The heating equipment segment is currently in a transitional period. This is due to the emergence of new concepts and technologies for the development of units, as well as the introduction of electronic control systems. Boiler devices have always been considered the basis of this group of equipment. With the help of such installations, it is possible to provide heat and a small private house, and public buildings, and industrial premises. The buyer is offered a fairly wide range of options to choose from, including the Ferroli gas boiler in different designs. The Italian company has been known in Europe for more than 50 years, and for the last 20 years, Russians have also been getting acquainted with its proposals. The manufacturer strives not only to maintain the most successful technological achievements introduced during its activity, but also to actively improve the products with modern developments.

Features and benefits of Ferroli boilers

Of course, this is far from the only manufacturer using new technologies. Therefore, in a competitive environment, engineers strive to offer effective solutions in a variety of ways. First of all, the Ferroli gas wall-mounted boiler provides the required level of performance, consuming a minimum amount of fuel. Together with automated control and the ability to control temperature conditions, this allows the owner to optimize heating costs. By the way, about automation: the manufacturer also provides for the possibility of self-diagnosis of boilers, which is very important for users without technical training.

It is for Russian clients that it is valuable that the company adapts the models to harsh operating conditions. Poor water quality and voltage drops sometimes become the main problem of heating equipment. In turn, the Ferroli gas boiler is completely ready for use in such conditions: according to the manufacturer, the service life of the equipment is more than 40 years.

Wall models

This is one of the most common types of boiler equipment, which in the line of the Italian brand is represented by the Diva, Divatop Domina, etc. models. Due to the affordable price and simple design, the Arena model is in the greatest demand. This is a double-circuit wall-mounted gas boiler Ferroli, in which there are two heat exchangers. The combustion chamber of such models can be open or closed, depending on the modification. The design itself allows for high heat transfer, but there are other advantages of boilers of this type precisely in the idea of Italian designers.

In particular, the developers use a primary heat exchanger made of copper, and its secondary counterpart is made of stainless steel. Branded parts are also used as accessories. For example, the valve is from Siemens, and the three-speed circulation pump is from WILO. To ensure stable operation, the Ferroli double-circuit gas boiler is equipped with a control board that is resistant to changes in the network. Together, the listed components provide high reliability of equipment and safety during operation.

Advantages and disadvantages

The advantages of Ferroli Zeus electric boilers include the following:

- Excellent quality of spare parts and components.

- Large selection of models with different power.

- The presence of an informative LCD display.

- Many different modern features.

- Technical support by phone "hot" line at any time of the day.

- Antifreeze liquid can be used in the heating system.

But there are also some disadvantages:

- Quite a big cost.

- The electric boiler does not include a room thermostat, therefore additional costs will be required.

- Chinese assembly.

Based on the technical characteristics of Ferroli Zeus electric boilers, it can be concluded that such heating equipment meets all the requirements for devices of this type. The main disadvantage of such boilers is their high cost. That is why reviews about this heating equipment are not often found on the Internet.

Units for floor installation

This variety is represented by the Pegasus and Atlas series in various modifications. As a rule, these are cast iron units supplied with atmospheric or hinged burners. The advantages of such models are well illustrated by the Ferroli floor-standing gas boiler in the initial version - Pegasus. The model is equipped with a cast iron heat exchanger, a Honeywell valve, a single-stage burner, a signal contact, as well as connectors for a circulation pump and a room thermostat. To facilitate operation, the developers have provided electric ignition and the ability to connect a boiler.

Security is also worth noting. The boiler has a smoke exhaust control, an ionization sensor for the flame, and also offers the ability to monitor overheating using a Ferroli bimetallic indicator. Gas heating boilers of this category also have an additional option. Suffice it to note the cascade control unit, means for connecting an external thermostat and a turbo nozzle.

About the manufacturer

The Ferroli brand belongs to the Ferroli Group, which has been manufacturing gas-fired boilers, water heaters and indirectly heated boilers since the 1950s. In Russia, there is an official representative office in the form of FerroliRus LLC, and products are also distributed through official dealers located in almost every region. During its activity on the territory of the Russian Federation, the company has established itself as a manufacturer of extremely affordable, high-tech gas boilers with very serious technical characteristics comparable to more expensive German and Japanese models. However, in the last decade, boiler reliability has been unpredictable.

The device is based on the Ferroli Domina F 32 N. model. Quite a typical and most effective design for today, modulating burner, built-in expansion tank. Great layout and build.

