When the question arises about heating a small country house, the best solution would be to build a stove. It is economical and practical, as the heat transfer from correctly stacked brick ovens is at least 90 percent.

Brick kilns have lived up to their purpose for centuries. And no matter how its design changes and improves, the basic requirements for it remain the same. These are safety in use, ease of use and the ability to keep warm for a long time.

With a strong desire, it is not difficult to lay out a mini brick oven with your own hands.

What are the benefits of small-sized wood-burning stoves

The advantage of a small stove is that it takes up a very small area with high heat transfer. For a country house, bathhouse, outbuildings, a mini wood-burning and coal-fired oven is ideal. There is a minimum of building materials, but if you put the hob on top, you can cook food and heat the water. Even in our time, a brick heating stove remains quite popular. The most important thing is that it will not be difficult for a novice master to make it. Having an ordering scheme in front of your eyes, you can fold the mini oven with your own hands in just one daylight. You just need to first prepare all the necessary tools and building materials.

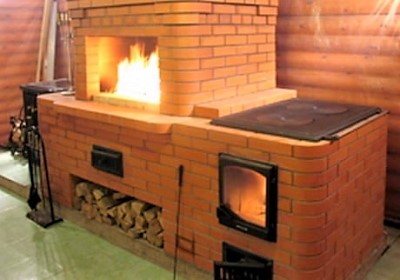

Compared to the "potbelly stove", a brick mini-oven for a dacha with wood looks aesthetically pleasing. Subsequently, it can be refined with tiles, and it will not only warm, but also decorate a country house.

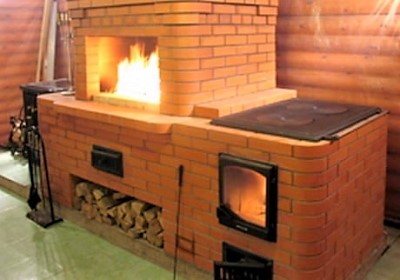

Sometimes its design is combined with a fireplace, and this will already be a mini fireplace stove. You can immediately build in a tank for heating water or provide a niche for drying vegetables and fruits.

There are a lot of options for brick ovens. But these are more complex designs, and you need to start building a mini-oven for a summer residence with your own hands from the simplest model.

It's time to make life more comfortable: building a small brick oven for a summer residence with your own hands

They build in country houses heating or heating and cooking mini brick ovens. These structures allow you to heat the house in the off-season and in the winter season.

A stove designed exclusively for heating is erected if there is gas and electricity at the summer cottage all year round. If there is nothing to cook food on, they build stoves with a hob.

Required tools

You need few tools, they can be easily purchased at any hardware store:

- trowel, or as it is also called, trowel;

- handy pickaxe hammer;

- building level;

- roulette;

- plumb line.

In addition, in the process of work you will need:

2 buckets (for water and mortar), construction sieve, trough where to sift the sand.

How to choose a country heating and cooking stove

The choice of such a furnace requires a responsible careful approachso as not to face problems later when cooking.

Main condition - correct design of the firebox, in which heat is not dissipated, but concentratedly transferred to the surface of the stove.

This is difficult to achieve, so attach the stove will not work with an ordinary oven - in the best case, it will be possible to heat food on it, but not to cook it.

Second required moment - the device, heating the stove to the required temperature, does not itself heat up to high values. It is also important in order to avoid burns, injuries, so that, while working in the kitchen, you do not suffer from overheating of the room, this is especially true in the summer.

Building materials for mini oven

You must first prepare the clay. To do this, it is poured with water and left so for about a day. You can speed up the process, for this, thoroughly knead it every five to seven minutes, preferably with a drill mixer, for an hour. Strain through a sieve. The sand must also be sieved beforehand.

To fold a mini heating stove, which will occupy an area of 0.4 sq. meter, you will need:

- 20 liters of solution;

- 60 pieces of red oven bricks;

- 38-40 pieces of fireclay bricks;

- firebox door;

- blower door;

- grate;

- hob;

- chimney valve.

Doors, grate and hob must be cast iron.

If you do without fireclay bricks, then it will be a model of a mini wood-fired stove, not coal. Even the highest quality red bricks will deteriorate over time from the high temperatures created by coal fuel. In general, to make a mini Russian stove with your own hands, you just need to follow the recommendations.

Wood stoves

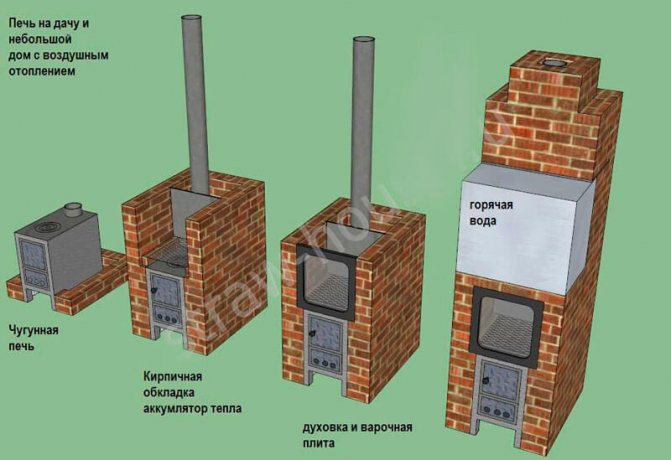

Modern potbelly stoves are a compact stove that can be placed even in a small room.

The most affordable type of fuel in the countryside is firewood. That is why people are actively buying wood stoves for heating houses and baths.

Earlier, potbelly stoves were produced with large sizes, which made it difficult to choose an installation site. Now, thanks to modern technologies, it has turned out to modify the device and make a compact miniature oven that can be placed even in a small room. Thick sheet steel and cast iron are used as materials for the heater. The stove needs a chimney, so the smoke extraction system must be thought out in advance.

When buying a model, it is important to pay attention to such a parameter as power. No less important factors are the rate of heating, the time of holding the heat, the frequency of adding fuel, and the specifics of installation and operation.

Features of metal furnaces

Metal stoves are associated with reliability and durability

Metal products are in great demand among summer residents. They are affordable, easy to install, and heat up the home well. They are made of various metal materials (steel, iron, aluminum).

There are two options for iron stoves. Thin-walled potbelly stoves heat up quickly, but they cool down at the same rate. They must not be overheated, as the temperature can destroy the body and weld seams. Thick-walled models can heat rooms up to 100 square meters. They are distinguished by their economy and minimum fuel consumption. They work on wood, coal, pellets.

The most expensive wood-burning stoves are cast iron products. They are distinguished by their reliability, high strength and durability. They are able to keep warm for a long time.

