Installation of bimetallic radiators

Sorted by relevance

| Sort by date

Author: Irina. and what is the coefficient for dismantling (to TEP18-03-001-02) radiators

it would be more correct to take, 0.4 or 0.7, if the same

radiator

dismantled and then put on another place I know that there is a direct price TERr65-19-1 for dismantling

radiators

, but something like that happened.

... pipelines ". According to clause 6. Appendix 3 to FSSTS-01-2001 (Appendix), the estimated price for radiators

cast iron does not take into account the cost of preparation

radiators

to install: “6. In estimated prices for

radiators

cast iron preparation cost is not included

radiators

to installation (grouping, regrouping, installing or replacing gaskets.

... cost of steel radiators

? Answer: In the monthly magazine "Estimated prices in construction" (SSC), the unit of measure for estimated prices for

radiators

steel installed in pieces, but at the same time in the name

radiators

their power is indicated in kW, so that you can determine the cost

radiators

and in kW. We believe that any of these meters can.

... heating. This indicator changes in kW of heat that a separate section can emit (for sectional aluminum or bimetallic radiators

) or all

radiator

(for solid steel or bimetallic

radiators

heating). Accordingly, when selecting specific models

radiators

.

... suits him, he needs this work (a 7-second shift would cost 2500 rubles) they decided to make their own calculation: dismantling radiator

- 900 rubles, installation

radiator

- 1300 rubles. and so that I would make an estimate taking into account their calculation, but without applying the prices from the collections for dismantling and installation

radiators

... How to be in this case, I can't just score such an amount, but what about payroll, HP, joint venture.

Author: Irina. Good afternoon, colleagues. Tell me the most correct price for dismantling the brackets radiators

since the customer writes in the comments that he was not taken into account (in the estimate, dismantling

radiators

by TERr 65-19-1)

Author: Tatiana Polubarieva. Good day! Please tell me what is the price for the regrouping of cast iron radiators

... Thank you.

... which collections should take into account these works? Answer: Radiators

cast iron MS (code 300 - 0555) are produced in 4 and 7 sections. If the contractor completes

radiators

at the facility, or at its base, then these additional works are paid according to the Collection TERr-2001 No. 65, tab. 65-02-020 "Rearrangement of old sections

radiators

»

Author: Vlad Svetlov. I am new to budgeting. I am making an estimate for replacing 10 cast iron radiators

7 sections MS-140. Heat flow of one section 0.160 kW 10

radiators

this is 11.2 kW, units of measurement in the estimate of 100 kW, I put 11.2 it turns out to be beyond the block.

Author: Olga. Good day. There is a question: how to take into account the bypass device during installation radiators

?

a source

Installation of bimetallic radiators

Sorted by relevance

| Sort by date

... pipelines ". According to clause 6. Appendix 3 to FSSTS-01-2001 (Appendix), the estimated price for radiators

cast iron does not take into account the cost of preparation

radiators

to

installation

: “6. In estimated prices for

radiators

cast iron preparation cost is not included

radiators

to

installation

(grouping, regrouping,

installation

or replacement of gaskets.

Author: Vlad Svetlov. I am new to budgeting. I am making an estimate for replacing 10 cast iron radiators

7 sections MS-140. Heat flow of one section 0.160 kW 10

radiators

this is 11.2 kW, units of measurement in the estimate of 100 kW, I put 11.2 it turns out to be beyond the block.

... please tell me what price can be applied when making horizontal holes in drywall about 5-7mm wide in places installations

radiators

? Drywall goes like a screen

radiator

Author: katya. Hello. Please tell me how you can translate one steel radiator

in kW. Thanks in advance.

Author: Natalya. Hello, tell me what price you can apply for installations

control valves on

radiator

heating. Air cock comes with

radiator

.

Author: katya. Hello. Help me please. How can I change one steel radiator

in kW. Thanks in advance.

Author: Galina. We work on municipal orders. I cannot understand how the amount of work for installation

radiator

... I multiply the kW of 1 section by the number of sections and divide by unit. measurements (100 kW). it turns out more than CMX offers. You are welcome.

Author: ProSlave. Judging by your investment, you should have: if 8 sections of 127W = 1016 W / h or 1.016 kW / h. If you have 8 radiators

you get 8.128 kW / h. Accordingly, the rate should be: 0.08128. Well, look what you have there.

