Scope of application

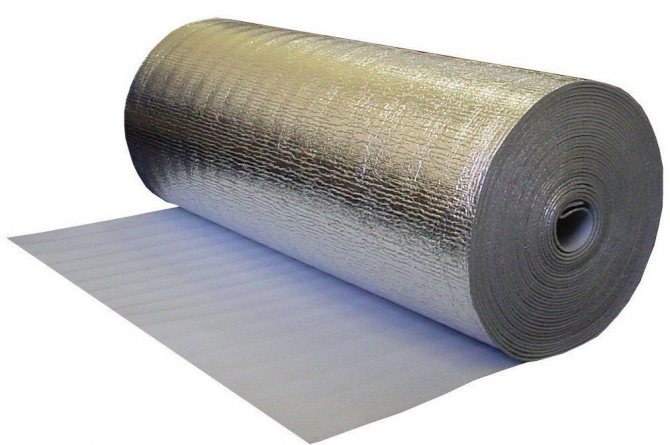

Reflective thermal insulation is applicable to all surfaces without dirt and dust, suitable for complex structures with corners, bends and drops. Insulation of walls from the outside can be maximized by creating an air gap of 20 mm on the foil side.

The material is effective for multi-storey and one-storey frame houses, while this will increase the resistance of the walls without increasing their volume. Installation is carried out end-to-end without overlaps, and the seams are glued with foil tape.

Application from the inside

If you want to insulate the room from the inside, then there are two options. The first option is to make 2 air gaps between the outer wall and the material, between the insulation and the cladding (for example, drywall). In this case, TIM with double foil is used.

The second option is to create one gap between the outer wall and the insulation, for which a material foil on one side is used. The foil is turned inside the room.

Roof insulation

Reflective TIMs mounted on the roof provide not only thermal insulation, but also vapor insulation. The under-roof space is also protected from moisture.

The reflective film is especially effective when insulating the ceiling of the bath.

Piping and ventilation

For pipes, insulation with double-sided foil is required. If the pipes have a diameter less than 159 mm, then it is possible not to create an air gap between the TIM and the pipe. If the pipes have a larger diameter, then the gap is required. The air gap is set up as follows:

- the first option is to fasten the foil film rings to the pipe with a distance of 300-400 mm from each other. And over the rings, the pipe is wrapped with insulation;

- the second option - wooden bars with a section of 10 by 10 mm or 20 by 20 mm are laid along the pipe, after which insulation is wound on top of them.

The joints must be sealed with aluminum tape. Insulation of ventilation ducts will eliminate heat loss and provide sound insulation.

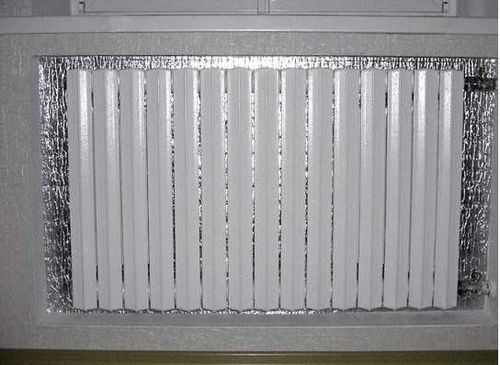

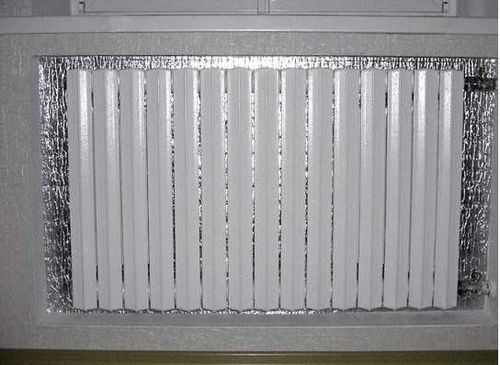

Installing a heat-reflecting shield behind the battery

In the context of constantly rising prices for energy sources, the issue of saving is especially important. Heating pipes are usually installed on the walls under the windows. Heat loss increases in these places. If the radiator is installed in a niche, the power required for heating is even higher due to the reduced wall thickness. The best solution in this case would be a heat-reflecting screen behind the radiator. It insulates the wall area from the heater and keeps the home warm.

Principle of operation and design features

Various materials are used in the production of heat reflecting screens. Their main property is a low level of thermal conductivity. First of all, these include:

Porileks can be used for thermal insulation.

Also, all screens have a layer of insulation. Sealing is achieved using metallized tape. The thermal conductivity coefficient should not exceed 0.05 W / m * ° С. There should be an interlayer between the foil and the wall to keep it warm. When creating heat-reflecting screens, roll foam can be used.

Due to the low cost, foamed polyethylene is most often used. It is installed with foil to the pipes, and the insulated side to the walls. It is best if there is a layer of air under the screen, which will increase the heating in the room.

