Why plaster walls with tile glue

In practice, there are often cases when instead of plastering walls, as well as floors in bathrooms and toilets, they are covered with tile adhesive. Is there any point in performing such work, no one can give an unequivocal answer. The number of different opinions is practically equal to the number of specialists in this issue. For the final clarification of this issue, it is worth considering the varieties and features of existing adhesives and the possibility of their use.

Types and properties of tile adhesive

The assortment of building stores has a large number of varieties of tile glue. The difference between them is in cost and composition. The latter difference can determine their strength, the ability to bond with the surface to be coated, the time it takes for the adhesive layer to dry completely and its viscosity.

According to their composition, all available glue mixtures can be divided into two large groups:

- Dry mixes based on sand or cement;

- Ready-to-use solutions, the preparation of which is carried out on a polymer base.

The first type of glue requires dilution with water without fail. The entire volume of the material obtained should be consumed within a few hours.

The level of its bonding properties is determined by the presence of added plasticizers in the composition. Its features include the following properties:

- If we compare it with cement, then it provides faster setting of the applied mixture, as well as more durable retention of it on the surface to be treated;

- Stable even in the presence of low temperatures and high humidity. This condition is characteristic exclusively for universal species.

- Low degree of fluidity, sufficient level of plasticity.

The above parameters make it clear that this type of mixture by its own indicators is an order of magnitude higher than an ordinary putty. The application of glue in a thick layer exceeding 1 cm should not be allowed due to the possible formation of cracks in the future. The main feature of the work is layer-by-layer application.

The second type of glue does not need to add water. But its cost is much higher than the previous type of mixtures. It can only be used on perfectly processed surfaces, and applied with a thin brush in neat layers.

Types of work in which glue is used

All materials used in construction have their own purpose. For leveling the walls, plaster is most often used together with putty. The first allows you to eliminate the presence of deep irregularities, the second gives the finished surface smoothness.

Carrying out work with its use is carried out in the same way as applying plaster to the walls. With careful and high-quality execution, such a wall or floor covering will serve for a long time. If, when applying such a mixture, all the developed technology is observed, then the result will be a long-lasting high quality plaster.

amstafkomanda.ru

Furnace plastering tools

To do the work, you need to prepare a tool than plaster the oven with your own hands:

- maklovitsa is a large wide brush for wetting the wall surface with different types of oven solutions;

- a plastering hammer will help trim the walls, chop off excess, remove the old stove covering;

- a plumb line is a tool that allows you to assess how vertical the plastered surface is;

- a large container in which a solution for plastering the oven is prepared;

- the rack level is a measuring tool with which they control the installation of beacons in the horizontal plane, so that in the future it is easier to plaster the stoves;

- a bucket with a volume of 1 to 1.5 liters is used to throw mortar onto the plastered surface;

- a trowel or trowel is the most common tool for carrying a small amount of consumable;

- spatulas of different sizes will help to apply a high-quality coating in the right places;

- lighthouses made of galvanized steel are mounted before plastering the surface;

- corners for forming corners, made of fiberglass or aluminum, are used to obtain smooth joints of two perpendicular walls during operation;

