When a land plot is located where groundwater is high, it must be diverted. Excess water can harm garden crops and the foundation of the house. The result of such destruction will be uneven shrinkage of the house and distortion of building structures. With constant humidity, mold will multiply, which poses a danger to human health. Well-laid drainage pipes eliminate these problems. How to make a drainage system yourself, this article will tell you.

What is drainage and how it works

Drainage is a structure created to drain the land from special drainage pipes and auxiliary devices. Serves to drain ground water from the local area.

Soil waters in central Russia are often located high - at a depth of 2 m from the surface of the earth and even higher. Underground moisture destroys the foundation of the structure and causes rotting of plant roots. Before building a house, it is imperative to carry out engineering surveys and find out the depth of the soil.

How to understand that drainage is needed?

- Your site is located on a slope or vice versa in a lowland;

- If the surface of the territory is flat and there is nowhere for water to drain, it stagnates and swamps the area;

- There are severe floods in your area;

- The walls of the house freeze in winter;

- The room is humid, mold and mildew form.

All these direct and indirect signs indicate the need for forced drainage of the site.

How does drainage work?

The soil drainage system can be of three types - open, closed and point.

- Open system

Serves to drain surface waters (rain, melted snow, flood waters, etc.).

For the device of an open structure, a trench 50 cm deep and 60-70 cm wide is dug along the entire perimeter of the site. The collected water should be poured into a general drain. If the site is not located on a slope, ditches should be dug with a certain slope so that the water does not stagnate, but flows down from the territory. The ditch is left empty (drainage without pipes), or reinforced with stones, cement. A special open drainage pipe can be laid.

- Closed system

More complex. The trenches here are from 1 to 1.5 m deep, 0.25-0.5 meters wide. The depth of the laying should be greater than the depth of soil freezing.

It is necessary to lay a sand and crushed stone pillow in the trench, and on top of it a special perforated pipe of the required diameter. You need to dig a ditch with a slope towards the well or drain. Remains of a gravel-sand mixture are laid on top. To avoid clogging and silting, drainage pipes must be additionally protected with filter material.

All collected water enters the storage tank, from it into the reservoir, or into the sewer. To control the state of the system, it is necessary to install special inspection chambers.

- Point

Single installed receivers in the places of the greatest water accumulation. Several installed local receivers can be connected to a single network. The main elements of point drainage are storm inlets and outlets.

A well-chosen and correctly installed drainage system will protect the upper layers of the soil from erosion, the foundation of the house - from cracks, will preserve the decorative coating in the yard and will have a beneficial effect on soil fertility. Therefore, in no case should you neglect drainage.

Why is plumbing or sewer not suitable?

Conventional water or sewer pipes are made without special holes.Products without perforation can only be used to drain already collected liquid.

What is perforation for?

Through the technological holes, water from the soil enters the pipe and moves along it to the drain common for the entire section.

The drainage pipe (deep) must be perforated.

Work order

Drains are laid in the following order:

- trenches are dug along the marking line, their depth should be below the freezing point of the soil; a plan is drawn up and marking is carried out on the ground; a layer of sand up to 10 centimeters thick is poured onto the bottom and carefully compacted with a roller; crushed stone or gravel is laid on top (layer thickness 20 cm); on pipes are laid on the prepared pillow; the system is mounted using couplings, and then the angle of inclination of the pipes towards the water collectors is checked; inspection wells are arranged at the joints and turns of the pipes (a piece of plastic pipe is cut off, a protective cover is mounted); backfilling is performed - a layer of crushed stone is laid out successively, sand, soil; turf can be laid on top or herbaceous plants can be sown; at the end of the outlet pipe, after the collector, a check valve is mounted or a well is arranged to collect water (a sealed plastic tank is used).

Types of drainage pipes

Products vary in material, surface, stiffness and load-carrying capacity. Let's consider each variety separately.

By material:

Most often, pipelines for water drainage are made of asbestos cement, ceramics, and plastic. Chrysotile cement, metal pipes and products with the addition of polystyrene are less common.

Asbestos-cement

Asbestos cement is a waterproof and fire-resistant material. Made from cement and asbestos fibers.

At the moment, asbestos pipes are rarely used due to the large weight of the product and the difficulties of installation. Drainage holes in such pipes are difficult to make on your own, and the finished system has low operational properties.