Screens can be used not only as an energy-saving mechanism, but also for thermal protection of ovens

This is especially important for the decoration of the steam room and sauna.The stove is a source of increased fire hazard, therefore it is important to insulate the walls from excessive overheating.

Basalt cardboard is used for thermal protection of furnaces

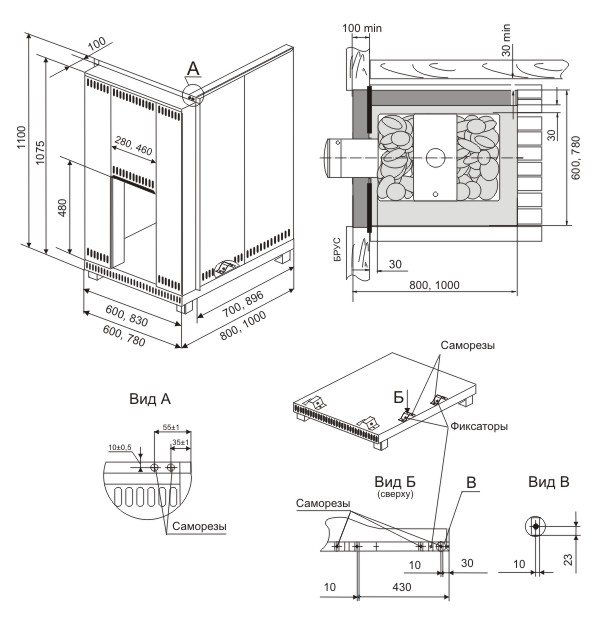

Stainless steel and minerite are used for these screens. In accordance with the standards, they are made in several sizes, the edges must be curved at a certain degree, and there must be a natural non-combustible material inside. Basalt cardboard is usually used for this purpose. The heat reflective screen is mounted behind the oven and on the ceiling. Minerite is mounted in two layers. This reduces the distance from the protected surface to the oven.

Frontal screens in baths began to successfully replace brickwork. In addition, with the help of them, the temperature rises and the adjacent rooms are heated. The thickness of the steel sheet must be at least 0.8mm. A special silicone paint can be used to cover the screens. They are usually assembled from hollow box-shaped elements. There must be a thermal gap between the oven and the screen. Ceramic sleeves can be used as fixation.

Under the wooden covering, aluminum foil is mounted on the walls in the steam room for thermal insulation and increased safety in the room. Next, the lining is installed. The joints between the layers are glued with tape. To seal the seams, an aluminum-bitumen tape is used. Convection screens can be used if the temperature of the outer walls of the oven does not exceed 400 o C.

The screens also reduce the effect of wood decomposition in steam baths and saunas by protecting them from humid steam and intense heat. The installation must be carried out strictly opposite the radiation from the stones of the stove.

Installation features

The screen allows you to keep warm behind the cast iron radiator and pipes. This is where the greatest losses occur. The use of energy-saving installations makes it possible to save up to 10% of heat when heating a room. The thermal resistance increases, the heat of the radiator and pipes remains in the room. When installing, it should be borne in mind that the size of the material used must be larger than the radiator.

It is important to pay attention to the location of the battery. If the pipe is in a niche, the thermal insulation layer must be made thicker.

Also, do not forget about the type of connection of the radiator during installation. It can be produced in a one-sided pattern or diagonally. In order to check the material, it is enough to set it on fire - the foil will not melt.

Heat shields for batteries can be attached using a construction stapler. In addition to retaining heat, they also protect the walls from moisture penetration. The installation can be done independently, for this you do not need to have specialized knowledge, the manufacturer's instructions are enough.

Heat-reflecting screens behind the radiator and pipes can be used in residential buildings, country cottages, office and industrial buildings, in children's institutions and hospitals. Technically simple installation makes it possible to save the energy of pipes during heating, to protect the walls from extreme heat in saunas and to avoid the appearance of mold.

Comparison of screens for sauna stoves

When talking about screens for stoves in a bath, they mean a protective barrier around a metal heat generator. Such thermal screens are not installed near brick ovens, since brickwork itself is thermal insulation. Protective screens allow installing the stove closer to surfaces made of combustible materials, which is important for wooden baths. SNiP 2.04.05 of 1991 prescribes indents from structures with heating elements:

- to the opposite wall - at least 1.25 m;

- to thermally protected walls - not less than 380 mm;

- to an unprotected wall - from 500 mm or more.

Note! If heat-resistant screens for sauna stoves are used, then the distance between the adjoining walls made of combustible material and the side surfaces of the structure can be reduced to 200-250 mm, leaving at least 1 m from its upper surface to the ceiling.

Metal protective screens

A protective metal fence is mounted around the perimeter of the heating structure. During installation, small gaps are left between the screen and the stove in order to activate air convection along the walls. The size of the gaps depends on the thermal conductivity of the material from which the thermal protection is made, and the characteristics of the sauna stove. You should focus on the manufacturer's recommendations. Usually they recede from the walls of the body by 3-5 cm.

