General DIY Installation Tips

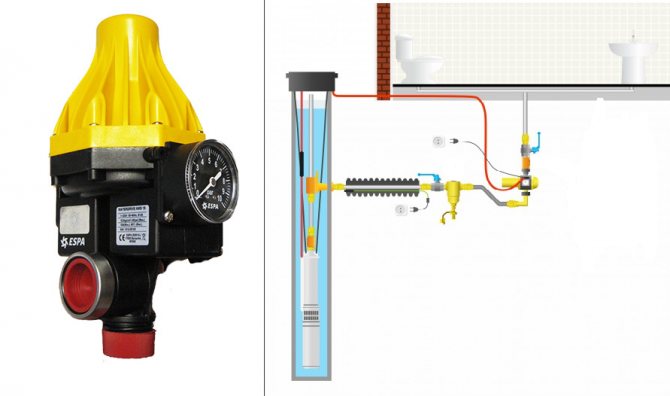

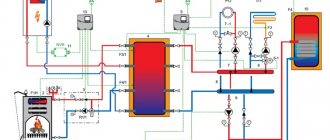

Uninterrupted water supply involves the installation of automation. The correct and uninterrupted operation of the water supply system depends on it. The kit for equipping a well or a well includes a deep pump, a check valve, a float with a sensor, a pressure switch, a hydroaccumulator tank and an electronic control unit.

The submersible pump is easy to move independently as it is compact in size

The pump is the main power element that lifts water from the well.

The check valve is a bypass membrane that is installed where the outlet of the power unit is located. The diaphragm prevents liquid from flowing out of the pipe. A float sensor is an automation element that detects the water level in a well or well.

Submersible pump installation tips:

- For immersion, it is best to use galvanized or nylon cables.

- The use of steel cables is not recommended as they wear out quickly.

- A sturdy steel frame is used to secure the cable.

- The frame is made from a corner and equipped with a head of the well.

- A hole is made in the frame to extend the cable through it.

- Place the pump at the end of the pipe and place the cable along it.

The system may not have a check valve. In this case, they need to equip the outlet. A coupling is installed on the valve, and the pipe is already attached to it.

