Home »Heating and water supply» Gas water heaters »What are the advantages of a gas water heater with a closed firebox?

Heating technology is constantly improving. Due to this, new modifications of instantaneous water heaters have been on sale for decades. Currently, a gas water heater with a closed combustion chamber is in great demand among consumers. It has the best safety and environmental performance in comparison with its counterpart equipped with an open firebox.

…

- 1 The principle of operation of a turbocharged column

- 2 What is the difference between a speaker with a closed chamber?

- 3 Pros and cons of turbocharged speakers

What are the advantages of a gas water heater with a closed firebox?

Heating technology is constantly improving. Due to this, new modifications of instantaneous water heaters have been on sale for decades. Currently, a gas water heater with a closed combustion chamber is in great demand among consumers. It has the best safety and environmental performance in comparison with its counterpart equipped with an open firebox.

The principle of operation of the turbocharged column

The principle of operation for all water heaters is the same - when you open the hot tap on the mixer in the device, the burner ignites from the pressure of the flow and begins to heat the water in the heat exchanger. The difference between the work of a gas water heater with a closed chamber is as follows:

- when the column is in standby mode, the burner igniter does not burn;

- when the DHW tap is opened, the flow sensor is triggered, the membrane bends and the gas valve opens the flow of fuel to the burner;

- sparking occurs at the command of the controller; after the flame has appeared, the sensor detects its presence, and the sparking stops;

- after the appearance of a flame, a fan turns on, which draws smoke into the chimney;

- the temperature of the coolant is maintained by the column automatics at a given level; so that the liquid does not overheat, the modulating burner reduces the combustion intensity.

Due to the design, the efficiency of devices with a closed chamber is higher than that of analogs with an open firebox. For the first, the indicator is 88-95%, for the second - 80-88%. Efficiency is achieved in the following ways:

- due to precise dosing of the required volume of air and fuel;

- flame modulation maintains the set temperature without consuming excess fuel;

- the air coming from the street to the burner is preheated in the coaxial pipe from the heat of the outgoing smoke.

The use of a coaxial chimney makes it possible to return some of the heat that goes away with the smoke.

Read here how to connect the gas column duct?

The safety system of the device with a closed firebox includes the following elements:

- flame sensor;

- chimney draft sensors;

- temperature sensors;

- automatic gas valve that controls the fuel pressure at the inlet;

- safety water valve that records the working water pressure.

Automation stops the operation of the device in the following situations:

- power outages;

- the pressure in the water supply system exceeds 10 bar;

- the burner has gone out;

- the controller is out of order;

- the boundary temperature of the coolant was exceeded.

Some models are equipped with the function of cooling the heat exchanger with a fan if the maximum possible water temperature is exceeded.

Many turbocharged models have an anti-freeze function for the heat exchanger.It works according to the following principle: if the room temperature drops below 0, the automation will turn on the electric heating element, which heats the heat exchanger to prevent water from freezing. "Anti-freezing" will prevent damage to expensive equipment in case of shutdown of the heating system in winter.

Types of boilers

Storage water heaters are electric and gas... Both types are very similar in principle of operation and internal structure. However, some indicators still differ. Consider the advantages and disadvantages of a gas boiler over an electric one.

- Higher efficiency. Gas storage devices heat water several times faster than electric ones.

- Gas boilers are slightly cheaper.

- Cheap operation. Natural gas is an inexpensive fuel, which is not the case with electricity.

Disadvantages:

- Safety. A gas leak, although unlikely, is, however, an extremely undesirable and dangerous phenomenon.

- The process of installing a gas boiler is much more troublesome and costly.

What is the difference between a speaker with a closed chamber?

For water heaters with an open hearth, combustion air is taken from the room in which the device is located. And the flue gases leave through the chimney. In turbocharged models, oxygen is forced from the street using a fan through a coaxial chimney. With the help of the same system, smoke is discharged into the street.

The coaxial chimney, which is connected to a turbocharged column, has a design of two channels of different diameters, which are inserted into one another. Through the inner pipe, the combustion products go out into the street, and through the outside air it enters the burner.

Pros and cons of turbocharged speakers

The installation of a gas water heater with a closed combustion chamber is easier than an analogue with an open firebox. In addition, the installation of this device requires compliance with a smaller number of fire and building codes. Therefore, turbocharged appliances are mainly installed in apartments. After all, not every apartment meets all safety requirements and has good ventilation.

Turbocharged geysers have a lot of advantages:

- Good performance.

- Tightness - a closed chamber prevents flue gases from entering the room.

- Convenience of placement and operation.

- High automation to ensure safe and economical operation of the column without user intervention.

There are devices with a closed firebox and certain disadvantages that should be considered when buying:

- High price.

- Dependence on electricity.

- Can only be repaired by a service center.

If power outages in your area are rare and there is a service center for gas water heaters within reach, it is better to purchase a turbocharged model. Its price will quickly pay off due to gas savings, and the precise operation of the automation will delight users with a high level of comfort.

Most popular models

The best gas water heater is an apparatus that is praised not by sellers and manufacturers, but by consumers. Therefore, before buying a gas instantaneous water heater, we strongly recommend reading reviews and paying attention to the most popular models. Let's take a look at which columns are the most popular buyers.

