Specifications

If you want to purchase insulation for indoor walls, you may prefer the described underlay. It has an insignificant thickness and weight, it has excellent technical characteristics. You can even use the material as an independent insulation, as well as in tandem with other thermal insulation. Before purchasing, you should familiarize yourself with the technical characteristics, among them thermal conductivity should be highlighted, it is 0.037 W / (m * K). This indicator is relevant for a temperature of +10 ° C. In terms of the level of thermal insulation, one layer of "Polyphoma" can be equated to a half-brick masonry.

Before making repairs to a room, you must take care of soundproofing. If you use "Polyphom", then it will be able to reduce the level of impact noise by 22 dB. This will eliminate extraneous noises and sounds. The material absorbs acoustic and impact noise. This insulation is also good in that it does not absorb moisture, which is due to the closed cellular structure. Does not pass through the layer and water vapor. If you look at the fire safety standards, you can see that it belongs to the G2 flammability class, which indicates that the material burns and ignites quite easily.

Selection and installation recommendations

When choosing a polymer insulation, it is worth knowing that, according to the manufacturing method, they are divided into:

- Uncrosslinked gas-foamed.

- Stitched: chemically and physically.

The simplest is uncrosslinked polyethylene. Its manufacturing technology is the simplest. The strength and thermal insulation properties of this material are 1/4 less and worse than the others.

Both chemically and physically cross-linked polyethylene are similar in their properties, therefore, when buying insulation, you need to focus on:

- Material color (uniform, white or light gray).

- How tightly the paper adheres to the base.

- The presence of a smell (normally it should not be).

- Elasticity (surface quickly recovers after finger pressure).

- Structure.

- Edge decoration.

- Durability and certificate availability.

When choosing a substrate, it should be borne in mind that their main difference from each other is thickness and density. The cork material is denser, therefore, before installation, it does not require a thorough leveling of the walls. Polyfom allows you not to putty the walls thoroughly. And the non-woven material, which is a very durable material, will protect the wallpaper from tearing, and the walls from cracking.

Some tips for laying the material:

- The joints must be treated with a wide masking tape to stabilize the canvas and prevent the formation of hills at the seams.

- It is impossible for the seam of the wallpaper to coincide with the seam of the insulation.

- If there is a suspicion of the presence of a fungus, the necessary antiseptic measures are urgently taken.

These tips will help keep the wallpaper intact and keep the seams from coming apart. It is better to use a primer that contains antiseptic substances. This is necessary to prevent the multiplication of various microorganisms. The finished surface must be dry and smooth.

How to calculate insulation thickness

Insulating walls in an apartment is quite a responsible, but also difficult task.

Therefore, every preparatory step should be taken seriously.

First, it is necessary to measure the wall thickness (D) and determine the conductivity of the material used.

The true resistance to heat transfer must be determined.

The calculation can be performed using the following formula:

R = D / L

Therefore, the difference must be compensated for by thermal insulation material.

To calculate the thickness of the insulation layer, an inverse formula is required: D = L * R

Which insulation material should I choose for the walls inside the dwelling, all personally based on the recommendations of this article.

Video for reference:

It is important to follow all practical advice and use high quality materials.

The main thing is that the insulation returns the warmth and comfort to the home, which is expected to be felt during the construction work.

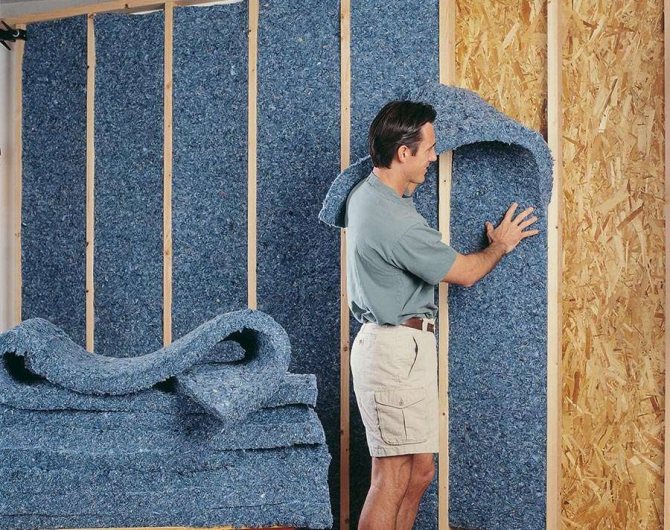

How to insulate the inside of the wall with your own hands with roll insulation

A common insulation is roll. DIY installation technique:

- The surface of the wall must be prepared: cleaned of the old coating, sand bumps and cracks.

- Prime and allow to dry completely. Sometimes it is necessary to repeat the procedure if the wall has large roughness.

- Then measure off the required amount of rolled insulation, be sure to leave a small gap. Cut into equal pieces.

- Prepare the adhesive solution strictly according to the instructions. Some types of Polyphome are self-adhesive.

- Next, you need to glue the insulation, in almost the same way as the wallpaper. It is important to smooth out and eliminate air bubbles.

