Important recommendations for warming the ceiling in a bath

Greetings, dear readers, the topic of today's article is how to insulate the ceiling of a bathhouse and what is the best way to do it. In the last article, we chose the optimal ceiling height, now we will go directly to the device and insulation of the bath ceiling.

A bit of theory. We all know perfectly well that warm air is lighter than cold air and rises up to the ceiling. And imagine the situation - hot steam has gone up, and the ceiling is cold. What's going to happen? That's right, condensation will fall out. You bathe with brooms in the bath, and the rain is dripping on you :). Let's see how improper insulation of the ceiling and the lack of vapor barrier can harm:

- Constant wetting of ceilings and, as a result, their premature destruction.

- Very fast cooling of the bath, perhaps in the cold season, the steam room will not be able to warm up properly.

- Excessive consumption of firewood or electricity.

- The real danger of collapsing ceilings.

https://www.youtube.com/watch?v=Xbn0i3smn0A

Correct insulation of the ceiling

In this one we will tell you how to avoid all these problems and properly insulate the ceiling. The whole process can be roughly divided into three key stages:

- Insulation of the ceiling of the steam room.

- Moisture insulation of the attic.

- Vapor barrier.

At this time, we, as builders, have a serious advantage over our ancestors - the modern construction market offers a wide range of various thermal insulation materials for every taste and budget. Let's take a look at the most popular thermal insulation materials.

The essence of thermal insulation of the ceiling of the bath

When heating a bath, the heated air rises and leaves without obstacles on the way. It turns out that without insulating the ceiling space, we simply heat the atmosphere.

The bathhouse is being built in two versions - with and without an attic. Typically, insulation materials for warming are laid during construction in the attic space. In this case, the ceiling turns out to be more powerful, and the warm air will not leave.

If you lay thermal insulation under the roof, then such an event will also slow down the escaping heat.

How to insulate the ceiling in a bath - popular materials.

The heated air tends upward and, if there is no obstacle in its path, then it escapes into the atmosphere. This barrier is the ceiling. In case of insufficient insulation, about 2/3 of the thermal energy can go through it. Therefore, in order not to incur unnecessary expenses for heating the street, it is necessary to insulate the ceiling of the bath with your own hands.

Depending on the design features of the roof, log baths or timber baths are subdivided into buildings with and without an attic.

Baths with an attic have a significantly more powerful ceiling, which prevents warm air from leaking out of the room. In this case, the thermal insulation of the bath ceiling is made during the construction process. The air mass, which fills the space under the roof, also helps to reduce losses. The insulation of the roof will hold back the heat a little more.

In a building that does not have an attic, there are much fewer barriers to retaining heat and they are too weak, so insulation is especially necessary here. But the insulation of the ceiling in a bath with an attic or an attic needs to be done.

In any case, the vapor barrier material is first laid, and only then the thermal insulation material.

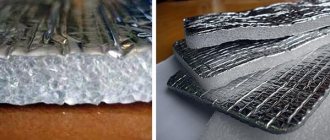

The following materials are used as a vapor barrier in saunas without an attic:

- aluminium foil;

- thick cardboard well impregnated with linseed oil;

- wax paper.

During the construction of a bath, the issue of its insulation is not even discussed. This is the most important stage, thanks to which you can keep warm in the room, as well as control its humidity. But, it all depends on how correctly you do this job. You need to find out in advance whether you want to make a ventilated roof in the bathhouse or equip the attic floor.

After all, the whole sequence of work and the selection of materials for the two types of roofs differ. In this article, you will learn how to properly insulate the roof of a bathhouse in two ways.

All work on warming a bath can be done in several ways:

- insulation of the building's ceiling;

- insulation of roof slopes.

If the first stage is simply necessary, then the rationality of warming the slopes of the bath, the attic of which is not heated and well ventilated, is questionable. The fact is that when the air temperature on the roof is close to the outside temperature, you will get rid of the eternal problem of condensation.

Note! In order for the attic to be well ventilated, it is important to make attic windows on it. When they are opened, natural ventilation is formed. In addition, it will be possible to dry, store brooms and other items in the attic.

If we are talking about the mansard roof of the bath, then everything is different here. In this case, it is necessary to insulate both the floor and the roof slopes. After all, the attic is used as a living room for recreation, which is necessarily insulated and soundproofed. But, with this option, special attention is paid to the vapor barrier layer of the floor.

To determine the choice of material, you need to consider the criteria and requirements for insulation for a bath. It will already be possible to build on this information, determining the type of heat insulator. This is a crucial moment, because if you choose the wrong insulation, then all efforts can be in vain, and the insulation is not so effective.

Consider 6 requirements for insulation that can be used to insulate a bath:

- High temperature resistant.

- The property of repelling moisture without absorbing it.

- Bio-resistant to mold and mildew, does not rot.

- Have low heat conductivity.

- Consist of natural, ecological ingredients.

- Have a long service life.

Since the bath is a specific room, the material must have these properties. After all, the room is characterized by high humidity and high temperatures. Therefore, the insulation must withstand these conditions.