This column of the Russian company Neva received quite high user ratings. The device has a capacity of 11 l / min and a power of 21 kW. The column is equipped with an open combustion chamber, an electric ignition system, indicators for switching on and heating, as well as a thermometer. Gas control is also provided. For its operation, the column requires batteries, from which the ignition system works. The design of the device is very simple, and the price will delight every customer.

The water heater has received many user reviews, both positive and negative. The number of positive reviews exceeds the number of negative reviews, which is already a big plus. Among the advantages we can include the undoubted simplicity of the model, ease of temperature control and the presence of a thermometer. Of the minuses - a rather weak heat exchanger and poor performance at low water pressure. But in general, this is a decent device from the budget segment.

This is one of the best gas water heaters from a renowned manufacturer. Her reviews are mostly positive - you can safely regard her as the best choice. Buyers praise the device for its stable operation at reduced water pressure and ease of adjustment. Also, users note the presence of such a useful option as monitoring the status of the batteries. The appearance of the device is also pleasing - you can immediately see that this is a completely modern gas flowing water heater.

Column Electrolux GWH 265 ERN Nano Plus has a power of 20 kW and a productivity of 10 l / min. It is equipped with an open combustion chamber, a pleasant control panel with an informative display, a thermometer, and numerous security systems. The support of the heating temperature at a given level is also implemented. The ignition system is electric and runs on batteries. The minimum inlet pressure is 0.15 atm.

The best gas water heater from Bosch according to users. Anyway, she's very popular. If we compare it with other models, then we can note the efficiency of the device - with a capacity of 10 l / min, its power is 17.4 kW. There is no electric ignition here, but there is a simple piezoelectric ignition. It instantly ignites the burner, saving users from loud popping when the batteries are dead. There is no flame modulation on board, so households will have to periodically adjust the heating temperature.

The reviews about the device are mostly positive - more than 70% of them. Therefore, it is not surprising that the column has gained such high popularity. It is difficult to identify critical breakdowns, since there are very few of them. Among the positive features are reliable start-up under reduced water pressure and the presence of automatic temperature maintenance.

Characteristics of a geyser with a closed combustion chamber

Unstable DHW (hot water supply) is gradually becoming a thing of the past, and in its place are models of new developments of water heaters operating on natural gas. An acceptable option for both apartments and private houses with no chimney duct is a gas water heater with a closed combustion chamber. This modern device is also called a turbocharged or non-chimney flow-through, since it does not need a chimney to eliminate exhaust gases.

Differences between a turbocharged device and a conventional one

An important design feature of the device is a closed chamber, into which air from the street enters with the help of a fan (turbine). Conventional water heaters use room air during burner operation through the opening located at the bottom of the column.

Any device that runs on gas emits toxic substances that must be removed to the outside. The turbo column is no exception, only here, instead of the usual chimney, a horizontal pipe (coaxial) is used, through a hole in the wall leading out into the street. Gas water heater with a closed combustion chamber has a few more features:

- for complete combustion of gas, the turbine delivers street air using a coaxial double-walled (double-circuit) chimney, through which toxic gases are discharged to the outside;

- the device of the apparatus is equipped with multi-stage and modulating burners that can change the power and intensity of heating;

- there is no constantly burning igniter, piezo ignition button or conventional batteries to start the process of heating water;

- the turbocharged column fully works in automatic mode from the moment of ignition until it is turned off;

- the electronic unit (controller) regulates the air and gas consumption in an optimal ratio with the corresponding heating mode;

- smokeless devices operate from the mains.

Typically pressurized gas water heaters with a coaxial chimney are equipped with an electric ignition system with electrodes to generate a spark. But in some types of columns, a mechanical hydrogenerator is involved, which generates energy from a moving water stream. Based on the features of the devices, it can be seen that they are endowed with many functions that increase the comfort and safety of operation.

How to install? - it's worth thinking about

Installation instructions for electric, gas or combined boilers have a number of technical differences. As well as a number of differences in the requirements for the premises where they are planned to be installed.

Depending on the design and installation option, storage heaters are installed either on the wall or on the base of the floor. In this case, it is important to take into account the type of piping, that is, on which side the fittings for connecting the pipelines are located. Distinguish between: top, bottom, side connection (left or right).

When positioning the boiler, it should be positioned so that it is easy to maintain. If this is a wall option, then fasteners are usually included in the kit. In this case, it is important to pay attention to what material the wall is made of, so that the installation of the anchor or other fasteners has a reliable fixation.

If the device has a display, control knobs or thermometer on the case, it is also important to pay attention to this during placement for better visualization of parameters and access to control.

All taps, connections, filters should be easily accessible for maintenance and replacement of seals.

Some models have a protective anode with periodic replacement from several months to several years (installed by the manufacturer); access is also required to its location.

In addition to all of the above, storage heaters must be equipped with a safety group and an expansion tank (receiver). They also need to plan a place.

Installation of an electric water heater

No special requirements for the premises, or any permits for the installation of an electric storage heater are required. It is important to observe the technical points that are detailed in the installation instructions for this device.