Diagram of how to connect with your own hands

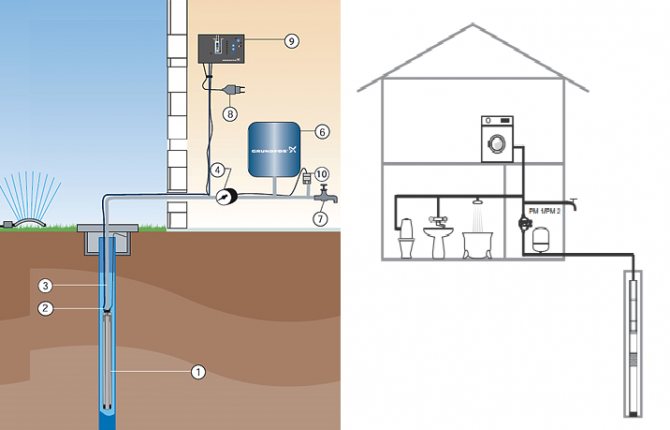

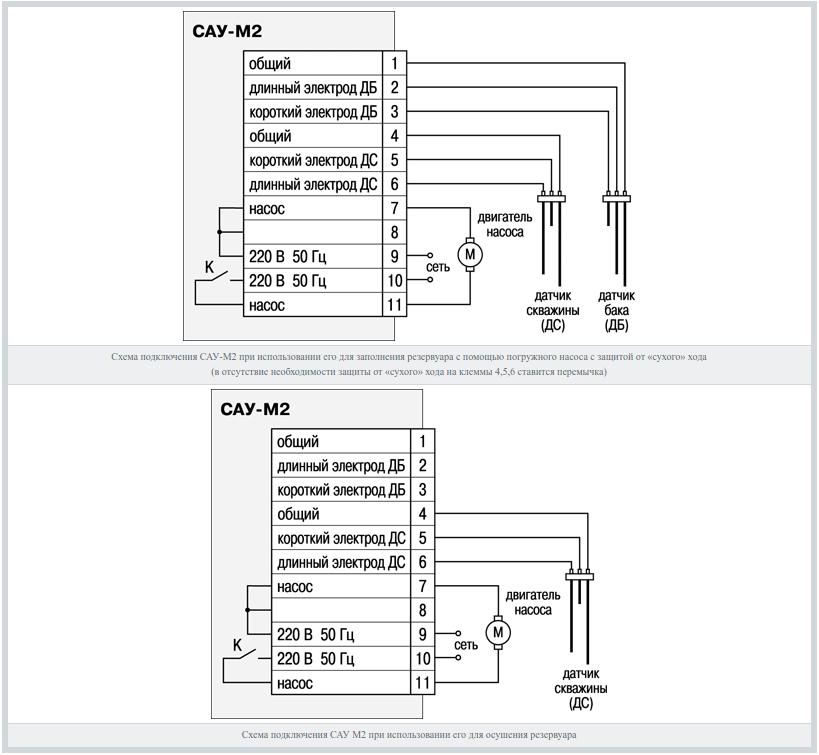

For trouble-free and long-term operation of autonomous water supply, the installation of an automatic control system for the operation of the equipment is mandatory.

The equipment installed in the technical room of the house includes:

- Hydroaccumulator. The diaphragm tank is used to maintain the pressure in the water supply system, which should be at 3.5 atmospheres. With a full hydraulic tank, water is consumed within 3-4 hours, avoiding frequent activation of the borehole pump. It protects the water supply system from water hammer that can break pipes.

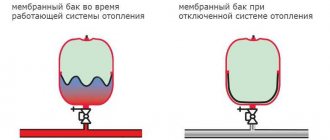

- In the body of the product there is a chamber made of hygienic rubber for water with a pressure valve, and the rest of the tank is filled with air, which creates pressure through a pneumatic valve using a compressor. A line from a submersible pump is connected to the hydraulic tank, through which water enters the water chamber.

- The principle of operation is based on maintaining the pressure in the water chamber with the help of air. With the flow of water and a decrease in pressure in the system, the downhole unit is turned on, and water is supplied to the chamber.

- A cabinet with electronic and relay control and equipment protection devices, which, through the supplied sensors, control the operation of the autonomous water supply.

- The installed mini-blocks in the pump control the pump and when the load of the low level of the aquifer increases and the single-phase motor heats up, the unit is turned off through the relay.

- Sensors located in the pipeline monitor the nominal fluid pressure. When it is lowered, the device turns on through the electronic system, filling the chamber with water.

- If the pressure is not set to the standard, it is necessary to adjust the relay.

Connection equipment

Water supply in a private house is most often autonomous. In order for its work to be uninterrupted, you should take care of the correct installation of special equipment. The choice of equipment is influenced by the depth and type of source.

A shallow well requires the use of a conventional hand pump.But the greater depth assumes the installation of more powerful equipment.

Before installation work, you should decide on the connection diagram. After that, you need to decide on the type of equipment. To do this, you need to familiarize yourself with the features of each of them.

When installing the submersible pump, observe the safety instructions

Equipment types:

- Superficial;

- Deep (submersible).

When using surface equipment, the installation is carried out near the source. In this case, the tube is lowered into water - it is through it that the liquid is supplied to the system. The submersible pump is mounted directly into the water.

Installation and wiring diagram of a submersible pump

Happy owners of country houses and summer cottages very often face the problem of water supply to their homes.

It is possible to bring and store water in large containers only at the construction stage, and subsequently the problem of water supply is solved in other ways. One of them is the arrangement of a separate well at the site.

A special device is installed in it for uninterrupted water supply. This unit can supply water not only to the house, but also to the garden. The connection and device of a submersible pump is not at all complicated and can well be done independently. Let's try to figure out how this is done.