What kind of materials can be considered?

- Basalt wool. Unlike mineral wool, its hygroscopicity is not so pronounced. Although mineral wool does not burn, it loses its properties when wet. And basalt wool does not burn, and does not absorb moisture so well.

- Ecowool is a new bulk material made from waste paper. Thanks to special treatments, it does not burn, rot and does not absorb moisture. Rodents do not eat it. Ideal for insulation.

- PPU (polyurethane foam) is a sprayed material that creates a monolithic structure without seams on the surface. Long-lasting, has the lowest thermal conductivity, moisture-repellent, can be applied to any surface. The mixture adheres well to most materials.

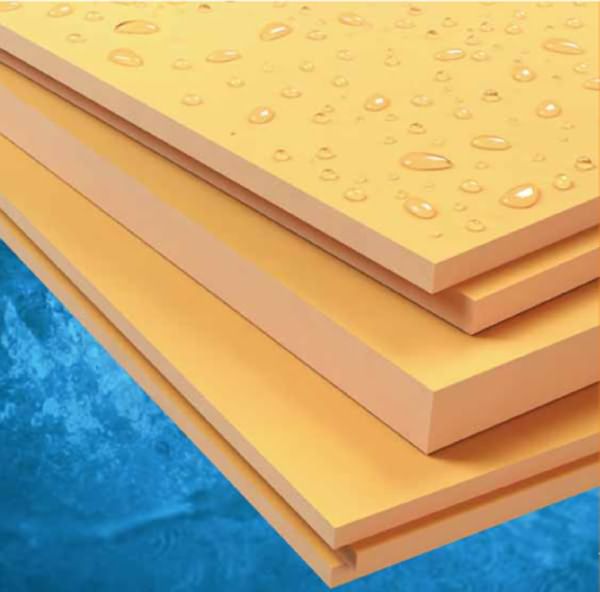

- EPPS (extruded polystyrene foam). A kind of foam. Some people also use polystyrene, but its huge disadvantage is that it melts at elevated temperatures, and rodents eat it perfectly. In this regard, EPS is better, but even at 80 ˚C it begins to melt. They can be used to insulate the ceiling from the outside.

These are the materials used for roof insulation. There are also others, old-fashioned. For example, half a roof is insulated with clay, sawdust, down or expanded clay. These are bulk materials. They are not used as often today.

After you have made your choice of material, you can start solving the question of how to insulate the roof of the bath with your own hands.We will consider two types of insulation and technology for each.

These options are often combined. But, as we said earlier, ceiling insulation is not necessary for a cold roof. You can choose from two types of ceiling insulation:

- Flooring.

- Hemming.

The methods are different, so it is important to consider each separately.

The insulated roof of the bath creates a barrier that prevents warm air from leaving the room. At the same time, thermal insulation should not create conditions for the appearance of mold, mildew and other inconveniences. Consider how to properly insulate the roof of a bath.

We suggest that you familiarize yourself with Correct insulation of the attic and the ceiling of the attic

Before you insulate the roof of the bath with your own hands, you should prepare the materials and tools necessary for work.

For roof insulation, the following materials must be purchased:

- Reiki. Required for the manufacture of battens for laying insulation material.

- Vapor barrier. The best option is an aluminized film.

- Metallic coated tape.

- Insulation.

Required tools:

- Sharpened knife.

- A jigsaw or a hacksaw for wood.

- Bulgarian.

- Construction tape.

- A hammer.

- Construction stapler.

- Screwdriver or screwdriver set.

- Fastening materials (nails, screws, screws).

It is not difficult to prepare everything you need, the main thing is to choose the material that is best in terms of operational properties and easy to install.

In many cases, when creating a roof structure, a serious mistake is made: the differences between a bath and a sauna are not taken into account. The steam room has a higher humidity than a sauna, so moisture and thermal insulation should be made more effective and thorough. Otherwise, steam will not linger in the room.