In practice, all, even the most budget models, have an efficiency in the range of 91-93% and, accordingly, one of the best indicators of gas consumption. For example, the maximum consumption of natural gas for the Fortuna model with a capacity of 24 kW is 2.72 m3 / h, which corresponds to the well-known economical Baxi, Buderus or Viessmann. All floor-standing models come with a durable, corrosion-resistant cast iron heat exchanger, and some mounted models come with a copper heat exchanger. The control is intuitive, all models have the ability to connect external control.

Dual-circuit models are distinguished by the technology of preheating the secondary DHW heat exchanger, which reduces the delay in the supply of hot water. All boilers are equipped with an almost complete set of protective functions available today: self-diagnostics, protection against freezing, overheating, stopping the circulation pump, etc. Some models can be connected to solar panels.

All models have a minimalistic stylish design and a minimum of communications around, which allows you to successfully place the boiler in almost any interior.

However, despite the popularity, high performance and functionality, we do not recommend wall-mounted models for choosing. It is worth thinking well whether it is worth choosing floor-standing Ferroli.It's all about reliability, namely, a large number of problems for the practice of installation and complaints on the forums, in terms of the number of service calls, gas Ferroli are among the five most unreliable foreign lines of gas boilers.

Malfunctions can be of various kinds, from problems with heating water or ignition, to failure of the make-up tap, circulation pump, plastic elements and even a heat exchanger in the first 3-4 years of operation (for more details, see the troubleshooting section below).

Moreover, even the same models of the same year of production can both work without problems for 10 years, and constantly fail in a neighboring house or apartment. There are many factors here: the not entirely successful transfer of the production of some models to China (although most are still really produced in Italy), and the poor quality of plastic, and the exactingness of maintenance, cleaning, and the quality of the coolant.

It is especially worth noting the vulnerability of automation to unstable voltage in the domestic power grid. Failure of a control board due to power surges is one of the most common problems. Therefore, we always recommend connecting any gas boiler with complex automation through a voltage stabilizer.

Otherwise, there are quite a few cases of trouble-free operation for 5 and 10 years, the installation of boilers is not complicated, but thanks to modern technologies it is effective. But is it worth the risk and buying models, the number of service calls for which today was a surprise to us, when for almost the same amount there are well-known Baxi or slightly more expensive Lamborghini, not to mention Japanese or German manufacturers.

It is enough to analyze discussions on forums, find out information in any of the service centers, view queries in search engines, or study the most common problems we have highlighted towards the end of the article.

Condensing models

Ferroli condensing equipment is available in the Econcept, Energy and Bluehelix series. These are already single-circuit units, among which there are options for increased power. For example, the Econcept model is capable of delivering power up to 300 kW. The features of condensing devices include the presence of weather-dependent automation and a large liquid crystal display. In addition, the Ferroli gas wall-hung boiler in the Econcept series has an aluminum heat exchanger and a ceramic burner. The use of these materials is due to lower safety requirements. Actually, purchasing a condensing unit is beneficial from the point of view of wide functionality and increased ergonomics. The user will be able to view all the main operating parameters, use the boiler modes depending on the season, and control the connected boiler using a remote control.

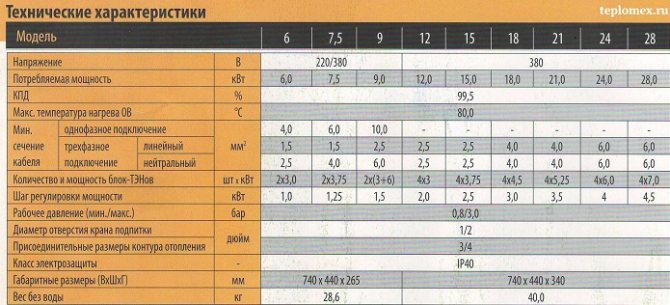

Features of electric boilers Ferroli Zeus

Ferroli Zeus electric boilers are made with a capacity of 6 to 9 kW for heating a house with an area of no more than 100 sq.m. For larger areas, an electric boiler with a capacity of 12 to 28 kW is used.

Depending on the type of connection, Ferroli Zeus electric boilers can be:

- Single-phase 220V. Up to 9 kW inclusive;

- Three-phase 380V. Over 12 kW.