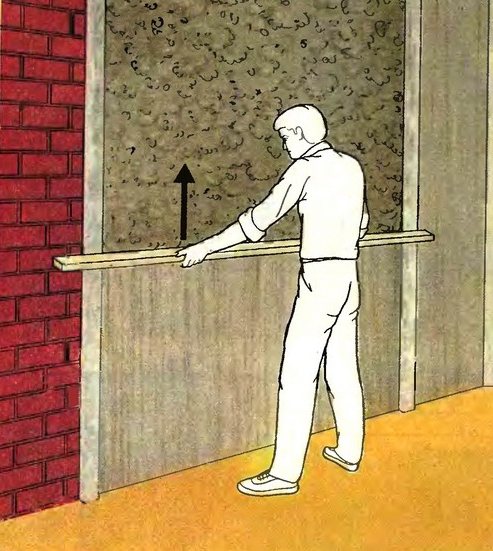

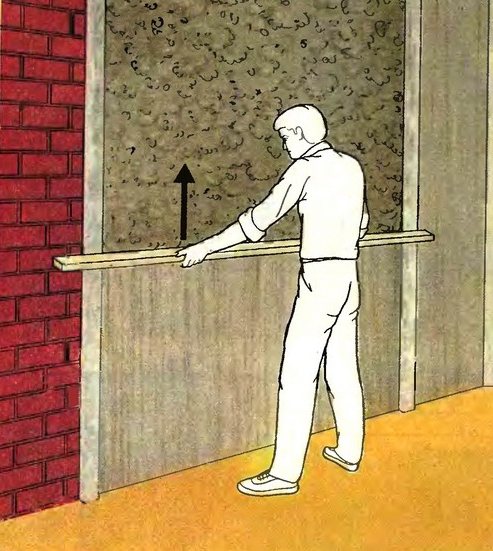

- the rule is a special wooden or aluminum strip for leveling a large surface of the solution between the beacons;

Furnace plastering tools

- a grater and a grater are used for grouting the solution;

- the trowel is similar in design to a trowel, but it is usually made of metal and used for finishing the surface;

- a chisel and a hammer will be needed when removing an old layer of oven plaster;

- a metal bristle brush is required for oven cleaning;

- A mixer is a special tool for a drill or hammer drill used to mix plaster mortar.

With the presented list of tools, you can perform a very high-quality finishing of furnaces.

Preparing a solution that will stick to a hot surface, and not just prevent leaks, is not easy. To this end, it is necessary to determine the quality and content of clay fat in order to accurately calculate the proportions of ingredients in the solution. It is much easier and safer to use a mixture that is already available as a finished product or simply diluted with water.

Special heat-resistant plaster has the following positive qualities.

- Environmentally friendly ingredients. This is very important, because under the influence of high temperature, substances that are harmless in the normal state decompose with the release of toxins.

- High strength and resistance to significant temperature fluctuations, low risk of cracking.

- Durability. Correctly prepared and applied to the surface of the plaster for the stove in the bath will last at least 50 years.

- High elasticity and viscosity. The material can be easily applied to almost any surface.

- Some of the mixtures can also be used for metal surfaces.

Traditional gypsum finishes can degrade at very high temperatures, and the fire resistant topcoat remains intact even when exposed to temperatures up to 650 degrees Celsius. Thanks to this, independent use of the heat-resistant compound becomes much safer and more functional.

Is it possible to plaster with tile glue

Alina asked a question:

If it doesn't bother you. Please give some advice. We still have a whole bag of tile glue. We didn’t calculate when we took it for renovations in the kitchen and bathroom. Can you plaster with tile adhesive? We have nowhere to use it for its intended purpose (in such quantities), but it would be quite enough to plaster the wall of a veranda built of blocks. It needs to be used somewhere before it gets damp. Can they be plastered or just glued tiles? Give answer. I really don't want to re-do the work if it falls off. What size spatula should I use? As I understand it, a notched tile will not work? Or do you need to take two, one large, the other smaller?

Tiler's answer:

Take a closer look at the foam blocks. They do not require large expenditures of plastering materials. And they do not need additional insulation. But this is a small nuance.Let's get back to business.

Isn't it a pity? Plaster is cheaper. I am answering your question. Tile adhesive can of course be used instead of plaster. It holds up better, lies well, but requires subsequent finishing putty. It's about its structure. It is coarser than gypsum mixes. This makes the surface rough to the touch. If you are satisfied, you can skip the finish line. But this is a matter of taste. I'm used to doing my job well. This is a fairly simple process if you follow the sequence of actions step by step.

- If your masonry is uneven (and most likely it is), you will need to do several layers. For better adhesion to the surface, treat with a primer. A solution in several layers has a large mass. This will avoid the risk of repeated repairs.

- After priming, dilute the solution with a consistency close to sour cream. Take a wide molar brush and paint over the entire wall well. After that, leave to dry for a day. Repeat the procedure if necessary. But maybe once will be enough.

