove, incomplete combustion of gases from wood occurs. Replacing the stove with a model in which both firewood and gases burn out completely will help here. Or replace the chimney with one that is designed for a temperature load of 900-1000 ° C. Plus - correctly lead it through all the ceilings, isolating it from wood and other flammable materials.

Chimney errors: what worries professionals

In June 2020, in Noginsk, at the Banya-Fest festival, a seminar of the Stove Makers and Bathhouse attendants was held. Guild Chairman Vladimir Lyakhov, among others, touched on chimney problems:

“_ Raspberry chimney - blew the chimney after the metal sauna stoves. This is a fire hazard and indicates low efficiency.

_ I did not burn metal sauna stoves in the firebox. Because of this, the chimney was overheated, the release of fuel and flame into the pipe, low efficiency, the danger of fire.

_ Long-burning ovens are actually long-term "smoking" ovens. The wood is underburned, a lot of soot is deposited in the chimney and released into the atmosphere. Black condensation forms, corroding chimneys. Efficiency is low, fuel is wasted, there is a danger of soot ignition in the chimney. In essence, this is a deception! "

Nevertheless, issues related to safety - fire and environmental - are completely solvable, it's just that this solution costs more than a person is usually willing to spend on a stove and chimney.

Vladimir Nikolaevich invited me to speak at this seminar.

“Vladimir Lyakhov, thank you for the invitation, I am pleased. I am not a bathhouse attendant or a bather, I am an expert in fire and environmental safety related to fireplaces and stoves.

To address the issues that you raise, you need to build on the result. Adherence to technology leads to the result.

For example, to get Levays jeans (as a result), you must strictly follow the technology of their sewing, patterns, requirements for fabric, threads and accessories. A deviation in any element leads to the fact that we do not get the left - we get something else.

The same with fireplaces and stoves - we focus on the result. Do you want nothing to catch fire? Follow technology. Do you want to breathe clean air? Follow technology. The technology includes insulation materials, chimneys and ovens. Nothing complicated.

In our country, it is customary to focus not on the result, but on the process. How to shaman so that the glass does not smoke? How to skillfully burn as much firewood as possible? How to clean the chimney more curiously - and then in everything.

The question should be that effective control of the stove or fireplace is available to everyone. And it would not be necessary for him to think at the same time, whether he can - right?

No need to shaman, no need to spend a lot of time at the stove, worrying about whether firewood is burning properly - you must initially buy a complete set focused on complete combustion of firewood, fire safety and clean air. Then mount - not with skillful handles, but again in compliance with safe installation technology. Half of the list of questions that you want to raise will be closed automatically. "

Raspberry chimney of a sauna stove

Functions and features of the operation of the chimney in the bath

The main purpose of the chimney in the steam room is high-quality and controlled removal of combustion products in order to completely eliminate the accumulation of harmful carbon dioxide and the formation of burning on surfaces. The resulting draft (with air suction into the combustion chamber) maintains a stable process of operation of the heat generator.

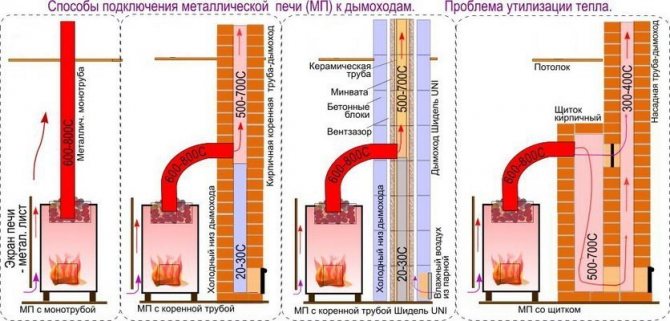

Features of heat distribution with different methods of connecting the stove to the chimney

The stove in the bathhouse does not heat continuously. Accordingly, the flue channel cools down completely between sessions, so the chimney parts are exposed to the strongest multiple thermodynamic loads. The second important factor is operating temperature. Unlike boilers and stoves used for heating, gases heated to 700 degrees or more are removed here.

Often, direct-flow ovens are used in the bath, due to the lack of heating shields or water jackets that remove part of the heat, the smoke turns out to be so hot. Therefore, the problem of burning out chimneys (danger of gas contamination and fire) always remains relevant. Chimneys for stoves in a bath are made of high quality materials. If these are factory-made products, they must be approved by the manufacturer for such challenging operating conditions.