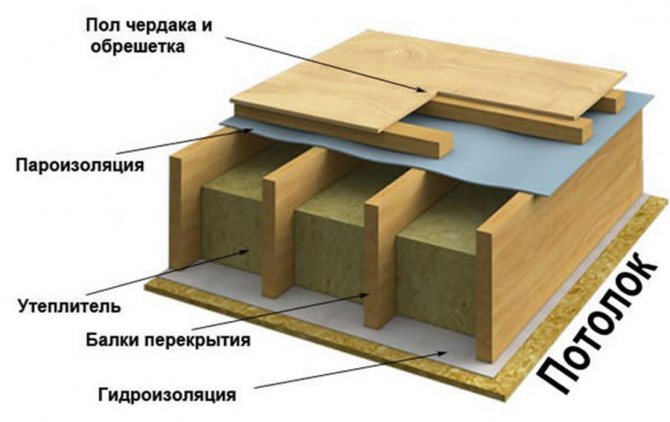

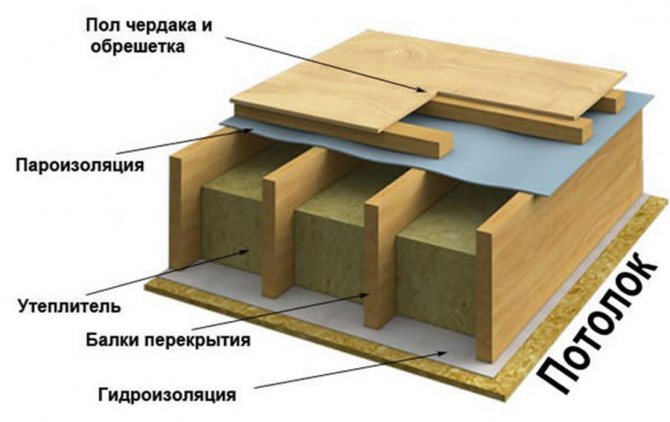

The set of measures for insulating the roof of a bathhouse with your own hands includes:

- device of a vapor barrier layer (in more detail: “Vapor barrier of a bath - the choice of material and its installation”);

- laying insulation;

- organization of waterproofing.

You should immediately choose the most suitable insulation for the roof of the bath. First you need to decide what materials will be used: natural and environmentally friendly or manufactured by industry using modern technologies.

There is a wide variety of roof insulation materials. Penoizol and mineral wool are most often used.

Mineral wool is made from artificial fibers, basalt, limestone and other materials. This insulating material perfectly retains heat in the room, does not support combustion. The disadvantages of this insulation include hygroscopicity.

Ecowool consists of small wood fibers with the addition of antiseptics and fire retardants. The material does not cause any harm to health, has excellent thermal insulation characteristics, and is inexpensive. However, the installation must be carried out using special equipment, and this is not entirely convenient and also increases the cost of thermal insulation.

You can also insulate the roof of the bath with penoizol. The material is of high quality and relatively inexpensive. In addition to the function of insulation, it also has the property of sound insulation. Insulation with penoizol is of the highest quality, since it fills even the most inaccessible places.

For insulation, bulk materials such as expanded clay, sand, sawdust, and earth are used. Expanded clay is most often used among them. While working with it, there are no problems.

From natural insulation, you can take felt, moss and a variety of materials from hemp and flax. They are practically not used as independent insulation, only as additional sealing and improving the efficiency of the main insulation material. For example, with red building moss, you can insulate the space between the crowns and fill up various cracks.As a rule, it is used as a mixture with tow and flax fiber.

However, natural materials can be spoiled by rodents, insects and other pests that inhabit them. Therefore, it is recommended to pre-treat the material with special chemical compounds.

Improved linen and jute based materials are now being produced. The latter can be used for sealing. Jute does not rot, can be easily cut into pieces of the desired size, and is available in various forms.

To carry out roof insulation in a bath, materials in the form of slabs are most convenient, since they are very easy to install. Such materials include expanded polystyrene, mineral wool, foam glass and others. They have soundproofing characteristics. Among the shortcomings, one can note that they are not environmentally friendly. For example, foam at very high temperatures emits substances harmful to the body, therefore, when using it as a heater in a bath, fire safety issues should be carefully considered.

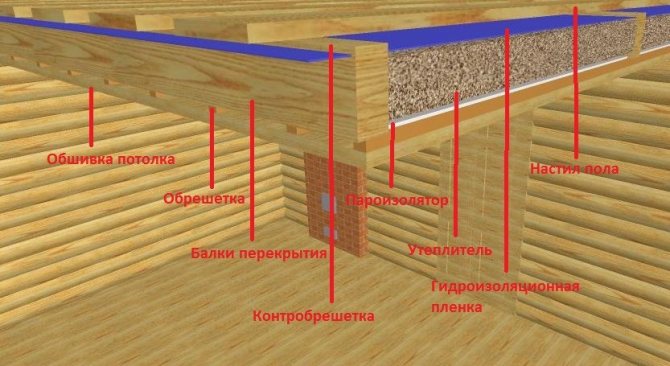

- Cold - for their installation, a crate is stuffed on the rafters, taking into account the roofing, roofing material is attached to it, insulation is performed along the ceiling, laying on it thermal insulation, which is closed from the side of the room with a vapor barrier, from the side of the attic - with a waterproofing membrane;

- insulated - for exploited under-roof spaces - attics, additional elements are added to the previous components: insulation, vapor barrier, waterproofing, counter-lattice - a bar with a section of 40 x 40, 50 x 50, 60 x 60 mm, stuffed onto the rafters along their length. A waterproofing material is laid on the beam, which protects the insulation and the roof from external moisture, then the crate is packed, on which the roofing is attached. The spaces between the rafters are filled with the appropriate insulation, and from the side of the attic it is closed with a vapor barrier layer.

- low weight of the structure;

- savings on the purchase of building materials and installation;

- lack of ice in the cold.

Minvata

Why insulate the ceiling in the bath

If the roof of a building is cold, it means that it is not insulated. The roof space is separated from the street only by a layer of waterproofing and roof elements. This gives certain advantages:

- low weight of the structure;

- savings on the purchase of building materials and installation;

- lack of ice in the cold.