The most popular models of metal wood stoves

4 oven options Fire-battery

The variety of ovens makes it difficult for users to find a good model to suit all their requirements. But there are a number of devices that are in demand and have proven themselves well.

- Fire-battery, Termofor. In the furnace of this model, you can adjust the draft and set the smoldering mode. The device has practically no drawback, customer reviews are good. The room is heated in 50 minutes. Withstands extreme temperatures and red-hot heat.

- Matrix, Teplodar. Another model with a smoldering mode and a fuel filling interval of 8 hours. It has a slotted convector, which increases efficiency. The stove has a heat-resistant glass door through which the combustion rate can be controlled. Equipped with a cooking hob. Professionals recommend making the first furnace on the street so that oil and paint will burn out from the product.

- Bavaria, Eco-fireplace.One of the most popular wood-burning stoves for home and summer cottages. The model can be additionally equipped with ceramic tiles and tiles. It has a compact size and looks stylish. The longest burning time is 6 hours. Of the shortcomings, users note a weak heating of the hob. It is enough only for heating food, and not for full cooking.

You can find other products with characteristics suitable for a particular case.

Location and preparation of the foundation

The best location for such a stove if the summer cottage consists of one room - in the center. In other cases, you need to focus on piers or intersections of interior partitions. Be sure to take into account the rules of fire safety.

No foundation is needed for a structure of this size. However, in the base it is necessary to put a thick, solid board, fixed with lags, on top - a fire layer. It can be a regular asbestos-cement sheet.

Then arrange a waterproofing layer of polyethylene and roofing felt about 80 by 55 cm in size. Pour a thin layer of sand.

Making a small stove for a summer residence with your own hands

In this example, we will consider in detail the preparatory and basic work on the construction of a compact heating mini-oven in the country. Important points works are:

- choice of ready project;

- the choice places in a country house for the construction of a stove;

- acquisition materials;

- purchase of metal parts and accessories;

- oven preparation instrument, purchase or rental of power tools (grinders, vibratory drills);

- building foundation;

- building stoves.

The procedure for laying a brick oven with your own hands

The next stage is the construction of the stove itself:

- In the first row, the solution is not applied. 12 pieces are laid out strictly horizontally on the sand. A blower is placed on the clay-sand mortar. The door is wrapped with asbestos cardboard, wrapped with a cord. Fastening is done with wire.

- Then the laying of the second row is made.

- In the third row, lined with refractory bricks, strictly above the blower, a grate is placed.

- The bricks in the fourth row go to the edge.

- In the chimney, a support for the partition is provided. The back wall is laid out without the use of mortar. These bricks will then need to be removed. Then they put the fire door, wrapping it with an asbestos cord. A couple of bricks are temporarily used for fastening. Secure with wire.

- The fifth row is laid out flat, like the fourth.

- The bricks of the sixth row go to the edge.

- The bricks in the seventh row are laid flat again. For inter-row bunching, you need to start with a brick chipped off three-quarters in size. Having placed two bricks with an edge, they begin to build the back wall.

- The eighth row will close the firebox door. To direct the fire towards the center of the hob, the brick is placed at an angle. Tightness is ensured with a wetted asbestos cord.

- The ninth row is also laid using an asbestos cord. The peculiarity of this row is that it is slightly shifted back so that the door remains open.

Homemade brick device

The unit should be small, because it will heat a small building with an area of up to 50 m2.