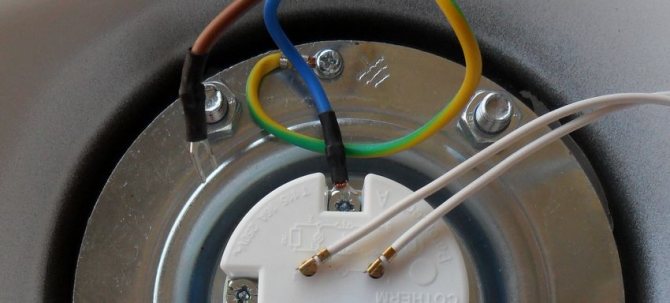

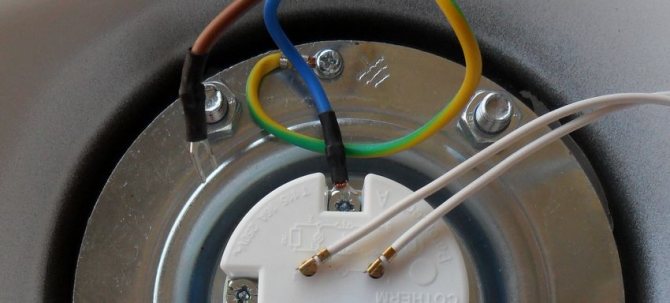

When connecting this type of water heater, it is important to supply it with the required amount of electrical energy. Correctly select the cross-section of the conductors of the wires and provide the necessary protection against electric leaks, which will protect against electric shock and fire in the event of a short circuit. In this case, a residual current device (RCD) is used, while the presence of a grounding conductor is important. When making a choice, please note: some models already include an RCD.

Installation of a gas storage water heater

Installing a gas heater is a more complex and responsible job. It is important to understand that gas acts as an energy carrier here. And neglect of a number of requirements necessary when working with it can lead to dangerous consequences.

Gas supply to the device can occur in 2 variants - main gas supply or from a tank. In some cases, a prerequisite for installing a gas installation in a house or apartment is to obtain permission from the relevant authorities.For this, it is important that not only the gas equipment itself meets the safety requirements, but also the room where it will be installed.

For reference. As the specialists of one of the gas supply companies explain, no permits are required for the installation and use of gas equipment and a gas holder on their site.

But there are a number of important requirements. Here is some of them.

So, for example, for models with an open combustion chamber, a minimum room area of 8 square meters is required. m., and for models with a closed chamber, an area of 6 m2 is enough. The height to the ceiling should not be less than 2.2 m. And the room should have supply and exhaust ventilation and a window. Installation of gas equipment in the basement and basements of buildings is prohibited.

The precondition for the operation of heaters with an open type of combustion chamber is the presence of natural draft, therefore they must have a chimney system, while the air intake is carried out from the same room where the water heater is installed. In this regard, the flow of air - required condition.

With a closed type - combustion takes place in a closed chamber, with forced draft. That makes it possible to abandon the classic chimney. Coaxial chimneys are used as a waste gas outlet.

Installation of indirect water heaters

They are also called indirect heating boilers. An installation of this type is not demanding in terms of location, but since it uses the energy of the coolant from the primary source of thermal energy, then the distance between them should be minimal. Suppose that the source of the coolant you have is a gas boiler, then the hot water boiler is located as close as possible, with straighter sections of the connecting pipelines. Of course, this is not critical, but the large length of the pipes can affect the losses and efficiency of water heating in general.

If it is not possible to shorten the length of the pipelines, then it is necessary to insulate this connection.

If an electric heater has only 2 or 3 fittings for connection, then indirect ones have 4 or more.

When choosing the location of one or another type of device, read the installation instructions in order to understand the location and purpose of all the fittings for connection. It is advisable to think over the piping before purchasing. Otherwise, a very ornate pipeline connection scheme may turn out and this can also affect hydraulic and heat losses.

Some models of storage indirect water heaters, in addition to a heat exchanger (coil) for heating, can also have a heating element. This option is convenient because in winter, heating occurs, for example, from the boiler, and in summer, when the heating is not working, we turn on the heating from electricity.

Availability of pipelines connected to water heating boilers of various types

| Purpose of the pipeline | Electric accumulative | Gas storage | Indirect heating boiler |

| Cold water supply for heating | + | + | + |

| Heated outlet water | + | + | + |

| Water return after circulation (for organizing heated towel rails) | If provided by the design | If provided by the design | If provided by the design |

| Coolant supply to the coil | — | — | + |

| Returning the coolant from the coil | — | — | + |

«+» - means that the connection is provided by the design;

«-« - connection is not provided.

Supercharged unit operation

All gas flow structures operate according to the same principle: when the hot water valve in the apparatus is opened, the burner ignites under the flow pressure and begins to heat the liquid circulating through the heat exchanger. In a smokeless appliance the process happens a little differently:

- While in standby mode, the device is connected to the mains.There is no combustion process in the chamber, since there is no igniter.

- When the mixer tap is opened, the flow sensor and the membrane of the water unit are turned on. Under its action, a valve is triggered, which opens gas access to the burner mechanism.