But there are also disadvantages. The biggest one is heat leakage. And as a result, the need to heat the room is much more intensive. If a bathhouse is covered with a cold roof, the situation is aggravated by the presence of moist heated air. It rises to the non-insulated ceiling, cools down and forms abundant condensation, which spoils building structures and drips onto people inside.

The presence of condensation on ceilings and on the ceiling is highly undesirable. Moisture penetrates into the structure and begins to destroy it. Depending on the type of coating, it passes at different speeds, but always fast enough. Fungus and mold, dangerous to humans, appear. The only way to solve all the problems is to insulate the ceiling.

Bath ceiling insulation

Bath ceiling insulation

Planning of works on thermal insulation of the bath roof

Expanded clay - this material is often used for insulation of ceilings. Expanded clay is a lot of small granules, each of which weighs less than a gram. The required layer of expanded clay laying is 20-30 centimeters. Although one granule weighs practically nothing, such a mass of expanded clay in a small section of the ceiling will exert a significant load on the ceiling slabs, which must also be taken into account when designing.

Basic materials for thermal insulation

People's insulation is a mixture of clay, earth, sawdust or straw. The most budgetary option, but unfortunately not the best.A layer of earth (2-3 centimeters) is laid on the ceilings, a layer of sawdust or straw is laid on top of the ground.

Polypropylene is a modern heat-insulating material that has recently replaced mineral wool. It is a very lightweight and comfortable foam structure material, which is specially designed for the insulation of saunas and baths. The material itself keeps heat well, and the foil side of polypropylene reflects thermal radiation in the manner of a mirror. The use of penotherm allows you to reduce the heating of the sauna and bath by 2, or even 3 times.

The inability to properly insulate the surface, as well as ineffectively performed thermal insulation work, will require increased energy consumption during heating. In addition, condensation will settle on the walls and ceiling, which, dripping and flowing, will interfere with enjoying all the benefits of a bath and will gradually damage the roof structure, increasing the threat of fungus.

- with a warm roof;

- with a cold roof, which provides for the installation of heat and waterproofing directly under the roof on the floor.

According to the laws of physics, heated air always rushes upward, and, without encountering obstacles in the form of insulation, it will freely leave the room, reducing energy efficiency.

Ceiling insulation in a bath with a cold roof can be done in two ways:

- from inside the premises - simple and easy-to-implement technologies that are suitable for objects with high ceilings, allowing them to be reduced by 15-20 cm, depending on the insulation and decoration used.

- outside the premises - it is advisable to use it for low buildings, the bearing capacity of the roof of which allows the installation of insulation on the ceiling in the attic space.

- resistance to sudden changes in temperature;

- low absorption and stability during prolonged exposure to a humid environment;

- resistance to fungi, rodents and other biological microorganisms;

- simplicity and high speed of do-it-yourself installation;

- sufficient level of fire safety;

- low thermal conductivity to create and maintain the desired indoor climate as long as possible;

- complete environmental safety of the material.

Consider the most common options for thermal insulation materials used for the ceiling in the bath. This will help determine the better one or the other insulation in each case.

- outside - it is more convenient in design, most effective for a ceiling located under an uninsulated roof, insulation is laid out on the attic floor and closed with a rough or finished floor;

- from the inside - it prolongs the durability of the material, there are no temperature changes, but you will have to "steal" a few centimeters of the bath height, a frame is mounted on the ceiling, after the first layer of vapor barrier is fixed, and a heater is placed in it, then again a vapor barrier and a ceiling covering is attached.

We offer you to familiarize yourself with Protective screens for stoves in a bath

There is an opinion that it is not necessary to insulate the ceiling in a bath with an attic, but it is more necessary to increase the thermal insulation characteristics in it than in a non-insulated attic space, where the heat penetrating outside does not encounter serious obstacles on its way.

With competently performed thermal insulation measures, the time for heating the room is significantly reduced, fuel is saved, heat and steam are saved longer, and the service life of the ceiling increases. Installing thermal insulation in a multi-layer top floor system prevents many types of thermal leakage.

How to insulate

Before laying the thermal insulation layer, a vapor barrier is laid.It prevents the transit of wet vapors and their settling in the insulation layer, because water accumulated in the thermal insulation will increase the weight of the ceiling system and deteriorate the insulation properties.

As a vapor barrier layer, they use: aluminum foil, thickened cardboard impregnated with linseed oil, waxed paper, a special film with lint, membrane material.

For more information on using foil, see this page.

How to insulate

Ceiling insulation in a cold-roofed bath includes 3 stages:

- Thermal insulation.

- Laying a vapor barrier layer.

- Waterproofing.

At the end of the work, a structure is obtained that looks like a puff cake, in which the lowest layer is the ceiling overlap, and above it layers are sequentially arranged: steam, heat and water insulators. Then you can start choosing the necessary building materials.

Minvata

- glass wool;

- slag wool produced from blast furnace waste (slag);

- stone wool, made from melts of basalt and other minerals.