- Level the plaster profile. Fasten properly. Take the rule (this is the tool). It will save you time. Of course, you can use a regular spatula, but this is a long and laborious job. At this stage, the plaster is made with tile adhesive. The mortar should be thicker, lay down well, not stick too much to the trowel. Place the mortar on the wall with a trowel. After that, align with the rule. Do this with each section of the wall in order to completely plaster it.

- Leave to dry. After a day, you can shoot a profile. With tile glue, it is necessary to cover up the voids from the profile, using a spatula. Then align the corners.

- The surface is prepared for the application of the filler. But you don't have to.

As you can see, the composition is quite suitable not only for gluing tiles. Compared to conventional gypsum plaster, it is moisture resistant and has improved adhesion. When it comes to tools, you definitely need a medium sized trowel, an angled trowel. Be sure to rule, otherwise your work will be done crookedly. A trowel for laying mortar is also necessary. And the last piece of advice. Since the glue dries quickly. You will have to scrape it off periodically. Do not dilute it in large portions. Do not leave the solution on for long. Otherwise, it will dry out. This will increase the consumption of materials.

izplitki.com

Types of materials

For the interior decoration of a brick bath, you can use several types of materials, here are some of them:

- lining;

- porcelain stoneware;

- ceramic tile;

- PVC panels.

The first has advantages in the form of a pleasant texture and naturalness, as well as the ability to combine the material with other solutions. The disadvantages of the lining are the complexity of maintenance and installation, fragility and a high degree of fire hazard. As for porcelain stoneware and tiles, they are reliable and resistant to chemical attack. Presented for sale in a wide variety of textures and shades.

Tiles and porcelain stoneware are strong and durable, fireproof and environmentally friendly. But when installing such products, the installation rules should be observed, which is not always possible for a novice bricklayer. The main disadvantages can be with

Plaster instead of tile adhesive - Construction portal

Plastering walls is one of the most important processes that is performed before laying tiles.

When repairs are done with their own hands, more than one problematic question arises for home craftsmen. Example - can you plaster the walls in the bathroom before tiling? So plastering the walls is not something that is possible - it is necessary, it will affect the quality of the finishing work. And the tile will take better, and aesthetically everything will be flawless.

Material content:

The content of the article:

Do I need to plaster the walls before laying the tiles

If you were covering the walls in the bathroom, for example, with plastic panels or instead of tiles you decided to use moisture-resistant drywall, you won't need wall plastering. But only before laying the tiles, plaster the surface without fail.

It is imperative to plaster the walls if they are uneven and damaged.

The choice of the mixture will involve two options:

- Gypsum-based mixtures. Not the best option for a bathroom, as gypsum is hygroscopic.

- Cement-based mixtures. And this option is exactly for the bathroom. It is intended for work in rooms with high humidity.

Also, when choosing a solution for wet rooms, make sure that it already contains antibacterial additives and the necessary plasticizers, which will protect against possible cracks on the walls. Sanitizing plasters are considered an excellent option - the walls are waterproofed, the walls are protected from efflorescence and mold stains, the material is environmentally friendly. Sanitizing compounds are intended only for internal work.

Is it possible to put tiles on gypsum plaster

As discussed above, this is undesirable. Yes, in some situations it is possible to apply gypsum plaster, but only if certain conditions are met. And these conditions are not always possible to fulfill.

So, the rules for applying gypsum plaster:

- The plastered walls will be completely finished with ceramic tiles, and the seams will be covered with a special moisture-resistant grout;

- The layer of gypsum plaster will not be more than 2 cm;

- The plastered surface will not be smoothed;

- Before laying the tiles, the surface will need to be treated with a special primer a la Aquastop.

Professionals in most cases do not recommend installing tiles on gypsum plaster

Nevertheless, the use of gypsum plaster is undesirable. Cement is many times better, gypsum plaster is simply not intended for work in the bathroom. Use it only in exceptional cases.

