Materials used and methods of sealing

How to seal the sewer pipe? There are several insulating materials with which it will be possible to complete the task.

The most popular ones are:

- silicone based sealants;

- sealing tapes;

- cold welding;

- cement solution with resin tow.

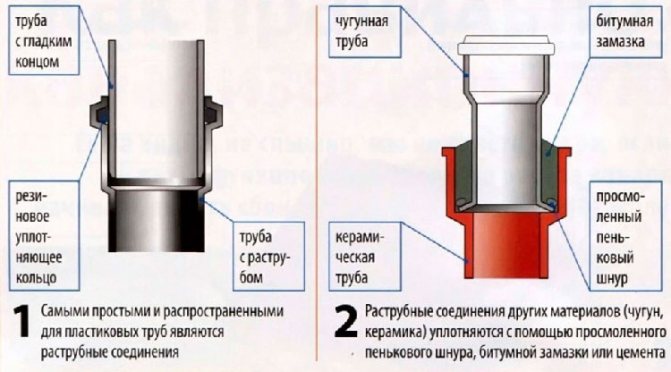

The presented funds are used mainly for cast iron sewers. At the same time, the most popular are silicone-based sealants. But there are special tools designed to insulate pipes from other materials. For example, it is best to use oil-based bitumen compositions or asphalt mastic to seal a ceramic sewage system, they will cope with the task with the highest quality. And to ensure the tightness of socket joints of cast iron pipes, technical sulfur is excellent.

When you install outdoor sewerage, you must also seal the pipes from the inside. In this case, there will be no overflow of the drainage system due to the ingress of groundwater.

There are several ways to seal sewer pipes that are currently in use. Each of them has its own advantages and disadvantages. It is worth making a choice in favor of this or that method based on their characteristics.

Views

The following sealants are available for connecting sewer pipes:

- Special tapes;

- Silicone compounds;

- Technical sulfur;

- Epoxy resin;

- Jute or hemp ropes;

- Portland cement;

- Various mastics.

Self-adhesive tapes are new to the market and are mainly used for plastic pipes for domestic sewage. They are known for their durability and ease of use. In addition, if you have reinforced-plastic pipes installed, these tapes can become additional protection of joints from corrosion processes. They are used not only to protect against leaks at the joints, but also to strengthen turns, plugs for mortise elements, etc.

Photo: self-adhesive aluminum tape

Silicone sealants are the most popular of all craftsmen. They can be matched to the pipe in color. They are used to seal fistulas in plastic and metal pipes, they also help to strengthen the connection, give it rigidity. According to their composition, silicone sealants for sewer pipes are divided into two types:

- Neutral;

- Acidic.

Neutrals are known for their composition, which does not destroy pipes that are afraid of "mineral" components. At the same time, acidic ones are a little cheaper, but they are not used on fragile pipes, as well as those that are destroyed under the influence of certain acids.

Silicone Sealant With Gun

Silicone sealant for external and internal sewer pipes has the following positive qualities: it is a sanitary composition (prevents the formation of mold and rot), protects PVC pipes from leaks, and resembles rubber when solidified. In addition, silicone formulations are known to be quick-setting, i. E. those that harden a few hours after use. Most brands need 4 to 6 hours for full fixation, although there are those that dry out only after a day. Also, silicone can be applied to pipes without disassembling them.

Related videos:

Industrial sulfur is mainly used for cast iron pipes. It is a fairly aggressive but very durable sealant. Moreover, its cost is an order of magnitude lower than self-adhesive tapes and silicone adhesives.Portland cement is also used for the same purposes. It should be noted that the latter is increasingly being replaced by sulfur cement or sulfur concrete. In most cases, these materials are used for sewerage in large industrial facilities or apartment buildings.

Photo: Industrial sulfur sealing compound

Epoxy resin is a special type of sealant that is very widely used not only in sewers, but also in the construction of various structures that require additional impregnation. For example, it is used for fiberglass, as a cold cure, hot cure, and even simple household glue.

In water supply and drainage communications, it is used for ceramic and cast iron pipes, which need a more serious connection than plastic ones. The advantages of epoxy resin include its durability and resistance to more than 50 aggressive chemical compounds. The resin is unstable only against nitric and sulfuric acid, acetone, methyl ethyl ketone and hydrogen peroxide. It is also negatively affected by fluoride gases.

Epoxy resin for sewer pipes

Previously, only resin-treated jute was used to seal various household pipes. They work in the same way as self-adhesive tapes, but differ significantly in the principle of attachment. The fact is that jute is an ordinary twine made in a special way. But if it is treated with certain resinous substances, then it becomes a fairly strong and durable hermetic agent for the bell of sewers made of cast iron or ceramics.

Impregnated jute

The book of Pereshivkin describes in some detail the varieties of mastics for sewer pipes. For different types of pipelines, the following mastics can be used: bitumen-talcum, bitumen-asbestos-polymer, bitumen-rubber, bitumen-polymer, and other types.

