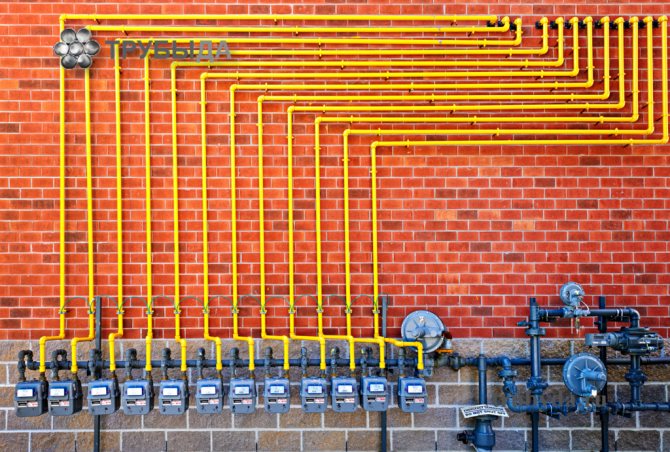

Anyone who builds a private house, or replaces communications in an apartment, is faced with the choice of pipes for a gas pipeline. Many are accustomed to the fact that gas supply systems are made of metal, but in recent years, plastic pipes for gas have become very popular. There are certain GOSTs according to which developers can make gas pipelines from plastic.

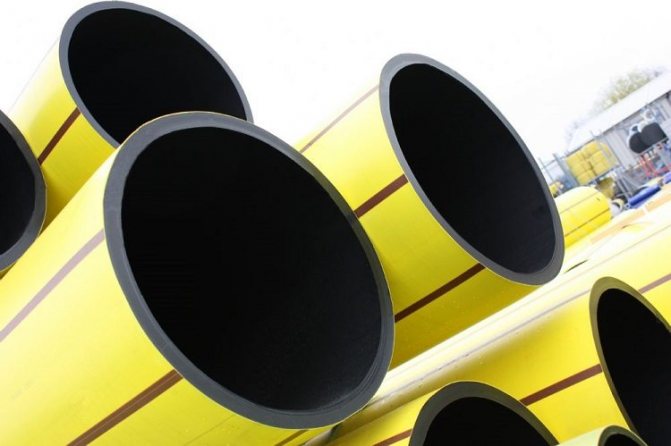

Plastic gas pipes

Can polypropylene pipes be used for gas?

In Western countries, metal pipes are used only for the assembly of industrial pipelines. In the manufacture of water and gas supply systems, plastic elements are used. This is due to the performance characteristics of the material. Gas passes through the plastic pipe without any difficulty. Before putting the gas pipeline into operation, it is necessary to check the tightness of the connections of individual elements in order to prevent violation of the integrity of the system.

To figure out which is better - a pipeline made of metal or plastic, you can compare these two materials. Differences:

- Weight - Plastic pipes weigh less than metal parts. Thanks to this, it is easier to mount them, they do not require additional fasteners on vertical surfaces.

- Versatility - There are more factors to consider when choosing metal pipes than when using plastic parts.

- Price - pipes made of polymers are cheaper than metal ones.

Metal tubes outperform plastic ones in terms of strength, durability, and resistance to mechanical stress.

Are there any disadvantages to plastic pipes?

Now let's talk about the disadvantages of plastic pipes. Unfortunately, plastic pipes are unstable when used in chlorinated water. In those places where water with a high concentration of chlorine is used, they are subjected to various tests for resistance to exposure.

Also, with some heat or light effects, plastic pipes begin to emit more toxic substances. So, for example, PVC as a result of heating emit hydrochloric acid, which, instantly evaporating, causes various severe burns. Also, due to favorable conditions, bacteria form on the inner walls, which can penetrate through pipes into kitchens and other human habitats.

Be careful when buying cheap gas pipes because not all of them can keep your home safe. You should immediately set the maximum value of the temperatures that your pipeline can definitely withstand without various changes in its composition.

The disadvantages of modern plastic pipes limit their scope of application, however, in the gas sector, there are fewer problems with such pipes. This is due to the chemically inactive gases flowing through the pipes and the certain properties of gas pipes, which make it possible to build gas pipelines that are ready to serve for decades. Gas pipes will serve you for a long time if they are in your house in conditions isolated from light and heat.

Characteristics

The technical characteristics of the material determine the scope of its application. In the manufacture of a gas pipeline, you can use different types of plastic pipes. Each of them has its own technical characteristics.