Preparatory work: plastering the walls in the bathroom under the tiles

Thoroughly clean the walls, get rid of the old coating. If there are stains on the walls, they need to be removed. Rust stains can be removed with a mild acid solution. If it seems to you that the walls are too smooth, process them with a notch, they will become rough to the required degree.

Work begins with the application of a starter layer. The first layer is applied with liquid plaster. First, the base is moistened with some water, then the liquid plaster is "pounced" on the walls with a trowel. The starting layer should not be thicker than half a millimeter. And you do not need to smooth and level this layer.

Base and finish layer: plaster under the tiles

The main layer is also called rough. It must be applied over the starter layer, and its thickness is the same - half a centimeter. If a layer of 5 mm, as it seems to you, is not enough, then after the first rough layer has dried, apply the same second one. Only the plaster mixture should be thicker.

Thanks to the plastering of the walls, you can significantly extend the life of the tiles.

When you apply a draft layer, the plastering will take place like this: you throw the mortar on the wall, and level it with a special tool, a long trowel. In this case, movements can be in any direction.

The finishing layer of plaster is applied as follows:

- This layer is very thin, about 2 m;

- It is applied after the base layer has completely dried;

- Before applying this layer, the walls must be moistened with water, then work with the mixture and a spatula.

Then a special trowel evens out the still uncured layer. This is done in a counterclockwise circular motion. So, you were able to plaster the wall with high quality, it remains to wait until it dries and you can lay the tiles.

Types of plaster: is it possible to plaster with tile adhesive

Experts assure that in some cases, subject to certain conditions, the plaster mixture can be replaced with high-quality tile adhesive. It is produced both as a ready-made solution and a dry mixture. Dry mixtures are traditionally diluted with water, and ready-made solutions containing polymers do not require dilution. But polymer compositions for plastering are not suitable, you can use only a dry mixture.

Before plastering the wall with glue, it must be prepared in the same way as in the case of the plaster mixture. The wall must be clean, if necessary - certain areas will have to be putty. Then a primer is applied to the wall in two layers.

Plastering with tile adhesive is recommended if you have the appropriate experience.

Tile adhesive plaster:

- Install beacons using a level and plumb lines;

- After that, you can apply the adhesive itself. The first layer should have the consistency of sour cream.

- Thoroughly trowel the walls with the mixture, trying to fill in all the cracks. This solution will dry out in a day. Then you can plaster further.

- For the second layer, you will need a thicker mixture. At this stage, it is required to achieve the desired layer thickness, therefore, at the end, the walls will be leveled. First, the rule is used, and the corners are conveniently formed with a special spatula.

- After this layer has dried completely, you can also glue the ceramic tiles to the surface.

As you can see, there is nothing hyper-complicated in this method either. The main thing is not to forget that the glue is not needed polymer, but in the form of a dry mixture. And to achieve the correct consistencies, as well as a two-layer application. Then everything will work out.

Plastering walls in the bathroom for tiles (video)

Of course, plastering the wall before cladding is not a desirable process, but an obligatory one. This makes your repairs of high quality and durable. So do not neglect the rules of competent repair, and the next one will not be needed soon.

Good work!

Source: kitchenremont.ru

Plastering walls with an adhesive mixture

Now let's look at how to properly perform plastering in order to end up with high-quality and. Like any other construction work, this procedure is performed step by step.

Preparation of the base

First of all, it is necessary to qualitatively prepare the base. It should be free of crumbling or peeling areas, as well as dirt that impairs adhesion.

This entails using 5 pieces of tile adhesive. This does not provide sufficient adhesive coverage or support for the tile. Do plaster walls need to be primed in front of shingles? When using cement based adhesives, the porous background must be primed with a suitable primer.

How to properly align walls with glue

When using ready-made mixed glue; no primer is required unless the surface is dusty or shiny. But don't sit back yet - risking sounding like a party opera is a fun bit. Now we need to think about adhesives and installation. After all, your new tiles will only look better if they are installed correctly.

In particular, concrete slabs must be cleaned of the oil used in their manufacture. You can use warm water and detergents for this. If there are traces of mold or mildew on the surface, then it must be cleaned with a metal brush.