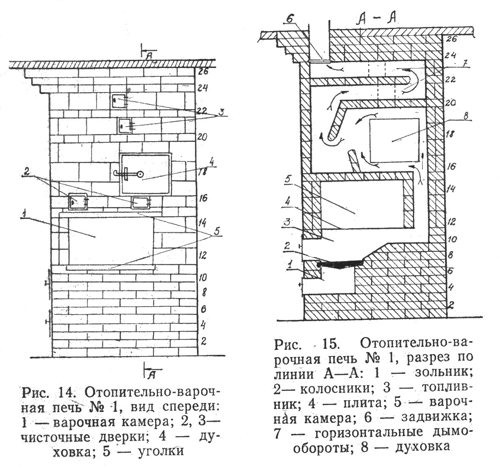

Working principle and design

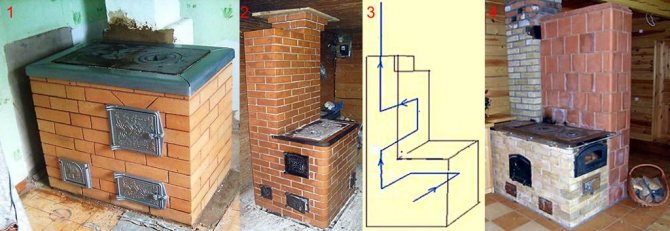

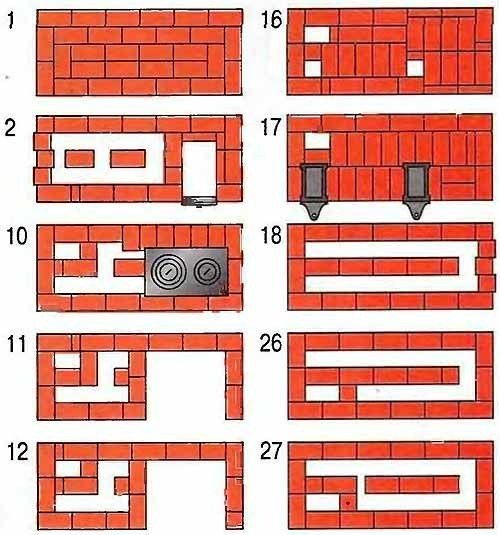

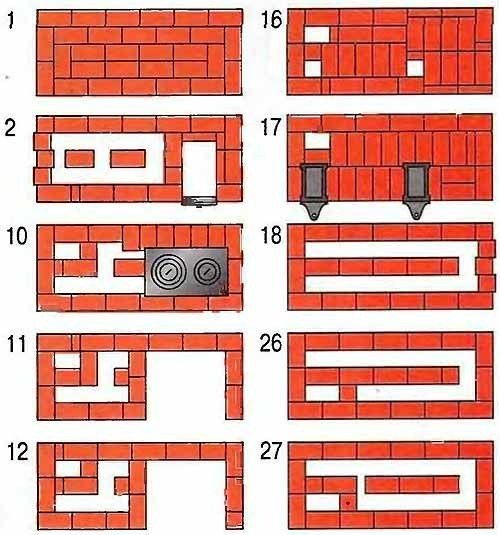

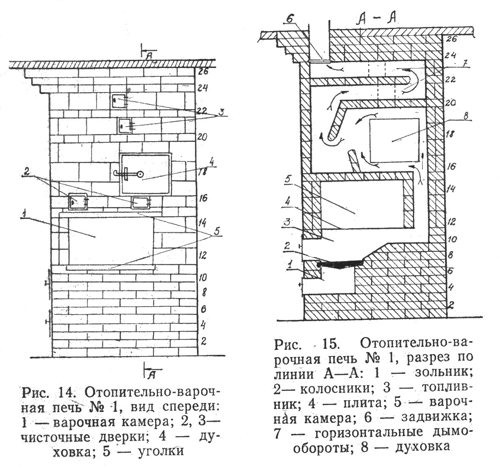

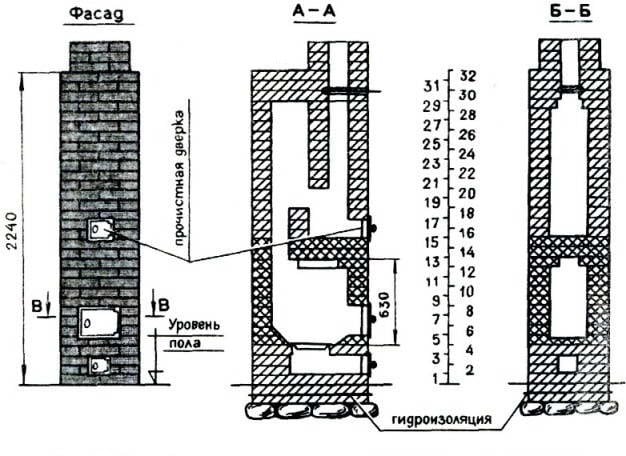

The photo shows an example of ordering for a relatively large oven.

- The outer walls of the oven can be laid out in half a brick.

- An oven and a hot water box should be included in the design of the unit.

- As a hob, you can use a cast iron stove with at least two burners.

- The furnace must be covered with a sheet of cast iron to improve heat transfer. Above, above it, a cooking chamber should be placed.

- The oven can be equipped both to the right and to the left of the firebox, based on the conditions of the room.

- For a small summer cottage, a stove consisting of 14 brick rows will be enough.

- Heating must be done at the grass-roots level. It is hygienic and efficient.

The principle of operation of such a unit is below.

Two options for a homemade cooking and heating stove.

- In summer, hot gas from the firebox passes under the hob, warming it up and the oven. Then it is discharged into the atmosphere through the chimney.

- In winter, the work of the stove is almost the same. But the gas, after heats up the hob, goes through the heating pipes into the upper closed box and heats it up. Only then the coolant goes into the chimney.

Materials (edit)

Assortment of blower doors.

Before getting started with your own hands, purchase the following.

- 230/250 pieces of oven (refractory) bricks.

- 200/210 kg of chamotte clay for mortar.

- 200/210 kg of pure fine quartz sand.

- Metal corner, dimensions 45 × 45 × 3 mm.

- Steel strip 40 × 3 mm.

- Fireplace door. In our example, its dimensions are 270 × 300 mm.

- Blower door, dimensions 150 × 270 mm.

- Cast iron hob with burners.

- View valve.

- Water heating box, dimensions 500 × 350 ×

- Drying analogue, starting from dimensions 350 × 350 ×

Note! If you have no experience with brickwork, please note that it is necessary to follow its order. For this you need her drawings. Either order them from specialists or find them on the Internet, including on our website.

Furnace masonry

The work on laying the stove has begun.

First, it will be necessary to equip the foundation of the unit. It is filled in as standard.

Next, brickwork is carried out.

- Lay the initial and next row completely. Place only whole bricks at the ends of the first row. You can also place a fight in the center.

- The second layer is mounted only in whole blocks.

- 3/5 rows serve as the basis for the ash pan. At this level, its door is mounted, and on the 5th row (top), an overlap is arranged. A place for the drying chamber is immediately formed. The dimensions must match the existing drying box.

- Further, from the sixth level, the base for the grate begins to build up.

- On the seventh row of bricks, it is installed by itself, and then the door of the fuel chamber.

- Level 8, 9 and 10 rows - this is the place for the firebox. An area for the drying box is immediately laid out.

- On the 11th row (on top of the dryer) steel strips are laid. They are filled with sandy-clay mortar. Immediately you need to choose a place for the arrangement of the chimney.

- At 12/13 levels, bricks are placed on the laid mortar, and a socket is prepared for mounting the hob.

- Next, the stove itself and a tank for heating water are placed (it will partially block the chimney).

- At the level of the last 14th row, a pipe is installed to remove combustion products.

Final activities

Three more rows of brickwork are made to connect to the pipe. Having taken out the "knock-out" bricks, the channels of the furnace are immediately cleaned of construction debris. The perimeter of the structure is carefully covered with a plinth.

The whitewashing or facing of the furnace is done after a test ignition.

Only after the whitewashed or tiled mini-oven is completely dry can it be used. In order for the mini stove for the summer residence to please for a long time, you should not rush to kindle it. Let it stand for a week or two with the doors open.

It is not recommended to use coal immediately; it is necessary to give the stove time to initially warm up with chips.

Many private houses are being built at a sufficiently large distance from the city, as a result of which it is impossible to install central communication systems in them. This includes heating, which must be autonomous. The traditional way of heating rooms is considered to be a stove that you can make yourself, and brick is most often used for this.

This design works on wood, which is an affordable type of fuel. Thus, for small buildings, a mini-oven made of bricks is considered an ideal solution, which is small in size and is also easy to create.

In addition to the undoubted benefits of using this equipment it should be noted that a brick mini-oven creates a cozy and pleasant atmosphere in any building. Such a design is suitable not only for a private house, but also for a summer residence, and its appearance and functions can be completely different, so you can choose a product that fits perfectly into the room and will have the necessary parameters.

Constructive decisions

The fireplace stove is made, in most cases, from steel and cast iron.

Steel - have an impressive weight and thick walls. They heat up quickly and also cool down quickly, designed for small rooms - summer cottages, country houses.

Cast iron - not much more by weight, but they warm up longer, they can heat large rooms, the cost is higher. Cast iron stoves, fireplaces are chosen mainly for the home.

Facing - ceramics, stone, less often - brick. Warm up the room quickly. A large enough observation glass will allow you to admire the play of fire.

Doors can be straight semicircular and three-sided. The opening mechanism can also vary - to the side or up. To keep the glass of the door always transparent, fireplace stoves have an option of clean glass - the air flow is supplied to the glass from the inside, forming an air cushion, it does not allow soot to settle on the glass. Firewood is also inserted into the combustion chamber through the door. The efficiency of closed fireplaces is quite high - 80-90%.