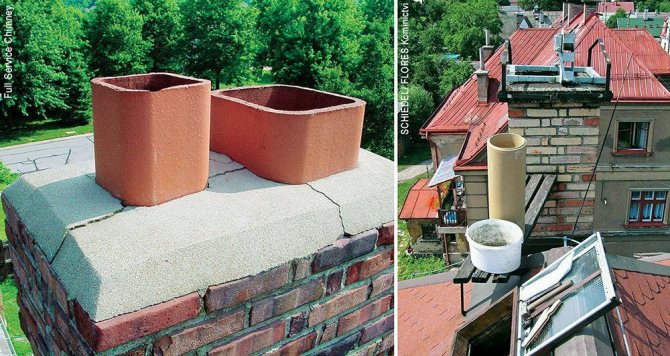

At elevated temperatures, refractory red brick retains its operational properties, therefore it is in demand when building a chimney in a bath with a stone stove. In this case, you are guaranteed protection of the pipe from fire and long-term preservation of heat.

The service life of the structure depends on how well the brick pipe is folded. Do not skimp on materials during the construction of the chimney, because then the repair will be much more expensive for you.

Let's take a closer look at how to isolate a pipe in a bath from the ceiling:

- Use asbestos to line the pipe outlet on the ceiling and through the roof.

- Using galvanized material, insulate the walls from the inside of the pipe. Standard iron sheets are completely unsuitable for this purpose due to their tendency to corrosion.

- Run a box around the pipe where it passes through the ceiling.

- Pour expanded clay into the box to preserve heat and protect wooden floors from fire.

You professionally wrapped the pipe, but the work on the arrangement of the chimney did not end there. The next step is measures to insulate the stove, ceiling and walls of the bath.

Factors affecting combustion temperature

Chimneys for long burning ovens have some specific design requirements. In our article we will talk about the installation of chimneys for long-burning heating units with our own hands.

Chimney - a device for removing fuel combustion products into the atmosphere. Usually it looks like a pipe installed vertically near the heating unit or mounted on it.

Simultaneously isolates gases from combustible materials and building structures. Smoke extraction protects housing and residents from fire and carbon dioxide and carbon monoxide poisoning.

How the chimney works

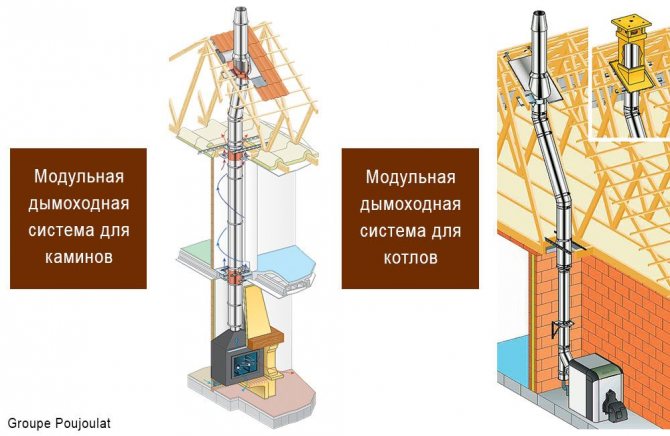

For modern long-burning furnaces, traditional brick pipes are practically not used. Modern chimneys made of ceramics or sandwich pipes have modules for connecting to a furnace, for collecting condensate, vertical, for cleaning.

Ceramic structures have an outer frame made of expanded clay concrete, mineral wool insulation between the ceramic pipe and the frame. Sandwich pipe modules consist of an outer and inner steel shell and insulation between them.

Principle of operation

The principle of operation of chimneys is based on the ability of gases to expand with increasing temperature, while their density decreases, they rise up, the pressure in the furnace decreases and cold air is sucked into it from below. The higher the temperature of the flue gases, the stronger the draft in the pipe.

Types and designs

Types of chimneys by material of manufacture:

- brick;

- metal - single and three-layer with insulation;

- asbestos-cement;

- reinforced concrete;

- ceramic.

Types of chimneys by design:

- wall - traditional brick structures made of red bricks, which are integral with the wall. The bottom of the structure rests on the foundation of the wall;

- indigenous - a free-standing structure with a separate foundation, most often located outside the wall of the house, most often brick with an insert or ceramic;

- mounted - mounted (mounted) on a stove or fireplace, have a low weight. In practice, this method is used to mount single-layer metal chimneys or sandwich pipes;

- modern prefabricated steel structures, suspended on supporting structures and without a foundation;

- we can also mention the coaxial structures of two pipes of the Schidel system, in which the incoming air and exhaust gases flow in a countercurrent flow (the most famous example is horizontal pipes used to connect gas boilers).

Which one is better to choose

When they talk about long-burning stoves, they usually mean solid fuel boilers for a variety of fuels:

- firewood;

- pellets;

- peat;

- coal.

Most often we are talking about all kinds of wood-burning metal stoves, fireplace stoves, buleryans with the main method of transferring heat into the room by convection.