The final stage of preparation is the application of a primer, which will not only improve the adhesion of materials, but also protect the base from the effects of microorganisms. The solution is applied to the walls in two layers.

In many cases, it makes sense to choose a fast-acting adhesive. However, there are many times when you prefer to use a longer opening time adhesive - when you are applying the floor to a complex pattern like a herringbone or when laying large format tiles on a wall and you want a flawless finish.

Therefore, to remind you that when cladding any floor and many walls, you need to use powdered glue. The exact choice of adhesive will depend on the color of your mortar and the desired flexibility and working time. There are a few more points to keep in mind while we are on the tile adhesive topic.Let's take a closer look.

Installation of beacons

This stage is quite difficult, as it requires extreme accuracy - all guide beacons must be located strictly horizontally, in the same plane. It depends on how smooth the walls turn out to be, i.e. what the plaster is done for.

If you want to install either wet or it is very important that you use flexible tile adhesive. Heating and cooling processes create significant stresses, and the flexible adhesive absorbs them, reducing the likelihood of tiles cracking over time.

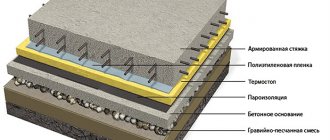

Electric underfloor heating systems consist of small cables that are laid on top of the underfloor layer and then sheathed. However, we do recommend using a self-leveling compound to cover the cables and provide a perfectly flat surface for the tiles - it can be a nightmare rubbing over exposed electrical cables!

As beacons, you should use a special plaster profile, which is fixed on the wall with lumps of gypsum or the same adhesive solution. To adjust the position of the beacon, self-tapping screws can be screwed on both sides. In this case, the profile with its edges "lies" on their hats.

Note! If it is necessary to check their position several times with a building level.

If you're on a time-critical project, our kits are in just 45 minutes. Mix, pour and leave while you have your tea break! Absorbent surfaces such as plaster can suck water out of the tile adhesive, reducing bond strength and working time. Applying a to the substrate in front of the shingles seals the surface, preventing water absorption and increasing bond strength. They are also useful if your substrate is too dusty or too smooth for tiles.

When applying two coats of primer, it is best to apply the first coat vertically and the second horizontally. When it comes to fixing tiles, the old adage that "Failure to prepare preparation for failure" couldn't be more true. Therefore, before opening the first bag or tub of tile adhesive, it is important that your subs are ready, i.e. they are flat, clean and strong enough to take your tiles.

Preparation of the solution

The peculiarity of the preparation of the solution in this case is that it can turn out to be too greasy, which will lead to cracking of the surface. Therefore, sand is usually added to it.

The fat content is determined during its preparation, if the solution sticks strongly to the instrument, then it is necessary to add sand. As a result, the composition should only slightly adhere to the trowel.

Nobody wants uneven floor tiles - it's hard to get the tiles to level and you'll end up losing your glue. Use a 2m straight edge to test how flat your backing is; if there is any deviation of more than 3 mm, then we recommend pouring a layer of self-leveling layer to ensure an even, even surface.

Uneven walls can be made flat using good plastering material or by fitting tile slabs. Dust and dirt can hinder tile adhesion and can get into the grout, so be careful to sweep your substrates in front of the tiles. There is a good reason why so many chicks swear by their Henry Hoover!

Applying the composition to the wall

After preparing the base and performing the mortar, you can proceed directly to plastering.

The instruction looks like this:

- The first layer is applied with a creamy consistency solution using a trowel. The mixture should fill all depressions, cracks and completely cover the surface of the wall. However, the thickness of the first layer should be no more than one centimeter, preferably even slightly less.

- After the first layer has dried, which usually takes a day, you can apply the second layer in the same way. If at the same time the required thickness is achieved, then the leveling of the surface should be performed using a rule that presses against the beacons and stretches from the bottom up.

- The final step is to align the corners. For these purposes, you can use a special angled spatula.