The main advantage of mineral wool, in addition to very low heat conductivity: mold and fungus spores do not develop on it, and insects and rodents bypass it. For a bathhouse located on a land plot, this advantage of mineral wool is very important. It should also be noted that this building material does not change its volume and shape when the ambient temperature changes, does not support combustion, it is very convenient for installation, due to its low weight. Mineral wool is produced in rolls or in the form of rectangular sheets / panels.

There are two disadvantages of mineral wool - this is the high ability of mineral wool to absorb any moisture (especially slag wool) and phenolic compounds contained in it. These 2 drawbacks are easily eliminated: with the help of good hydro and vapor barrier and prevention of contact of air flows and mineral wool, especially in the interior of the bath room.

Expanded clay

This building material is represented by small porous clay pebbles. For all its properties, expanded clay is considered the most suitable heat insulator to insulate the ceiling in a bath with a cold roof.

Thermal insulation of the roof of a bath with expanded clay

This material is safe - it does not support combustion, does not harm people and the environment, does not emit pollutants and substances harmful to humans. Expanded clay - durable, does not collapse under the influence of sun rays. Spores of fungi and bacteria do not develop in this building material, it is inexpensive and its installation is simple.

Also, expanded clay absorbs significantly less water than mineral wool, however, for its installation, it is necessary to use hydro and steam insulators.

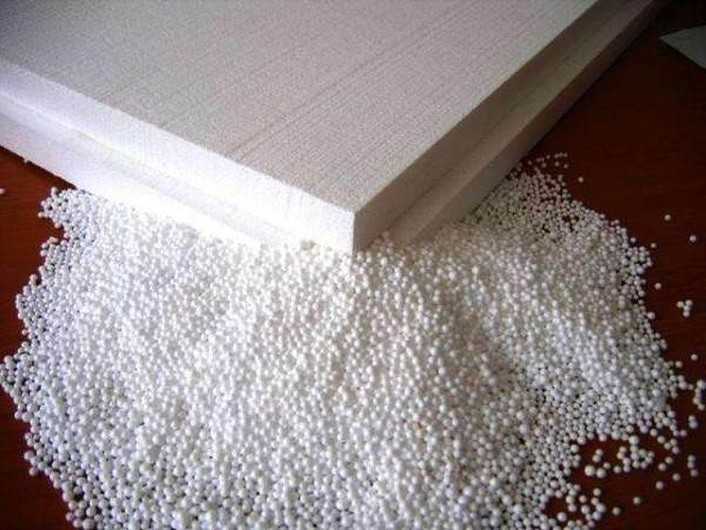

Styrofoam

More recently, this thermal insulator was one of the most popular among all thermal insulation building materials. But, despite its excellent heat-insulating properties, it is impossible to use polystyrene to insulate the roof or ceiling of the bath - this building material is flammable, and when burned, it releases toxic substances that are dangerous to human life. It can also decompose and lose its shape when exposed to high temperatures in the bath.

Ecowool

It is a fibrous natural heat insulator made from cellulose fibers with various additives that give additional properties - resistance to combustion and protect against rodents, microorganisms and insects. Ecowool has a low specific weight and can fill absolutely all gaps and crevices.

As well as expanded clay, ecowool is an environmentally friendly heat insulator that does not emit hazardous substances into the air.

Roof insulation with ecowool

However, this heat insulator has a significant drawback - it absorbs a lot of liquid, which leads to a deterioration in the heat insulating properties. Therefore, when using ecowool, excellent ventilation of the under-roof space and a high-quality layer of waterproofing are required.Another disadvantage of its use is the complexity of installation, with the "wet" method of installation, special equipment is required.

This is a "classic" building material, insulation, which was used before the appearance of foam and mineral wool. Sometimes clay is used instead of Portland cement, and sawdust is replaced with straw.

This is a very cheap and environmentally friendly thermal insulator, but with low thermal insulation characteristics. In addition, the preparation of the mixture is very laborious.

The roof of the bath must be insulated immediately after its installation.

The roof of the bath should not only play the role of reliable protection from external harmful influences, but also create conditions under which the loss of steam and heat in the bath and steam room will be minimal. The conditions will only be achieved if the roof is well and correctly insulated. How to insulate the roof and with what material, it is necessary to plan even at the construction stage of the bath.

Roof insulation is not difficult to do with your own hands.

For a bath in a garden or summer cottage, where in winter the bath is not used, it is enough to lay roofing material under the main roof. Roofing material is installed directly on the crate, under the main roof.

In the bathhouse of a private house and structures with residential attics, it is necessary to thoroughly insulate. Before work, the entire wooden truss system must be treated with antiseptics and fire resistance agents. In this way, you can additionally protect the roof structure from fungi, rot and fire. Only after that, the installation of insulation begins.

Our grandfathers also insulated the roof of the bathhouse with various natural materials: moss, tow, felt or hemp. They are environmentally friendly and keep warm well in the bath. In addition, the price of such heaters is low, and some can even be prepared independently. But there are a number of disadvantages that have had a significant impact on the emergence of modern heaters:

- Rodents love to build nests in natural insulation.

