Modern Russian baths no longer correspond to the traditional steam rooms used by our grandfathers and great-grandfathers. This applies to both the interior decoration and the number of rooms in the building, and fuel. In modern realities, a gas stove for a bath is considered an ideal solution.

The owners of the baths are ready to sacrifice the unique smell of wood burning and replace the traditional stove with gas boilers. This is due to the fact that a gas bath, namely its operation, is much cheaper. In addition, the gas burner for the bath is easy to operate.

People who decide to install modern gas burners for sauna stoves in the steam room should be aware of the types of such heating devices, the peculiarities of their use and installation rules.

An attempt to operate a gas stove for a bath without such knowledge can end in disaster both for the building itself and for its owner.

Main advantages

Traditional wood-burning stoves installed in a bath are good, especially with free access to fuel. In any other situation, an economical gas stove in a bath can be an excellent alternative to a solid fuel boiler. Its installation is straightforward. The main thing is to follow all the necessary rules and precautions.

According to statistics, gas boilers for baths are the sales leaders among all types of heating devices installed in steam rooms. This is due to the fact that their benefits are undeniable:

- Compactness. Gas stoves for saunas and baths do not have a bulky firebox and an ash collection compartment, so they take up a minimum of space in the room.

- Optimum temperature. The gas sauna stove allows you to regulate the temperature level. All that is needed is to set the optimal mode.

- Ease of operation. The gas sauna stove does not require any special maintenance. Its operation does not imply ash pan cleaning and fuel burnout control.

The main disadvantage is the rather high frequency of emergencies. They are caused by the installation of uncertified equipment and violation of operating standards.

If you choose a stove wisely and do not violate safety precautions, then gas burners will serve in the normal mode for tens of years.

Advantages and Disadvantages of Electric Furnaces

Nowadays, electric baths are becoming very popular. They are equipped with a compact electric oven. It differs from a traditional electric boiler not only in the principle of operation, but also in design. The design includes a heater, where stones are heated in the same way as in a regular stone one.

Electrical products have many advantages

- Low weight and dimensions. The stove can be placed on the floor of the bath, hung on one of the walls using brackets. It is easy to move it, or move to another place.

- Easy to care for. The device does not need to be cleaned of soot and fuel residues.

- Easy to install. The electric heater does not need a chimney or special requirements for installation, it is enough to take care of the presence of a socket, to ensure reliable insulation of the wires.

- Fast ignition. The oven heats up in a few minutes, temperature control is easy, and flame control is not necessary at all.

- Different modes of voltage supply. Depending on the characteristics of the wiring in the house, you can choose a single-phase or three-phase current supply.

- Aesthetics. Manufacturers offer interesting modifications of electric heaters using modern facing materials.

- Minimal risks.Electric ovens do not create sparks and fire hazardous situations, but only if properly equipped wiring.

Disadvantages include

- They do not possess authenticity, do not give "natural" warmth and a special spirit in the bath.

- They do not emit those useful resins that are formed during the combustion of wood.

- The air in the room is too dry.

- Cool down quickly as power is cut off.

- The ovens cannot operate autonomously, since they are powered from the mains.

- Requires laying of a copper cable with a large cross-section.

- They have a limited service life.

There is an opinion that sauna heaters create unfavorable electromagnetic radiation, therefore it is recommended to switch off the device from time to time while in the steam room.