Modern equipment has an efficiency from 87% for pyrolysis units to 92% for pellet units. The fuel burns out almost completely, while a little sulfuric, nitric and other acids and a lot of moisture are released. When not very hot exhaust gases rise, they cool against the walls of the chimney and fall out in the form of aggressive condensate.

Old brick and asbestos-cement chimneys are not too resistant to acids and require the installation of an inner stainless steel liner. In addition, they need to be additionally insulated - and it is not very convenient to carry out insulation at a height. If possible, it is better not to use such chimneys.

note

In principle, it is impossible to use steel single-layer structures without insulation - condensate will ruin the stove, and in frosts it can even put out the fire in the firebox.With insulation - it is difficult and troublesome to install, but not very expensive. But not for long - for a maximum of 10 years.

The best options are ceramic structures and sandwich. They have high acid resistance, very long service life, corrosion resistance, smooth inner surface, good thermal insulation, a large assortment of ready-made prefabricated modules, quick installation, easy repair.

The sandwich is lightweight. A serious advantage of ceramics is its durability (up to 50 years) and the ability to withstand high temperatures. Both types of structures can be installed both inside and outside the building.

The outer shell of the sandwich should not be 0.5-0.7 mm thick - only 1 mm (should not bend when pushed by hand).

The solution to this question depends on many factors:

- having at least minimal construction skills;

- the presence of at least two assistants;

- roof structures - installation on flat roofs is much easier;

- chimney designs;

- and even if you have a fear of heights.

The ideal choice is the most advanced sandwich and ceramics. The sandwich is much easier to assemble and easier to install on your own: ceramics are fragile, the presence of a foundation and an outer box complicates the work - it is better to entrust its installation to professionals.

Self-made pipes is nonsense. You can fold a brick pipe with your own hands - but this is quite difficult, not every bricklayer will lay out an even vertical masonry. Insulated asbestos concrete and steel pipes can be installed independently, but this is a poor choice.

We suggest that you familiarize yourself with How to install a vapor barrier correctly

The chimney arrangement is determined by the provisions of SNiP 41-01-2003.

The chimney design must meet the following regulatory requirements:

- the minimum height must be at least 5 meters from the combustion point or grate;

- the pipe must rise above the flat roof to a height of at least 1 meter;

- when located on the roof slope at a distance of less than 1.5 m to the ridge - the pipe must be 0.5 m higher than the ridge;

- when located on the roof slope at a distance of 1.5-3 m to the ridge - the pipe may not be lower than the ridge;

- when located on the roof slope at a distance of more than 3 m from the ridge - the angle between the horizontal and the line passing through the ridge and the top of the pipe should be no more than 10 °;

- the maximum length of each horizontal and inclined sections should not exceed 1 m, the total length of their projections onto the horizontal should not exceed 2 m. In the presence of oblique and horizontal sections, it is necessary to lengthen the pipe by the length of the horizontal projections. For ceramics, the presence of horizontal sections is not allowed.

The distance from the surface of chimneys made of ceramics, insulated steel and asbestos-cement to the combustible structures of the house must be at least 0.25 m; for brick chimneys and sandwich pipe structures - not less than 130 mm.

If the roof is covered with combustible materials (roofing material, bituminous tiles, ondulin), or leaves or fluff can accumulate on it, a spark arrester from a mesh must be installed on the pipe head.

Traction force

Factors affecting traction:

- the height of the structure;

- the state of the internal channel - smoothness of the walls, regularity of cleaning from soot;

the presence of inclined or horizontal sections. For pipes of long-burning units, the presence of horizontal and inclined sections is not allowed, since the exhaust gases have a low temperature and the elongation of the chimney is undesirable - the gases will be cooled, the thrust will decrease up to overturning;

- deflector installation;

- quality and thickness of insulation;

- air supply to the firebox.

Your safety depends on the presence and strength of traction, therefore it is necessary to check for the presence of traction and take measures to clean the channel from soot and icing of the pipe head.

We will not consider the installation of galvanized and stainless steel pipes with insulation - this is already the last century.

The choice of the optimal material is described above. You cannot make a sandwich or ceramics with your own hands.

Here we will consider the installation of the most advanced ceramic pipes with our own hands, which, moreover, have the most complex installation. Sandwich pipes have modules that resemble ceramic in purpose and design, and their installation is not difficult. The main thing is not to forget to coat the joints with sealant and additionally insulate the passages through the ceiling and roof.

Drawing and diagrams

The life of the residents of the house depends on the parameters of the pipe. Therefore, you cannot start work without a drawn drawing or at least detailed diagrams! Before starting work, it is necessary to carefully measure the height of the room, attic, floors. Then make a diagram or drawing and determine how many and what components you need.