The procedure for calculating the heat transfer of a heating radiator

The choice of heating devices for installation in a house or apartment is based on the most accurate calculation of heat transfer from heating radiators. On the one hand, each consumer wants to save on heating his home and therefore there is no desire to purchase extra batteries, but if they are not enough, it will not be possible to achieve a comfortable temperature. There are several ways to calculate the heat transfer of a radiator.

Option one

... This is the easiest way to calculate radiators, based on the number of external walls and windows in them.

The calculation order is as follows:

- when there is only one wall and a window in the room, then for every 10 "squares" of the area, 1 kW of thermal power of heating devices is required (in more detail: "How to calculate the power of a heating radiator - we do the calculation of the power correctly");

- if there are 2 external walls, then the minimum battery power should be 1.3 kW per 10 m².

Option two

... It is more complex, but allows you to have more accurate data on the required power of the devices.

In this case, the calculation of the heat transfer of the heating radiator (batteries) is carried out according to the formula:

S x h x41, where S is the area of the room for which the calculations are performed; H is the height of the room; 41 - minimum power per cubic meter of room volume.

The resulting result will be the required heat transfer for heating radiators. Further, this figure is divided by the rated thermal power that one section of this battery model has. You can find out this figure in the instructions supplied by the manufacturer to your product. The result of calculating the heating batteries will be the required number of sections so that the heat supply of a particular room is effective. If the resulting number is fractional, then it is rounded up. Better a little excess heat than a lack of it.

Installation of bimetallic radiators

Sorted by relevance

| Sort by date

Author: Vlad Svetlov. I am new to budgeting. I am making an estimate for replacing 10 cast iron radiators

7 sections MS-140. Heat flow of one section 0.160 kW 10

radiators

this is 11.2 kW, units of measurement in the estimate of 100 kW, I put 11.2 it turns out to be beyond the block.

Author: Olga. Good day! Tell me rate

on the

installation

oil

radiator

?

Author: Anna Vorontsova. I did not quite understand you, for example 1 radiator

consists of 12 sections, as in this

rates

then put the quantity? )) Our head is already going with these

radiators

)

Author: Tanya Bazhenova. “Natalya writes: Hello, tell me what rate

can be applied for

installations

control valves on

radiator

heating. Air cock comes with

radiator

. "If you are not only installing

radiators

, but also install the pipeline itself.

According to clause 1.18.7. GESN 81-02-017-2001 norm 18-03-001-01 "Installation

radiators

cast iron "does not take into account the work before. ... Appendix 3 to FSSTs-01-2001 (Appendices) estimated price for

radiators

cast iron does not include preparation costs. ... the current estimate and normative base of the FSNB - 2001 norms and

rates

for crimping, grouping, replacement of gaskets.

Author: Alena. Good day! please tell me which one rate

can be used when making horizontal holes in drywall with a width of about 5-7 mm in places

installationsradiators

? Drywall goes like a screen

radiator

Author: Anna Vorontsova. Good day. Please tell me which or which rates

apply to assembly

radiators

bimetallic? Those. separate sections come to the object, we need to collect them in

radiators

(different in the number of sections) and then install.

Author: katya. Hello. Please tell me how you can translate one steel radiator

in kW. Thanks in advance.

Author: Natalya. Hello, tell me which one rate

can be applied for

installations

control valves on

radiator

heating. Air cock comes with

radiator

.

Author: katya. Hello. Help me please. How can I change one steel radiator

in kW. Thanks in advance.

a source

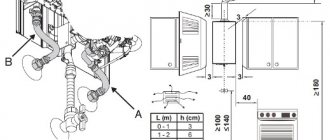

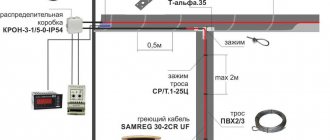

Installation of heating devices in rooms

Heating devices are installed only on a prepared plastered wall with a floor covering mark applied on it. Before their installation, as a rule, they are prepared at procurement enterprises or in the centralized metalworking shop, i.e. completing according to specification, strapping, checking the tightness of assembled units and blocks, etc.

The regrouping and crimping of cast-iron radiators is carried out at procurement enterprises using the BMC-111M mechanism. At the same time, it is impossible to allow the connection of the upper part of one section with the lower part of the other, the use of non-heat-resistant rubber for gaskets.

Convectors for installation are supplied with complete construction readiness, complete with fastening means. When tying them at procurement enterprises and transportation, their paint and varnish or decorative coating must not be disturbed. Therefore, before the end of all finishing work, it is not allowed to remove the packaging from the heating element, and the casing or parts of the casing of the convectors must be previously removed and stored in the warehouse. The casing is installed only after the completion of all installation and finishing work in the room.