Parameters of metal-plastic:

- High chemical resistance.

- The material is not subject to oxidation.

- The maximum temperature of the coolant is up to 95 degrees.

- The maximum allowable pressure is up to 25 bar. If the temperature is high, the allowable pressure is reduced to 10 bar.

- The thickness of the metal layer between the plastic is up to 0.3 mm.

Polyethylene characteristics:

- the outer diameter of the tubes is 10–110 mm;

- the maximum temperature of the coolant is up to 95 degrees;

- at high temperatures, the maximum pressure is up to 10 bar.

Polypropylene parameters:

- the maximum temperature of the coolant is 90 degrees;

- allowable pressure at maximum temperature - up to 10 bar.

Polypropylene pipes can withstand short-term overheating up to 110 degrees.

Diameter of plastic pipes

Laying methods

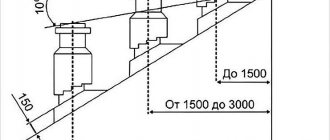

The technical characteristics of the gas pipeline are regulated by the corresponding GOST. The material is selected on the basis of the category of the system, that is, the value of the supply pressure, and the method of installation: underground, aboveground or installation inside a building.

- Underground is the safest, especially when it comes to high pressure lines. Depending on the class of the transmitted gas mixture, laying is carried out either below the freezing level of the soil - wet gas, or from 0.8 m to the ground level - dry gas.

- Above ground - implemented with unavoidable obstacles: residential buildings, ravines, rivers, canals, and so on. This method of installation is allowed on the territory of factories.

- Gas pipeline in the house - the installation of the riser, like the gas pipe in the apartment, is carried out only in an open way. It is allowed to place communications in the grooves, but only if they are interrupted by easily removable shields. Easy and quick access to any part of the system is a prerequisite for safety.

Stamps

For the manufacture of pipelines, polypropylene or polyethylene is often used. These types of polymers are labeled by manufacturers depending on their technical characteristics.

Polyethylene marking:

- PE-80 - indicated by a yellow stripe;

- PE-100 - marked with an orange stripe.

Polypropylene marking:

- PN10 - withstand pressure up to 10 atmospheres. Suitable for the manufacture of cold water pipelines due to the maximum allowable temperature of 45 degrees Celsius.

- PN16 - the maximum allowable pressure is 16 atmospheres. The operating temperature of the coolant should not exceed 60 degrees.

- PN20 - pipes with this marking can withstand pressures up to 20 atmospheres. They are suitable for assembling heating circuits, cold and hot water supply systems.

- PN25 - products made of this material can withstand pressure up to 25 atmospheres, temperatures up to 95 degrees. They are considered the best in the manufacture of pipelines for heating, central water supply.

Additionally, the SDR parameter is indicated on polyethylene pipes. It means the ratio between the wall thickness of the tube, the diameter. The lower this parameter, the greater the wall thickness. The thicker the walls of the parts, the more pressure they withstand during operation.

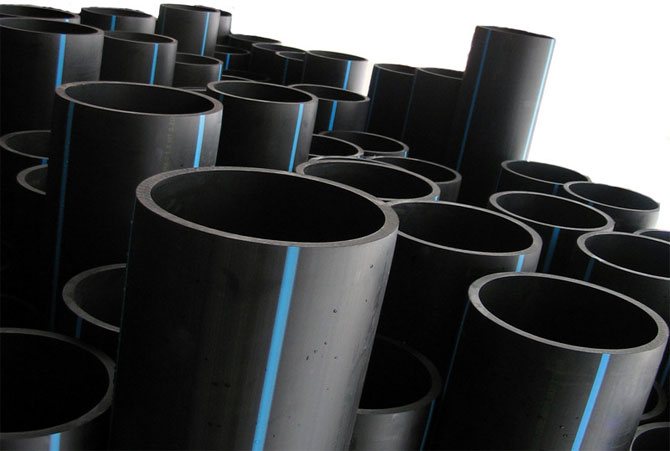

Views

Different types of plastic are used in the manufacture. Each of them has differences in technical characteristics, installation features:

- PVC. Parts made from this material are popular due to their low price, but this type of polymer has one significant drawback that narrows the scope of its application. During operation, this material emits chloroethylene, a poisonous substance. Because of this, it cannot be used for water supply pipelines.