- The controller sends a command to the electrodes located next to the burner, a spark appears, which ignites the gas. The sensor reacts to a flame and signals to the control unit that the formation of a spark stops, and at the same time the turbine that blows air is turned on.

- When the DHW tap is closed, the gas supply stops, the burner goes out, therefore the water heating process is completed.

Thanks to the improved design, the efficiency of the turbocharged unit reaches 88-90%, while the usual atmospheric 84%. Efficiency is determined by the following functions:

- accurate metering of the supplied gas and air required for the combustion process;

- maintaining the required temperature regime - a function that allows you to save gas, since the consumption for excessive heating is excluded;

- preheating of the street air flow with a coaxial chimney.

This function is most effective in compensating for the heat that is carried away with the gas toxins. Cold air, flowing through the same pipe, only in a different plane, takes heat from the oncoming smoke waste through the steel wall of the inner pipe.

The gas water heater with a coaxial chimney is endowed with protective safety equipment. They work in situations like this:

- lack of draft in the chimney due to the termination of the turbine, which stopped when the electricity was cut off;

- the burner spontaneously went out;

- reduced water consumption;

- failure of the controller function.

How to manage? - what to press and how to twist

The setting options for modern water heaters are varied, it all depends on the specific model and its functionality. Boilers operating on different types of energy also differ in the way they are controlled. Despite this, the most basic setting for all types of boilers is the water heating temperature.

The control method is distinguished: manual and automatic control.

The type can be mechanically or electronically controlled.

Mechanical control, as a rule, is the control of basic parameters. Electronic control has more advanced options for setting and monitoring the operation of the heater, as well as for the number of functions.

Electric boiler and its control:

- Enabling and disabling

- Water heating temperature

Mechanical regulation - by means of a thermostat by turning the knob, the desired value of the preset heating temperature is set During operation, the heater is periodically turned off when this temperature is reached and then turned on when it cools down by a predetermined value.

With the electronic type, the temperature is controlled by the controller, together with the temperature sensor, it can maintain it at a given level, while the temperature can be set more accurately.

- Heating power

Some models allow you to control the heating power, thereby changing the heating time. The mode switch is used for this. These models include heaters with the "fast heating" function, where, to accelerate heating, this mode is turned on, while additional heating power is added (second heating element).

Some models have the ability to operate using a remote control, which also provides some advantages in certain situations.

Gas boiler - how to operate

In most cases, gas technology is operated mechanically. And this is justified, firstly, the simpler, the more reliable. Secondly, control over the process at every stage. And in general, despite the primitive, as it might seem at first glance, all systems have a lot of fairly reliable and proven protection elements.

Ignition of the igniter.

The flame of the starting burner - lights up once, burns constantly throughout the entire operating time of the water heater. The very first and budget models were launched from open fire or other third-party devices. Today it is a piezoelectric element, or a spark from batteries (from batteries). The start-up is quick and very convenient, only 2 movements: press and turn the gas supply knob, then press the spark generator button, the gas of the pilot burner is ignited.

It is important that the gas supply knob must be held down for some time in order to give time for the protection element to warm up, literally a few seconds. If this is not done, then the gas will turn off and the flame will go out, then the starting operation must be repeated again.

When the pilot flame is on, the main heating can be started.

Starting the main burner

For this, the thermostat knob is used, which makes it possible to set the desired temperature for heating the water. On some models, the gas supply function and temperature control are performed with the same knob. The handle has a scale of steps from 1 to 7 (Ariston-sga model), which allows you to adjust the water heating from 40 to 70 ° C. Some models have push-button electronic control (Ariston-NHRE-PRO model).

Shutdown

Basically, the sequence is the same - with the thermostat control knob, the gas supply is closed (“off” position). Restarting is possible 10 minutes after the burner flame goes out.

Each model has its own specific features in regulation and control, therefore it is always important to study the instructions before use!

How to set up boilers of combined type and indirect heating

The control of this type of heaters does not have any difficulties and peculiarities. When operating in the indirect heating mode, the parameters of water heating completely depend on the parameters of the coolant - temperature and flow rate, which come from the primary thermal devices. In this case, the mixing unit will act as a regulating element. By the way, they are manual or automatic.

This mode of operation of combined heaters is suitable in winter, when the main heating system is operating (gas, electric, solid fuel, wood, pellet boiler). In warm weather, when the boiler is turned off, the heating element is turned on.

In this case, the adjustment is the same as for the electric water heater, which was described above.

Benefits of a smokeless appliance

A geyser without a chimney does not exist, and in devices with a pressurization function, its design has been simplified. Now you can use turbocharged devices not only in private houses, but also in apartments. You just need to make a hole in the wall that communicates with the street and through it bring the chimney horizontally along the shortest path.

If necessary, the coaxial chimney can be installed vertically on the roof of a private building, having previously prepared a shaft made of non-combustible material for it. There are other advantages of a column with a coaxial chimney:

- It is characterized by high efficiency and economy when compared with conventional water heating devices.

- The closed combustion chamber eliminates hazardous flue gas emissions and unpleasant odors in the room.

- Simple installation of supply and exhaust ventilation, since you cannot do without it.

- The presence of a high degree of automation of the coaxial apparatus brings convenience in the operation of the equipment.