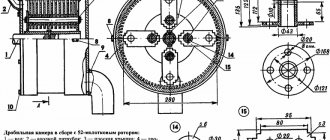

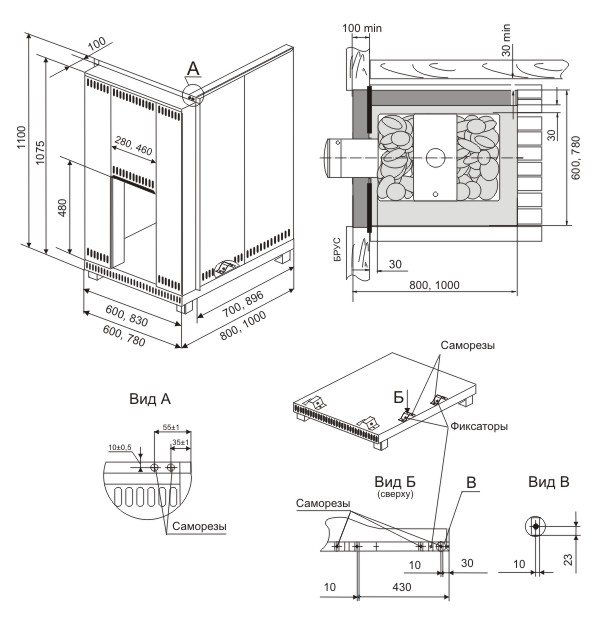

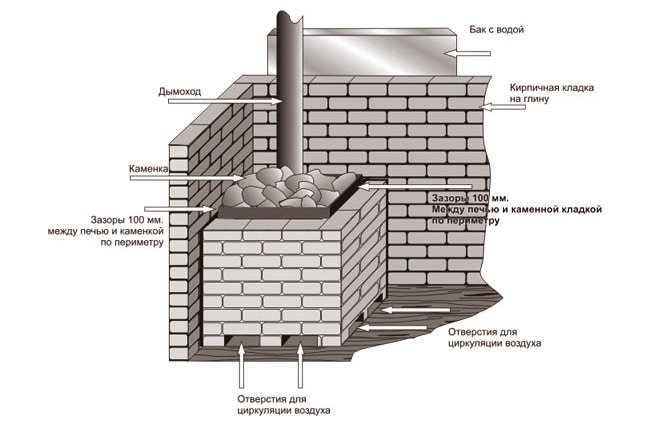

An approximate diagram of the installation of a metal protective screen around the furnace

If you make a screen for the oven with your own hands, then you need to choose stainless steel. At the factory, the screens are box-shaped elements made of stainless steel. The elements are hollow inside and have ventilation holes. For ease of installation, safety barriers are equipped with adjustable feet. The presence of the legs allows you to set the bottom clearance for additional air flow. The screens are covered with heat-resistant paint, for example, silicone paint.

What does the installation of a metal thermal shield give:

- the intensity of infrared radiation decreases;

- due to the air flows directed along the walls of the structures, the room is quickly warmed up;

- the presence of ventilation holes helps to lower the temperature of the furnace body.

The disadvantage of metal shielding is called hard heat, but it is softer than without the shielding. Of the advantages - the absence of slots through which contact of the flame with unprotected surfaces is possible.

Brick thermal screens

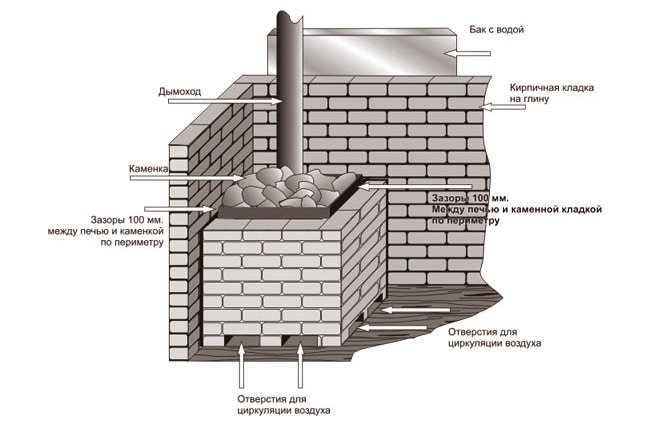

Instead of metal thermal screens, you can make brickwork. A brick fence is also made around the perimeter - around the furnace body. It is enough to lay in half a brick at a distance of 5 cm from the side walls of the structure.

Important! The lower part of the masonry is made with gaps (air passages) every 3 cm. The size of the gaps is 6 * 7 cm. For the manufacture of brick insulation, ceramic bricks are suitable, which will withstand high temperatures and high humidity.