- The last step is to seal all joints with masking tape.

After finishing the work, you need to wait a while, usually from one to three days. This is indicated in the instructions. Then you can carry out further finishing.

When making repairs in an apartment, you should definitely pay attention to the issue of keeping warm. Modern materials have great functionality, the main thing is to choose the right one and consult with specialists. The most popular are roll and cork insulation. By following the advice, the material is easy to install by yourself.

How to protect yourself from the unpleasant consequences of internal isolation

To avoid condensation and to avoid mold and mildew, effective wall pretreatment methods should be used:

- It is necessary to choose a well-sealed vapor barrier film and carefully monitor its sealing during installation;

- The thermal insulator must have maximum moisture resistance and minimum vapor permeability.

- The insulating layer should be fixed as close to the wall as possible;

- Indoors, you need to reduce humidity with additional ventilation;

- It is necessary to accurately calculate the thickness of the insulating layer;

- Before heating, the surface of the walls of a special solution should be treated against the formation of mold and mildew;

- The heater must not have gaps, cracks or joints;

- The insulating layer can only be used on dry walls.

Why choose "Polyphom"

If repairs are to be made in a cold and damp room, then its decorative finish will imply the need to use insulation under the finishing material. If we are talking about "Polyphome", then it will be able to reduce the coefficient of vapor permeability and heat transfer.

The material does not form condensation, which indicates that there will be no dampness in the room. Such a substrate is simply necessary for corner apartments in which the capabilities of the heating system are limited. The substrate is perfect for those rooms whose walls are in contact with the staircase. From the latter, cold and noise comes inside.

Feedback on operational features

According to consumers, "Polyfom" is quite easy to stick. The process is similar to installing vinyl heavy wallpaper. Such work allows to achieve excellent internal thermal insulation and helps to eliminate dampness, as well as form a soundproof layer and hide small irregularities.

Buyers especially emphasize that the layer thickness is only 5 mm.The material is sold in convenient packages in the form of rolls, the dimensions of which are equal to 0.5 × 14 m. The density of the material is equivalent to 30 kg / m2.

How to avoid mistakes when choosing a heater

As already mentioned, when choosing a heater for walls in an apartment, all the nuances must be taken into account.

The modern construction market offers many materials that can be used to heat walls indoors.

Mineral wool. Many people choose this material because it is easy to assemble in a drywall structure and has a low price.

Unfortunately, it is not suitable for internal insulation as it has a low coefficient of thermal resistance.

Moisture enters the material through the fibers of mineral wool and is retained there, so that mold and fungus form.

Polyfoam (plain and extruded).

It is most suitable for heating walls inside a building because it has the most suitable properties.

It practically does not heat and does not reflect moisture, but also has a low degree of impermeability.

We recommend that you review:

Expanded polystyrene supports high loads and high compression.

It is easy to install because it is lightweight and easy to handle (cut with a knife).

When installing thermal insulation, you cannot use a vapor barrier because it does not absorb water and does not deform over time.

Styrofoam has many advantages, but there are also minor disadvantages.

It is poorly protected from noise and decomposes above 80 ° C. Another disadvantage is that the plates dissolve in organic solvents.

Polyurethane foam is a great option for heating walls in an apartment. It has good thermal conductivity and does not require additional layers of waterproofing.

Polyurethane foam has cells in which air or an inert gas is located.

Thanks to this composition, the insulation is not wet and does not contain moisture.

The insulation layer is easy to install as it does not need to be attached or installed in the frame. Easy to spray on the wall.

In the composition, there are two elements on the surface, which are foam.

After application, the polyurethane foam freezes in a few seconds and creates the perfect insulating layer.

The material firmly holds any surface that forms one whole and does not penetrate into the water in the room.

The coating has no seams, which allows hermetically isolating the entire surface of the wall, regardless of its defects.

Installation is very fast with minimal material consumption, which saves a lot of money.

Additional areas of use

The underlay for wallpaper "Polifom" is used in industry due to its outstanding mechanical characteristics. During operation, the material shows resistance to mechanical stress. It can have different levels of density, which varies from 30 to 180 kg / m2. This makes it possible to use the substrate in shipbuilding, mechanical engineering and aircraft construction. Quite often, such a substrate is also used when installing air conditioning systems.

Feedback on the features of production

"Polyfom" under the wallpaper, reviews of which you can read in the article, is foamed during the manufacturing process by adding chemicals. Cooling down, the material turns into a mass of air bubbles. As buyers emphasize, they do not contact each other and represent a closed cellular structure. Consumers love that this design guarantees low thermal conductivity.

The resistivity of the finished material increases due to the technology of polyethylene crosslinking. The material acquires the ability to withstand the effects of chemicals. "Polyfom" can be operated when exposed to direct sunlight and temperature changes.If you need insulation for the walls inside the room, then you can prefer "Polyfom", which is laminated on both sides with white paper, it is, as it were, welded to the structure, so there is no way to tear it when the material is deformed.