Chrysotile cement

Chrysotile-cement parts are the closest relatives of asbestos-cement ones. They also contain white asbestos fibers called chrysotile. Chrysotile is packed in a concrete matrix. In the last century, the material was considered carcinogenic.

The advantages of chrysotile cement drainage systems are water tightness, resistance to mechanical stress, good response to high pressure, service life of -25 years and more. Cons - heavy weight, installation difficulties, slow assembly process.

Ceramic

They are made from a special type of clay with subsequent firing. Ceramic drainage products are durable, high pressure resistant, environmentally friendly. The range of diameters produced is not great - from 5 to 30 cm.

A too low coefficient of surface friction makes it difficult to install filters.

Polymer

Polymer parts, in turn, are subdivided into products made of polyethylene (HDPE), polyvinyl chloride (PVC), and polypropylene.

Mon

Drainage pipes HDPE are made of polyethylene of sufficiently high stiffness classes SN4 and SN8. They are used for both deep and surface pipelines. Sizes range from 5 to 70 cm in diameter.

There are single-layer, double-layer and perforated versions of products with joints in the form of couplings, welding and socket.

Details from HDPE are flammable.

Made of polypropylene

A frequently used product. The closest relative of the HDPE. Available in crimped and smooth. The minimum pipe diameter is 50mm, stiffness class SN8.

Pvc

Drainage pipes made of PVC (polyvinyl chloride) are no less popular for the arrangement of pipelines than the previous 2 plastic types of pipes.

Produced in the following modifications:

- Rigid and flexible;

- With and without filter material;

- Single layer and double layer.

Supplied in lengths of 6 and 12m and in coils.

When buying a pipe, you should pay attention to the stiffness class, PVC products are available in a wide range, from SN2 to SN16.

With expanded polystyrene

The structure is a perforated pipe inside a geotextile filtering shell filled with expanded polystyrene granules. Special pellet channels improve water drainage. Expanded polystyrene is resistant to all liquid media, tolerates low temperatures, has a long service life (up to 100 years) and is unattractive to rodents.

The need to use this particular type is due to the following factors:

- Groundwater is too close to the surface;

- The site is dominated by alumina;

- The site is located in a lowland and is prone to waterlogging;

Standard dimensions - core D = 110 mm, total diameter of the drainage system - 300 mm.

Corrugated

Corrugated pipes are made in the form of a plastic accordion. Drainage holes in such products can be either round or slotted.

Advantages of corrugated products:

- Light weight;

- Simple and fast styling technology;

- Reliability;

- High corrosion resistance;

- Strength and durability;

- High level of ring stiffness;

- A wide range of applications - pipes are produced with different degrees of rigidity, which makes it possible to select products directly for

Single-layer and multi-layer

Pros of multilayer pipes:

- Several layers give the product extra strength and durability. The top layer is often corrugated, the inner layer is smooth. They are designated by the SNX marking, where X is the maximum drainage depth in meters.

- Single-layer pipes are most often used for local drainage systems. They can be smooth or corrugated.

Flexible and tough

Pipes are divided into 2 types, depending on the stiffness:

- Flexible models: Used to create flows with a rounded perimeter. They are characterized by lower ring stiffness and strength. Produced in the form of bays. Convenient because there is no need to install a large number of connecting elements.

- Rigid pipes: Used for laying straight sections. Available in thick-walled and thin-walled. They have a higher strength factor compared to flexible ones, but when laying, you cannot do without additional fittings.

Perforated

Drainage pipes for groundwater drainage are produced with perforations. The diameter of the technological holes is made from 1.5 to 5 mm. Holes are located in different products either around the entire circle, or ½ and 1/3 of it.

Non-perforated products are only suitable for specially designed systems where moisture is collected from a common source and transported to the drain.

Perforated drains are called suction (collecting) drains.

With filtering layer

Without filtration, the process holes quickly become clogged and their throughput decreases. The filtering layer of pipes is made of geotextile or coconut fiber.

In geotextile

Geotextile is a non-woven fabric, most often black. Placed on top of the pipe and used as a sieve to prevent dirt from entering.

Such a drainage pipe lives in the ground for a long time and, accordingly, retains its operational properties for a long time.