Convectors are connected to heat pipes of the heating system by means of threads (including by means of union nuts) or by welding. To obtain high-quality welded joints without sagging and burr and to prevent an increase in the hydraulic resistance of the connections at the junction, the smooth ends of the pipes are processed on the STD-672 mechanism in high-frequency currents with the formation of cups (sockets).

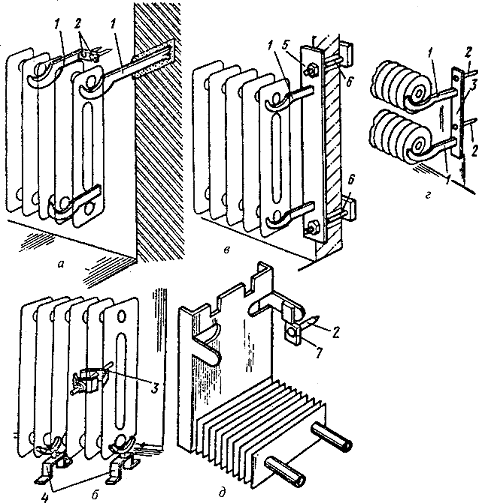

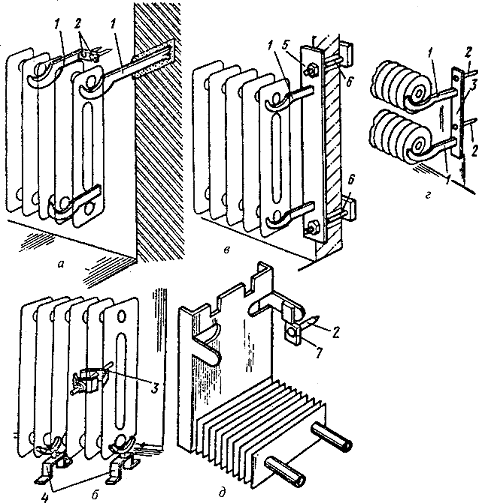

Installation of devices begins with marking the mounting locations of the mounts. The designs of fasteners for cast iron radiators, finned pipes and convectors with a casing are shown in Fig. 1.

Radiators, convectors, finned pipes are attached to the surface of building structures using brackets 1 (Fig. 3, a). Brackets are attached to concrete walls with dowels 2, and to brick walls - with dowels or cement mortar of a grade of at least 100 to a depth of at least 100 mm, excluding the thickness of the plaster layer. The number of brackets for radiators is shown below.

| The number of sections in the radiator | 3…9 | 10…14 | 15…20 | 21…24 | 25…28 |

| Number of brackets: | |||||

| upper | 1 | 2 | 2 | 2 | 3 |

| lower | 2 | 2 | 3 | 4 | 4 |

When fixing radiators to the wall, instead of the upper brackets, you can install radiator strips 3 (Fig. 3, b), located at a height equal to 2/3 of the radiator height; instead of the lower brackets, there are 4 stands attached to the floor.When installing radiators on stands, the number of the latter should be: two - with the number of sections up to 10 and three - with a larger number of sections. In this case, the top of the radiator is fixed.

Fig. 3. Fastening heating devices:

a - radiators; b - the same, on stands; c - the same, on the walls of lightweight structures;

d - finned tubes; d - convectors; 1 - brackets; 2 - dowels; 3 - bar; 4 - stand; 5 - bar; 6 - bolt; 7 - bracket

In winter, in unheated rooms, brackets for radiators can be wedged with scrap steel or cast iron, followed by embedding with cement mortar. The sockets for the brackets are cleaned and moistened with water before filling with the solution.

When installing brackets on wooden walls, on walls of lightweight structures and on internal partitions, they are fixed with screws, wood grouses, through bolts 6 with metal strips 5 (Fig. 3, c).

Finned pipes are fixed on the wall with brackets (Fig. 3, d), convectors - with brackets 7 (Fig. 3, e).

Steel panel radiators are installed on two KR2-RS brackets, the axis of which should be at a distance of 200 mm from the side ends of the radiator. Brackets are fastened to expanded clay concrete walls with 3x80 mm nails, to brick ones, sealing fastening means into pre-drilled holes, to reinforced concrete - with at least two DGPCh 5x30 mm dowel-nails using a PC 84 pistol.