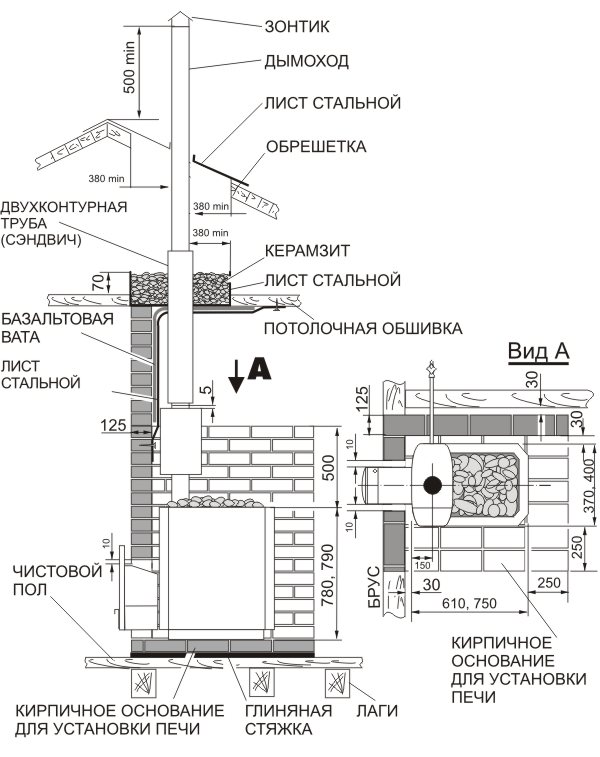

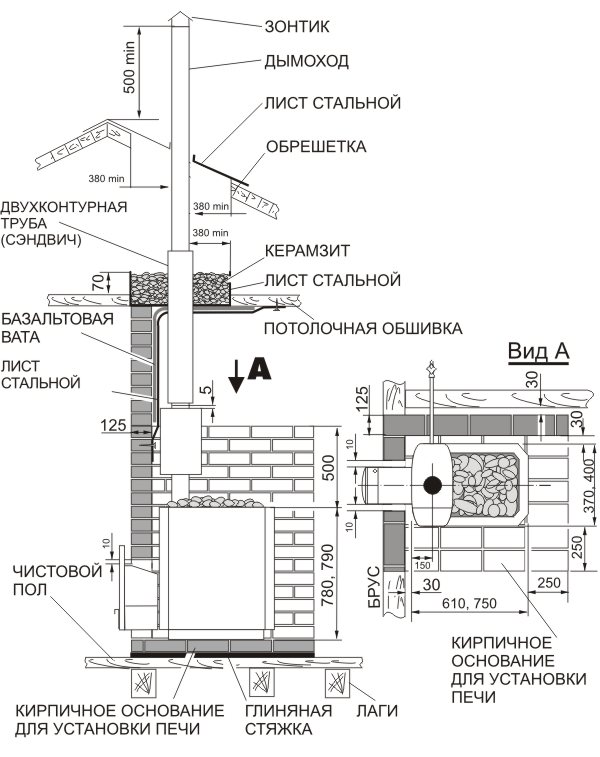

Scheme - laying a brick heat-resistant screen for a metal furnace

For masonry, special stones with low thermal conductivity are sometimes used, paying attention to the properties of the material - it must withstand temperature changes and not collapse from moisture. Cons of brickwork:

- increase in air heating time;

- the appearance of gaps between the bricks is possible, which reduces the thermal protection and can lead to the ignition of combustible materials.

Advantages of brick protective barriers:

- heat accumulates in the bricks, which maintains the temperature in the bath for a long time;

- the slow heating of the bricks creates a milder heat that is pleasing to the body.

Homemade brick thermo-screen - heater lining diagram

Principle of operation

To understand the principle of operation of such insulation, consider the main methods of transferring heat from one coating to another:

- thermal conductivity - the ability to conduct heat (solids);

- convection - the transfer of heat through the air due to the different density of cold and warm air flows;

- radiation - any body with a temperature above zero emits heat waves, which are absorbed by walls and ceiling (surfaces), converted into heat and transferred to a cold external environment. This exchange accounts for about 60-90% of heat loss.

Thus, heat loss is inevitable. It turns out that in order to create the effect of thermal insulation, it is necessary to minimize heat loss from radiation. But traditional TIMs are not able to protect a building from this type of heat transfer.And the optimal material was found - foil insulation, known for its reflective and low emitting ability.

Reflective insulation works on all heat transfer processes: radiation, convection and heat conduction, inhibiting heat loss.

Installation of films for radiators is a simple sequence of actions

From a technological point of view, the foil behind the heating coil is installed without any difficulty. You will perform all the work efficiently and quickly, if you listen to some advice.

First, don't buy matte metallized material. Use only polished foil.

Second, don't buy double-sided films. One air gap is enough to ensure high-quality heat reflection.

Third, leave a gap of about 1.5–2 cm on both sides of the insulator layer. It is necessary to obtain the optimal thermal resistance of the reflector (1.15 m2 * ° C / W).

Prepare liquid nails or standard adhesive used for wallpaper installation, as well as directly reflective foil, and proceed to install it. The procedure is as follows. First, carefully measure the dimensions of the wall sections where you plan to install the screen, or niches.