Coconut wrapped

Coconut fiber as a pipe wrapper has its pros and cons. The advantages include environmental friendliness, high elasticity and permeability, high resistance to decay and deformation. The only negative is the high cost of construction.

Yet

In addition to the above, metal perforated pipelines from special alloys are extremely rarely used. They are used in industries where chemical waste can enter the wastewater. Using such products at home does not make sense.

Maintenance

Even a properly installed and well-functioning drainage system requires regular maintenance. Drainage and inspection wells are inspected once or twice a year. The owners should be alerted by the low water level, which may indicate:

- about clogged drains; about the appearance of a leak in the pipeline; about silting of the drainage well.

Silt is the easiest to deal with. To do this, it is necessary to clean the drainage flow using a faecal pump with a float shut-off mechanism. Such a unit will automatically cope with contaminated water containing large impurities.

Drains are flushed with special equipment. To solve the problem with clogging the system, you need to contact a specialist.

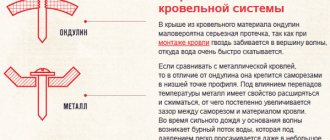

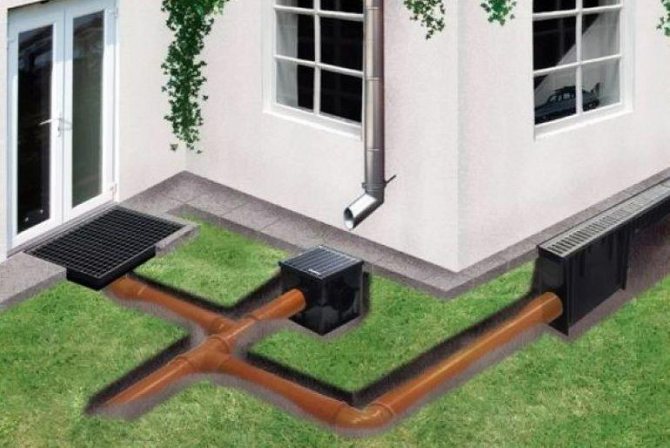

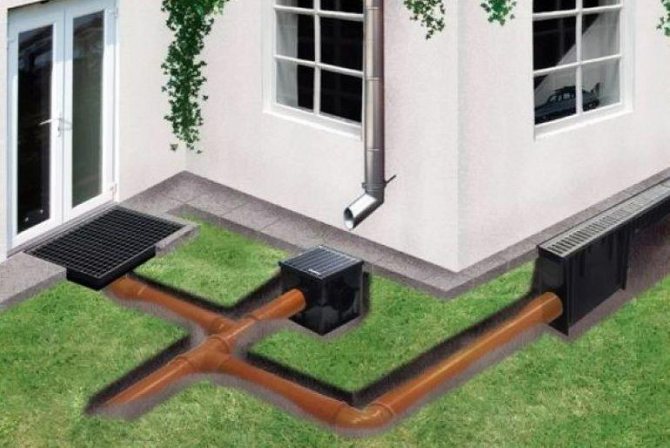

In the photo: Drainage sewerage device

The construction of a country house or summer cottage is often complicated by a high level of groundwater at the site and low water permeability of the soil, which further lead to flooding of the foundation, water seepage into basements and waterlogging of the soil. The installation of drainage will help eliminate the risk of these problems.

That is why the installation of storm sewers should be started at the very beginning of creating your country house.

has been successfully designing and installing such systems for many years. Do you need to rid your area of excess moisture? Do you need a storm drain at home?

We are always happy to help you with this. We carry out our work conscientiously and professionally. At the same time, the cost of storm sewers in Moscow is democratic and affordable.

Which is better?

For storm water

Smooth plastic pipes with a minimum stiffness factor (eg SN2) are ideal for collecting surface water.

Do not overpay for products with high strength characteristics. Corrugation is not needed here either.

For groundwater drainage

For groundwater drainage, the most successful choice will be a corrugated multilayer pipe with perforation and protection in the form of a coconut filter. Yes, this product is not the cheapest on the market. But such a pipe will 100% save your foundation from destruction, and, accordingly, from huge financial costs.

It is imperative to choose a pipe based on the SN parameter.

What is a drainage system?

In the photo: installation of the storm water inlet

Drainage sewerage is an engineering and technical structure that is used to collect and remove water from the site.