- The function of an energy carrier can be performed not only by natural, but also by liquefied gas. But this requires the use of a special hood, arranged closer to the floor (propane is heavier than air).

In addition to sensors that ensure the safety and temperature of the water, the turbocharged units have an anti-freeze system for the heat exchanger.The principle of operation is as follows: at a negative temperature in the room, the heating element is automatically turned on, powered by electricity, which heats the heat exchanger and does not freeze the water.

The anti-freeze function in the coaxial column will be useful in the event of an emergency shutdown of the heating system in winter. It will prevent expensive equipment from defrosting and failing.

Gas storage water heaters

On the one hand, recommendations for using expensive, in theory, high-quality equipment can lead to a refusal on the part of the client to purchase or services. On the other hand, the use of cheap outdated equipment can lead to irreparable consequences. In this case, the attitude changes not only to the manufacturer, but also to the one who recommended and installed this equipment. Even the most stingy client will not agree to change every month what was paid for once. There are quite a few examples when installation firms do not install equipment from individual manufacturers. Firstly, this may be due to the lack of a license or accreditation to work with this type of equipment, and secondly, it may depend on the personal interest of the company's management in promoting specific equipment. Often this is due to a contractual relationship with the supplier on the "exclusive" use of only its equipment at "exclusive" prices in this case and with the greatest discount. Here we are talking, most likely, about large Moscow firms. Private entrepreneurs and small firms are happy with any order and undertake the installation of any equipment, often without proper knowledge about the features of the device and operation, relying only on experience and the relative similarity of equipment. Sometimes this approach becomes the reason, at best, equipment breakdown, at worst - the payment of lawsuits to the injured party. The choice of equipment is a complicated matter that requires taking into account a variety of factors and wishes. The existence on the market of a huge number of devices from various manufacturers only complicates the choice. The possibility of solving one problem in different ways, on the one hand, makes it easier, on the other, it complicates the situation. If we talk about the preparation of water using gas, then here, along with traditional gas water heaters, there are storage gas water heaters. The speakers are widely used due to their compactness. Space is limited in small apartments, so the installation of bulky equipment, even if it is a super system at a super cheap price, is illogical. If the scope of application of gas flowing water heaters - gas water heaters - is wide enough, then the use of storage gas water heaters is somewhat limited. Again, due to the overall dimensions. Perhaps that is why storage gas water heaters are lost on the market among many of their flow-through “brothers”. The number of manufacturers of storage gas water heaters is incomparably smaller. Many manufacturers of heating and water-heating gas equipment do not present storage gas water heaters of direct heating in their program. For the preparation of hot water, the range includes gas water heaters, double-circuit wall-mounted heating boilers, storage water heaters for indirect heating. There are only three manufacturers of directly heated gas storage water heaters on the Russian market: Ariston, American Water Heater Group and Vaillant. One of the manufacturers of storage gas water heaters on the Russian market, Merloni Termosanitari, differs from its competitors in that, along with floor-standing gas water heaters, it has wall-mounted gas storage water heaters.The main advantage of wall-mounted storage-type gas water heaters is that they replace gas water heaters familiar to Russians. Without changing anything in the chimney, gas and cold water supply, you can install a boiler with a capacity of 50-100 liters in the same place where the gas water heater was hanging. Water heaters of the model range from 120 to 200 liters are installed on the floor. Floor-standing models of gas boilers have, in addition to the cold water inlet and hot water outlet, an additional outlet from the tank, which is used to drain water or recirculate in the hot water supply system. The presence of a reverse circulation loop increases the comfort of using hot water, which is impossible when using gas water heaters. Model S / SGA 80 T has a built-in heat exchanger. Water heating in this case is carried out not only with the help of gas, but also from the heating system, which is sometimes very convenient. The water heater has a stainless steel burner pre-installed for natural gas consumption. With a conversion kit, the boiler can be converted to LPG operation. The piezoelectric ignition burner ignition system eliminates the need for matches. All devices have a heating indicator, a main and backup thermostat and are equipped with a thermometer that displays the temperature of water heating. The working thermostat provides regulation of the water temperature in the range of 40-72 ° C. An additional safety thermostat ensures that the gas valve is closed when the water in the boiler overheats in the event of a failure of the operating thermostat. S / SGA gas boilers are available with open or closed combustion chambers. In the latter, air for gas combustion is supplied from the outside through a special channel or through a coaxial chimney. Models with an open combustion chamber have another safety device - a draft sensor, which stops the supply of gas to the device if there is insufficient draft in the chimney duct. If there is no flame on the pilot burner, the gas valve also closes. The water heater ensures stable operation even at low water and gas pressures. A magnesium anode is mounted inside the storage tank. The service life of this anode depends on the average temperature, on the chemical composition and on the amount of water consumed. The anode is designed for approximately 5 years of operation under normal conditions. Checking its condition should be carried out once every one and a half to two years. Ariston gas water heaters of the SGA series are recommended for domestic use. Merloni Termosanitari offers a full service of its devices in all major cities of the Russian Federation. The company's pricing policy makes it possible to make heating devices available to the end consumer, while maintaining fairly low retail prices. The main technical characteristics of gas water heaters of the SGA model range are shown in the table. AWHG