- The material is afraid of moisture and quickly begins to rot.

- Installation is laborious and requires a lot of knowledge and free time.

Ecowool

How to insulate the ceiling of a bath with your own hands

Insulation of the ceiling of the floor type

The plinth ceiling is used in rooms with a small area. Its main difference is the absence of support beams. The ceiling boards are laid directly on top of the wall. This greatly simplifies and reduces the cost of installation, but also gives some restrictions. The structure is not designed for a large mass, so the insulating layer should be light.

Insulation of a floor ceiling

Insulation of a floor ceiling

The installation of thermal insulation is carried out in this way:

- We lay and fix the ceiling strips. If it is assumed that the layer of insulation will be high and free space is needed, we fix the boards below the upper edge of the walls. Or, above the ceiling, we nail small sides along the entire perimeter.

- We carry out vapor barrier. We put the selected material on the boards from the attic... If the coating is foil, the metallized side should be laid down. We put the strips with an overlap of at least 10 cm. Be sure to fix the seams and joints with tape.

- We install thermal insulation. The installation method depends on the type of insulation. Plates are placed one next to the other end-to-end, the roll material is rolled out in strips. Laying is done tightly, there should be no distance between the fragments of the insulation.

- We install waterproofing. A film, membrane or material such as roofing felt is rolled out in strips. We put the panels with an overlap of 10 or 15 cm and be sure to glue all the resulting joints and seams.

Insulation of a floor ceiling

Insulation of a floor ceiling

Finished insulation is covered with boards or plywood sheets.

Warming of a false ceiling

This type of construction is more durable and reliable. It assumes the presence of support beams that fit onto the walls.From below, a ceiling is sewn to these beams, hence the name. From above - the floor of the attic is attached, if it is planned. Thanks to this design sauna heater on the ceiling can be anything. True, the technology for laying it may vary somewhat.

Warming of a false ceiling

Warming of a false ceiling

We will analyze it using the example of mineral wool.

- On top of the beams from the side of the roof, we lay waterproofing. We fix the film to the tree with a stapler. We overlap the strips, overlapping one another by 10 or 15 cm. Carefully glue the joints with tape.

- We lay sheets of plywood or boards on top of the insulation. The resulting flooring can be used as an attic floor.

- From the side of the room, we lay the insulation, placing it between the beams. The number of layers varies, but in any case, one will not be enough. We put the insulator so that the joints of the first layer overlap with strips of material in the second.

- We install the vapor barrier. Cut the strips of film or membrane so that they go over the walls. We unfold the cover with the "breathing" side down and fix it to the beams. We do this very carefully so that there are no gaps.

- On top of the finished insulation, perpendicular to the beams, we mount the slats on which we hem the ceiling.

Insulation laying

Insulation laying

If you need to lay bulk insulation, for example, expanded clay, ecowool, etc., another technology is used. In this case, a rough ceiling is first sewn to the beams. Its slots are sealed, a vapor barrier is installed. Then the insulation is poured, waterproofing is placed. A decorative ceiling covering is mounted on top of the rough ceiling.

Insulation of a panel ceiling

To perform quality insulation of the ceiling in a bath with a cold roof, you can use panels. These are a kind of modules, inside which there is a heater. The ceiling is subsequently assembled from them. This is a more laborious method than all the others.

Bath ceiling insulation

Bath ceiling insulation

Work begins with the manufacture of panel modules:

- We knock down a shield from the boards, the size of which should correspond to the future module. From the inside, we nail the boards, which will act as sides.

- We put a vapor barrier in the resulting box. We spread it along the sides and bottom in stripes with an overlap. We glue the joints. We fix the film with a stapler.

- We install thermal insulation. You can take any, but it is better to choose insulation with a minimum weight. Panels with expanded clay or a mixture of sawdust and cement will turn out to be heavy, which will greatly complicate their installation.

- We put waterproofing on top. The strips are overlapped, the joints are glued. Next, we lay the boards. They will become an attic floor.

Ceiling insulation

Ceiling insulation

The panels prepared in this way remain to be lifted up and put in place. A seal must be placed between them. This can be jute, mineral wool trimmings, or a mixture of sawdust and cement. It is advisable to lay solid boards under the panels, which will become the ceiling in the room. Do the same from the attic side, laying floorboards on top of the panels.

With a cold roof or with an attic - what's the difference

Ecowool

We do it on time or for free. The construction is divided into stages with an agreed delivery date.

"Full construction". All work is done by one company.

Possibility of accepting payments by installments or on credit.

No hidden fees. The price is final at the stage of the contract.

Quality control is carried out at every stage of the construction of the house by our competent services.

Quality construction work thanks to. We have more than 300 successfully completed projects on our account.

Ecowool

Expanded clay

It is a natural bulk material obtained by firing clay shale. The packing density of the material depends on the selected fraction. The smaller it is, the higher the density.Among the main advantages of this insulation is complete environmental safety, as well as resistance to any humidity in the air and temperature extremes. It is non-flammable and odorless, and does not generate dust during operation.