As we touched on above, it is important to consider the weight of the tile and adhesive when facing plaster or drywall walls. Fresh plaster can support 20 kg per square meter and drywall 32 kg per square meter. Typically, you will need up to 2 - 4 kg per square meter for glue and mortar, on top of the weight of the tiles. This weight may vary; small ceramic tiles are generally quite lightweight, but larger porcelain tiles can weigh over 20kg per square meter. Where possible, we advise you to fix wall tiles to walls without a wall, or better.

This completes the plastering procedure. If technological errors are not allowed in the process of its application, then the adhesive plaster will turn out to be quite durable and of high quality.

We use glue instead of plaster: advice from experienced

Today, the choice of building materials in any store is huge. When planning to make repairs, you do not need to look for acquaintances who can sell imported wallpaper or scarce tiles from under the counter. And cement mixes no longer need to be mixed by ourselves.

However, on the forums, the question is often asked: "Is it possible to plaster with tile glue?" As a rule, the reason for such a craving for experimentation is banal economy. Firstly, it happens that tile adhesive costs an order of magnitude cheaper than a plaster composition from a good manufacturer. And secondly, if you are going to glue ceramic tiles in the bathroom and have already purchased the necessary materials with a margin, then plastering the walls with tile adhesive will help solve the problem of unexpectedly revealed surface irregularities.

Is it possible or not?

Manufacturers of adhesives based on Portland cement (for example, Ceresit) themselves sometimes indicate on the packaging the possibility of using glue as a leveling material. Plastering with tile glue, as practice shows, fully justifies itself if the instructions for use are followed (that is, the thickness of the layer must not be exceeded, it is imperative to wait until it dries, it is recommended to apply a primer before and after application).

However, when replacing one material with another, as in the case of using tile adhesive as a plaster, one must also bear in mind the differences in technical characteristics. If we compare, for example, SK KVARTs tile glue and the universal DSP M-150 of the same brand, we will see that the compressive strength of the cement-sand mixture is higher. In addition, dry mix is much cheaper. And, by the way, this universal plaster is used no less often instead of tile glue.

And if you connect?

The inquisitive mind of folk craftsmen went even further: on the net you can also find questions about mixing the above two compositions. According to the experimenters themselves, the resulting material is resistant to cracking and durable. But the exact proportions of adding glue to the plaster are difficult to determine. After all, it is necessary to proceed from the characteristics of this or that glue and plaster mixture. Therefore, we do not recommend carrying out such tests on the walls of your own home. Especially if you are new to decorating.

Types and types of plaster for the oven

This type of mortar should differ from ordinary ones by increased resistance to high temperatures, while maintaining strength and adhesion. Conventional cement mix is destroyed by temperature.

This type of refractory mixture is subdivided into:

- Simple solutions.

- Complex types of mixtures.

To prepare simple plaster, you need to prepare clay and sand. Complex mixtures are kneaded based on 3 or more ingredients:

- asbestos, clay, sand;

- lime, refractory chamotte clay, river sand;

- clay, sand, cement and asbestos;

- gypsum, lime, fiberglass, sand.

Note that asbestos is not recommended for plastering surfaces in residential premises. This material can be added to ovens in a garage or workshop. For living quarters, it is better to use a simple solution or add fiberglass.

We also recommend that you read the article "DIY plaster solution". Here is a complete, comprehensive instruction on how to make the mixture yourself.

Output

Plastering with tile glue is possible taking into account the peculiarities of the glue mixtures, the conditions of the room, a sufficient amount of money that the homeowner is ready to invest in repairs. In some cases, this finish is even more advantageous.

The article addresses a question often asked on the forums: is it possible and how to use tile adhesive as plaster. As you can see, there is nothing impossible in this, in which case it is required, without deviating, to follow the instructions when laying. After all, the task of repair is to protect the wall material from external destructive factors for a long time and, at the same time, to decorate the home according to your taste. Tile adhesive is a material suitable for high-quality protective wall covering.

