The principle of operation and functions of automation for solid fuel boilers

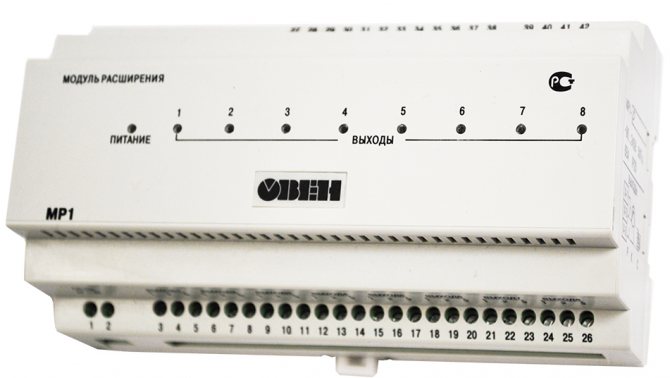

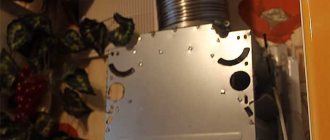

Retrofitted automatic control unit on TT boiler.

Automatic control can be both volatile and non-volatile. In modern solid fuel models, a non-volatile option - a draft regulator - is installed from the factory and works according to the principle of expansion when heated: the temperature-sensitive metal heats up when the temperature in the boiler rises and mechanically covers the blower, reducing the combustion rate (and vice versa).

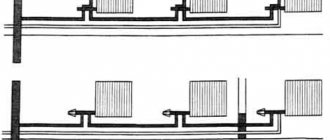

The non-volatile option (requiring connection to the mains) is more efficient and multifunctional. A standard set of automation for solid fuel boilers consists of two main elements:

- fan - installed in the bottom of the boiler, on the door of the air supply (blower) or ash pan, it is used to force air into the combustion chamber. The intensity of combustion depends on the volume of incoming air.

- controller - electronic control unit that sets the fan speed. At maximum speed of rotation, the maximum volume of air is supplied to the combustion chamber and the most intensive combustion is maintained. When minimum temperature requirements are set, the minimum rotation speed of the blower is maintained or it is assumed to be completely stopped.

The controller and fan can be purchased either as a ready-made kit or separately. However, they only work in pairs. Also, most controllers support control of a circulation pump, a smoke exhauster, it is possible to control it using a room thermostat, and organize weather-dependent control. The most functional models have a built-in GSM module.

A ready-made complete set of automation.

As a result, the functions of the automation kit are:

- increasing the efficiency of fuel combustion (boiler efficiency) by controlling the blowing;

- stable maintenance of the set temperature or its change depending on the set settings of the room thermostat;

- automatic ignition (optional, in the presence of an igniter);

- increase in the duration of combustion of one load of fuel.

There is no division by type of fuel used. One set of automation can work with both coal and wood or pellet boilers.

Automatic fuel supply

Separately, it is worth highlighting the automatic fuel supply systems, their work can also be controlled by some of the controller models. The autoloading system is, most often, a bunker with fuel (wood, coal, pellets, peat), installed on the boiler or next to it. Fuel from it can be supplied by means of: embankment (falling under its own weight), auger (gear-screw mechanism), conveyor belt. In any case, the feed system is controlled by the controller.

The use of an automatic feeding system solves the issue of low autonomy, since one loading of the bunker is enough for continuous operation of the boiler for 2-30 days, depending on the volume of the bunker and the intensity of combustion.

Are pellet boilers with automatic fuel supply worth the money?

Gas boiler control unit (controller): what kind of device it is and how does it work

New control devices for heating devices allow users to significantly save time and not experience anxiety during their absence from home.

…

It is enough to purchase a controller of a modern type, and you can forget about constant monitoring of the boiler operation.

What is a gas boiler control unit

The gas boiler control unit (CU) is a device that regulates, optimizes and monitors the operation of the heater with maximum accuracy. This device is equipped with the function of programming preset operating modes, sensors that capture all changes in readings and supply these data to the control unit.

The main functions assigned to the boiler control unit:

- burner operation control;

- gas supply regulation:

- ensuring the supply of heat;

- chimney draft control;

- turn off the gas supply if the maximum temperature is reached;

- turn on the gas supply at the mark at the minimum temperature.