We suggest that you familiarize yourself with Ceilings with expanded clay in a private house and for a bath, what layer of material is needed

Given the structure of this material, expanded clay insulation is carried out only outside the premises. He falls asleep from the side of the attic floor, if the design of the bath provides for such a space.

The technology for performing work with this material provides for the following procedure:

- cleaning the surface from dirt and foreign objects;

- installation of a vapor barrier film, which is attached with a stapler or double-sided tape;

- expanded clay is backfilled with a layer of 15-30 cm;

- from above, the material is covered with a waterproofing film;

- the final stage of such insulation is the installation of the roof or plank floor of the attic.

Among the main disadvantages of the solution to insulate the ceiling in the bath with expanded clay, experts call the inability to perform installation from the inside of the room, as well as use only on flat surfaces or with a minimum slope.

Arrangement of the insulated ceiling

First, let's figure out how the ceiling itself in the bath is arranged. The supporting frame is beams supported on walls made of logs, beams, or on a Mauerlat (if the object is built of bricks). Wooden elements are necessarily treated with antiprenes, antiseptics, beams are wrapped in two layers of roofing material at the junction points with concrete, metal elements.

The ceiling in the steam room section is set up in one of the selected ways:

- Sheathed with boards from the inside, fasteners for floor beams. Then you can plaster the base or fix the planks apart.

- The skull block is mounted on the lower part of the side edges of the beams on both sides. In this case, a roll of wooden planks is laid on top between the load-bearing elements, and in the lamellas it is imperative to cut grooves along the height of the cranial bars in order to maintain the evenness of the ceiling in the same plane with the beams.

- Skull and roll bars can be installed above the side edges of the beams. It should be fixed to the diaphragm bars, and the bottom of the beams should be hemmed with a regular board.

Using mineral wool or expanded clay as insulation, it is necessary to lay out a layer of waterproofing so that it lies above the insulation and protects the materials from condensation from the attic.

What you need to remember when equipping the ceiling in the bath:

Correct insulation of the ceiling in a private house with a cold roof

- The roll-up boards are laid so that there is a gap of 25 mm between them and the girder floor on each side. Such a technical gap is necessary for free expansion, contraction of materials with changes in climate, humidity levels.

- In areas of contact with the chimney through wooden floor structures, the gap must be at least 250 mm. Otherwise, the wood will heat up and may catch fire.

- A vapor barrier membrane that goes around the beams should be laid under the filing or roll-up boards. Layout with an overlap, glue the joints with tape.

- It is necessary to lay thermal insulation in the voids between the supporting elements. The layer thickness should be equal to the beam thickness. It is better to sew up a layer of thermal insulation with a rough floor.

Instead of boards, cement-particle boards or fiberboard are used. The area adjacent to the chimney is necessarily protected with asbestos plates, and the material of the building is treated with antiprenes.

Ecowool

Although this material has not yet become very widespread, it can be used as a modern, high-performance insulation for the ceiling.It consists of the finest cellulose fibers, which are harmless to humans and perfectly perform thermal insulation functions in the room.

The technology of working with this material provides for two methods of application. Dry installation involves laying the material outside with subsequent compaction. In turn, the wet application of ecowool is more effective, but requires special equipment, with the help of which the material is applied under pressure to the insulated surface. Among the main advantages of using this insulating material, experts point out:

- complete environmental safety and the ability to easily endure sudden temperature changes;

- has a long service life and does not lose its qualities during use;

- minimum weight allows installation on surfaces with low load-bearing capacities;

- non-susceptibility to the occurrence of fungi and lack of attractiveness to rodents;

- treatment with fire retardants speaks of increased fire safety and a tendency to self-extinguishing in case of fires.

Mineral wool

When deciding which insulation is better, many opt for this particular insulating material. Building supermarkets offer users three types of this fibrous heat insulator:

- glass wool;

- basalt wool, which includes waste from the mining industry;

- slag wool made from blast furnace melts.

This material has low thermal conductivity and is resistant to fungal growth and other biological organisms. Mineral wool is resistant to sudden changes in temperature and is classified as non-flammable. It comes in the form of slabs or rolls that can be conveniently mounted on any surface.

Thermal insulation of the ceiling is effective, which with the help of this material can be performed both inside and outside the ceiling. In both versions, a vapor barrier must be installed at the bottom of the material, and a hydro-barrier at the top. This will help rid the material of its main disadvantages:

- the ability to absorb and accumulate moisture;

- evaporation of phenols, which may be part of the insulation.

Installation of mineral wool from the inside of the building is carried out on a pre-prepared crate, in the openings of which the material is installed. The frame is most often made of wood, but in some cases a galvanized profile can also be used. The surface of the insulation is closed with a vapor barrier and finishing material.

The technology for installing this insulation from the attic side is the same as from inside the room. The only difference is the lack of lathing, since the laying is done between the lags. In general, mineral wool can be laid on any surface, both in a frame bath and in a permanent brick structure.