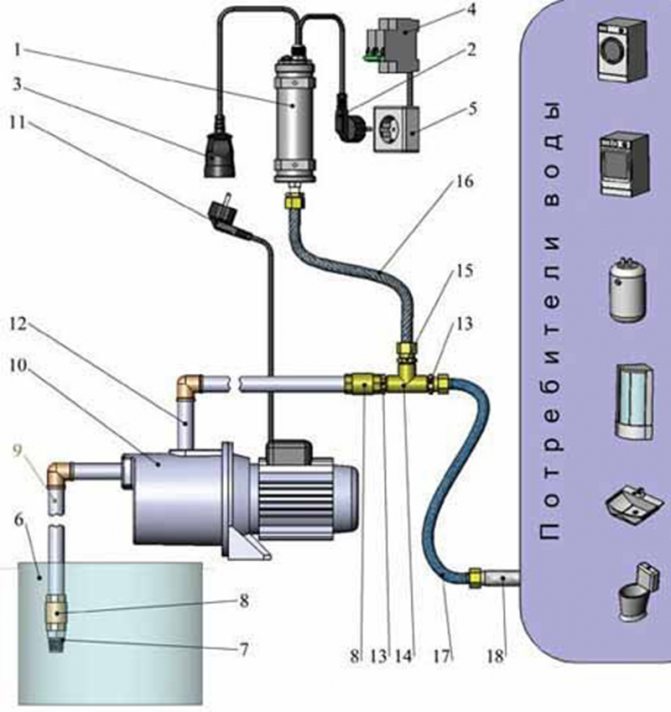

Elements of the automatic system

Self-arrangement of the water supply system should be carried out provided that the master knows how its main components work. A pump that is submerged in a well creates water pressure when it is energized. The pump cable can be connected directly to the electricity network, then the use of additional devices is not required.

If the house needs constant water supply, it is best to use automatic equipment.

The automatic system is triggered when a tap is turned on in the house or household appliances are turned on. The pump is turned on after the relay gives the appropriate command. The accumulator forms the required pressure, which provokes the shutdown of the device.

Elements of automation:

- Pressure switch;

- Level sensor;

- Hydraulic accumulator.

The submersible pump has a long service life when properly operated

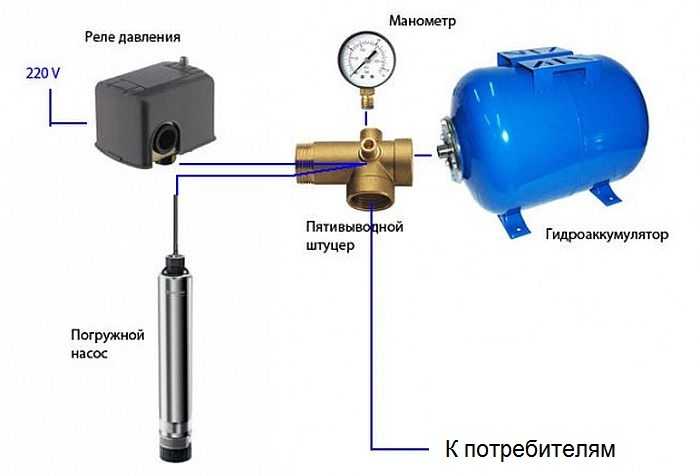

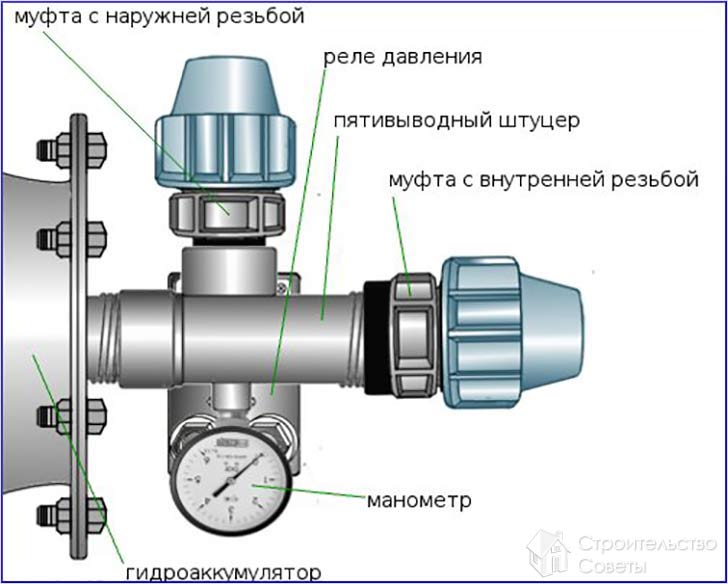

In the process of connecting, the hydraulic tank is wrapped with fum tape. After that, the American adapter is screwed on. The brass adapter is equipped with a pressure switch and a pressure gauge. For the manufacture of a special elbow, a plastic pipe and fitting are used. To connect the hose, a collet-type coupling is used.