Ferroli Zews electric boilers are manufactured at a factory in China under the supervision of Italian specialists. The barcode on equipment 693 indicates these nuances. Such an assembly is a disadvantage of this equipment, since not everyone trusts the Chinese assembly. The cost of electric boilers is considerable, and if they were assembled in Italy, the amount would be huge. Therefore, the Chinese assembly, to some extent, can be a positive point.

Components

For each category of boilers, the manufacturer also provides additional accessories.In particular, wall-mounted models of the double-circuit type can be supplemented with a kit for smoke exhaust systems and devices that allow the equipment to operate on liquefied gas. In turn, the Ferroli floor-standing gas boiler can be equipped with boilers, DHW priority systems, turbo nozzles and cascade control devices. Condensing units have the largest range of additional options. They can be provided with outdoor temperature sensors, control boards for multi-circuit systems, hydraulic switches, a mounting manifold frame, as well as special sets of fittings for connecting boilers.

User's manual

Most Ferroli models are fitted as standard or optionally with automated controls for ease of use. The user sets the modes and makes settings through a special panel. To start the equipment, it is necessary to open the burner and perform ignition. But before that, you should turn on the unit to the network, and then press the special start button, which is equipped with the Ferroli gas boiler. The instruction also provides for a situation in which starting the equipment will not work. If the boiler does not start up within 15 seconds, the system should be restarted. The boiler should be turned off not only by closing the valve and turning off the button. It is recommended to disconnect the unit from the mains, but it is important to take into account that in this state the boiler will not be protected from freezing. To avoid this, you should either drain the water or add antifreeze to it.

Installation and operation of boilers Ferroli

Combustion waste from gas equipment is removed using a coaxial chimney

Heating equipment is installed in a room that meets safety requirements. It must have a ventilation system and an emergency exit. Shut-off valves are installed between the boiler and the heating system, allowing it to be cut off from the system in case of a breakdown. After fixing the unit in the selected place, a serial connection of the communication systems takes place:

- gas duct connection;

- heating water connection;

- connection to the gas main with the installation of a gas valve and meter;

- connection to the mains with the boiler grounding;

- installation of a thermostat.

Thermal equipment operation is controlled from the LCD panel. As a preventive measure for the operability of Ferroli boilers, according to the instructions, the channels are periodically cleaned. The sequence of work and the permitted chemical compositions are indicated in the manufacturer's instructions.

Maintenance instructions

To maintain the boiler in good condition, the user must regularly clean the equipment casing with rags and soapy water. A complete technical inspection must be carried out at least once a year. Combustion analysis is also recommended. It is important to monitor the operating parameters at which the Ferroli gas boiler operates. The instruction instructs the owners of the equipment to carefully monitor the indication of faults. Most of the cases of incorrect operation of equipment are associated either with voltage surges or with a lack of gas. It is recommended to contact the service center only after the elimination of such problems and the next check of the boiler.

Ferroli boilers reviews

There are practically no frankly negative reviews about Ferroli products. On the other hand, there is a high performance, well-thought-out design and low fuel consumption. Separately, the owners point to the low noise level of the equipment, which is very important when installing in residential buildings. And yet there are nuances of operation that should be remembered when buying Ferroli gas boilers. Reviews quite often note leaks in heat exchangers. This is a common problem, but it has nothing to do with the quality of the hardware.Similar phenomena occur due to improper operation when working with hard water is allowed. Therefore, you should initially focus on models that can work with both gas and water. For example, bimetallic heat exchangers are not suitable for such needs.

Possible boiler malfunctions

Equipment parts wear out during operation. Constant contact with poor quality water leads to corrosion and deposits. The circulation pump may fail, a leak occurs in the heat exchanger, or water stops circulating through it. Due to voltage surges, damage to the control board is possible. Boiler electronics are sensitive to the parameters of the electrical network. Install a voltage stabilizer to prevent damage.