Furnace complete set

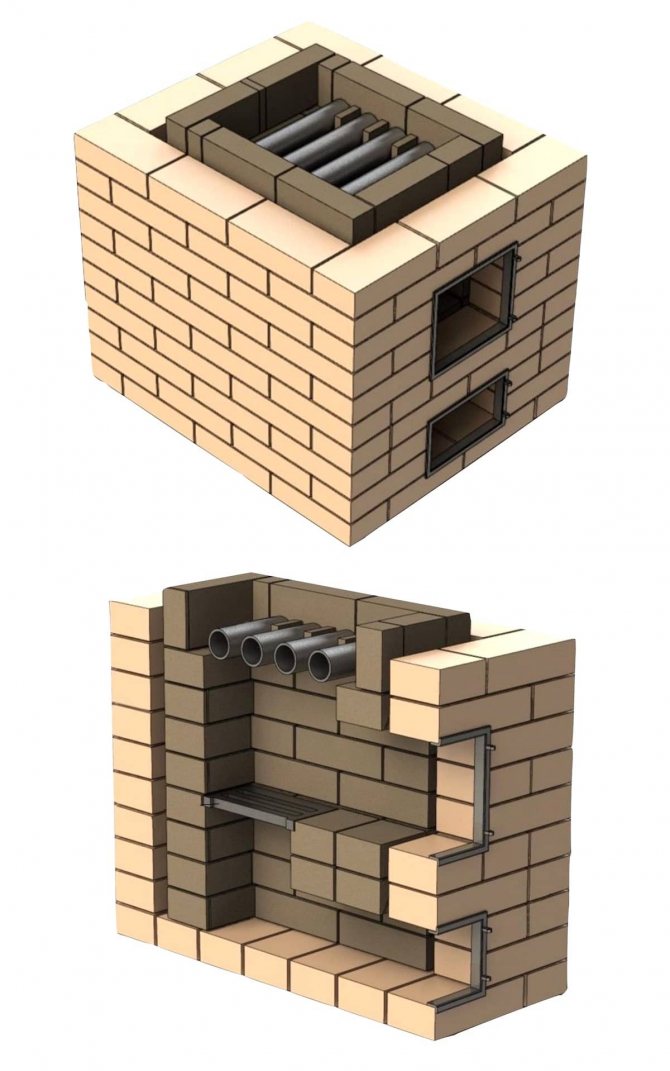

Gas bath stoves have a rather simple structure:

- a burner is installed in the housing, to which a gas pipe is hermetically connected;

- a water tank is located above the burner, which is an integral part of the heat exchange and heating system;

- a tray for the heater is installed on top of the body. It should be understood that the performance indicators of gas and wood-burning stoves are significantly different, therefore, for the heater, you need to use cobblestones from the river or seabed. Due to the combustion of gas, the stove can be heated up to 200 degrees. This, coupled with the ingress of water on it, can lead to a quick failure of the heater. River and sea stones, unlike others, are capable of enduring such influences;

- in addition to the tray for the heater, there is an outlet on top of the gas stove body;

- for gas stoves for a bath with a water tank and models that do not have this element of the heat exchange system, there is a fuse in the design that is responsible for automatically turning off the gas supply when the fire is extinguished.

Having studied the design of the device, you can understand that a gas oven for a bath with your own hands is a reality. You can assemble it yourself. An exception is burners that must be purchased from a trusted manufacturer.

Design features of metal sauna stoves

Let's try to figure it out what does a classic metal sauna stove consist of?, which we all have seen at least once in our lives.

- a coil that heats water;

- heater - compartment, pallet with stones that retain heat and create inertia;

- wood-burning appliances have grates and an ash pan;

- gas-fired products are equipped with burners, an auto-control and management system;

- an electric furnace without a furnace, burners, chimney. The unit is equipped with several heating elements. Plus - heat is transferred faster (almost immediately) into the space of the bath.

- fuel-fired units consist of a firebox and a chimney (pipe, with fire protection, holes for cleaning, valves, gate, visor);

Closed type sauna stoves

Metal heating structures for saunas with a closed (safe) stove are divided into three main functional segments:

- Firebox, ash compartment, blower. The market is saturated with different variants of modifications, the assortment depends only on the manufacturer's imagination. There are devices with a cast iron furnace, with additional elements for more efficient combustion;

- The heater is a lockable compartment for stones needed to increase the temperature inertia. The cobblestones heat up, then slowly and steadily release heat. Stones can be heated by convection, open fire;

- tank and related parts for storage, heating, water supply.

When irrigating stones heated to + 100 ° C, "light steam" is obtained. A truly lively, hot, finely dispersed haze is achieved at temperatures of about + 500 ° C. When water comes into contact with hot cobblestones, a powerful release of a large volume of steam is generated, which is extremely dangerous. Stoves with closed heaters are equipped with heat exchangers that direct the flow in a safe direction.