The device of drainage sewerage allows to lower the level of groundwater and eliminate the possibility of their rapid rise. The drainage sewer consists of many interconnected pipes, which are located on the site according to a pre-developed scheme. It is recommended to carry out the installation of the drainage system at the stage of erecting the foundation of the building.

To exclude the possibility of flooding as a result of heavy atmospheric precipitation (rain, snow), a storm drainage system is being installed. Storm and drainage sewerage implies the installation of gutters, storm inlets and other elements that eliminate the possibility of water entering the blind area. Installation of a drainage system reduces the cost of repair work, increases the life of the building and has a positive effect on its safety.

In the photo: laying a storm sewer branch

The device of drainage at the site involves a complex of works, which are aimed at ensuring the collection and disposal of water. A preliminary study of soil properties and structural features of the building, which will be located on the territory, is required. So, if it is planned to build underground structures (basement, parking), the right solution would be to organize a deep drainage system.

The drainage sewerage device assumes:

- measurement of object parameters; development of project documentation; performance of installation work.

The calculation of the drainage system is carried out after taking measurements and drawing up a sketch of the site.

Drainage table for different soils

If the pipeline is laid incorrectly, for example, above the level of soil freezing, then in winter it will freeze. There are 2 options here - either lay the pipes below this level, or insulate them well. Let's summarize the data on the recommended types of drainage pipes, depending on the types of soil in the table.

| Soil Type | Type of drains |

| Crushed stone | Perforated without filter material |

| Sandy | Any kind with the obligatory use of a filter |

| Clayey | You can use pipes made of any material, it is possible without a filter, but with the obligatory addition of crushed stone |

| Loam | Be sure to use geotextiles or coconut fiber. |

The table of the dependence of the distance between the drainage areas on the type of soil and the depth of the drains is given below:

| Drain depth, m | Distance between drains, m | ||

| Light soils | Medium soils | Heavy clayey soils | |

| 1.8 | 18-22 | 15-18 | 7-11 |

| 1.5 | 15.5-18 | 12-15 | 6.5-9 |

| 1.2 | 12-15 | 10-12 | 4.5-7 |

| 0.9 | 9-11 | 7-9 | 4-5.5 |

| 0.6 | 6.5-7.5 | 5=6.5 | 3-4 |

| 0.45 | 4.5-5.5 | 4-5 | 2-3 |

Drainage pipe manufacturers

I propose to consider several leading manufacturers of plastic elements and find out how their products differ from each other.

Pragma

PRAGMA® is a brand of high-strength polypropylene pipes. Corrugated, red, made with a double structured wall made of PPR-B polypropylene. Withstands temperatures up to +60 degrees.

Perforated

A kind of Korsis pipes. The products of this brand use high-modulus polyethylene with the addition of mineral impurities, which give additional rigidity. They are produced in two types - with perforation only in the upper part or with holes along the entire surface.

Corsis

These are two-layer polyethylene pipes for storm water and shallow drainage. The outer layer is black and corrugated for UV resistance. The inner one is smooth to allow water to pass through, it is made in white. The white color makes it easier to inspect the inner surface of the pipe.

Softrock

Softrock is a ready-made system that allows you to reduce the amount of work on laying and assembling drainage.

Flexible perforated pipes are surrounded by expanded polystyrene core, packed in a geotextile mesh. Additionally, the kit includes additional fittings. Pipe diameters -110, 160, 200mm. Outside diameter -300mm, Strength class SN4, pipe length -3m.

Pipes Logistics

The Logistics pipe is a flat rectangular pipe, supplied in coils. Made of polyethylene. Has internal reinforcing elements. The tube is compact and takes up 2.5 times less than conventional round tubes.

Uponor

Products made of high density polyethylene with a double wall. The single-layer pipes are equipped with a coconut fiber filter.

SK-Plast

The company produces smooth and perforated products in both multi-layer and single-layer versions. Products of the STS brand are distinguished by their versatility and affordable price.

Highlights when laying

The drainage system must meet the technical requirements. Amateur activities in this matter are not encouraged. For this reason, owners should pay attention to some important points:

To carry out the work, it will be necessary to create a vertical plan of the site, taking into account the occurrence of groundwater in a particular area.