The parameters of the film must correspond to the projection of the radiator onto the wall. Add about 10% more to the result. In this case, the heat-reflecting potential of the foil will be slightly high. Some masters say that extra centimeters are not needed.

The effect of them will be insignificant, but the edges of the screen sticking out from behind the radiator will greatly spoil the aesthetics of the room. See for yourself, choose the option that suits you personally.

Then make sure that there is a gap of at least 1.5 cm between the heater and the film that you will be installing. When there is not enough free space, you will have to adjust the radiator suspension to accommodate the missing centimeters.

Next, remove the radiator. Mark the places where its mounting brackets are located. Dismantle them. Examining a brick or concrete wall surface.

In the presence of cracks, cracks, other defects, plaster them (or putty). Align the wall, glue the screen (coat the reverse side with wallpaper or polymer composition).

Instead of glue, as noted, it is allowed to use liquid nails. In some cases, it is allowed to use stapling staples or small nails to attach the foil (if they fit into the wall material without any problems and are firmly held in it). Carefully return the suspensions to their place and install the battery.

In addition, we will give some useful recommendations for home craftsmen who are installing heat-reflecting products for the first time. If during the installation of the screen you damaged its outer covering, the cut site can be masked with LAMS or LAS films.

They are made of foil and do not reduce the efficiency of heat reflection. Don't try to find screens that are too thick. Practice shows that five centimeters is quite enough for high-quality heat conservation in the house.

Installation recommendations

- Installing a heat-reflecting shield behind the battery is technologically simple, but it will be done faster and better if you take into account the following practical recommendations:

- the maximum effect when using penofol and similar materials is achieved when there is an air gap of 15-20 mm on both sides of the insulating layer. In this case, the thermal resistance of the insulating structure is reached up to 1.1-1.2 (m ∙ ° C) / W. Installation is carried out on wooden slats, and penofol should be double-sided foil (type B);

- in most cases, to equip a reflector for batteries, one air gap is sufficient - between the radiator and the insulating material. Double-sided foiling is optional in this case;

- when choosing a reflector, it should be borne in mind that the foil must be polished (not matte).

Heat-reflecting shield for the battery. Varieties

Currently, to prevent a decrease in the thermal efficiency of radiators by minimizing the loss of thermal energy, which is spent on heating the outer wall of the building, a reflective screen is used for the battery. They are made of various materials and allow, by reducing losses, to increase the efficiency of the radiator by almost 20%. This leads to an increase in the temperature in the heated room, on average, by 2 - 3 degrees.

Most often, a heat-reflecting shield for a battery is made of the following materials

Folgoplast SP (FSP)

This material is practically similar to the insulation Izlon NPE, which is widely in demand on the market, and is a self-adhesive insulation doubled with aluminum foil. It is made of expanded polyethylene, on which foil is applied on one side, and on the other a layer of special glue with increased water resistance. This allows high-quality fastening of the material on various bases (wood, concrete, brick, metal, drywall, etc.).

Foamed polyethylene, which is the basis of FSP, has very high thermal insulation properties and practically does not absorb liquid. It does not rot and is environmentally friendly, which makes it possible to widely use it in any living space.

Polished Al foil from the outer layer reflects up to 97% of thermal energy, being a highly efficient vapor barrier. The sticky layer is made of waterproof grades of glue based on synthetic rubbers, which increases its adhesion to almost all materials. To prevent the material from sticking together in the roll, it is laid with a special siliconized film.

The material is offered in rolls with the following geometrical parameters:

- foil thickness - 10/8/5/4/3/2 mm;

- roll length - 10 - 50 meters;

- roll width - 1 meter.

FSP is supplied to the trade in the following modifications: SP2 - SP10 (differs in the thickness of the web).

Parameters.

| Parameter | Working temperatures | Heat reflection percentage | K-t of thermal conductivity (W / m * deg) | Specific heat (kJ / kg * deg) | Vapor permeability |

| Value | -60/+100 | 97 | 0,038 – 0,051 | 1,95 | 0 |

Folgoplast SPMP (FSPMP)

Aluminum foil in the specified material is covered with a metallized lavsan film, which protects it from mechanical damage and oxidation. The material makes an excellent heat-reflecting screen behind the battery.

Folgoplast P.

There is no adhesive layer on the side opposite to the aluminum foil.

Folgoplast PMP.

A layer of foamed polyethylene is laminated on one side with a metallized polyethylene film.

Foam in various modifications can also be used to make a reflective screen behind the radiator.

Reflectors for radiators Heating system

»Heating batteries

The heating system includes, fasteners, pipes, thermostats, an expansion tank, air supply, batteries, manifolds, a boiler connection system, pressure-increasing pumps.

On this page we will try to find and select certain installation components for the desired summer residence. Installation of heating a summer cottage has different elements. All elements of the installation are very important.

Therefore, the choice of parts of the structure must be done technically correctly.