The American company American Water Heater Group is one of the largest US manufacturers of storage gas and electric water heaters. This company produces a huge volume of gas water heaters both for its market and for the markets of Europe, China and other countries. Gas storage water heaters of the PROLine brand operate on natural gas and are intended for hot water supply. The maximum hot water outlet temperature is 71 ° C. The water heater does not have a piezoelectric ignition device. The ignition burner is ignited using a match. After switching on, the water heater works in automatic mode and maintains the temperature set by the regulator. The water heater automatics maintains the required gas pressure in front of the burner and automatically turns off the water heater if the water temperature in the tank exceeds 94 ° C.The water heater can be installed in private houses, apartments and office buildings to provide hot water to several users at the same time. The water heater tank has a ceramic coating. Between the heat exchanger and the casing there is a highly efficient thermal insulation that reduces heat loss. Depending on the model of the water heater, one or two magnesium anodes are installed inside the heating tank, which provide protection against corrosion and extend the life of the tank. A routine inspection of the condition of the anode should be carried out once every two years. The bimetallic gas burner contributes to increased corrosion resistance and therefore a longer service life. The DVG62-40S38-NV model water heater, unlike other models, has a fan burner. Combustion air intake and product discharge is carried out through a special coaxial chimney horizontally through the wall or vertically through the roof. The water heaters are certified and have a permit from Gosgortekhnadzor of the Russian Federation. They are highly economical, have regulation of the temperature of the heated water, automatic maintenance of the set temperature and protection against overheating. They are easy to install and maintain and have low NOx formation. In Russia, this manufacturer is represented by the only company "Tenzona", which has the exclusive right to supply and sell gas water heaters of the entire production sector in the territory of the Russian Federation. According to a representative of the Tenzon company, “water heaters with tank volumes of 190 and 284 liters, used in cottages, are the most popular. The AWHG water heater is a reliable and high-quality device that works well and for a long time in our, most often non-standard operating conditions (for example, low gas pressure). There are similar devices of Italian, Canadian and German production on the market, but there is no equipment equal to the American one in terms of power and performance. The gas burners of AWHG water heaters are twice as powerful as those of other manufacturers with the corresponding capacities. When a consumer compares equipment, he compares price and volume and does not always pay attention to performance, where the power of the burners is the most important thing. "

Vaillant

One of the largest manufacturers of heating and water heating equipment, the German company Vaillant, has for a long time in its range, in addition to electric instantaneous and storage water heaters, indirect heating boilers, double-circuit gas heating boilers, has storage gas water heaters of direct heating. VGH series storage gas water heaters are stationary closed-system boilers with atmospheric injection gas burners for natural and liquefied gas with ceramic heat-dissipating rods. They are designed for economical hot water supply of apartments, cottages, office and industrial establishments. VGH water heaters can be installed directly in residential, basement, utility and other multi-purpose premises. A large supply of water allows the simultaneous use of hot water at several taps. The possibility of connecting a return circulation pipe makes the use of hot water very comfortable. Thanks to the high efficiency and high-quality thermal insulation 50 mm thick, an optimal utilization of thermal energy is achieved. Vaillant gas water heaters have a steel enamelled tank and are equipped with a protective magnesium anode. The life of the anode is about five years. Depending on the intensity of the water heater and on the chemical composition of the water, the scheduled replacement of this element can be performed more often. There is a lateral technological opening in the tank for maintenance work.The boiler has a piezoelectric ignition independent of the mains, a thermostat with the ability to continuously adjust the water temperature up to 80 ° C. If the thermostat fails, the safety temperature limiter will shut off the gas supply and prevent the water from boiling. The function of thermoelectric control of the presence of a flame of the pilot burner and a sensor for the removal of combustion products will allow you to timely turn off the gas supply when the ignition burner goes out and the chimney is clogged or poor-quality removal of combustion products. The multifunctional gas regulator can be used to regulate the pressure in front of the nozzle and the gas flow rate. This makes it possible to adapt to local gas supply conditions. This regulator prevents pressure fluctuations in the gas network from affecting the gas burner. Vaillant storage gas water heaters are available in four standard sizes.