The combustion process and the consumption of wood can be controlled by ourselves by increasing or decreasing the air supply. You can save even more on fuel by using fuel briquettes - compressed sawdust, which are much more efficient in terms of their fuel qualities.

Some models have a built-in heat exchanger in their design. It can be used to heat adjacent rooms by installing radiators, even if there is a blind partition. It is especially worth noting the structures with a water circuit - this is a good solution for permanent residences.

Beauty, comfort, warm home. What else can fireplaces give you? Delicious dinner. As in the traditional Russian oven, you can cook and reheat food in them and even cook barbecue over an open fire. Choose a stove or fireplace, or two in one, of course, it's up to you.

6a438c8c5c28014ff21990d5f9fc2b1e.jpe

Fireplace power

To choose the perfect unit for a summer cottage or home, you first need to decide on the power. It will not be difficult to calculate this: based on the calculations of 1 kW of energy per 10 square meters with a ceiling height of 2.5-2.7 meters.

For example, if the area of the house is 350 square meters, you will need a fireplace stove giving 35 kW

It is also worth taking into account the number of window and door openings, rooms - the heat in the room circulates constantly, as it warms up and cools down. Do not forget about the climatic features of the region in which the construction is located.

Based on all these parameters, we calculate with a margin and add another 15-30% to the estimated power (depending on the factors listed).

The most popular wood-burning stoves are models that have a secondary combustion system, which will dramatically reduce wood consumption. Ceramic cladding allows you to warm up the room even after the fire has finished. Glass also gives off heat. Dark cladding is less of a brand name. The manufacturer has a line of furnaces made of cast iron.

If all the calculations have been made, and you have decided on the type of heating device, consider the most popular models in this segment.

VIDEO: The principle of operation and difference from the Russian stove

Positive and negative characteristics of the mini oven

This design has both pros and cons. That is why, before the very work associated with its construction, you should evaluate all the features of this equipment.

DIY brick oven, wood-fired, possesses the following positive parameters:

- The resulting design has a long service life, as a result of which you can get a high-quality and attractive stove for many years.

- Warming up occurs quickly, and also, even after the end of fuel combustion, the stove will give off heat to the premises for a long time.

- You can make the equipment with your own hands, however, for this, there must be a preliminary drawn up diagram of the entire structure, following which you can achieve an ideal work result.

- The walls of the stove, made of brick, do not get very hot during the heating, so there is a very small chance of getting burned.

- If a structure is being built for a summer cottage or a small country house, then it can be a mini-stove, so it will not take up much space.

- If desired, you can get such an oven that will be equipped with additional elements for cooking and other processes, however, in this case, a suitable and appropriate scheme should be used, in which all the necessary nuances of construction should be worked out.

- If you watch the training video in advance, then the construction process itself will be implemented without problems and delays.

- You can make a furnace that will have the desired shape, size and other characteristics, since the process is carried out on its own.

- The scheme of the future chimney must be worked out especially carefully so that the stove has a high efficiency, as well as is reliable and safe to use.

However, brick mini-ovens have not only advantages, but also some disadvantages:

- Even a mini wood-fired oven made of bricks needs a foundation, since it has a fairly large weight, so it will be important to initially devote a lot of time to forming the base.

- A clear, high-quality and correct scheme of the future masonry must first be formed, without which many mistakes can be made during work, they can be eliminated only after the complete destruction of the already created structure.

- During operation, it is imperative and always necessary to use and take into account the rules and safety requirements so that the future stove can be used for its intended purpose without fear of harming the health or life of people.

Long burning ovens

Very often you can find options for slow or long burning stoves, along with pyrolysis stoves, but in fact, this cannot be done. Despite the fact that pyrolysis is a very important part, in this case the combustion of pyrolysis gases and gasification of fuel take place in a burning bed, in contrast to classical pyrolysis furnaces, where these processes take place in separate chambers.

In order to see all this by example, it is enough to perform a few simple experiments. To carry out this experiment, you need to take a glass from a school aluminum calorimeter. Next, you need to fill it with water, and then insert a thermometer into it. Now you just need to burn just one match under it, but you only need to hold it head down in order for the flame to be more intense. As soon as the match completely finishes, it is necessary to return the glass as quickly as possible, back to the calorimeter and then detect the temperature. After the device has completely cooled down, you need to do the same experiment, but only in this case, keep the match head up.

Now you need to figure it out, because all the heat energy from the match has completely passed into the glass and then into the water, but the glass itself can be easily held with your hands without feeling much heating. But it is worth noting that when the match was held with its head up, less soot remains on the bottom of the glass, and the water temperature will eventually become on average 2-3 degrees higher. This is exactly what is a vivid example of pyrolysis gases that did not slip out of the fuel, without having time to completely burn out, due to which the maximum heat was released.

As for stoves that are designed to burn for a long time, their structures are often made of metal. It should be noted that long burning, without fail, requires a metered amount of air. For example, even during the experiment with matches, the one that was head vertically upwards, for constant high-quality combustion, had to be tilted or turned a little.It is this adjustment of the air supply that is capable of providing the power of the stove within a fairly large range. That is why, if you put a long brick stove, but the thermal inertia will be "parasitic", and in order to set up the stove for high-quality combustion, you need to spend a lot of time, effort and sometimes financial resources, and changing the air supply sometimes leads directly too a huge uneconomical flame, or vice versa, to extinction.

The shaft scheme of long-burning furnaces, in fact, is the same match that burns with its head vertically up, but only much more. Among the positive aspects of this design, it should be noted a fairly wide range of power adjustment. Due to the fact that this design involves one stage of combustion, it is very problematic to attach a water heater or a cooking surface to such a stove. Each manipulation, which is meant by the extraction of heat, necessarily leads to a decrease in the efficiency, failure of pyrolysis and greater sedimentation inside the soot. Furnaces of this design are often used exclusively for air heating.

The design of the two-stage combustion chamber furnace is built in such a way that most of the pyrolysis gases burn out directly in the afterburner, which is separated by a partition. In such a design, the range of adjustment of the heat energy pressure force is much smaller, but right above the afterburner itself, you can easily modify the surface intended for cooking, which is already done on various models.

It makes no sense at all to mount a hob made of cast iron with an additional burner. This is due to the fact that the temperature on its surface varies greatly and thus, if food can be fried in the front, it can be cooked in the middle, and food can be heated directly at the pipe itself. There are many options for do-it-yourself designs of this type, but the most popular is Loginov's modified long-burning stove. In order to obtain an efficiency of more than 60%, it is imperative to put a screen around the oven, which is best done double. Such ovens are mobile, which is very important for country houses or seasonal premises.