Reflectors for radiators

Battery reflectors are an energy-saving technology available to any city dweller. Even now, such brilliant battery reflectors can be seen in Kiev hospitals, schools and kindergartens.

They return the heat from the batteries to the apartments, which uselessly goes into the wall closest to them.

The foil installed under the battery acts like a thermos - heat is reflected from such surfaces like the sun's rays from a mirror.

Russian-made material is called "Penofol", Ukrainian - "Alyuf", there are also a lot of imported reflectors. The basis of the material is aluminum foil, which is attached to a soft foam material with a thickness of 2 to 10 mm.

Head Department of Building Physics and Resource Saving of the Research Institute of Building Structures Gennady Farenyuk told how best to choose a reflector:

- Thanks to "Penofol" or "Alyufom" it is possible to save about 5% of room heat (about 1 "extra" degree). Believe me, this is a lot! In 1993, I received a patent for the idea of preserving heat in apartments using this foil material, and now it is installed in several hundred schools as part of an energy saving program.

Ready-made reflectors are not sold in stores, but they are easy to make on your own - you need to buy special material in the market or in a store and cut out pieces of suitable size.

“It must be metal foil,” the physicist advised. “It reflects heat better. Aluminum spraying on a lavsan base works much worse. It is very simple to check whether it is foil or not - you need to set fire to the edge of the material with a lighter. If it doesn’t melt, it’s foil.

The price of a heat reflector depends on the thickness. The material is sold in construction markets and in supermarkets.

Removal and prevention of air congestion in the heating system.

One of the main reasons for the deterioration of heating, and sometimes its absence, is the formation of air jams in the heating system of buildings. This causes the indignation of consumers towards heat supply organizations, which is sometimes unfounded, because at that time, the source of heat energy was the boiler house, which was operating in normal mode.

The first reason is that water itself contains dissolved air. If the water is heated, then air begins to evolve in the form of bubbles, which rise to the uppermost sections of the pipelines. It is there, accumulating, that they create air jams.

The second reason is that when the pressure in the heating system decreases or changes, it is partially emptied, and all the voids formed are air locks.

The third reason - leaks from pipelines also contribute to the "airing" of the system as a whole.

The fourth reason is the repair of the piping system and subsequent assembly. There is no way to avoid the likelihood of "airborne".

Practice shows that air is collected most often in heating devices installed on the upper floors.

In such cases, at the upper points of the heating system, air is removed through special devices - Mayevsky taps.

Mayevsky crane

When looking for the place of formation of an air lock, pipes and heating devices are tapped with a light hammer. In places where air congestions are located, the sound becomes stronger and more resonant.

Air pockets can form at kinked pipelines. Therefore, when installing the system, it is necessary to observe the size and direction of the slopes of the distribution pipelines.

Air locks are eliminated by opening the air vents until all air has been removed from the system. This method of air removal is repeated several times, especially on contaminated systems.

The news uses materials from the magazine "Miske Gospodarstvo Ukrainy"

Protection of the walls of the bath from the heat of the stove: the device of protective sheathing and screens

In a home bath, there is always some likelihood of a burn from careless handling of the stove. This is a rather serious danger - the operating temperature of the sauna stove is very high. However, this problem can be solved very easily by installing protective screens for bath stoves, which will be discussed in this article.

The fencing of the sauna stove in the steam room can perform several functions at once:

- Protection of all visitors to the bath from accidental burns;

- Improving the visual qualities of the sauna interior;

- Adjusting the heat flow in the bath.

Before installing protective screens in the bath, you need to choose the right design. The choice is influenced by a lot of different parameters, ranging from the material of the heater and its power, ending with the heating temperature and other factors.

To create the most effective and reliable screen for the oven in the bath, the following indicators must be taken into account:

- The degree of heat resistance of the material;

- The complexity of the installation of the selected structure;

- Wear resistance and resistance to temperature extremes, since the operating conditions of the protective screens are rather unfavorable;

- The cost of the material, on which its effectiveness often depends.

Heat-resistant screens for sauna stoves are divided into two types, depending on the material used:

- Basalt cardboard screens. The average thickness of such protection is about 10 mm. Such designs are quite reliable, practical and convenient. During installation, the material is installed at an angle to the furnace equipment.

- Brick screens. The laying of brick reflectors is carried out even at the construction stage of the bath - the brick protection weighs a lot, so there must be a reliable foundation under it. If you equip such protection after installing the bath itself, then the installation process will be complicated. In addition, it is worth remembering that silicate bricks are not suitable for protection, so you will have to use red or clinker products.

When planning a protective screen, you should pay attention to the decorative qualities of the building. The fact is that the outer lining of the stove can act as a protection, which will significantly increase the visual qualities of the interior - just look at any photos with a similar design.

For the arrangement of protection, full-bodied furnace materials are most often used, which are stacked with in-line dressing. To lay them, a special solution is used, mixed in a ratio of 1:30:10 (cement, sand and clay, respectively).