Recent articles:

- Decorative wet silk plaster

Silk plaster - its application, effects and rules of application. In photographs of expensive interiors on the Internet and ... - Decorative plaster strips Decorative plaster. Views. How to make, apply and moreDecoration of the house with decorative plaster is becoming more and more widespread. ...

- Decorative plaster: what is it? Textured plaster - stunning effects for walls Textured plaster is a decorative type of finish that is used for ...

- Fine-grained plaster Fine-grained decorative plaster

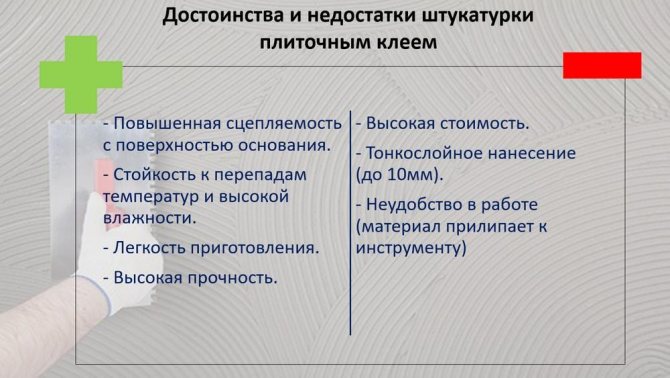

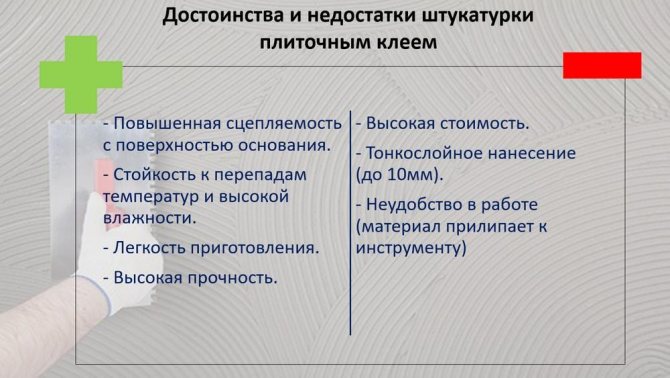

Pros and cons of such a solution

Let's list the advantages that adhesives have:

- increased adhesiveness, mortars adhere well to concrete;

- being thin, adheres to the base without sliding down;

- high plasticity, workability;

- the lifespan allows you to work with the material without haste;

- easy to make, easy to apply;

- environmentally friendly;

- resistance to temperature extremes,

- mechanical strength is comparable to cement plasters;

- quick set of strength;

- the possibility of using for finishing facades;

- long service life.

For some positions, coatings on glue as a plaster outperform gypsum compositions and putties. For example, for a bathroom, these mixtures are irreplaceable material. They do not exfoliate, do not collapse from shock or pressure, do not allow moisture to pass to the walls. While gypsum is afraid of water, easily cracks and bursts upon impact, with multilayer application it is able to move away in layers.

Disadvantages include:

- High price.

- Do not apply adhesive materials with a layer of more than 10 mm. If for leveling the thickness of the coating is required more, then it is necessary to apply the mass several times. Plasters can be applied in layers thicker than 1 cm.

- It is not convenient to work with glue. It is not intended for plastering and sticks to the rule.

What is moisture-resistant plaster for?

Moisture-resistant plaster is designed to protect premises from unnecessary corrosion. Special additives help repel water. This prevents the appearance of rust on the supporting structures, prevents the growth of mold and mildew.

In order for the composition to withstand moisture for many years, it is produced with an average vapor permeability. Thus, the thin layers continue to "breathe" and the natural microclimate in the room is not disturbed.

With all the rest, one should not ignore high-quality ventilation at the place of application.

Plasters of this type are suitable for aggressive internal and external conditions. With their use, bathrooms, baths, basements, pools, basements, utility rooms and toilets without heating are processed.

In addition, moisture-resistant plaster perfectly prepares walls for subsequent finishing. Paint, tiles, decorative materials, drywall adhere to them as firmly as possible. There is huge scope for design with both a thin and a thick finish.