Sizing calculation

The height of the pipe is determined taking into account the height of the building and the requirements of SNiP 41-01-2003 (see above).

By the diameter of the outlet of the heating unit, we determine the inner diameter of the chimney - they must be equal.

Installation video

All the intricacies of installing ceramics and sandwich can be seen in our video.

Chimney design

Brick system

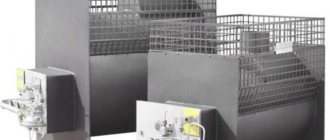

As the main protection of the walls of the bath, heat-resistant screens are used - special insulation shields to close the side surfaces of the stove and reduce the intensity of the spread of infrared radiation in the room.

Screens are divided into two categories: metal and brick.

Metallic

Protective shield made of steel or cast iron sheets. It is mounted around the perimeter of the sauna stove, while maintaining small technological gaps (3-5 cm) between the screen and the outer walls of the heating structure to provide additional air convection.

We offer you to familiarize yourself with Flexible bitumen shingles installation

Depending on the features of the walls of the bath and the type of stove, metal screens can be front and side. Some models of metal stoves are produced with an additional protective casing, which is installed when installing the firebox.

Installation of metal screens is carried out using adjustable feet, bolted to the floor covering. In addition, the legs allow for clearance at the bottom of the structure for additional ventilation. To increase the service life, the screens are covered with a refractory paint layer.

Benefits:

- decrease in the intensity of infrared rays;

- improvement of air convection between the walls of the oven and the screen;

- reduction of the overall heating temperature of the outer walls of the heating structure.

Brick

A protective brick screen is designed to enclose the walls of the sauna stove.

The laying is done in ½ brick around the perimeter, observing the technological gaps of 6 cm. The lower part of the structure is equipped with additional air ducts at a distance of 2.5 cm from each other.

For arranging a brick screen for furnaces, heat-resistant fireclay bricks without voids are used. As a joint mixture - a thick solution of cement or clay.

The finished walls of the screen should be 22–25 cm higher than the wall of the heating structure.

Benefits:

- low thermal conductivity of the material from which the screen is made;

- resistance to high humidity and high temperatures;

- long-term accumulation of heat in the room;

- receiving mild heat from the oven.

Every single building and every fireplace requires a suitable chimney with individual parameters and characteristics.

The parameters by which the choice of the chimney should be carried out:

- Chimney material;

- The location of its structure;

- Steel chimney. The structure of the chimney made of steel includes pipes, insulation and an outer contour. For the manufacture of pipes, stainless or galvanized steel is used. The steel chimney structure is easy to install and light in weight.

Galvanized steel pipe has a lower cost, but is less reliable than the previous model. Accordingly, the best stainless steel chimneys.

- Ceramic chimney construction. To install a ceramic chimney requires a certain training of specialists and, very important, accuracy. Ceramics provide excellent thermal insulation. The service life of the material is approximately 30 years. The ceramic structure consists of an inner ceramic liner, lightweight concrete blocks are located outside and, necessarily, a heat-insulating gasket, which must be placed between the layers. (See also: )

- The glass structure is considered to be the most expensive and is very difficult to install. Certain installation experience is required, but glass fits perfectly into the interior of the house and looks very impressive and irresistible. Glass is very resistant to the formation of corrosive deposits, heat from the resulting combustion products and any moisture. Undoubtedly, these design advantages bring it to a high level of use.

Why is a brick stove-heater better for a Russian bath than a metal stove

030

In this article I will present my own vision of the topic in the title.

To begin with, let us briefly recall what temperature and humidity conditions are typical for a Russian bath. For those who want to get acquainted in more detail with all possible existing modes of taking bath procedures and choose the most preferable ones for themselves, I recommend taking a look HERE.