In the case of metal stoves, you can use one of the following schemes:

- Protective screen for the case. This protection, which is usually made of bricks, blocks the heat generated by the furnace body.

- Protective screen for nearby walls. With the help of such screens made of refractory materials, the walls adjacent to the sauna stove are closed.

- Floor protection. Non-combustible materials are laid on the floor - brick, porcelain stoneware, natural stone or metal sheet, laid on top of a heat-insulating layer.

A brick screen for a metal stove in a bathhouse is equipped in compliance with certain rules that will ensure high efficiency of the structure:

- A brick screen for a sauna stove should not be laid close to it. The distance between the masonry and the walls of the heating device must be at least 30 mm.

- In the lower part of the protective screen, it is necessary to leave holes that will ensure rapid heating of the steam room when the stove is started. To regulate the temperature in the steam room, the openings are equipped with oven doors.

- A brick screen for a sauna stove with your own hands is usually laid out in half a brick, but there may be nuances. For example, to achieve the maximum temperature in the steam room, the screen is made in a quarter of a brick or with a large number of holes. To lower the temperature, you need to lay a whole brick protection - the heating will be very long, but the heat transfer time will also increase.

- When laying, a solution of clay and sand is used. If necessary, the clay can be replaced with cement.

- The brick wall surrounding the sauna stove must be at least at the same height as the top edge of the firebox.

The installation of a metal screen is usually carried out in such a way as to obtain a structure like a box. Outside is stainless steel or sheet metal coated with heat resistant paint. As a result, an air gap appears between the metal sheets, due to which good thermal insulation is provided.

There are openings in the lower part of the structure that provide air circulation and prevent overheating of the metal box. To implement such protection, you can use one of two schemes.

Scheme 1

A polished metal sheet is selected, which has much better heat transfer. Typically, these screens are used on the back of the oven to prevent heat loss. Of course, you should not fix this protection directly to the wall - the risk of fire from this will increase many times over.

For correct installation, it is required to place a non-combustible layer between the protection and the wall so that there is an air space behind the sheet. There should also be a small distance from the protection to the floor - this makes it possible to blow air around the screen, removing heat.

Scheme 2

To implement such a scheme, thermal insulation is first laid on the wall, and already on top of it metal protection. The design will largely depend on the chosen insulation.

Depending on the selected thermal insulation, the arrangement of the protective screen will look like this:

- When using roll material, the cladding is created in such a way that the distance between the slats is slightly less than the width of the material. The insulation is laid between the planks and fixed with special dowels with a large cap.

- If, however, mineral cardboard or an asbestos sheet is used as a heat-insulating material, then it must first be attached to the wall, and the metal sheet is fixed from above.

It should be understood that not all situations require a protective screen at all. For example, for brick ovens with an initially protected firebox, fences are not required. If the screen needs to be installed, then red ceramic materials are selected for it, capable of withstanding severe temperature changes and exposure to moisture.

A do-it-yourself sauna stove screen is an important sauna design that can prevent accidental burns and balance the operation of the stove. By implementing one of the proposed schemes, you can achieve a combination of protection efficiency, good functionality of the stove and good visual qualities of the entire system.

Sauna stoves heat the air in the room to the desired temperature and maintain it for the required time. The main indicator of their efficiency is considered to be fast heating of the case and maximum heat transfer. This process is accompanied by intense infrared radiation, and the metal surface of the structure can heat up to 400 ° C.

Important! To protect those who like to steam from burns in contact with the hot surface of the case and to get rid of the unpleasant scalding heat, a screen for the sauna stove is installed from a heat-resistant material.

When talking about screens for stoves in a bath, they mean a protective barrier around a metal heat generator.

Such thermal screens are not installed near brick ovens, since brickwork itself is thermal insulation.

Protective screens allow installing the stove closer to surfaces made of combustible materials, which is important for wooden baths. SNiP 2.04.05 of 1991 prescribes indents from structures with heating elements:

- to the opposite wall - at least 1.25 m;

- to thermally protected walls - not less than 380 mm;

- to an unprotected wall - from 500 mm or more.

Note! If heat-resistant screens for sauna stoves are used, then the distance between the adjoining walls made of combustible material and the side surfaces of the structure can be reduced to 200-250 mm, leaving at least 1 m from its upper surface to the ceiling.

Protective screens for sauna stoves are made of various non-combustible materials in compliance with certain air gaps.

Also, often in order to create an effective thermal barrier, a reflective sheet of polished stainless steel is placed between the wall and the metal stove at a certain distance from the protected surface and the heated furnace body.

Another common option for thermal protection is arranging a brick wall between the stove and the combustible exterior wall decoration, but this solution is quite laborious and requires certain skills.

The most durable and reliable barrier that prevents excessive heating of the wall surface from the heat of the stove is the air space between them. Subject to all the distances established by standard regulatory documents, you can be 100% sure that there is no reason to fear heating the walls from the stove body.