Sewer pipe sealing mastic

Sewer pipe silicone sealants

Silicone sealants are mastic coatings that harden when exposed to air. Among the advantages of this material is ease of use. The pipe surface does not need to be primed beforehand.

These sealants are made from silicone rubber with plasticizers. They increase the degree of adhesion, at the same time, the strength of the protective coating increases.

It takes a minimum of time to seal pipes with silicone sealant. Anyone can handle the task. The composition is applied with an assembly gun. If there is no tool, but an urgent need to seal the pipe, then the work can be done with an ordinary hammer. Its handle will act as a piston for supplying the composition. When the mastic dries up, it will reliably protect the joints from leaking. Silicone waterproofing for sewer pipes is simple and quick to apply.

Sealing the joint of cast iron and plastic pipes

When it becomes necessary to repair the old sewage system, in which cast iron pipes were used, many owners try to take advantage of the opportunity and replace the pipes with plastic ones. But in the end, the question arises: how to seal sewer pipes made of different materials?

To perform such an operation, you will have to act according to this algorithm. First, adapters are purchased that are used to connect pipes made of different materials. The cast iron pipe must be thoroughly cleaned, and for better sealing, the socket should be degreased. Its inner cavity is subsequently sealed with a sealant, as is the outer part of the structure. The adapter is arranged in the socket, after which you need to wait until the sealant hardens.Then you can insert the pipes with each other, and they will be properly sealed. After a while, you need to test the sewage system for tightness.

Conclusion

Sealing sewer pipes is not the easiest process, but there is nothing special about it: it is enough to follow the instructions and know what should be the result. It is, of course, important to choose the right sewer pipe sealant. If everything has been done correctly, the drain will work perfectly, providing a high degree of user comfort.

How to seal a pipe with cement mortar and resin tow

It is possible to seal the sewerage system with these materials. The method itself consists in the fact that two-thirds of the depth of the socket is caulked with a resin rope. And the remaining third is filled with cement mortar, mixed in a ratio of one to nine. It is necessary to use a cement composition with the M300 brand.

For people who want to insulate sewer pipe joints at a minimum cost, expanding waterproof cement is the best choice. In this case, the use of resin tow is not required. After all, such cement quickly sets, while expanding. The composition must be prepared right before use by mixing the base with water in a ratio of 1 to 2.5.

What to be guided by when choosing a sealant for sewer pipelines

It is not difficult to buy plumbing sealant for sewage. But, the variety of offers from manufacturers poses a choice problem for buyers. What product should I buy? And what is guided by this will be discussed further.

- Tape plumbing sealant. These building materials are classified as progressive types. A distinctive feature in this case is ease of installation and high efficiency.

- Silicone sanitary sealants. They are based on silicone rubber. The vulcanization process takes place under the influence of moisture in the air.

- Technical sulfur. It is used for cast iron sewer pipes.

- Epoxy resin. The adhesive based on it is the most common home sealant.

- Portland cement. It is used for caulking the socket joints of cast iron sewer pipes.

- Asphalt mastic. Most often it is taken for actions with ceramic sewer lines.

- A strand of resin and a rope. This is usually used to seal cast iron and ceramic pipes.

Self-adhesive tape

Experts consider this material to be one of the best ways to isolate joints. In addition, the self-adhesive tape has dielectric and anti-corrosion properties. One of the main reasons for its popularity is its ease of use.

The material is also called FUM tape. It is used for sealing sewer pipe joints, system corners, tie-ins and plugs. In the first case, it is necessary to first prepare the surface of the products. They need to be degreased, cleaned of dirt and dust, and wait until dry. Pipes must be primed if required.

Types of modern pipe sealants

Modern sealants seal and seal, when connecting joints, the joints of water and sewer pipes, plumbing fixtures (taps, fittings, couplings) and have several of the most common types.

Sealing tape

Fig. 3 Pipe sealing tape

This type of sealant is most suitable for steel pipes for heating or water supply when laid underground or in basements. The tape protects the pipelines from the formation of condensate on the surface of the pipes, and also protects the pipe from corrosion.

The tape consists of a reinforced or aluminum film, to which a bituminous layer is glued, before using it, remove the protective film and press it tightly by hand to the surface of the pipes, winding it overlapping in a spiral onto the treated area.

There are three types of sealing tapes, depending on the conditions of use:

- Summer ones with L marking for insulation in hot water supply systems, heating, heating boilers, in this case the joint is designed for an operating temperature range of up to 300 C.

- Winter ones with Z marking can operate in systems at temperatures from -200 to +100 C.

- Heat-resistant ones with the letter T in the marking can withstand a temperature range of up to 1500 C., they are usually used in pipelines of exhaust systems of automobiles.

Is it possible to properly seal plastic pipes with your own hands?

The answer to this question is simple and unambiguous: yes, even an inexperienced master can handle the problem in question.

Most of the materials used in the format of the situation under consideration (silicone, epoxy resin, sulfur, hemp rope) are budgetary and easy to use. Even if something goes wrong, throwing away some of the silicone and squeezing new material out of the tube will not be difficult. In the same way, the problem is solved with other specified materials.