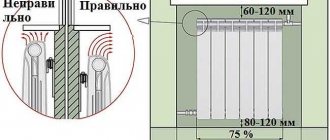

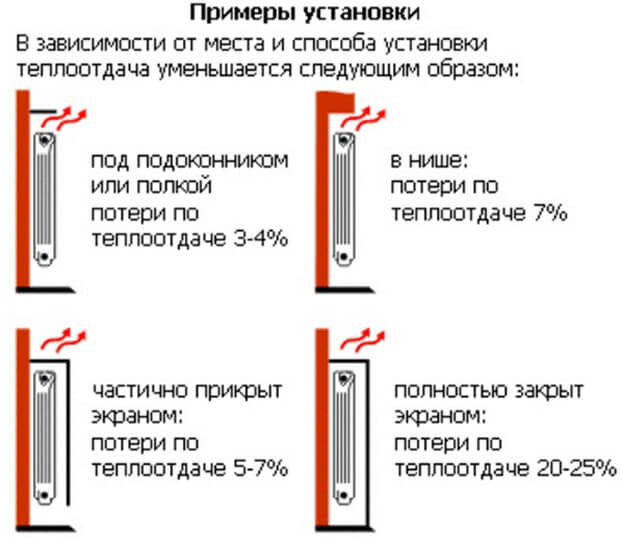

All heaters in one room must be installed on the same level. If possible, they are placed on the outer wall under the window, overlapping at least 75% of the length of the window sill in order to neutralize the falling flow of cold air from the window.

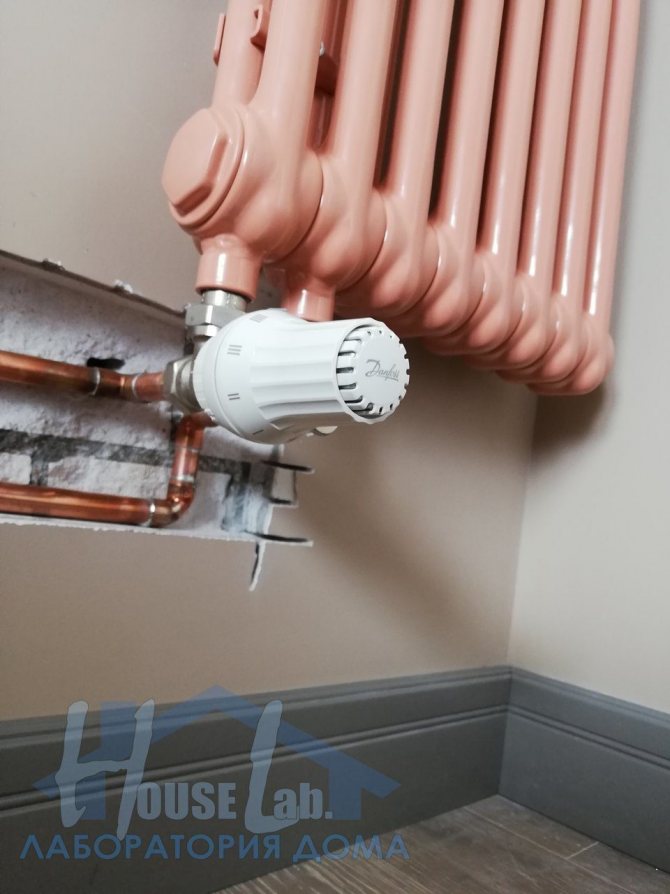

Radiators are mounted strictly vertically (see Fig. 4, b). In the premises of medical and prophylactic, sanatorium and children's institutions, radiators are installed at a distance of at least 100 mm from the floor and 60 mm from the wall surface.