According to the standards taken from SNiP 2.04.05-91, the distance from the furnace to an unprotected wall that has a REI 60 fire resistance limit should be at least 500 mm (in diagram A), that is, half a meter.

If you install a dense sheet of non-combustible material (minerite or glass magnesite) on the wall and additionally fix a reflective stainless steel layer on it, then this standard distance is reduced to 380 mm (in diagram B).

Also, the dimensions of the parts of the structure of the protective screen, which protrude beyond the dimensions of the furnace (in diagram C), are regulated. This distance should be taken into account when calculating the material by at least 150 mm. As for the distance from the firebox door to the wall opposite it, it cannot be less than 1250 mm (in diagram F).

However, as practice shows, in order to comply with all these norms, you need to have a fairly spacious steam room. And usually this room has a very limited space and most of it is planned for shelves, which you want to make as spacious and comfortable as possible. Therefore, it is difficult to imagine a stove located at intervals of half a meter from the walls on each side.

Of course, this is not an excuse for violating fire safety standards established by special responsible authorities based on experimental scientific research.

Important

At the same time, manufacturers of Finnish stoves in the technological documents for their products indicate other figures for the safe placement of their metal stoves in the walls of the steam room.

Types of sauna stoves

Operating principle

If the insulation is foiled, it acquires an increased ability to repel condensate, retain heat, and each layer in it is responsible for certain functions:

- The first layer of the material consists of glass, mineral fibers, foamed polyethylene, expanded polystyrene, which does not allow heat to go anywhere. It tends to reflect waves into the home, creating a favorable microclimate for living.

- The second is a 7-15 mm foil, which can reflect the heat flux as much as possible. According to the laws of physics, a material, if it is foiled, accumulates up to 90-95% of thermal energy, the remaining 5-10% is held by polyethylene, fiber.

- The production process is simple: the metal is soldered onto the material, joining with it into a single whole, after which it gains the ability to reflect the body.

- Thermal insulation is available one- or two-sided, which determines the range of use. Insulation, in which one layer of aluminum is used, is used for insulation inside the room. If the material is foiled on both sides, refrigeration plants, heating mains, industrial buildings, and factory mains are insulated with them.

Application nuances

When choosing thermal insulation, it is worth remembering that not everyone can reflect heat. For the indicator to be maximum, the foil must be thick enough. Most often, the insulation, its basis, is extruded polyethylene, which has a thick aluminum layer that retains maximum thermal energy. These include insulation Teplofol, Penofol, Alyufol, others.

Teplofol

Sheathing that can reflect is available in the form of mats, rolls, pipe cylinders. If it is made according to technology, testing, the characteristic of thermal resistance must be indicated in the accompanying documents. If you foil a material, its range of applications will expand to infinity. It is ideal for

for interior work, metallized polyethylene material is ideal, which is capable of reflecting heat. When installing, you will need to leave a distance between the casing and the wall for ventilation. This will preserve the material, prevent moisture accumulation, mold growth. If this is external thermal insulation, it is worth stopping at mineral wool or polyethylene with metal

When laying, it is important that the material is docked, the gaps are glued with special tape. When the ceiling is insulated, mineral wool is used, an air layer between it and the finish. To create such a structure, a crate of wooden bars is mounted, and a metal profile is also used.

For heating networks, water mains of small diameter, insulation without an air gap will become indispensable. If the pipe is of large diameter, a pillow between it and the casing is required, an exception to the rule is foil mineral wool. When piping insulation is made on the basis of polyethylene, it is desirable that it be foiled on both sides. In order for heating radiators to work at full capacity, they take a material that is capable of effectively reflecting heat. Cut a sheet to the size of the battery, place it between the wall and the heating device, while the foil should be directed towards the room. The insulation is easy to install, but it guarantees high efficiency of heaters, batteries, air heaters, increasing it by 30-35%.

battery insulation

Installation rules for a heat-reflecting screen

- When installing between the radiator and the outer wall, it is necessary to ensure the tightness of the installed shield. To do this, it is enough to glue all the joints with a special metallized tape.

- When installing a reflective screen for a battery, remember that the expected effect can only be achieved when using metallized Al foil for the specified purposes. The use of a material with a metal deposition made by a thermal method does not allow the expected effect to be achieved, since the thickness of such a metal layer is too small, and such a material cannot work as a heat-reflecting screen.

- If it is not possible to use a special material, reflective screens behind the heating radiators can be made of ordinary plywood, covered with foil, or galvanized sheet can be used as a screen.

- Screens are most effective when the distance between their surface and the radiator is three or more centimeters. Otherwise, air conversion may be impaired.

- The thickness of the insulation layer must be 5 millimeters or more.

- The reflective screen for the battery with its reflective side should be located towards the radiator.

- If there is no self-adhesive layer on the material you are using, then you can fix it on the wall using a construction stapler.

- The size of the reflective screen must exceed the dimensions of the radiator by at least 20-30 millimeters in all directions.

Article rating: (2 votes total, rating: 5.00 out of 5)