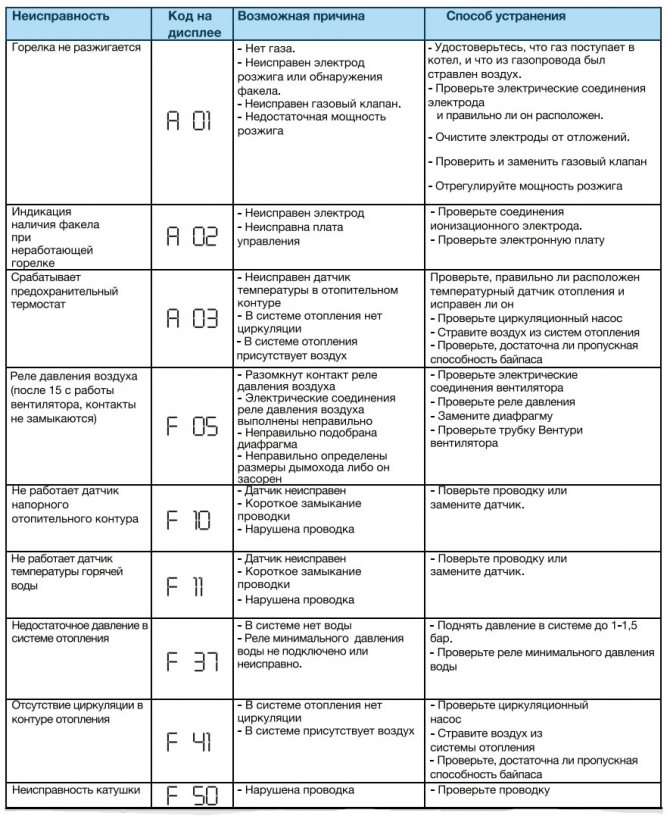

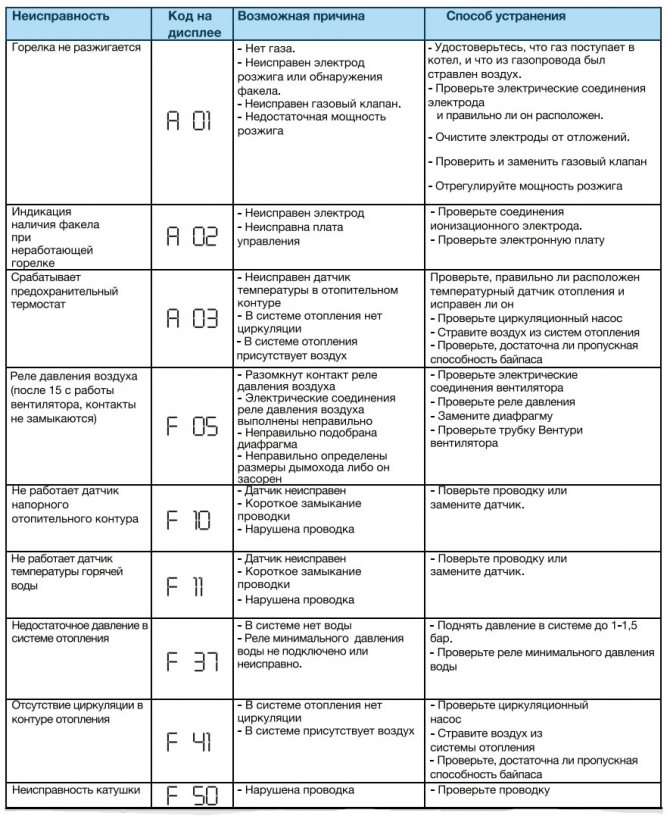

Error codes

Error codes that can block hardware

The errors shown on the boiler display are divided into 2 groups:

- Non-critical F, causing a temporary failure of the settings, which can be eliminated after bringing the parameters back to normal.

- Critical A - malfunctions causing boiler shutdown.

The most common error codes are:

- A 01 - no burner flame and no ignition. You will need to check the gas flow, the installed power, the pressure in the nozzle. When air accumulates in the system, it is released through the taps.

- A 03 - overheating protection tripping. It is necessary to diagnose the pump and sensor. The fluid in the pipeline is checked, excess air is vented.

- F 04 - activation of the smoke exhaust indicator. Cleaning of the chimney shaft is required. Possible sensor breakage. The boiler restarts.

- F 05 - incorrect fan connection. Inspect the wiring, tighten the contacts.

- F 37 - pressure drop in the system. Occurs due to leaks. It is necessary to check the boiler and the tightness of all connections.

- F 40 - pressure above normal. Clean or replace the relief valve.

Most errors result in hardware blocking. To turn it on, in some cases, it is enough to remove the plug from the outlet and then reconnect it to the power supply. The appearance of any malfunctions is a reason for contacting the service department. But minor repairs and cleaning of the burner or chimney can be done by yourself.

To restore the performance of the equipment after eliminating the error, you must press the "Reset" key. The system will reboot within 30 seconds.