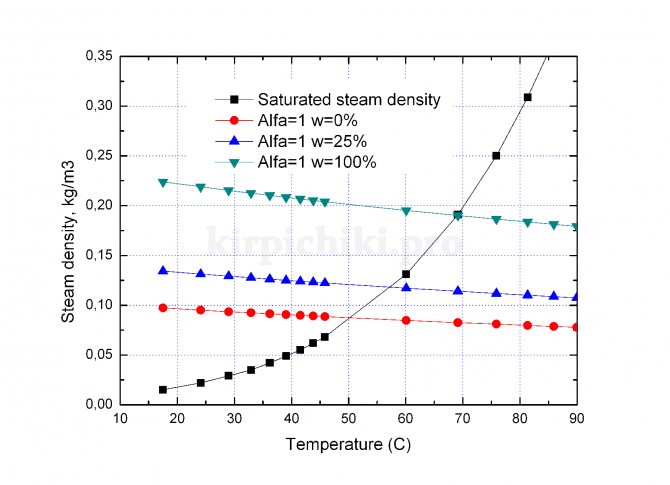

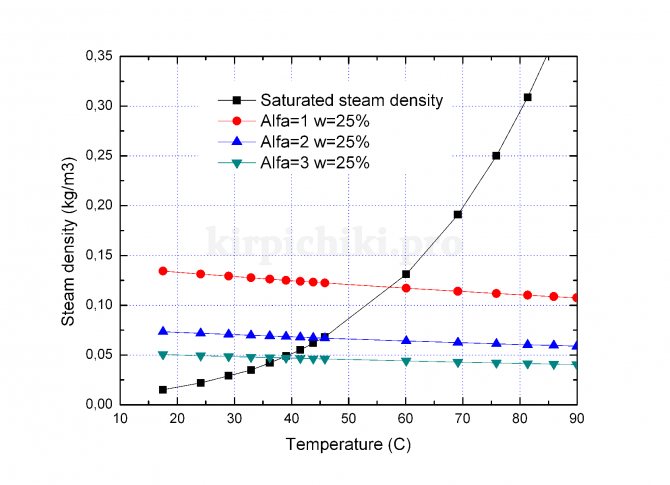

So, a steam Russian bath is characterized by air heating temperatures in the steam room up to T = 45-65 ° C and relative humidity φ = 50-90%. The absolute humidity of the air in the steam room of the Russian bath varies within ρ = 60-150 g / m³.

At the same time, the temperature and humidity conditions typical for a dry-air sauna lie in the temperature range Т = 90-130ºC and relative humidity φ = 2-10%. In this case, the absolute air humidity is ρ = 8-16 g / m³.

It can be seen from the above figures that if the air temperatures in the baths of these types differ by a factor of two, then the amount of water vapor in the air differs by an order of magnitude.

In a Russian steam bath, a person is heated by a high-humidity air environment, while in a dry-air sauna, a person is heated by dry air.

Washing a person in a steam bath takes place in steam with a broom (by settling condensate of water vapor from the air on the surface of the body with a bath broom and using a bath broom as a washcloth).

Washing in the steam room of a dry air sauna is not provided initially. In such a steam room, you can only warm yourself up with dry air. Body washing is carried out, as a rule, under a regular shower outside the steam room. The use of a broom in a steam room of a dry-air sauna is more of a ritual rather than a functional one.

Thus, the purpose of a Russian steam bath is to create conditions in a steam room: T = 45-65 ° C, φ = 50-90%, ρ = 60-150 g / m³.

In addition, the heat content of humid air in the steam room of a Russian bath, which allows you to get modes of "light steam", should be equal I = 165-200 kJ / kg d.w. - at the stage of preliminary heating of the organism and I = 200-270 kJ / kg d.w. - at the stage of steaming with brooms.

The question arises, with the help of which furnace (metal or brick) it is easiest to achieve these modes.

First, consider the features of metal bath stoves.

Metal furnaces are characterized by a temperature of their outer surface, as a rule, exceeding 120 ° C... This is observed even in cases where the metal stove has external protective metal screens that cover the outside of the firebox, which heats up to much higher temperatures. (T> 300 ° C). The temperature of the part of the chimney located in the steam room and in direct contact with the stove practically does not differ from the temperature of a red-hot firebox.

A metal furnace with relatively small external dimensions (with the area of the side surfaces from 1 to 2m²), is a source of powerful infrared radiation. The values of radiant heat fluxes (depending on the model and dimensions of the furnace) from the walls of such furnaces unprotected by heat shields can reach very large values of the order of 10-30 kW / m². For comparison, the critical heat fluxes that a person is able to withstand with his bare skin for a few seconds are fluxes

Metal furnaces have low heat consumption and low response time. They heat up very quickly when kindling, but also quickly cool down when the process of burning wood in the firebox stops.

Metal stoves, in most cases, are not able to dry the bath after the end of the bath procedures.

Convection air currents created by metal stoves, passing between the outer protective screen of the stove and the metal walls of the firebox, very quickly heat the air in the steam room to temperatures inherent in dry air saunas (T = 90-130 ° C). In addition, as a rule, in metal stoves, the heater is located outside the stove. This placement of stones also creates convective air currents, contributing to the overheating of the steam room.

Due to the existence of powerful convection air currents in a steam room with a metal oven and, as a rule, uneven heating of the elements of the steam room enclosing structures (ceiling, walls, floor) in such conditions it is very difficult to keep the required air humidity at the required level for at least 5-8 minutesduring which the broom steaming mode occurs.

If, nevertheless, at the established air temperature in the steam room, typical for dry-air sauna modes (T> 90 ° C), evaporate the volume of water on the stove, which will create absolute humidity in the steam room ρ> 50g / m², it will be impossible to bathe in these conditions. And that's why.