Expanded polystyrene

Despite some disadvantages, this material is one of the most common and is excellent for effectively insulating the ceiling of the bath from the outside. It is easy to install, does not absorb moisture and has low thermal conductivity. Low weight and the ability to cut to any required size, allow installation on the surface, without regard to the bearing capacity of the building.

The disadvantage of extruded polystyrene is the risk of emission of harmful particles during combustion. Work with this material is carried out as follows:

- leveling, cleaning and surface preparation;

- laying of vapor barrier material;

- installation of heat-insulating material;

- fixing plates with special plastic dowels;

- insulation of seams between plates;

- screed pouring or laying on top of the thermal insulation layer in the outer part of the ceiling.

Polyurethane foam

This material is one of the answers to the question - how can you insulate the ceiling in a bath.The only limiting factor in its use is the need for specialized equipment for its application, the rental of which can be quite expensive. Among the main advantages of such material are:

- high thermal insulation properties;

- resistance to sudden temperature changes;

- high strength of the coating;

- the ability to work both in a log bath and frame, brick or cinder block buildings.

Materials for hydro and vapor barrier

The vapor barrier of the ceiling in the bath is very important, otherwise the moisture circulating in the room will worsen the properties of the heat insulator and lead to the development of mold and mildew both on the ceiling itself and on the details of the rafter structure. For vapor barrier, special films and coatings are most often used - in particular, with anti-condensation membranes (preferably with a foil layer). At the moment, the leading positions in the market are occupied by Technonikol vapor barriers.

This is also important to know: Roof heating or de-icing

As a waterproofer, you can also use both special films and cheaper building materials - roofing material or thick polyethylene.

Insulation of the ceiling in the steam room

The main function that the ceiling in the steam room should perform is to isolate it from the penetration of steam, which should accumulate in the room and not leave it during operation. For this, two layers of vapor barrier and a layer of insulation are installed from inside the room.

The standard scheme for insulating a steam room is as follows:

- the lower part of the floor beams is sewn up with boards;

- roll-up shields are made. These are structures consisting of two layers of perpendicularly knocked down boards, between which a vapor barrier film is fixed. They should be located loosely to each other with a gap of 5 cm. Wooden surfaces should also be at least 25 cm away from the chimney;

- the wooden surface of the boards is impregnated with special antiseptic compounds;

- insulation is mounted on the shields. It is necessary to isolate all sections of the ceiling;

- then the ceiling of the steam room is upholstered with foil. It increases the vapor barrier function and makes the surface fire resistant;

- the next layer is the finishing layer, which is treated with fire-fighting compounds.

After that, the insulation of the ceiling in the steam room from the inside can be considered complete.

Features of insulation in different rooms

You can make the ceiling warm in a bath, where there is an attic or attic, in different ways. There are some nuances here. The material that will cover the floor of the attic must be breathable, well ventilated, otherwise humid, very warm air will accumulate on the upper floor, because according to the laws of physics, the hot stream rises up. The best material will be mineral wool or basalt wool, which has the properties we need.

Buildings with an attic and an attic

If the bathhouse is on the ground floor, and then the attic room follows, then a floor structure of several layers is used: a layer of foil, then the selected insulation, then steam and hydro insulation. Between the floor covering and the vapor barrier, a crate should be made, leaving free space. The advantage of such a multi-layer construction will be reliability and good ventilation.

If the bath has an attic, then it retains heat, especially when the necessary insulation is observed. Usually, the insulation is laid out on the attic floor and covered with a floor. This method is called “outside insulation”. There is another method as well. You can insulate a bath with an attic from the inside by mounting the frame on the ceiling, placing a layer of vapor barrier and insulation in it, then again vapor barrier and ceiling.

Steam room ceiling

In the room where there is a maximum of steam, it is better to lay 2 layers of vapor barrier material. It is good to use foil, it is more effective. And add insulation.

If you are insulating the ceiling in a steam room, then you need to pay attention to the chimney. It should protrude from the ceiling beams by 20 cm. A frame should be made around the device. Mineral wool insulation is used for insulation. The distance between the frame and the chimney is at least 20 cm.

Competent insulation technique

Under the insulation, it is supposed to lay a layer of insulating material that will keep the heat inside the room. However, only the insulating layer in the bath is not enough. He will not be able to fulfill his task, since it will become saturated with moisture and deteriorate. In order for the insulation to last for a long time, it is required to lay three layers of insulating materials.

The main task of this layer is to prevent fumes from entering the inside of the insulation. All vapors rising from the heated room must be contained. As an insulator for this layer, materials such as glassine or roofing that have been tested over the years can be used. Or more modern geosynthetic coatings, various membranes and thermofol. Well, if the coating is foil, then it can also screen heat, returning it to the room.

The second layer of insulating cake should trap heat without letting it out. A wide variety of materials can be used here. Which one to choose will tell you the budget and your own skills in carrying out construction work. It is important that the insulation is as light as possible (then it will not create an unnecessary load on structures that is resistant to moisture) and non-combustible, as simple and convenient as possible to install.