- Polyethylene pipes. They are used to manufacture water supply and gas supply lines. During operation, this material does not emit harmful components, but to maintain technical characteristics, the tubes must be additionally insulated.

- Reinforced tubes. The reinforcing layer can be made of aluminum foil or fiberglass. Thanks to additional reinforcement, the scope of application of parts is expanding.

Polypropylene pipes are also used for carrying out the mains.

Polypropylene gas pipe

Hose connections

To perform gas distribution, you can use not only pipes, but also rubber hoses.but these should be special double-layer hoses made of vulcanized rubber

... There should be a textile reinforcement between their layers. These hoses are used when connecting a torch or torch to gas cylinders.

Fittings of the required diameter are used as fittings connecting the gas hoses. The hose must be pulled onto the fitting by applying force and secured with an aluminum clamp.

To facilitate the assembly of the gas line, made with a hose, grease must be applied to them before connecting the hoses. The same substance will seal the joint.

In the process of connecting the reducer to the gas cylinder, a connection consisting of a union nut and a gasket is used. As a rule, in this case, a gasket made of fluoroplastic is used. If the latter is lost or destroyed, vulcanized rubber can be used instead.

Advantages and disadvantages

Benefits:

- Resistant to prolonged exposure to gas.

- The service life is about 100 years if the pipeline is not overloaded.

- High rate of flexibility. Due to this, it is possible to manufacture lines of complex configuration.

- Light weight of individual elements.

- Sediment does not accumulate on the smooth walls of the product.

- The material is not susceptible to rust formation.

Disadvantages:

- Not resistant to high temperatures.

- Do not install plastic pipelines outdoors, as the material loses its technical characteristics in the cold.

- When heated strongly, the material expands. Because of this, expansion joints must be installed in order to increase the strength of the joints, individual sections of the pipeline.

- Low resistance to UV rays.

If the pipeline is not overloaded, it will not break down, it will withstand decades of active operation.

Ways of connecting elements of communication systems

Install plastic piping underground or in another environment (hidden method). Pipes are connected mainly by welding.

Welding of plastic pipes is carried out using a special welding machine, its type depends on the chosen welding method

There are three main welding methods:

- Electrofusion. Plastic pipe for gas melts under the influence of current and is connected to another with a fitting. This technique is used for polypropylene and polyethylene gas communications.

- Butykova. In this way, a plastic pipe of all types with a diameter of 5 to 16 millimeters is connected.

- Vrastrub. This is a type of welding designed mainly for the repair and installation of sewerage and water supply systems. They are connected to pipes with a diameter of 15 to 90 millimeters.

As for the plastic pipes for gas in a private house made of polyvinyl chloride, they are connected to each other with glue. You should not be skeptical about this type of fastening, since modern technologies make it possible to make durable glue that provides a strong connection for several decades. This method is more convenient and does not require special equipment, providing special conditions for the soldering process.

Installation

When installing plastic gas pipes, you need to take into account a number of nuances:

- Due to thermal expansion, the location of the expansion joints must be carefully selected.

- Avoid many bends, joints of individual elements.

- Lay pipes away from open flames.

- If it is necessary to lay the pipeline underground, it is advisable to make additional insulation. For this, you can use a concrete channel or an additional plastic pipe.

- When dismantling an old system, you need to make a line from one material. This will allow achieving a high strength index, maximum service life.

- It is advisable to remove pipes from an open place due to the low resistance of the material to mechanical stress.

- Fasteners to the pipeline on vertical surfaces must be installed no further than 2 meters from each other.

To create sealed connections, a special soldering iron is required. In its kit there are nozzles of different diameters on which pipes, couplings, shut-off valves are put on. After heating, the parts are joined together. It remains to wait for the plastic to cool down, perform a test run of the system. During the check, you need to carefully inspect the joints of the individual elements of the pipeline for leaks.

People are used to seeing that gas pipelines are made of metal, but this material is gradually giving way to plastic. Polyethylene, polypropylene pipes are slightly inferior to metal in terms of technical characteristics, but are cheaper.

Output

Many homeowners cannot imagine how they would live without gas. However, his supply is not always able to satisfy all the needs of homeowners. Often there is a desire to change it, for example, when the gas pipe behind the refrigerator does not provide its normal service.

All this can be done, but only on one condition - all work must be carried out by an organization that has the necessary licenses. The video in this article will help you find additional information on this topic.

Did you like the article? Subscribe to our channel Yandex.Zen