Under these conditions, moisture will begin to condense on a person with a temperature equal to the air temperature, that is, with T> 90 ° C. Agree, the situation is not pleasant.

And this will happen for the following reason. A human being as a biological species cannot heat up to a temperature of more than 40 ° C... Sometimes, however, after preliminary gradual heating, you can raise the temperature of the human skin to a temperature

50 ° C. But this does not change the essence of the picture being drawn.

Absolute air humidity equal 50g / m³ at a temperature 40 ° C will give 100% relative humidity. In other words, the temperature 40 ° C is the dew point for humidity 50g / m³. Under these conditions, from the air to any object with a surface temperature equal to 40 ° C, dew will begin to fall with a temperature equal to the air temperature.

And what is our temperature in the steam room?

Right. More 90 ° C.

And here we are in the situation: "Did you order the boiling water?"

As for me, it's BUNK.

And lastly, regarding metal stoves.

External placement of the stove on top of the stove does not allow them to be heated to the temperatures required to obtain "light steam" These temperatures are the heating temperatures of stones T> 300 ° C.

The desire to achieve the specified temperatures of the masonry inevitably leads to overheating of the steam room to temperatures exceeding the required range (T = 46-65 ° C).

The desire to prevent overheating of the steam room leads to underheating of stones.

And so, and so not great!

Now let's see what the brick ovens give us in the steam room.

Unlike metal ovens, brick ovens are inertial in terms of their own heating and heating of the steam room, as well as heat capacity.

Brief description and dimensions of the metal stove

Our design will have a separate tank for heating water and a heater built into the top of the stove. The flame heats the stove from all sides, which significantly increases the efficiency of the stove.You can take arbitrary sizes, take into account the parameters of the steam room and the number of people washing at the same time. For example, we give the dimensions of our stove.

- External heater. Width 50 cm, length 50 cm, height 80 cm.

- Internal heater. Width 40 cm, length 40 cm, height 50 cm. The distance between the walls of the inner and outer heaters is five centimeters around the perimeter.

- Bake. Width 50 cm, length 90 cm, height 50 cm. You can change the stove length, make it only for an external stove 50 cm long (then the water tank will have to be fixed from the side on stops) or increase the length to increase the volume of the tank.

- Water tank. Width 40 cm, length 50 cm, height 60 cm. The tank holds 120 liters of water, which is enough for washing three or four people. Of course, hot water must be diluted with cold water.

Normal temperature of flue gases from the furnace

In order for the water present in hot gases to evaporate better, the temperature of the latter must be increased. On well-heated pipe walls, the settled moisture droplets evaporate quickly.

The normal temperature of gases leaving the furnace before leaving the pipe is 12O ... 14O ° C, when leaving the pipe into the atmosphere - not lower than 100 ° C.

If the flue gases at the exit into the chimney, that is, near the view, reach a temperature of about 250 ° C, then condensate does not form, the draft improves, the furnaces heat up faster, while consuming less fuel.

It is possible to determine the temperature of the outgoing gases with the help of a dry torch, which is placed across the opening of the view during the furnace. If after 30 ... 40 minutes remove the torch and scrape off the smoked surface with a knife, you can set the temperature of the gases. The color of the torch does not change at temperatures up to 150 ° C. If the torch turns yellow (to the color of the crust of white bread), then the temperature has reached 200 ° C;

Thus, when firing the furnace, the temperature of the gases should be adjusted so that the view is within 250 ° C.

You should be aware that in the summer, condensation either does not form at all, or it happens in a small amount. The formation of condensation depends to a large extent on the size of the grate, the correctly raised flue and the device of the furnace in the Russian stove, the size of the channel, the thickness of the walls, clay and the height of the chimney, the temperature of its heating, the moisture content of the fuel used, the temperature of the gases leaving the chimney and the excess amount of flues in the furnace.

The height of the chimney should be at least 5 ... 6 m, counting from the level of the ash pan or the bottom of the Russian stove. The thickness of the masonry of the pipe walls should be made in half a brick of 20 mm). Thinner pipe walls heat up quickly and cool down quickly, leading to condensation.

Such pipes must be insulated. Various cracks in the pipe and furnace, through which cold air penetrates, also contribute to the cooling of gases and the formation of condensate. When the cross-section of the pipe channel (chimney) is higher than that required for a given furnace, the flue gases rise through it very slowly and the cold outside air cools them in the pipe.

We suggest that you familiarize yourself with How to eliminate the creak of the floor from the boards

Sometimes, to improve the draft in the stoves, it is necessary to rearrange the pipes, reducing the size of the chimney, lowering or raising the height of the pipe on the roof, until a satisfactory result is obtained. Where the chimney narrows, right angles should be cut to ensure a smoother transition of gases.