The first pump-water heating device in Russia was tested in the early years of the 19th century when heating the Mikhailovsky Theater in St. Petersburg. After a successful experiment, the systems were installed in the Hermitage, the Mariinsky Theater and the Engineering Institute of Communications.

Benefits of control units

The main advantage is an optimally debugged boiler operating mode, gas flow control and the function of programming the desired mode. This is convenient in the absence of tenants.

Modern controllers completely control the operation of the heater, regulate the heating mode, taking into account the weather conditions.

…

Almost all gas boilers are equipped with an external gas boiler control unit - a microcontroller, if it is not included in the package. This block allows you to set the operating mode for a specific period, for example, a week.

The control unit distributes heat flows to several water systems, which simplifies heating in houses and apartments. For example, correcting the operation of a collector that heats the floor.

Having set all the necessary parameters with an accuracy of a degree, the user can eliminate himself, all errors and problems in the operation of the control unit are highlighted on the display.

The principle of operation of the control unit (controller) for boilers

Controllers are electronic devices that are designed to optimize the control of a gas heating device under changing conditions in the external environment. The capabilities and functions of various devices differ, but they are united by the presence of pressure and temperature sensors.

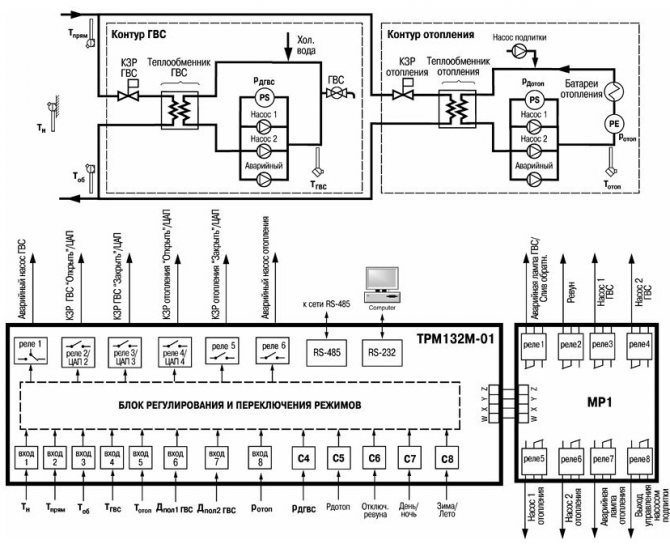

Example of controller wiring diagram

The electronic control unit for the gas boiler (ECU) is responsible for the operation of the gas burner, heating the coolant and the safety of the system as a whole. Its principle of operation is based on the use of an electromagnetic valve.

…

The controllers of the latest heating devices are equipped with an automatic mode function, which allows you to regulate the operation of the device during the week without human intervention.

Connecting the ECU to external temperature sensors and boiler control terminals allows setting up an independent change in the burner operation.

For such a controller, it is necessary to install a voltage stabilizer and an uninterruptible power supply in order to ensure the operation of the boiler in case of voltage surges in the network or in its absence.

The most frequent breakdowns in the control unit

Since the control unit is a whole system, a failure can occur from any deviation of a component of this system. The most common malfunctions and their causes:

- the burner has gone out - air has entered the gas pipeline;

- heating problems - poor gas supply, lack of oxygen;

- overheating of the boiler - contacts are closed, long-term operation at high temperatures, factory defects of sensors;

- breakdown of a pneumatic relay (draft sensor) - incorrect connection, fan breakdown, incorrect chimney system;

- breakdown of the temperature sensor - incorrect connection of contacts, short circuit, overheating of the board;

- breakdown of the pressure switch - low water pressure in the pipes, defect of contacts in the board.

Most of these problems can be easily eliminated, even described in the instructions, but some require specialist intervention.

Do not replace sensors or other parts yourself - it can be dangerous.

Expert Tips: How to Protect Yourself from Controller Damage

Repair of control units for gas boilers is not a frequent phenomenon. However, before making a purchase of equipment from a particular manufacturer, ask if there are service centers in your area.