How to install a surface pump in a well

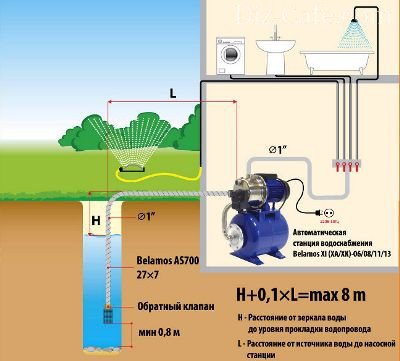

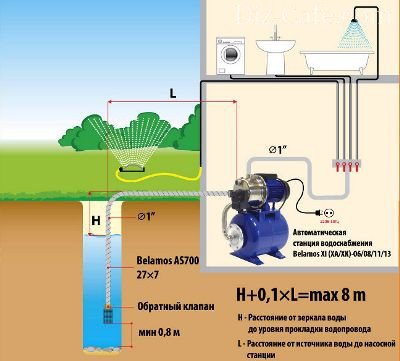

The instruction indicates that surface pumps can be installed in a well if its depth is up to 20 meters. In this case, water comes directly from the well to the parsing points.

The scheme for connecting a surface pump to a well includes the following equipment:

- A centrifugal pump that lifts water and supplies it to the house.

- The hydraulic accumulator softens the water hammer. It consists of two parts, separated by a membrane.

- The electric motor is connected to the pump and pressure switch.

- The pressure switch monitors its level in the system. In case of a strong drop in pressure, the relay starts the motor, in case of an excess, it turns off.

- The pressure gauge is used to determine the value and adjust the pressure.

- Water intake system with non-return valve.

- The main line connects the pump and water intake.

Installation diagram of a surface pump for a well

When installing a surface pump or station, you need to adhere to some rules that will ensure the correct operation of the equipment:

- Stable water suction ensures close location to the well.

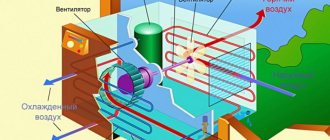

- The room must be ventilated, warm and dry.

- The location should not be cramped.During operation, it will be necessary to carry out preventive and repair work.

- The room should absorb the noise emitted by the pumping equipment.

Suitable locations for installation include:

- The room is inside the house, but with poor sound insulation, this will be a big disadvantage of the installation.

- Basement. In the absence of heating and insulation of floors and walls, additional funds must be spent on their preparation.

- Special well. But here it is difficult to maintain the required level of pressure and repair work is difficult.

- Caisson. The basic rule is the correct depth of the location of the special installation site.

Tip: For the installation of a pumping station for a well, it is best to arrange a separate room.

Downhole device connection

To properly connect a borehole pump in the country or in a country house, you need to study its types. You also need to familiarize yourself with the principles of their functioning.

Pumps are horizontal and vertical, semi-submersible, self-priming, adjustable, sealed, etc. Most often, vertical, monoblock, single-stage, sealed and submersible pumps are used for installation.

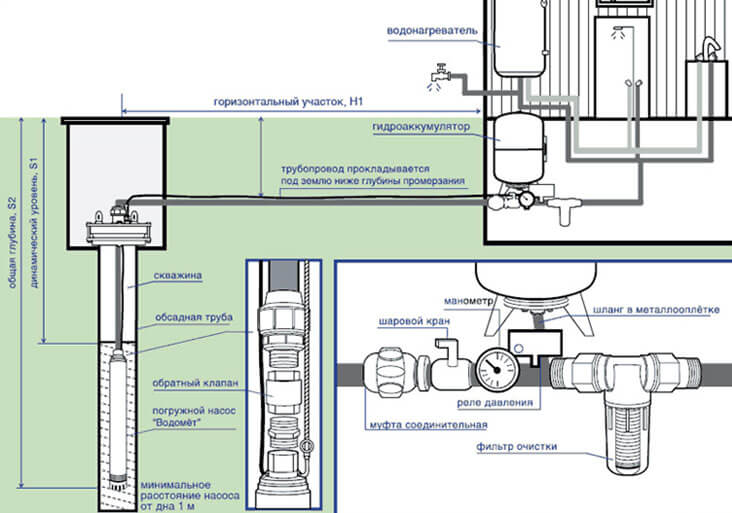

The downhole submersible pump consists of a pumping part, a filter, an electric motor, a pipe thread, a box of capacitors. It is important that the installation conforms to the wiring diagram. Schemes can be different.

To ensure that the downhole tool is working correctly, a trial run should be performed initially at the surface.

Electrical connection diagram:

- Water heater;

- Battery tank;

- Pressure switch;

- Coarse filter;

- Hot water pipeline;

- Cold water pipeline.