DIY stove masonry

How to see the quality of sandwich pipes with a routine visual inspection:

- Pipes are geometrically round (ovality is allowed no more than 1 mm). For double-walled chimneys (sandwiches), it is necessary to check the alignment of the inner chimney with the outer shell - it must be within 1mm, otherwise you will have difficulties with joining the elements together.

- The welded seams are thin (no more than two metal thicknesses in width), the color of the seam is almost the same as the metal itself, without lack of fusion. At the ends of the pipes, 2-3 mm undercooking is allowed - according to the technological features of manufacturing.The thin laser-welded seam does not burn out alloying elements (chrome and titanium) and guarantees the tightness of the pipe.

- If you buy sandwiches with a galvanized shell, make sure it is laser welded or plasma butt welded. Only with this type of welding can damage to the zinc coating be minimized and corrosion of the weld (joint) can be prevented. Remember, zinc plating does not weld well!

- If the chimney seats are made according to the bell-shaped landing pattern, this is very good, because ensures the tightness of the docking.

- Curly elements - knee, tee, start-sandwich, head, cone - should be beautiful, without rough seams, joints and abrasions.

- Each element of the chimney, designed to work with fireplaces and stoves, is marked with a nameplate, where all the parameters are indicated: barcode, name, steel grade and thickness, diameter, auxiliary designations. Only in the presence of such a nameplate can claims be made to the manufacturer in the event of defects or inconsistencies in quality. Some manufacturers additionally mark the elements with a corporate holographic sign. Pipes are packed in individual corrugated cardboard, marked with a branded tape or brand name.

In table 3 you can see the difference in prices (why some chimneys are more expensive than others), the main characteristics of steel grades and recommendations for use.

How to simplify the choice of a chimney

What is a fireplace chimney? This is a set of pipes in which one end is connected to a heating device, and the other is brought out into the street. Its installation is a rather complicated and time-consuming process that requires certain knowledge and professionalism. Chimneys can be made of bricks, stainless steel, ceramics, Each of these types has its own advantages, disadvantages, as well as installation features.

When choosing a chimney design, you need to pay attention to the following factors:

- The material of the chimney needs to be stable so that it can withstand the high temperature of the outgoing products; (See also: )

- Must withstand a mixture of soot and condensation;

- The chimney design must fully meet all required standards (construction, fire, technological, operational).

For a fireplace that will be fired from gas, a stainless steel chimney is perfect, for coal it is better to choose a brick chimney, and for firewood a construction made of ceramics, bricks and stainless steel is suitable.

Advantages and disadvantages of ceramic fireplace flues

The advantages of a ceramic pipe include the following characteristics:

- the material is very fast in installation and assembly;

- is a guarantee of high efficiency;

- long operational life;

- the range of blocks is large, which makes it possible to mount a chimney opening with any configuration;

- the presence of a special hole that makes it possible to clean the chimney;

- the resulting condensation is drained away by the opening located at the bottom of the chimney.

Among the disadvantages of block ceramic pipe systems, it is customary to distinguish the following:

- relatively high price;

- due to the fact that most of these chimneys are manufactured abroad, the delivery time is sometimes very long.

To the rescue - sandwich pipes

A feature of modern sauna stoves is their heating temperature, which can reach 400 degrees. An important indicator of the efficiency of the furnace is the instantaneous heating of the body and the maximum heat output.

The entire heating process is accompanied by the release of infrared radiation, which is distributed on the surfaces adjacent to the oven. Under the influence of high temperature conditions, the wooden structure of the bath can be charred or ignited.

That is why it is so important to ensure reliable insulation of wooden surfaces from the heat of the stove. For this, a protective screen and sheathing made of refractory materials are suitable.

For those who wish to equip a safe chimney in the bath, we suggest using a sandwich pipe. This design includes several sections that can be easily placed into each other, i.e. looks like a layered cake.

Here are the main components of a sandwich pipe:

- stainless steel layer (inside);

- insulation in the form of basalt / mineral wool (in the middle);

- zinc coated steel (outside).

This creative design represents the insulation of the chimney integrated into the overall system and is designed to solve two problems at the same time:

- protection against accumulation of soot inside;

- maintaining an optimal temperature outside.

Definition of condensate

When wet smoke comes into contact with a cold pipe, the steam turns into liquid

Moisture is present in hydrocarbons, wood and coal. When heated, it evaporates and, together with the smoke, leaves the furnace. Upon contact with the pipe walls, the steam cools down, turns into a liquid state and is retained on the walls in the form of water droplets. Condensation forms in the chimney when its temperature is below the dew point, which for combustion products of various fuels is 45-60 degrees.