A stove with a closed heater can have extended functionality: with a water circuit, it is also used to provide a house with hot water

The advantages of a closed system

- Safe;

- Steam can be directed to the right places;

- More efficient increase in humidity and stability of heating;

- Stones and closure create excellent thermal inertia.

- Closed heater - a good choice for a real Russian bath. Air heating is moderate (not too intense), even, the best conditions are created in the steam room. The steam is hot with an optimal level of comfort in a high humidity environment.

Open system

- Stove with open heater Is a symbiosis of the classic Russian and overheated Finnish baths (saunas). The design feature is an open grate for placing stones on top of the unit. In the process of work, almost all the heat is immediately and faster transferred to the space of the steam room.

Temperature can reach more + 100 ° C, there is a feeling of dry heat, and the steam is very active, so this open heater is ideal for saunas.

The open-type sauna stove is suitable for lovers of high temperatures in a steam room with low humidity

Combined ovens

Combined metal stoves have blocks with a closed and open stove. Standard device:

- several compartments for combustion, double-type valves, blower;

- there is a block with a closed stove, and an open one is realized as an opportunity to lay stones on the housing lid, surrounding the chimney.

- Combined oven - a universal option with wide customization options. In the chambers, you can adjust the amount of fuel and the rate of combustion, obtaining, if necessary, a moderate temperature with high humidity and dry heat.

How to choose a gas stove

If the time has come to replace the wood-burning stove with a modern heating device, then its choice should be approached with all responsibility.

Gas burners for a bath are called "Bombs" for a reason. This is due to the fact that unlucky buyers trust sellers and purchase devices of dubious origin, the result of which are explosions, fires, burns and even death. Because of this, there is a myth among the people about the danger of gas heating appliances.

Often the reason for the above emergencies is the desire to save money and buy burners or a stove as cheaply as possible. Gas heating devices should be chosen according to certain rules:

- firstly, each burner has a certain fuel consumption, which determines the economy and power of the furnace. To find out it, you need to read the description in the instructions for use. For a small bath, a device is suitable, the technical characteristics of which state that the fuel consumption is 1-4 cubic meters per hour;

- secondly, all assembled gas ovens, as well as burners sold separately, have documents confirming quality and safety standards. If the sellers do not have them, then it is better to bypass this store;

- thirdly, in the steam room it is unacceptable to operate burners and boilers with damage, leaking connections and an expired shelf life. In other words, gas ovens for a bath should be in perfect condition.

During operation, gas ovens must be prevented. This measure is mandatory. This rule must be followed strictly. Failure to comply significantly increases the risk of an emergency.

What materials are used for sauna stoves

Conservatives, adherents of solid products, the most natural materials in the bath, select brick ovens that have been tested for centuries, but they are costly and laborious to create and maintain. If you need to equip a sauna in the shortest possible time with a simple heating source and the same operation, then put electric heaters, infrared devices.Fuel preferences and availability are also an important factor.

In most cases, they always strive to quickly thoroughly heat the room and start to steam. But speed does not mean the quality of heating, economy and duration of heat retention (inertia). The specified parameters largely depend on the materials, they also affect the device, the dimensions of the heat source.

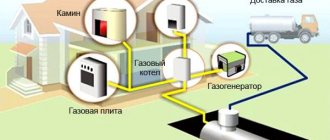

Gas-wood boiler

For those who cannot imagine visiting a steam room without the unique smell of burning firewood and who wants to save money on the operation of the bath, a gas-wood stove can be an ideal solution.

Such a heating device is a modern universal design, which allows the use of various types of fuel: natural and liquefied gas, coal and firewood. This is possible due to the fact that such stoves have removable elements required for operation on solid fuels and gas.

Devices designed for gas combustion consist of burners, filters and various valves. At the same time, a fuel receiver is needed to operate a solid fuel furnace. Such heating devices are not new to the modern market. They were operated back in Soviet times. A striking example of this is the OGV (heating gas water heating) boiler.