Among all the positive aspects, such as high efficiency, long-burning stoves have two very fundamental negative points:

- Without a visible decrease in the efficiency, no more than 1/10 of the heat output of the furnace can be taken off the surface intended for cooking. So, for example, if you take the Butakovs ovens, they can heat a room of 250 square meters. m, and have only 2 factory burners. Such a stove will be relevant for staff or guards in some small room, but if we talk about a congress in a camp site, then for all people, it will not be enough;

- Such stoves are most sensitive to wet fuel. If we are talking about coals, then the main thing for him is that it is kept dry, even if on the street, but always under a canopy, and if we are talking about a wood-burning stove, then in the room where the stove is heated, it is imperative to arrange a firewood. Moreover, it is best to bring the wood to dry before kindling, but this takes time, and at the same time increases the risk of fire hazard.

Attention: it should be borne in mind that brick ovens designed for continuous burning are often made according to the stoker scheme. This system involves the gradual settling of fuel from a bulky bunker into the combustion area. Due to the fact that the brick practically does not come into contact with fire, the thermal inertia of the masonry is practically absent.

Furnaces made according to the stoker system are capable of providing up to 30 days of heat transfer at one full load, while the power adjustment should be no more than 5% of the nominal. It is worth noting that such ovens are exclusively heating, so you don't even need to think about installing the hob.

Mini oven parameters

Since these wood-fired structures are small in size, then their device is considered simplified. It is enough to choose a product that will occupy only 0.5 sq. m. Brick laying can be done both on the edge and flat. This design, which is easy to make, gives off a large amount of heat and provides uniform and high-quality heating.

Since the mini oven is small in size, its weight is not considered significant, so the base should not be too complicated and expensive. You can make a structure literally in one day on your own if you watch the training video in advance, as well as prepare drawings that will fully describe the entire process of the upcoming work.

Choosing a stove for a summer cottage

The choice of a heating unit for a steam room has a number of features, and they must be taken into account:

- The temperature of the heated stones is 550-600 degrees. The oven is melted for 4 hours. Among the main disadvantages of the stove-heater is its large weight and significant dimensions. And also in the cold season, additional heating will be required not only for the steam room, but also for the entire bath room.

- An easier way to heat the steam room is to install a stove made of steel or cast iron. Steel structures are inexpensive in cost. Cast iron units keep heat remarkably, and besides, they do not burn out. In metal appliances there is a reservoir for stones. The more there are, the more evenly heat is given off and the longer it is retained (read: “How to install the stove in a bath, tips for self-installation”).

Features of metal furnaces:

- they can be melted in less than an hour;

- they are small in size and light in weight;

- cool down quickly, because they have a low heat capacity;

- radiate hard heat.

There are certain requirements for brick ovens installed in baths:

- their kindling cannot take more than 4-5 hours;

- brick ovens for a bath should have high heat capacity, not overheat the steam room and keep warm for a long time;

- it is necessary that the given warmth be soft and pleasant.

Which stove is better for a bath - types of heating bath stovesWhich stove to choose for a summer residence, watch the video:

Manufacturing process

All work can be divided into separate stages, which are executed only in the correct sequence. Each work needs to be given a lot of attention, since mistakes at any stage can cause the need to disassemble the stove and correct violations. Stages of work:

Base

- Determination of the location of the future structure. A mini-oven that runs on wood should be located in a place in the room where it will be safe to use it, so there should not be any flammable elements near it.

- Drawing up drawings of the future design, which should contain careful and accurate calculations and diagrams. It is on them that you need to focus on during the work process.

- In the chosen place, you need to disassemble the floor covering in order to get to the base, since this is where the foundation for the future stove will need to be made. This work can be viewed carefully on a special video presented on the Internet. Usually a standard concrete base is created, all subsequent steps should be performed only after the cement mortar has completely solidified.

- A layer of roofing material is laid on the frozen foundation, which performs the function of waterproofing. In this case, it is important to ensure that there are no holes or other opportunities for moisture to penetrate to the base.

- Sand is laid out on the waterproofing layer, which must be clean and of high quality.

Ordering and structural elements

- Next, the direct laying of a mini-oven, operating on wood, begins. For this, the first row is created, for which a small number of bricks are used, and 12 elements are most often used. They are fastened together with a reliable fastener, and also aligned and adjusted using a level and suitable equipment. The evenness of the location of each element must be monitored especially carefully, since the evenness and safety of using the final structure depends on it.

- A clay mortar is applied to the first row, after which the second row is laid, and here you can immediately install a blower door. This door should be wrapped in asbestos to avoid unnecessary gaps and holes.

- The next step is to lay the third row of the wood-fired oven. For this, fireclay brick is considered the most optimal choice.

- Next, a grate is mounted, which is located under the blower.

- When creating the fourth row of masonry, it is important to lay all the bricks on the edge, and the back wall is usually created by laying bricks with a special protrusion outward, and it must also be taken into account that clay mortar is not used in this process.

- Next, a furnace door is mounted, which, like the other door, is wrapped in asbestos. It is best if this door opens upwards.

- The fifth row of masonry is laid flat. In this case, it is important to repeat the contour and features of the fourth row.

- The sixth row is laid with an edge, the seventh is done flat again. We must not forget about the dressing.

- The eighth row of masonry should completely cover the furnace door, above which the sloped brick is mounted. It is important to create a perfect seal between the slab and the bricks.

- Laying the ninth row should be done with a certain offset, which will allow the fire door to be well kept open when necessary.

- During the laying of the tenth row, the formation of the chimney begins, so it is important to decide what parameters the chimney will have. It can be vertical or horizontal, straight or bell-type, direct-flow or counter-flow, as well as combined. Each can be formed independently if you watch the video of its creation by specialists.

After creating the stove and chimney whitewash the structure, and also make sure that there are no large gaps and other problems, but if they are present, they must be eliminated. To prevent sand from spilling out during the operation of the structure, you can nail a special plinth along its edging. It is not only a protective element, but will also improve the appearance of the oven.

Thus, the process of creating a mini wood-fired oven is considered quite simple and straightforward. With the right approach to the formation of this element, one can expect a durable, reliable and completely safe structure for use, which will not only be a means of heating rooms, but also a bright unusual decoration that increases the comfort of using the structure as a whole. Due to the small size of the stove, it will not take up much space in a small house, but it will have a high efficiency, which ensures thorough and uniform heating of a summer house or a private building.

Features of installing a cast iron stove

A few words must also be said about the features of installation work on the installation of a long-burning cast-iron stove and preparation for them.

The installation of a cast-iron device itself is not particularly difficult, with the exception of transportation - due to the large weight of the unit.However, before buying it, and even more so installing it, you need to carry out preparatory measures:

- For the correct choice of the device, it is necessary to collect some data - this is the size of the heated area, it is necessary to determine the power of the furnace. In addition, you need to consider the height of the ceilings in the rooms.