Pros and cons

Gas boilers are not yet very common in Russia, but, nevertheless, they have a number of significant advantages over the well-known gas water heaters. The main advantage of gas boilers is the ability to obtain a large flow of high temperature water simultaneously at several water points. When using a gas water heater, the amount of hot water at the required temperature is limited by the power. In storage systems (this applies to electric storage water heaters and indirect heating boilers), it is not the power of the device that is decisive, but its volume, since the water is heated in advance. The increased power of the equipment (see AWHG) allows you to quickly heat up the cold water entering the boiler in the shortest possible time. Under certain conditions, these devices can operate in flow mode. Power allows. True, the very concept of a storage water heater implies the use of preheated water. Therefore, most often the volume of the storage device is selected based on the requests of an individual consumer, the number of consumers and types of water consumption (bath, shower, etc.). Below are some data on the consumption of 40 ° C hot water, calculated for one-time use by one person. Sink / washbasin 15 liters Kitchen sink 25 liters Shower 70-100 liters Bath 180 liters The table shows that the highest water consumption occurs when using the bathtub. The boiler is capable of heating water up to 70 ° C. Recommended by literally all manufacturers, the so-called economical operating temperature of this type of equipment is 60 ° C. That is, when diluted with cold water equal to 10 ° C (average water temperature in the water supply system) one hundred liters of hot water, we get Mm = (m2 „(T1 – T2)) / (Tm – T1) = (100x (60 ° C – 10 ° C)) / (40 ° C -10 ° C) = 160 liters of forty-degree water. Where Mm is the amount of diluted water, m2 is the volume of heated water, T1 is the temperature of the heated water, T2 is the temperature of cold water in the water supply, Tm is the temperature of the water you want to receive. Another clear advantage of storage gas water heaters is the ability to connect a return circulation pipe, which allows you to comfortably use hot water even in the most remote points. This is especially true with centralized hot water supply for a cottage or a house for several families, when the water points are far enough from each other and from the storage device itself. Gas water heaters are deprived of this opportunity. The issue of heat loss during the installation of such a system is solved through the use of highly efficient heat-insulating materials. The third advantage is non-criticality to the pressure drop of gas and water. Low gas pressure will only affect the power of the apparatus, that is, the heating time will increase. Low pressure of water and gas for geysers, if you take each of these parameters separately or together, we can say, is unacceptable.In gas boilers, the heating capacity is low - up to 10 kW (for Vaillant and Ariston models) and is comparable to a gas stove. The maximum values of the heating capacity of the gas columns are 17-28 kW. Such a difference in values indicates that the gas accumulator per unit of time requires significantly less air for the burner operation, and the amount of combustion products per unit time during the operation of the accumulator is significantly less compared to the column. This makes it possible to install gas boilers in rooms, the dimensions and air flow in which do not allow the installation of a gas water heater. Another advantage over the columns is due to the design of the heat exchanger, which is one of the most expensive units in gas columns. During operation, scale deposits on the walls of the column heat exchanger tubes. In the absence of preventive cleaning, it not only reduces the amount of prepared hot water and increases gas consumption due to a decrease in the efficiency of heat exchange, but can completely clog the heat exchanger, which will necessitate its replacement. In a gas boiler, scale is deposited on the walls of the internal tank and, in the absence of preventive cleaning, leads to an increase in gas consumption and the time for heating the water in the boiler, as well as to a certain decrease in the capacity of the tank. But even with a significant thickness of the scale layer, the boiler continues to function. Talking about the advantages, it would be correct to note the disadvantages. As mentioned above, these are the dimensions of the drives that limit their use. The second is the gas consumption by the boiler in the mode of maintaining the temperature during the day. For gas water heaters, gas is consumed only when using hot water. The calculation here does not take into account the combustion of the pilot burner (models with piezo ignition) - the gas consumption in this case is minimal. In gas columns with electronic ignition, there is generally no constant combustion of the ignition wick. Its ignition occurs only when the hot water tap is opened. Therefore, in the presence of only liquefied gas, it will be most optimal to use a gas column, and with electronic ignition. To minimize costs in storage water heaters, effective thermal insulation of the internal tank is provided. If hot water is not used for a long time, for example, at night, it is recommended to turn off the boiler. For 8-10 hours, the water temperature in it will drop only by 5-7 degrees. Another relative disadvantage of gas storage water heaters can be considered a more complex connection. For the installation of both electric and gas storage tanks, it is necessary to connect the sewage system. The water in the container heats up and expands, overpressure arises. To relieve pressure, in this case, to remove excess water, there is a special fittings - a safety valve or an overpressure valve, which is connected to the sewer drain. The safety and check valve set is called a safety group. Without it, the connection of any boiler (except for open-type electric models used with special mixers) is strictly prohibited. In conclusion, I would like to repeat that the selection of equipment is a rather complicated matter and depends on several factors - from overall dimensions, technical characteristics and functionality to the cost of equipment, necessary consumables and components, as well as installation costs. With the modern approach, the cost of preventive maintenance and service is added here.

Cons when using the device

The disadvantage of a coaxial gas column is volatility.If there is a power outage, there will be no hot water. You will need to use an electric generator or a reliable uninterruptible power supply. Other negative aspects of these devices:

- A coaxial gas unit is almost twice as expensive as an atmospheric one. But when comparing the purchase and installation in a complex, a coaxial chimney will cost much less than making it out of bricks or installing an insulated sandwich.

- Fan noise is heard on some speaker models.

- It is better to entrust the cleaning of the device to a specialist. Modern equipment has a complex structure, therefore, it is not recommended to try to find a malfunction on your own and eliminate it.

For the installation of this type of unit, the permission of the organization supplying the natural gas is required. You should also notify the neighbors that a chimney will be installed on the facade of the house.

Boiler column with a closed chamber

This is a type of gas devices, which is a reservoir in which water is heated, and then spreads along pipe lines to water points. The water in the tank is constantly hot, and not at the moment the DHW tap is opened, as when using a flow-through heat generator. The non-flue column works according to the following principle: when the temperature in the tank drops, the temperature sensor sends a signal to the burner to turn on. During the operation of the burner, hot air enters the flame tube surrounded by water and transfers heat to it. As soon as the water heats up to the set mode, the burner turns off.