The process of sealing and sealing in itself is also not difficult, even regardless of whether internal work (in the apartment) or external work is performed outside it.

At the same time, it is worth taking into account that despite the apparent and actual simplicity of the process, it is impossible to treat it with negligence, otherwise the result will be unsatisfactory. A significant feature of the process under consideration is that for its full implementation it does not imply the presence of any complex, expensive tools. All the technician may need is a rag to clean the workpieces and a silicone gun.

Provided that the master paid sufficient attention to the implementation of the process under consideration and performed the work in good faith, and also used high-quality materials, the result will be no less durable than the pipes themselves, the service life of which is most often at least half a century.

As a rule, the whole process of sealing is reduced to placing the seal in a particular state of aggregation in the cavity between the parts, followed by installation. All that is required from the contractor is the correct choice of sealant, taking into account the individual specifics of the intended operation (temperature regime, pressure, location of the structure on the territory of the object or on the street, the correct choice of the acidity of the agent used) and its correct use.

In 99 cases out of 100, the solution of such a task does not cause any difficulties even to those craftsmen who do not have experience in doing such work with their own hands.

Dismantling the cast-iron sewage system and switching to plastic, video 6min 49sec:

An alternative to silicone seals: polyurethane sealants

In recent years, polyurethane sealants have competed with sealing compounds based on organosilicon polymers.

Their advantages:

- practically zero shrinkage during polymerization;

- high self-adhesion;

- resistance to deformation;

- good adhesion to most materials, including sealants of a different composition;

- water, frost and heat resistance;

- durability;

- polymerization under the influence of moisture in the air;

- UV resistance;

- sufficient elasticity when dry;

- low fluidity;

- ease of use.

The disadvantages include the relatively high cost.

Polymerization of polyurethane sealant takes 30-45 minutes

How is sewer pipes sealed with epoxy resin?

Another popular sealant solution is epoxy.The main advantages of such a composition are high efficiency with maximum ease of use and low cost.

The whole process of using the mixture in question is reduced to its preparation (mixing the resin with a warm or cold hardener) and filling the cavity between the parts of the product with it.

How to work with EDP (20, 40) - freezes quickly, stored for a month. Different proportions - experiment see video:

Actions with cast iron pipelines

Cast iron sewer pipe sealant can be used in different ways. For example, a tape.

Cast iron pipe sealing tape is laid for comprehensive protection. Its use makes it possible to finish not only connections, but also inserts, angles of rotation, bends, plugs, etc.

The sealing of cast iron products with tape is performed as follows:

- Preparation - cleaning the areas from dust and drying them.

- The tape is tightly wound around the circumference of the intended joint. At the same time, the formation of irregularities is avoided.

- It is wound in coils, with an overlap.

- Ultimately, the joint ends up under a pair of sealing layers.

IMPORTANT! The tape is afraid of the influence of ultraviolet radiation. For these reasons, if cast iron pipes pass in an open space, it must be covered with an auxiliary protective layer.

Traditional method of sealing

Its essence is as follows. I fill the pipeline by two-thirds with a resinous rope. The remaining space is poured with a thick cement solution.

Often the material is replaced with asbestos cement. But, you can only take it of high quality. The bookmark itself takes a lot of time and effort.

Video

Then they take a special mixture of cement to help. It freezes in a short time, but this is not the most important thing. When dry, this product expands and compresses itself.

For a sanitary sealant, these qualities are called ideal. Another important advantage is called the property not to allow moisture to pass through. Now the liquid will not be able to flow from any pipe not into it.

For the correct application of the self-expanding agent, the workpieces are cemented and the compound is poured with a mixture. When doing this, it is important to maintain the correct ratio of ingredients. It equals five parts water to two parts cement.

Cable duct

Sealing cable ducts requires a special approach. For such tasks, special mastic inserts are used.

Even when laying cable ducts, collapsible mechanical seals made of plastic are used. They are intended to ensure the watertightness of the cable network.

Such systems of collapsible elements are used in wells, collectors and entrances to premises. These sealing devices are easy to install and remove by hand or simple tools.

They are resistant to corrosion and can be reused. The design is completely collapsible and can be used in ducts where cables or protective sleeves already pass in any alignment.

You do not need to use any additional sealants. Components are selected using special tables, which contain all standard sizes.

Video

Also, heat-shrinkable plugs are used to seal cable ducts. They are designed specifically for this job.

They are placed on the outer part of the workpiece with a cable passing through it. They are also placed on pipe-rolling products where there is no cable yet.

Which material is best suited for sealing joints?

The vast majority of specialists who install water pipes and sewerage systems agree that silicone sealants are best suited for processing joints, which were already discussed above.

In simple terms, such a sealant is a universal gasket that can easily take the required diameter, volume, shape, and also easily cope with temperature changes without compromising its own operational parameters.

At the moment, there are varieties of silicone on the market that can withstand temperatures of 260 degrees for a long time.

As a rule, the need for the use of other means for sealing arises when the use of silicone is not possible, for example, when it is necessary to perform a seal without dismantling.