Before installing a borehole pump, it is necessary to take into account its type, the operating point of the unit, the presence of a self-priming surface, and the quality of the unit. It is important that the self-priming device is installed close to the fluid source and that the well piping is correct. This will prevent dirt and dust from entering the system. After installation, connect to the mains. It is important that the source is grounded.

A well or well can be equipped with a submersible pump in order to ensure an uninterrupted flow of water into the house. You can put it on your own, but for this you need to decide on its type and familiarize yourself with the principles of work. The assembly does not imply any difficulties, but it requires the implementation of the installation rules, otherwise the system will not work correctly. Uninterrupted operation of the system will be obliged to the automation unit. Vodoley devices are very popular among consumers.

Types of equipment for the water supply system

This type of device differs from others in that it works on pressure, it pushes liquid to the surface. As a result, they are subject to significantly less stress and, as a result, consume much less electricity. And this is nowadays an essential factor for any economy.

The pump, unlike a conventional stationary station, makes much less noise and does not lead to vibration on the surface and in the house. Another advantage should be considered the fact that it is made of parts that do not give in to rust and cannot fail under the influence of water. After opening the tap in the house, you will hear only a small click, indicating that the pump installed in the well has been connected.

Preparation of materials accompanying installation

A pump stuck in the casing can be a headache. And it is necessary to pull it out (as well as to lower it) using a special cable. If the pump is already equipped with a polymer cord, you must make sure that it is of high quality and of sufficient length. Sometimes it is wiser to purchase this item separately.

It is believed that a reliable cable or cord must be capable of carrying a load that is at least five times the weight of the equipment attached to it. Of course, it must tolerate moisture well, since part of it will constantly be in the water.

If the device is suspended relatively shallow, less than ten meters from the surface, you need to take care of additional depreciation of the equipment during its operation. To do this, use a piece of flexible rubber or medical tourniquet. Metal rope or suspension wires are not suitable as they do not damp vibration but can destroy the mount.

A special electrical cable is used to power the pump. Its length must be sufficient so that the cable lies loose and not taut.

To supply water from the pump to the household water supply, special plastic pipes are used. Designs with a diameter of 32 mm or more are recommended. Otherwise, the water pressure in the system will be insufficient.

Both metal and plastic pipes can be used. There is controversy over the connection of metal pipes. Some experts object to the threaded connection as less reliable. It is recommended to use flanges with the bolt on top to prevent it from accidentally falling into the hole.

But the threaded connection in wells is used quite successfully. During installation, reeling is mandatory. Some experts recommend taking linen cloth or “Tangit” sealing tape instead of the usual FUM-tape or tow. Linen roll is additionally reinforced with silicone sealant or similar material.

The characteristics of the water supply pipe should be selected in accordance with the conditions of its operation. For depths up to 50 meters, HDPE pipes are used, designed for a pressure of 10 atm. For a depth of 50-80 m, pipes will be needed that can work under a pressure of 12.5 atm., And for deeper wells, pipes at 16 atm are used.

In addition to the pump, pipes and a cord or cable, before installing a submersible pump in a well, it is recommended to stock up on the following materials:

Before connecting the pipe to the pump, a nipple adapter must be attached to its outlet. Usually modern submersible pumps are equipped with such a device, but if it is not there, this unit must be purchased separately.

It should be remembered that for pumping a well immediately after drilling, i.e. to remove a large amount of very dirty water from the well, such a pump cannot be used. It will quickly fail. Usually the well is pumped with a separate pump, which is cheaper and functions better when working with dirty water.

Installation of a submersible pump

Submersible pumps are installed directly in the well. For them, unlike surface models, you do not need to equip a caisson or a separate room.

First, the pump is assembled and executed, i.e. connect to it a water supply pipe, electric cable, cord or cable, etc. After that, the pump is lowered into the well.

Step 1. Preparation for equipment installation

A check valve is attached to the pump nozzle so that when it is turned off, water remains in the device. Then a special bowl-shaped filter is installed, designed to filter small particles of sludge. A pipe or discharge hose is installed behind the check valve.

A non-return valve is necessary so that water remains in the plumbing system even after the pump is turned off. This situation can lead to complete damage to the equipment. The bowl-shaped filter protects the pump working chamber from siltation.

Sometimes a check valve is already provided by the manufacturer and is part of the design. In this case, no additional valve is required.