The container of the device is equipped with thermal insulation, therefore, like a thermos, it can keep the temperature for a long time. You can always use hot water instantly and in the required amount. The capacity of the storage tank is different for all models, ranging from 10 to 500 liters. The body is made of steel, covered with enamel or glass porcelain. The main advantage of the boiler is the use of a large volume of hot water even when the water supply is completely cut off.

But, like any technological design, a turbocharged column has a drawback - hot water remains in the gap between the DHW valve and the tank, which then cools down. Therefore, the user, having opened the tap, has to wait for the cold water to drain.

This problem is solved by a circulation system consisting of a small pump connected with a small diameter pipe to a pipe system leading to the end points. With the help of the pump, the remaining unused water is pumped back into the tank, this prevents it from cooling.

Design and principle of operation of a gas boiler

Instantaneous and storage gas boilers

According to the principle of their operation, gas water heaters are divided into two types - flow-through and storage. Direct-flow models or gas boilers heat the flowing water while it is in the heat exchanger. Directly in front of it there is a built-in flow sensor, in the inoperative position of the system, which is in a disconnected state.

When the hot water tap is turned on, this sensor sends a signal to the control circuit, which opens the fuel supply and ignites the gas burner. By means of another control circuit with a sensor, the temperature of the liquid at the outlet of the device is monitored. With the function of controlling the intensity of combustion, the electronic unit regulates the supply of the mixture to the main burner, so that it is possible to maintain the specified operating mode. If the flow of water stops or the temperature exceeds the permissible limit, the gas burner automatically turns off.

All flow-through units are compact in size and relatively low cost.

Their characteristic shortcomings include:

- the impossibility of maintaining a stable regime in terms of the temperature of the water carrier - this applies only to inexpensive models;

- relatively low productivity, according to the passport, not exceeding 15 liters per minute.

There is always a supply of hot water in the storage tank

At sites that consume significant amounts of water, productivity is usually inadequate. To meet the current user needs, the indicator is chosen at least a third higher.

Storage-type gas boilers heat up a small amount of liquid poured to a predetermined temperature, so that a certain amount of hot water is always in the working container. Automation in such heaters is simpler, since electronic devices only need to start the burner when the temperature drops below the set level and, when the set heating value is reached, close it. In this case, there is no special need to adjust the flame level in the burner and control the liquid flow.

Boilers consist of the following main parts:

- bearing body with working units located in it;

- gas burner with igniter;

- a system of pipes with a liquid circulating through them;

- container for running or accumulated water;

- heat exchanger.

The water heaters also include a set of automation with sensitive sensors that control the flow at the inlet to the system, as well as the operation of the gas burner (its igniter).

Recommendations when choosing

It is impossible to give any specific advice regarding the place of purchase of the gas appliance. You need to focus on stores that are known for the quality of service, a variety of assortments, and the presence of decent models.

In specialized stores of plumbing and heating equipment, a large selection of products is presented, with the characteristics of which can be seen live, to evaluate the appearance of the column. Purchasing through an online store also has its advantages - the ability to exchange and return goods within two weeks, without specifying the reasons, a huge selection, ordering a rare model, reviewing reviews from other buyers.

The Neva gas water heater with a closed combustion chamber is popular. This equipment is characterized by instantaneous heating of water, the use of liquefied gas, the ability to connect to bottled gas. Based on the practice of operation, it is known that with the help of this device it is possible to obtain 6 liters of hot water per minute. The flow column is equipped with sensors and timers, which are responsible for the high-quality operation of the device. It has a power of 9 kW.

When purchasing a gas water heater, first of all, you should make sure that there is a decent security system for comfortable use of the equipment. It must be equipped with sensors that monitor flame, overheating and chimney backflow. You can choose any ignition option based on your preferences and wishes.

Anti-corrosion tank

Just as in electric storage water heaters, an anti-corrosion anode is used to combat corrosion of the inner surface of the tank of gas heaters. The essence of its work is simple: those places where the enamel coating is damaged for some reason - namely, they are potential foci of corrosion - have a lower electrical resistance compared to the rest of the surface. Therefore, the current flowing from the anode will rush there, preventing rust from forming. Of course, this anode must be monitored from time to time and, if necessary, changed: all these actions are performed during routine maintenance of the unit. To replace the anode, it is necessary to completely drain the water from the tank.

Range

Today, storage gas water heaters in the range are significantly inferior to their electrical counterparts, being represented by only a few manufacturers.Almost all water heaters have modifications for wall and floor mounting, respectively, differing in overall dimensions and volume of the water tank - from 50 to 220 liters. At the same time, a two-hundred-liter unit has a thermal power of only 8 kW and, depending on the hot water consumption, consumes from 0.6 m³ of gas per day.

The choice of instantaneous gas water heaters is much wider - from inexpensive and obviously outdated domestic samples to much more modern devices from Korea and European countries. Nevertheless, experts say that gas water heaters should be used only where it is not possible to install a storage unit, and best of all - a full-fledged gas boiler with a built-in hot water boiler.