To protect yourself from troubles at the wrong time, you should inspect the boiler with the help of specialists before and after the heating season. A voltage stabilizer in the network will help protect the electrical controller from pressure surges, thereby protecting the device from damage.

Possible breakdowns of the control unit can be prevented the very first time it is put into operation. The block system is complex and fragile in its own way, the settings can get lost during transportation or assembly of equipment. Therefore, during installation, they first carefully check all the subtleties associated with wiring, water and gas supply, and then check the operation of the control unit sensors.

The latest models of controllers have been brought to almost complete independence. The gas boiler control unit reports faults using indicators, as can be seen in the diagram below.

If you notice any failure, even a minor one, it is better to immediately call a boiler maintenance specialist, this will prevent serious damage and save yourself from more serious problems.

Heating devices are often the subject of experimentation, the result of which is towel dryers, for example. In a 2007 technology competition in the United States, among the various designs, a rack-of-hanger radiator could be seen, designed in the shape of a chair with a heated seat.

Modern home heating equipment is as convenient as possible for users. Having set the necessary parameters for the device, you do not need to constantly monitor its operation, relying on the automatic mode. And timely diagnostics of heating devices will allow you to avoid troubles due to incorrect operation or breakdowns.

An example of installing the controller can be found in the video:

No comments yet

oteple.com

Reviews on the use of household automation kits: advantages and disadvantages

| Benefits | disadvantages |

| Increased efficiency - carried out due to precise adjustment of the blowing, stable heat output throughout the entire combustion (in contrast to the peak values during intensive combustion and the minimum values during the afterburning period with a standard boiler design) | Additional noise - the operation of the fan assumes the presence of additional sounds, however, according to the owners' reviews, the noise is practically inaudible even through the thin walls of the boiler room. |

| Fuel savings - less fuel is required to achieve the same heating capacity, a huge part of the excess heat does not "fly into the chimney" | Additional costs - the cost of a standard set "controller + fan" is on average 7-11 thousand rubles. If desired, a room thermostat (about 1-3 thousand rubles), an auto-feed system (from 10 thousand rubles) |

| Maintaining a constant temperature | Volatility - the boiler will need to be connected to the mains to operate |

| Automatic ignition and extinguishing (optional) | |

| Possibility of external control - by connecting a room thermostat or outdoor sensors, the automation will be guided not by the temperature of the coolant, but by the temperature in the room or outside, which is more efficient and comfortable | |

| Increasing the burning time of one bookmark, the ability to connect an auto-feed system | |

| Safety - most controllers are equipped with protection against overheating or stopping the circulation pump |

Purpose of the controller

This unit belongs to the functionality "smart House"... Allocate the main tasks with which he copes:

- taking readings and smooth functioning of the temperature regime of the liquid in the circuits of hot water supply and heating;

- flow and return fluid temperature control in heating circuits, protection against its overheating;

- determination of pressure in the heating circuit;

- assessment of the condition and location of valves;

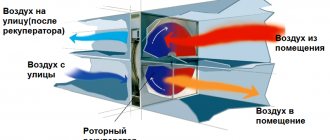

- measurement of the temperature index of the outside air according to the criteria day / night and winter / summer;

- response to a possible emergency and transmission of notification to external signaling;

- receiving data from a PC in order to change the information on the sensors;

- storage of the set parameters in case of power outages;

- generation of control signals elements of hot water supply and heating systems;

- setting the required parameters using the built-in control keyboard;

- protection of received data from external industrial interference;

- display of control results on LCD;

- possibility of manual control the functioning of the system;

- stopping the heating process for the summer period.

The best known manufacturers and models: characteristics and prices

ATOS + WPA 120

One of the best and most common sets of automation for a solid fuel heating boiler.

The ATOS controller has an extremely wide functionality, a considerable number of adjustable operating parameters and an affordable cost. In addition to the standard functions, there is: frost protection for the heating system; notification of temperature drop or overheating, lack of fuel; LED indicators of the circulation pump and fan operation; adjustable hysteresis. It is also known for its reliability for its operational practice. Manufacturer: KOM-STER, Poland.