The equipment required for gas combustion is installed in the ash pan of the furnace. If it is dismantled, then the boiler will function properly on solid fuel.

Gas-wood stoves are very popular not only because of their versatility. Their cost is at an acceptable level, which is an important factor for bath owners.

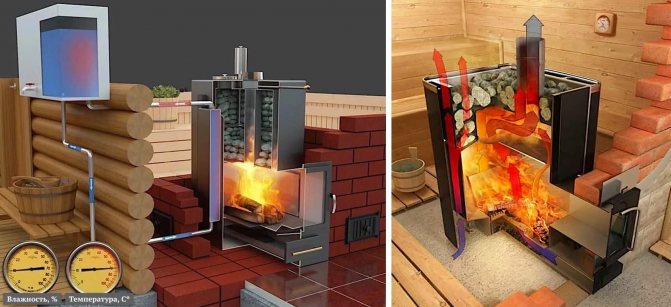

Installation rules for gas ovens

The process of installing gas-fired heating devices must be approached as responsibly as possible. Not only the efficiency of functioning depends on the correct installation, but also the safety of people visiting the bathhouse.

Experienced specialists with extensive experience in this area should work with gas ovens. Having entrusted the installation of a gas boiler to a professional, the installation process should still be monitored. When carrying out such work, you need to pay attention to the following things:

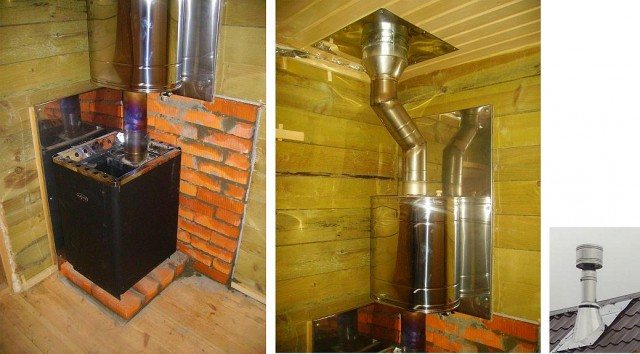

- the distance from the wall to the stove must be at least 50 mm. In this case, all surfaces parallel to the walls of the boiler are made of non-combustible materials or sheathed with such;

- the refractory base of the boiler must protrude at least 100 mm from its edges;

- the height of the connector for the burner without a cover should vary from 470 to 550 mm, with a cover - from 615 to 680 mm, width - from 350 to 450 mm and from 515 to 665 mm, respectively.

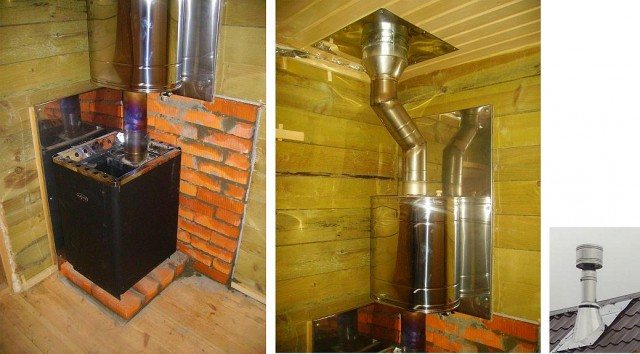

Particular attention should be paid to the chimney. The gas oven is connected to the chimney with stainless steel pipes. In this case, the pipe elbows must enter each other by at least half a diameter.

The gas boiler is installed simultaneously in the steam room and the dressing room. The front side with burners should be located in the dressing room. This eliminates the possibility of fire extinguishing due to water ingress. A boiler with water and a heater are placed in the steam room.

A prerequisite for the operation of a gas oven is the presence of a hood and windows with vents in the dressing room. Doors must open outward. The length of the chimney must be at least 5 meters.

If the chimney is made of different materials, for example, stainless steel pipes are attached to the stove, and then the channel is made of brick, then the junction must be completely sealed. This location in the heating system should be checked as often as possible.