- Next, you need to draw up a plan of the room where the stove will be installed, and the attic floors above it. The last parameter will be needed if the chimney will go outside through the attic floor and the roof.

- Having received all the data, you can go to the store for the device and all the additional accessories that are needed to install it. Very often, sandwich chimney kits are purchased for such an installation - they are perfect for devices of this type.

The place of the future installation of the cast iron stove must be properly prepared

- Next, you need to prepare the place where the oven will be installed. For this, walls and floors are finished with ceramic tiles, bricks, artificial stone, or surfaces are sheathed with non-combustible material - this can be asbestos (not recommended for residential premises) or gypsum plasterboards. Drywall must have a designation of heat resistance - GKLVO. From these materials, a screen can be installed on the wall. If necessary, the overlap under the flooring is reinforced, and their surface is leveled with a screed, and then decorated with ceramic floor tiles.

- The stove is installed on a prepared surface, leveled to the building level. All chimney joints are sealed with a special heat-resistant sealant. The material from which it is made is heat-resistant silicone. Additionally, it will be necessary to insulate all chimney passages through walls or ceilings.

- The section of the chimney located on the street must be insulated, or use special sandwich pipes for its installation, in which there is already an insulating layer.

- If the cast-iron stove will be installed in a wooden house, then in addition to equipping the installation site with heat-resistant materials. a number of certain rules should be followed. These requirements include:

- the combustion chamber must be of a closed type with gas heating no more than 400 degrees;

- the outer surface of the chimney should not be heated above 85 degrees, and in passages through ceilings or walls, the pipe is separated from them by heat-resistant insulation with a width of at least 100-150 mm.

Work sequence

After you have decided and chosen the right location, pay attention to the surface. It is important that it is made of well-fixed, thick and durable boards. Place a 78 x 53 cm plastic wrap on the stove site. Make a 1 cm thick sand pillow.

First row. On the sand you need to lay out 12 bricks, do not make fasteners between them. Align at the same height so that they are exactly in the horizontal position.

Second row. Apply the clay solution in a non-greasy layer and install the blower door, wrapping it in asbestos cardboard in advance. We fix the door with wire.

We build the third row with refractory bricks. Now you can install a cast-iron grate for the firebox above the blower, but only if the row has been completely completed.

Fourth row. We put the brick on the edge in the middle of the chimney. We lay out the rack for the wall from the inside of the oven. We make the reverse side with a protrusion on the outside without clay mortar. These bricks can then be knocked out to clean the well. Wrap the firebox door with an asbestos cord so that it can open from the bottom up. Install. We fix it with wire and put a couple of bricks for a while. We install one behind the door, and the second on top.

Lay the fifth row in a layer. We repeat the outline of the last row.

We put the sixth row with an edge. We rub the walls of the stove with a damp cloth.

Lay the seventh row in a layer. We make a bunch from three quarters of a brick with subsequent rows. Put a couple of bricks on the edge again. We build a back wall near the stove.

We lay the eighth row so that it blocks the furnace door. Be sure to install a sloped brick above the firebox. Thanks to him, the flame in the stove will tend to the center of the burner on the cast iron stove.

We spread a slightly wetted asbestos cord. We install the cast iron stove. This will create an airtight seal between the bricks and the slab.

We shift the ninth row slightly to keep the door open.

Tenth row. We form a chimney with an extension at the back. The chimney must be straight.

Eleventh row. We fill the valve with an asbestos cord, pre-lubricated with clay mortar and install. Now the chimney is tightly connected to the metal one. If the pipe tilts to the side, it needs to be covered with three rows of bricks.

Remove dirt from the chimney. To do this, you need to pull out the bricks from the fourth row. White oven. We cover the walls and the metal part. In lime for whitewashing, you need to pour a small amount of milk and blue. It is important to thoroughly coat all seams of bricks and cast iron surfaces.

How to build a stove correctly?

The manufacture of the structure begins with the formation of the base. The second stage is brick laying. The creation of the base begins with determining the place where the heating stove will stand. The place is selected safe and accessible at the same time. Accurate calculations are carried out, which are applied to the structure diagram. If the dimensions of the structure are large, then the floor covering is removed and construction begins with the formation of the foundation. Stove-makers recommend that a place for a heating element be foreseen in the foundation of the house in advance. If the stove is planned to be compact and will be fired exclusively with wood, then a metal sheet with asbestos is used as the base.

When the foundation is ready, roofing material and sand are laid on it, and then proceed to the construction of the box itself. Procedure:

- The formation of the order is carried out from the first row. This process uses 12 bricks. They are securely fastened and adjusted to the level.

- The first row is covered with a solution and the second is laid. A blower door is installed above it, wrapped in asbestos.

- At this stage, the next row of mortar bricks is laid.

- The grate is being installed.

- The next row is laid on the edge, and the back wall is formed with a protrusion of bricks without the use of clay mortar.

- A firebox door is mounted on top.

- The subsequent rows of bricks are laid flat and alternating on the edge.

- Next, the furnace space is covered with bricks, and a beveled row is laid above them.

- The next order is formed so that you can easily open the firebox door.

- The last step will be the formation of the chimney.

To avoid the destruction of the structure, only 1 row of clay bricks is allowed.

The shape and dimensions of the pipe are provided in advance. Distinguish between horizontal and vertical chimneys, straight, bell-type. Each of them will help remove smoke from the chimney and leave heat in the house. If everything is done correctly, then wood stoves give maximum efficiency. Folding brick stoves is not that difficult. After studying the instructions and creating a diagram, the stove-maker will build an airtight and stable structure.

Drying the oven

Close all gaps between the original row of bricks and the floor. We nail a plinth along the edge of the stove, this will prevent sand spilling out and give a marvelous look. At the end of all work, the oven will need to be heated for the first time with chips and paper or cardboard. Then leave the doors and cooking zones open until the oven is dry. After that, it will be possible to drown it in full force.

This design is suitable for a summer residence or a small residential building. It will be convenient for cooking food, it will save electricity or gas.The oven will be able to withstand all temperature fluctuations. By following these simple instructions, the oven will serve you for years to come. Looking at it, you will experience aesthetic pleasure and pride in having laid out each brick with your own hands.

Furnace fuel

Wood with a moisture content of no more than 20% serves as fuel for long-burning stoves - it can be whole logs of the same length, waste from the woodworking industry, chips and other sawn timber. In addition, pellets, fuel briquettes and coal are used. For this type of furnace, it is better to choose brown coal, since other varieties are more energy-intensive, which can lead to burnout of the surfaces of the walls of the device, especially if the furnace is made in a combined version, that is, it is assembled from different materials, and steel is used as the walls of the furnace.