Specialists will help to draw up it for a fee. The exact depth of the pipeline, its diameter and type is calculated. At this stage, you will also need the help of specialists. When digging a trench, you need to make sure that its size is about 40 centimeters larger than the diameter of the pipes used. The slope of the trench is from three degrees (from 0.5 to 1 meter of slope). Inspection wells are located no closer than fifty meters from each other. The installation of a check valve or the arrangement of a water collector is a prerequisite for the correct functioning of the entire system.

Dimensions and diameters

The choice of the pipe diameter is the most important step in the design of the drainage system.

To drain a significant volume of water, you will need products of large diameter (at least 300-400mm). For domestic needs 200mm is enough. The most commonly used pipe is 110mm.To calculate the required diameter, it is necessary to take into account the degree of soil moisture, filtration coefficient, freezing capacity, inflow volume and other terrain features (indicated in the relevant reference books).

For an area of 400m2, 110mm in cross-section will be enough. If the area is larger, 200mm pipes will do. Industrial areas are drained with larger diameter products. The width of the trench should be 40 cm larger than the diameter of the pipe.

Tools and materials

For work you will need:

- shovel and bayonet shovel; garden wheelbarrow for soil; manual roller for compacting sand and gravel; mounting knife for cutting pipes; drill or grinder, if you want to make incisions (perforation); geotextile scissors.

You should also prepare building materials:

- pipes; adapters for manholes and collectors; fittings for installing pipes; plastic pipes with a diameter of 30 to 50 cm for arranging inspection and drainage wells (you can also purchase ready-made manholes with a hatch or plastic tanks); geofabric in rolls; crushed stone or gravel, sand.

Where to buy and how much they cost

You can buy products at any hardware or hardware store, on the market, or order delivery directly to your home on the Internet. The approximate cost of popular plastic products per 1 running meter:

- Single layer with the most popular diameter 110mm 110-130rub;

- Single-layer with a geotextile filter - 240-280 rubles;

- With a filter made of coconut fiber-300-350 rubles / m;

- Two-layer - 130-150 rubles / m.

The cost of products depends on the manufacturer and the material of manufacture.

Drainage installation and maintenance

Ditch preparation

Ditches for the drainage system can be dug manually or using special equipment. The width of the trenches should be 40-45 cm larger than the diameter of the pipeline. The distance between the drainage ditches is shown in the table above.

Trenches must be dug with a slope of 0.5-0.7% towards the collection of moisture. At the bottom of the trench, a layer of sandy soil 20 cm thick is laid, then the same layer of crushed stone.

DIY styling

It is done as follows:

- Drainage pipes are placed in the prepared ditch. If the perforation is made only on one side, then during assembly they should be laid with the holes down;

- The elements of the pipeline are connected to each other using special fittings with sockets.

- At the turns of the line, it is necessary to provide for the installation of wells.

Backfilling

- The buried pipe is covered with a layer of rubble;

- A layer of sand must be poured over the rubble;

- A previously cut sod is laid on top of the trench.

Installation instructions for perforated pipes

Before proceeding directly with the installation, it is necessary to perform calculations and select the appropriate material.

For design work, you will need a site layout and special data, which are best requested from your local land department:

- the seasonal level of groundwater; soil characteristics and soil structure; the amount of moisture falling out in the form of precipitation and flood waters.

Using this data, specialists will carry out the necessary calculations and determine the required trench depth and pipe diameter.

The most affordable solution for arranging the system is plastic parts.

The extremely simple device of the drainage pipe assumes the presence of two layers of polyvinyl chloride or polyethylene, which allows them to serve for at least 50 years at a fairly significant depth. In addition, the double-layer design promotes self-cleaning, preventing blockages. As a prevention of clogging of the holes on the pipe body with soil particles and small debris, before laying them, they are wrapped with a coconut fiber cloth or geotextile.

The order of work is as follows:

The installation of the drainage system begins with the marking of the territory, which is carried out according to a previously drawn up scheme. Trenches are dug along the marked lines, the depth of which is determined by a preliminary calculation. To determine the width of the structure, add 40 cm to the outer diameter of the prepared parts.

When carrying out work, you need to remember about the necessary slope of the drainage pipe, which is usually at least 3 °. At the bottom of the prepared trench, a crushed stone-sand cushion is mounted. To do this, first fill in a layer of sand 10 cm thick. The material is well compacted.