Condensate is water that forms in different volumes in the outlet channel under the influence of low temperature. The process begins with fogging of the material, then droplets form, partly flowing down, and partly absorbing solid particles and toxic gases. The result of such a phenomenon is always negative - the formation of build-ups consisting of a dense and flammable substance.

Functions and features of the operation of the chimney in the bath

It is a unique material with polyethylene foam sandwiched between a pair of foil sheets. With the help of thermal insulation, you can qualitatively insulate the chimney, moreover, independently.

The thickness of the thermal insulation varies from 2 to 10 mm, and the thicker the material, the greater its resistance to high temperatures.

The top layer of foil serves as a reliable protection of the pipe from significant overheating. With the help of a wire or tape of a metal master, heat insulation is attached, which is then wrapped around the chimney.

You can wrap the chimney with foil insulation

Modern material includes two layers: heat insulator and foil. The second one plays a reflective function and can store up to 90% of thermal energy in a building. Folgoizol is a harmless material in comparison with other analogues, since compacted food foil acts as a foil. The material is resistant to ultraviolet light and high temperatures in the range of -65 to 175 degrees Celsius, a good insulator.

Whoever does not yet know how to insulate the chimney pipe in a sauna, we recommend covering the ceiling of the steam room, walls and chimney with foil insulation. As a result, you will get a room that resembles a thermos in design. The heat will remain in the sauna, and the bath will quickly pick up the temperature, and then slowly cool down. Sometimes a mesh is installed on the pipe for stones in the bath, which is very convenient and practical.

Stove fire protection

Modern metal stoves are mounted on a foundation, while sheathed with sheets of the same material on the back and side of the wall. If you independently beat the stove with only metal, then its appearance will not be very aesthetic. It is better to make the external brickwork with red brick, which insulates the stove from fire and keeps the heat in the bath.

Due to the fact that asbestos emits toxic substances at elevated temperatures, it is not recommended to use it in a steam room. Natural felt is considered harmless, which, moreover, is a good insulator. For the price, this material is more expensive than asbestos sheets, and when smoldering, it emits a specific smell (felt does not ignite), which can be immediately felt.

If you intend to install the stove on a wooden floor, then first it is better to spread the felt material in a couple of layers, then lay out the brick in three rows.For walls and floors, it is advised to lay sheets of metal as an insulator, the height of which varies from 50 to 70 cm.

Having followed all our recommendations correctly, you will extend the term of operation of the entire smoke exhaust structure and protect it from fire. And you will no longer have any questions about how to wind chimney pipes.

Hot topic

In stoves and fireplaces, the temperature of the exhaust gases is quite high, and therefore it is most reasonable to use brick or concrete chimneys with them, which, of course, does not exclude the possibility of using steel or clay structures. In principle, asbestos-cement analogs are also suitable, but in accordance with the norms, the flue gases in this case should not be heated above 300 ° C. It is advisable to provide for each stove a separate chimney duct, but it is possible to connect two stove inserts to one chimney if they are located on the same floor. When connecting chimneys, they should provide for incisions with a height of at least 1 m from the bottom of the joint.

If stoves are allowed to be placed only in one- or two-story buildings, and for heat generators on each floor there must be a chimney, then solid fuel fireplaces with closed fireboxes can be installed even in multi-storey residential and public buildings. At the same time, they must be connected to the collective smoke exhaust system through an air seal with a length of at least 2 m, which excludes the spread of combustion products.

Chimneys made of technical ceramics are resistant to moisture and acids, as well as temperatures up to 1250 ° C

Errors in the construction of brick chimneys may also relate to the quality and characteristics of the masonry or the choice of bricks. In this case, you cannot use its slightly burnt wall or partition varieties. The thickness of the masonry joints should not exceed 5 mm, and the installation of the bars on the edge is not allowed. Significant miscalculations include the stepped shape of the inclined sections of the channel, which leads to the formation of eddies and a decrease in thrust. Inaccurate splitting of bricks, improper preparation of the mortar, the presence of voids in masonry joints and double vertical joints - all this causes problems when operating brick chimneys.

When constructing such structures, the use of hollow or porous bricks is not allowed. Only refractory ceramics are used for masonry of furnaces and fireplaces, as well as chimneys. The technology of their production provides for firing at a temperature of 1300-1350 ° C, while the color of the finished product is different - from almost white to light brown, more often - straw with brown blotches. Taking into account the design features of furnace furnaces of various types, straight and wedge-shaped (end and ribbed) refractory bricks are produced.

The condition of the brick chimney must be periodically monitored: to simplify this task, the structures are whitewashed, since black soot, indicating the presence of cracks and flue gas leaks, is clearly visible on the light surface.