The moisture content of the fuel has a great influence on the quality of heating, since raw wood significantly reduces the efficiency of the device, and also contributes to the formation of soot deposits on the walls of the chimney. In addition, the processes of pyrolysis in such wood are defective.

Do-it-yourself summer cottage mini-oven: simple orders and an option with a ready-made firebox

In late autumn and early spring, there is not enough comfort at the dacha - it becomes damp and cool in the house. The problem can be solved with an electric heater, but in a suburban home it is better to give preference to a traditional wood-burning hearth. The heat from a stove or fireplace warms not only the body, but also the soul, filling the room with a special aroma and comfort. To build a mini-oven with your own hands, you do not need large costs - the cost of a home-made unit will cost much less than finished devices.

Heating and cooking country stove: where to start and how to build

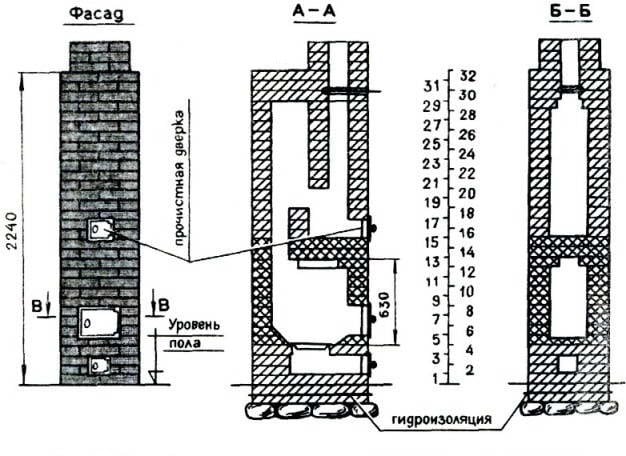

Small-sized furnaces, despite their small dimensions, are installed on a solid foundation. Only in some cases can you get by with reinforcing the floor. Experienced craftsmen work without diagrams and drawings, and beginners are advised to take the order of reputable stove-makers as a basis.