The blower M + M WPA 120 is also the most common, time-tested Polish model. Designed to work with boilers with a capacity of 25-50 kW. There are other versions on the market for more or less powerful boilers.

Kit cost: RUB 8,900-10,000

Boilers with the duration of burning one fuel tab up to 7 days

COMFORT-ECO + NWS-100

The controller is another Polish model: with almost the same functionality and reliability for an even more modest price. The functionality implies the presence of all safety functions, the ability to connect a room thermostat and outdoor sensors, control of a circulation pump (but not DHW). Differs in the presence of anti-failure filter and overload fuse.

The Nowosolar NWS-100 turbine is a simple Polish aluminum model, one of the most inexpensive on the market. It has an unremarkable standard design and is known for its quality assembly and reliability. The model is designed for installation in boilers with a capacity of 30-50 kW.

Kit cost: RUB 8,500-9,800

Tech ST24 + WPA 120

The controller is a hassle-free, simpler model, equipped with only standard functions: control of the blower fan speed, control of the circulation pump, LED indication of the operation of the elements. Installation of external sensors and automatic feeding systems is also not provided. An excellent choice, but at a price comparable to more functional models. The fan is the most common model already described above.

Kit cost: 9 200-10 500 rubles.

KG Elektronik CS-18S + DP-120

Polish controller KG Elektronik CS-18S is one of the most modern and functional on the market. Differs in the presence of a touch screen control, the ability to control the fan, circulation pump, hot water supply, automatic supply system. The hot water pump can be made a priority; there are also special modes adapted for each type of fuel: wood, wood and coal, coal, sawdust. All existing protective mechanisms are also provided: from overheating and freezing, stopping the circulation pump.

The KG Elektronik CS-18S + DP-120 fan is also one of the best. It features an asynchronous motor and high performance with a relatively low noise level up to 63-65 dB. It has a metal outlet flap that blocks the return flow of exhaust gases.

Kit cost: 11,000-12,500 rubles.

Overview of popular controller models

Having decided on the required parameters of controllers for heating and hot water supply, you can begin to analyze the proposed products. Despite the large assortment, the market is oversaturated with low-quality models. Their actual parameters do not correspond to the declared ones, which subsequently leads to incorrect operation of the heating. Let's look at some really popular and reliable examples of heating controllers.

Honeywell

Honeywell controller

Among the entire product range of the company, the Smile SDC7-21N model occupies a special place. In addition to the affordable price, it is characterized by optimal functionality, which is important for controllers of heating systems.

It is important for the consumer to know the characteristics of the electronic device. It should be noted right away that for optimal operation of the Honeywell controller in the heating system, you will need to purchase additional modules - terminal blocks for connecting system components, a set of temperature sensors, a 3-way mixing valve and actuator. After assembling the controller, it will be possible to control heating and hot water supply according to the following parameters:

- Possibility of regulating the operation of the boiler burner with two-stage control;

- Simultaneous control of 2 cascade boilers. But for this you will need to install an additional temperature sensor at the outlet of the second;

- The controller for the heating system can regulate the direct and mixing circuits depending on the outside and room temperature;

- DHW pump control;

- Possibility of setting a 7-day heating control program.

In the minimum configuration, it will only work as a controller for a heating boiler. But this will not prevent you from purchasing additional modules and upgrading the system over time. The cost of a complete set is about 45 thousand rubles.

It is best to purchase a complete set of equipment, as all of its components are guaranteed to work properly when connected to each other.

Connecting automation to a solid fuel boiler

The installation process begins with a fan, which is installed on the air intake or ash pan door. In many modern solid-fuel models, there are already places and holes for the boost mount. Otherwise, you need to drill the holes yourself and fix the blower fan with four bolts.

Pay attention to the presence of a heat-resistant gasket: it is required, but not available on all fan models. As a result, the turbine must be installed in accordance with the photo below.

A well-installed blower fan.

The second step is the installation and connection of the automation itself to a solid fuel boiler. The controller is installed on top or on the side of the case through the holes provided for this device. Despite the fact that the body of many controllers is made of heat-resistant materials, it is advisable to install the device on the coldest part of the boiler body, if necessary, place a heat-resistant gasket made of non-combustible material.