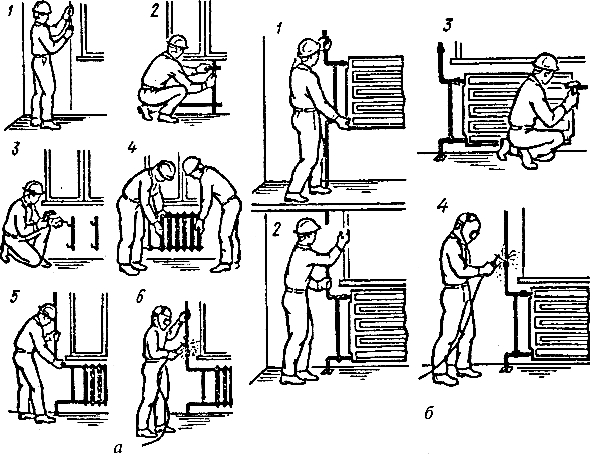

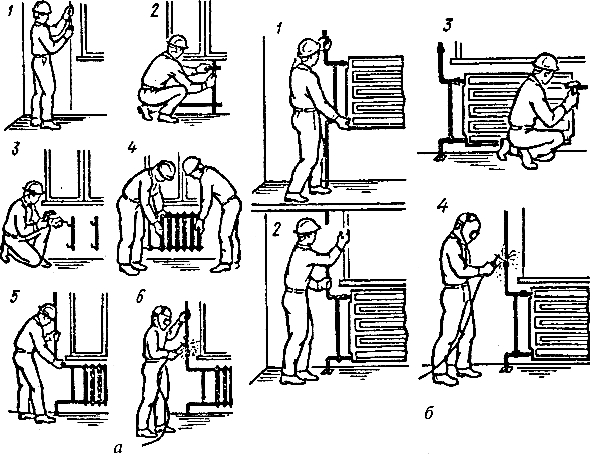

The sequence of mounting radiators is shown in Fig. 4.

Fig. 4. Radiator mounting sequence:

a - cast iron sectional; 1 - marking of places for installation of floor stands; 2 - marking of the places of installation of the brackets;

3 - installation of brackets; 4 - installation of cast iron radiators; 5 - installation of a floor stand; 6 - welding of joints;

b - steel; 1, 2 - block installation according to preliminary marking; 3 - fixing the unit to the wall; 4 - butt welding

Installation of bimetallic radiators

Sorted by relevance

| Sort by date

Author: Vlad Svetlov. I am new to budgeting. I am making an estimate for replacing 10 cast iron radiators

7 sections MS-140. Heat flow of one section 0.160 kW 10

radiators

this is 11.2 kW, units of measurement in the estimate of 100 kW, I put 11.2 it turns out to be beyond the block.

Author: Olga. Good day! Tell me rate

on the

installation

oil

radiator

?

Author: Anna Vorontsova. I did not quite understand you, for example 1 radiator

consists of 12 sections, as in this

rates

then put the quantity? )) Our head is already going with these

radiators

)

Author: Tanya Bazhenova. “Natalya writes: Hello, tell me what rate

can be applied for

installations

control valves on

radiator

heating. Air cock comes with

radiator

. "If you are not only installing

radiators

, but also install the pipeline itself.

According to clause 1.18.7. GESN 81-02-017-2001 norm 18-03-001-01 "Installation

radiators

cast iron "does not take into account the work before. ... Appendix 3 to FSSTs-01-2001 (Appendices) estimated price for

radiators

cast iron does not include preparation costs. ... the current estimate and normative base of the FSNB - 2001 norms and

rates

for crimping, grouping, replacement of gaskets.

Author: Alena. Good day! please tell me which one rate

can be used when making horizontal holes in drywall with a width of about 5-7 mm in places

installationsradiators

? Drywall goes like a screen

radiator

Author: Anna Vorontsova.Good day. Please tell me which or which rates

apply to assembly

radiators

bimetallic? Those. separate sections come to the object, we need to collect them in

radiators

(different in the number of sections) and then install.

Author: katya. Hello. Please tell me how you can translate one steel radiator

in kW. Thanks in advance.

Author: Natalya. Hello, tell me which one rate

can be applied for

installations

control valves on

radiator

heating. Air cock comes with

radiator

.