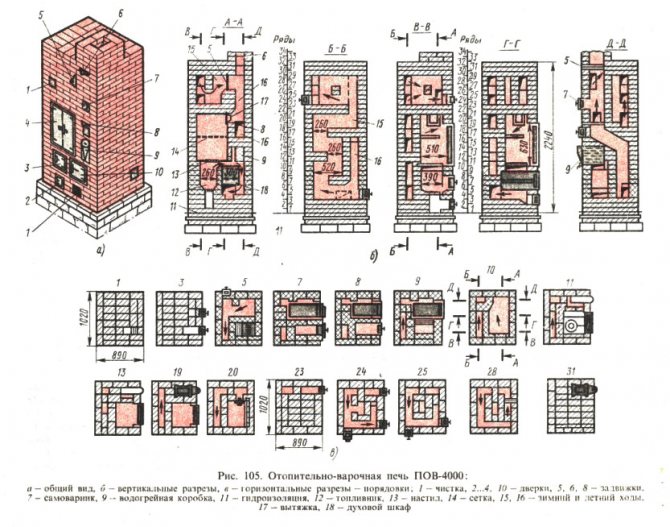

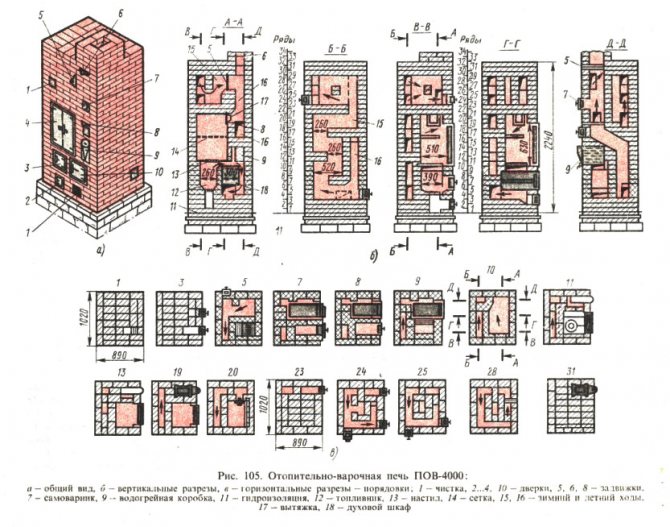

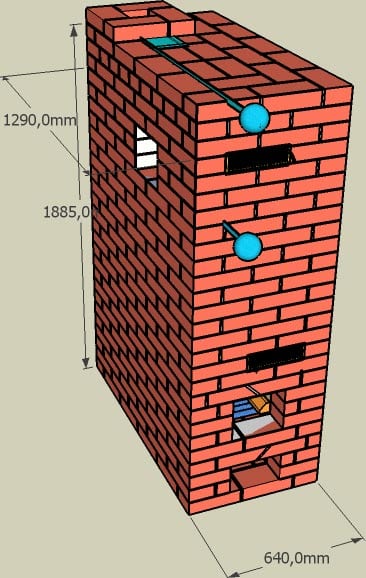

Construction diagram and materials

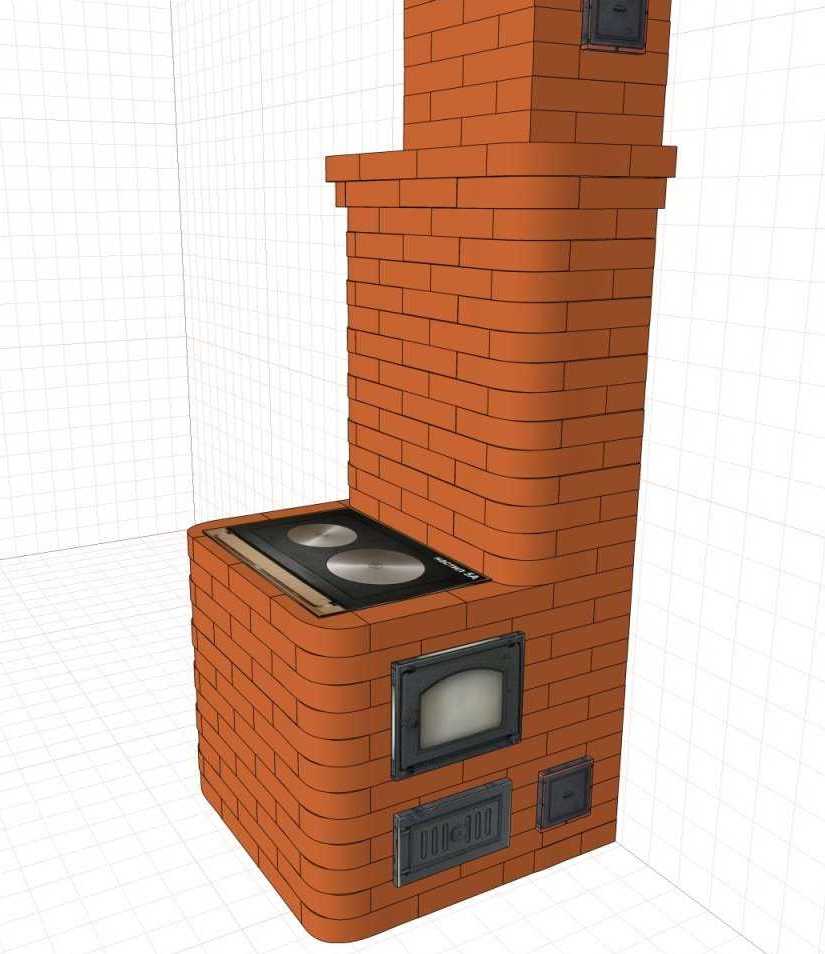

Ideal for a small house, this square mini brick oven is simple, compact and efficient. The design includes a low chimney with a channel section of 13 * 13 cm. The stove has an oven that allows you to cook and warm up dishes. The cabinet is made of sheet steel, but if desired, it can be replaced with a ready-made oven of suitable dimensions.

The appearance and structure of the furnace

A fireproof mortar is required for laying a mini-oven on wood. You can make it yourself from clay, but it will take more time, and the result will depend on the quality of the clay and the correct determination of its fat content. It is much easier to trust the manufacturers and purchase a ready-made heat-resistant mixture in the store - in this case, the product will remain to be diluted with clean water in the proportions indicated on the package.

The dimensions of the compact structure are 51 * 51 cm, the height of the hearth is 175 cm. To strengthen the firebox, fireclay bricks must be taken - it is not afraid of direct contact with the flame and does not crack. The walls of a mini-oven for a country house are laid out with red brick.

Consumption of materials:

- ceramic bricks - 170 pieces;

- refractory masonry mortar - 35–40 liters;

- door for the firebox measuring 23 * 25 cm;

- blower door (13 * 14 cm);

- cleaning door (13 * 9 cm);

- grate (25 * 18 cm);

- latch (12 * 34 cm);

- steel sheet;

- steel wire - about 2.5 m;

- roofing material for waterproofing.

Masonry diagram and oven drawing

The first row, as always, is laid out without mortar. On the second row, a blower door is mounted using steel wire for fastening, and an ash pan is laid. On the fourth row, a grate is laid, providing a gap of about 4 mm between the grate and the masonry.

Ordinary masonry scheme

Top rows and oven drawing

Laying the fifth row begins with the installation of a combustion door.The door frame is wrapped with an asbestos cord, and the door is walled up in the masonry using steel wire. Then they follow according to the scheme: form an oven, a chimney, a pipe.

Preparing the door

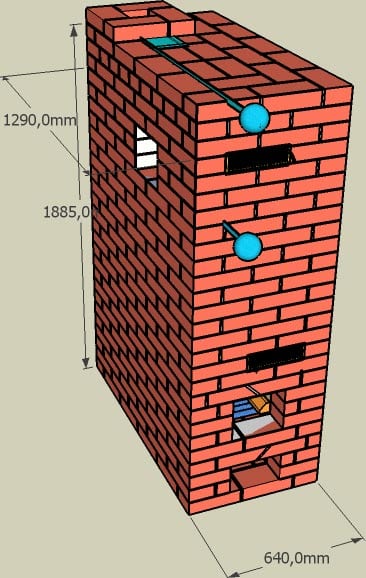

Baby stove with stove and oven

Another mini-oven for a summer residence has dimensions at the base of only 51 * 64 cm, while the depth of the firebox is 50 cm. The model is perfect for a country house or a summer kitchen. Firewood, coal, peat, briquettes can be used as fuel.

Design features and materials

Despite its small dimensions, the compact stove is quite functional and is equipped with a hob and oven, which allows it to be used not only for heating the room, but also for household needs. According to the reviews of those who have already built this assistant in their country house, the kettle on the stove boils in literally minutes.

The compactness was preserved thanks to the vertical arrangement of all elements. The chimney has a cross section of one brick. The exhaust gases pass through the channels located behind the cooking chamber, then enter the horizontal chimney, bypass the oven on both sides and go into the chimney.

Diagram of a mini-oven for a country house or summer kitchen

For construction you will need materials:

- red brick - 220 pieces;

- clay masonry mortar or ready-made - about 50 liters;

- grate;

- steel sheet (pre-furnace) with a size of 50 * 70 cm;

- steel strip 4 mm thick with parameters 350 * 25 cm;

- slate sheet 51 * 30 cm;

- gate valve - 2 pieces;

- firebox door;

- 3 cleaning doors;

- blower door;

- oven (32 * 38 * 42 cm);

- stove (38 * 35 cm) with one burner.

Masonry order

The first row of a brick mini-oven is laid without mortar. After the second row, a blower door is installed, the next row is placed and the firebox begins to form. The grate is laid without mortar. The sequential diagram clearly shows where and how the doors, stove, oven and latches should be installed.

Masonry scheme for a miniature stove with a stove

Continuation of ordering

Ordering the upper part of the oven

To protect the ceramic bricks from fire, a lining is carried out - fireclay refractory bricks are laid in a separate row. It is important to remember that different types of bricks cannot be tied together - they have different expansion temperatures. Failure to follow this rule leads to cracks.

Lining principle

Option for novice stove makers: a stove with a cast iron firebox

A brick mini-oven can be built with your own hands on the basis of a finished cast-iron firebox. Cast iron fireboxes are durable - they do not crack or burn out. This option is more suitable for beginners, since all the main elements are already provided for in the design. The combined oven heats up quickly and cools down for a long time, due to which the efficiency of the hearth is significantly increased. If you wish, you can choose a fireplace-type hearth with a fire-resistant glass door - such a model will not only warm, but also decorate the room.

Before starting work, prepare a solid and even base. To do this, you can fill in a small concrete podium. The lining of the cast-iron firebox is made in half a brick, leaving an air cushion with a thickness of 1 to 10 cm between the walls and the cladding.In addition, it is necessary to provide small ventilation holes in the lower part of the building - they will provide the outlet of heated air and improve heat transfer.

Example of lining a cast iron firebox

You can start building a mini-oven with your own hands only with firm confidence in your knowledge and skills. Any doubts are a good reason to postpone independent work and entrust the construction to a professional stove-maker.

Video: do-it-yourself masonry of a small country stove

teploguru.ru