It remains only to connect all the elements and connect the controller to the mains. A detailed connection diagram is always indicated in the automation manual, for example, this is how the connection diagram to the Komfort ECO control unit looks like:

Automation connection diagram using the example of Komfort ECO.

How to set up

The detailed tuning algorithm also depends on the model and is always described in the instructions. In general terms, setting implies the following procedure:

- Setting the temperature for turning on the circulation pump - allows you to turn on the pump not immediately, but when the coolant is already warming up, it is necessary to prevent the formation of condensation (usually set at 50 ° C).

- Setting the desired temperature for the heating circuit or room air, depending on the model and controls.

- Setting the fan speed (from 1 to 10) or choosing one of the automatic modes for controlling its speed. When manually setting the airflow, it is also necessary to set the parameters of the fan operation time and the frequency of its activation in the combustion support mode.

- Fuel filling and boiler firing up. Monitoring its work and, if necessary, adjusting the parameters.

In some models, it is also possible to program the operation for a day or a week in advance, set a temperature threshold, after which the fan will begin to smoothly reduce speed, etc.

Boilers

GSM module for heating boilers: controller for control

There is nothing surprising in the fact that previously inaccessible technologies are becoming in demand by an increasing number of people and are beginning to penetrate widely into everyday life. Convenience and comfort - that's what in many cases is the determining factor in making a decision. Using the GSM communication standard, heating control is possible from anywhere, which provides additional opportunities when using the heating system of a country house.

Heating system control via mobile phone

In general, how to achieve heating control using the GSM standard is purely intuitive. In fact, GSM is used by many developers to organize remote control. One of the examples of such use of GSM is heating control, which allows remotely:

- receive reports on the room temperature;

- receive notifications about the current state of the equipment;

- change the operating mode of the system by raising or lowering the temperature, including separately in each room.

Heating control is not limited to these functions. In principle, any heating system can be turned into a remote one. To do this, it must have an automatic mode of operation, and a special GSM controller must be connected to it - for heating control and communication with the subscriber.

GSM controller for heating control

Without going into technical details, the GSM heating control module is a highly specialized computer. As a rule, the controller is docked with external sensors and, in addition, it has the ability to change the operating modes of the heating boiler. Well, as a matter of course, it should be in the zone of reliable reception of mobile operators.

The JSM module used for heating can operate in several modes:

- automatic, when all control is carried out according to a given program;

- sms heating control, in this case it is possible to turn off and on the heating by sms, as well as change the operating mode of the system by sending a message;

- work as a center for sending alarm messages about the current state of the house (about gas leaks, breakthrough of the water supply system, etc.);

- remote control of other devices connected to the GSM module heating (performing, for example, such functions as watering, lighting, alarm, etc.).

In fact, the use of the GSM standard, the module for heating is equipped with such a communication channel or it is used as a separate unit, is the basis for remote control of a country house or any other object.

Such a module can act as a kind of multi-channel switch, to which more than one heating system is connected, but besides it, several more that perform other tasks.

GSM heating control module

How does the remote control system work?

The principle of operation of a remotely controlled system is quite simple. For the most part, this happens automatically. According to the signals from the installed sensors, the controller maintains the specified modes according to the available program. At the same time, the system is actually under control, its current state is notified by a kind of GSM alarm system - for heating, water supply, in case of fire, unauthorized entry into the house, etc.

And although the automatic mode of operation of such a system is considered the main one, manual control of the entire process is possible.

It can be either voice or via SMS. In this case, when new data arrives, say about the same room temperature, the controller accepts them for execution and begins to support them in automatic mode.

A controller with a GSM communication channel allows remote control of the heating system. This can be done using a regular mobile phone by sending SMS messages. In addition, the GSM module notifies the owners about the current state of the equipment and emergencies in the house.

Rate the publication:

otoplenie-doma.org

What can be controlled by automation

Automatic systems perform a number of important tasks:

- optimally dose the air supply required for traction;

- control the performance of the heat generator;

- adjust the power of the device depending on weather and temperature factors;

- guarantee a safe operating mode of the hot water installation of the device;

- firewood, pellets, briquettes or coal are served automatically;

- fire up and extinguish the firebox.