Then a layer of rubble 20 cm wide is laid on top of it. Pipes wrapped in geotextiles are laid on the prepared base. You can cut the part of the required length with a regular assembly knife. To connect the elements, special couplings are used.

In order to prevent freezing of the system, it is recommended to lay drainage pipes deeper than the level of freezing of the soil. After laying the pipes, their slope is checked again. To do this, you can use a regular cord stretched along the pipeline.In places where trenches turn and in areas where the slope angle changes, special inspection wells must be equipped. They are equipped with lids to prevent debris from building up.

These structures are necessary for the control and periodic cleaning of the drainage system.At the last stage, backfilling is carried out, that is, all actions are performed in reverse order. A layer of rubble is poured on top of the pipe, followed by sand, and the last layer of soil, which was taken out when digging a trench. Sod can be laid on top.

The output of the system is carried out into an open reservoir or rainwater drain.

In any case, a check valve is installed at the end of the outlet pipe. If it is impossible to organize such an outlet, a so-called collecting well is equipped. As it is filled, it is necessary to pump out water from it.

Perforated drainage pipes are laid on a sand-gravel bed

During installation, you should try to avoid common mistakes that lead to a violation of the functionality of the drain. These include:

- Insufficient depth of trenches, which can lead to disruption of the water balance of the site; Use of inappropriate pipes, which leads to rapid failure of the system; Incorrect angle of inclination of the drainage, which disrupts the functioning of the structure and can lead to serious problems with the water regime on the site.

Practice shows that laying drainage pipes with your own hands is a completely doable event. The only thing that must be entrusted to specialists is the calculation of the system and drawing up a pipe laying scheme. Everything else is a fairly simple job.

When performing it, it is very important to follow the instructions, carefully monitoring the key points: the slope of the system, the reliability of the pipe connection, the organization of inspection wells, etc. A well-equipped drainage system will serve for many years, preventing excess moisture from damaging the foundation of the house and spoiling the site.

The increased humidity of the site is always a source of big problems for the owners.

Moistened soil destroys plants - due to insufficient oxygen supply, roots rot and almost the entire crop is destroyed. The buildings do not feel in the best way either. The foundations are damp, water appears in the basements in the spring, the walls are covered with a network of cracks and colonies of fungus.

Excess moisture can be easily removed using special engineering structures known as drainage. The owners should pay attention to the arrangement of the drainage system, first of all, immediately after the acquisition of the site. And preferably before carrying out large-scale construction work, if any are planned.

Savings tips

Tips for saving when installing a drainage system go from the opposite.T, E, boil down to the fact that it is better to spend money on a competent drainage device than on the subsequent reconstruction of the house.

- Geological surveys must always be carried out before the installation of the drainage system! This will allow you to make the system working the first time and not to alter it later.

- Choose either coconut filters or quality geotextiles. Do not be lazy to familiarize yourself with its characteristics when buying;

- Instead of cheap limestone crushed stone, it is better to use granite, which will not be washed out with water later.

Typical mistakes

The most common mistakes when arranging a drainage system are as follows:

- shallow depth of trenches (reduced efficiency of the system and increased risk of freezing of drains in winter); use of pipes of the wrong type and diameter (leads to a quick failure of the system); lack of an angle of inclination or a small angle (the system is paralyzed at maximum load).

Installation of a drainage system is a job that the owners of the house can do. However, it is better to entrust the drawing up of the plan and carrying out all the necessary calculations.

Also, special attention is paid to compliance with all technical standards. The selection of pipes, the depth and angle of their laying are important points of installation work.

Drainage pipe cleaning

Even with a good filter, the pipeline gradually clogs up. There are 2 ways to clean it.

Mechanical method

The mechanical cleaning method is used for heavy contamination of pipelines. The basic principle of operation is the use of brute force. Either a cleaning ball or a plumbing cable with a spiral is used as a working tool.

In case of severe contamination, flushing is not enough, the water is not able to cope with all layers of silt and dense plugs. We'll have to resort to a mechanical method of cleaning the drain. Some blockages can only be destroyed by brute force.

A plumbing cable or ball can be used as a working tool for mechanical cleaning.

Hydrodynamic method

In most cases, a regular garden hose filled with water is sufficient to flush the system. Water must be supplied to the system under pressure.