Dependence of the degree of heat transfer on the connection method

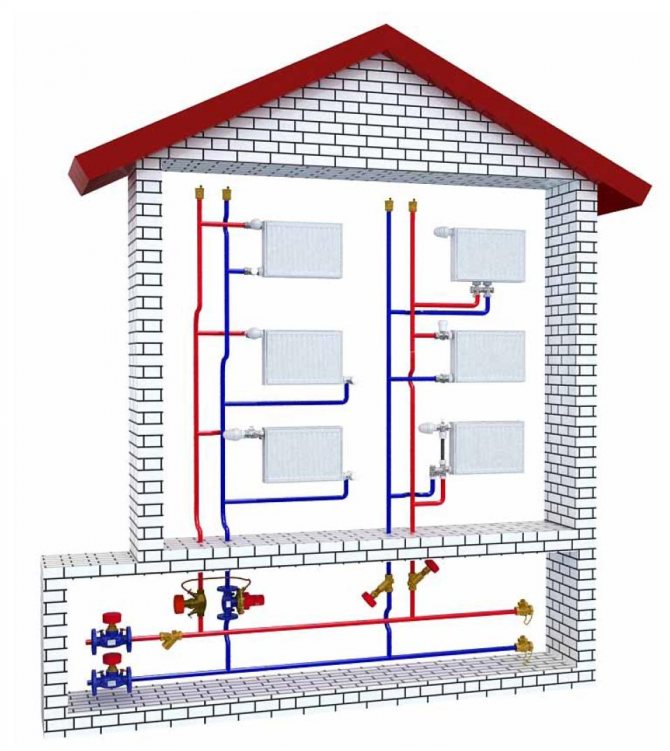

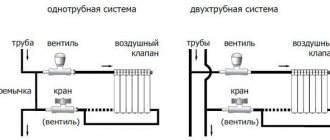

The heat transfer of heating radiators is influenced not only by the material of manufacture and the temperature of the coolant circulating through the pipes, but also by the selected option for connecting the device to the system:

- Direct one-way connection

... It is the most advantageous in relation to the indicator of thermal power. For this reason, the calculation of heat transfer from a heating radiator is performed precisely with a direct connection. - Diagonal connection

... It is used if a radiator is planned to be connected to the system, in which the number of sections exceeds 12. This method allows you to minimize heat loss as much as possible. - Bottom connection

... It is used when the battery is connected to the floor screed, in which the heating system is hidden. As the calculation of the heat transfer of the radiator shows, with such a connection, the loss of thermal energy does not exceed 10%. - One pipe connection

... The least profitable way in terms of heat output. Heat transfer losses with a single-pipe connection most often reach 25 - 45%.

Installation of bimetallic radiators

Sorted by relevance

| Sort by date

Author: Vlad Svetlov. I am new to budgeting. I am making an estimate for replacing 10 cast iron radiators

7 sections MS-140. Heat flow of one section 0.160 kW 10

radiators

this is 11.2 kW, units of measurement in the estimate of 100 kW, I put 11.2 it turns out to be beyond the block.

Author: Olga. Good day! Tell me rate

on the

installation

oil

radiator

?

Author: Anna Vorontsova. I did not quite understand you, for example 1 radiator

consists of 12 sections, as in this

rates

then put the quantity? )) Our head is already going with these

radiators

)

Author: Tanya Bazhenova. “Natalya writes: Hello, tell me what rate

can be applied for

installations

control valves on

radiator

heating. Air cock comes with

radiator

. "If you are not only installing

radiators

, but also install the pipeline itself.

According to clause 1.18.7. GESN 81-02-017-2001 norm 18-03-001-01 "Installation

radiators

cast iron "does not take into account the work before. ... Appendix 3 to FSSTs-01-2001 (Appendices) estimated price for

radiators

cast iron does not include preparation costs. ... the current estimate and normative base of the FSNB - 2001 norms and

rates

for crimping, grouping, replacement of gaskets.

Author: Alena. Good day! please tell me which one rate

can be used when making horizontal holes in drywall with a width of about 5-7 mm in places

installationsradiators

? Drywall goes like a screen

radiator

Author: Anna Vorontsova. Good day. Please tell me which or which rates

apply to assembly

radiators

bimetallic? Those. separate sections come to the object, we need to collect them in

radiators

(different in the number of sections) and then install.

Author: katya. Hello. Please tell me how you can translate one steel radiator

in kW. Thanks in advance.

Author: Natalya. Hello, tell me which one rate

can be applied for

installations

control valves on

radiator

heating. Air cock comes with

radiator

.

Author: katya. Hello. Help me please. How can I change one steel radiator

in kW. Thanks in advance.

a source

Estimates for the replacement and repair of heating batteries

If the replacement of communication networks is carried out in an apartment of a residential building, then for any changes in the arrangement of electrical and plumbing equipment, appropriate amendments must be made to those. passport of the entire residential building. But this does not apply to heating devices, so their independent replacement is prohibited. But in a private house, the owner can easily replace the batteries on his own.

You need to figure out which radiators are best to choose.

- Cast iron - they are not susceptible to corrosion and are very durable, but they are distinguished by a large mass.

- Steel - very durable, have an attractive appearance, but they are made of thin (1.5 mm thick) steel sheet, therefore they are sensitive to mechanical damage.

- Aluminum - have a rather low weight, look good, but do not imply contact of the coolant with other metals, an air outlet is also required.

- Bimetallic - have a steel core and aluminum fins, have a high efficiency, at the same time they are quite strong and presentable.

Having decided on the type and brand of the radiator, you should calculate the number of required radiator sections. It is calculated according to a simple formula - 1 section per 2 sq. m. area of the room. You can install spare ones, the number of which does not exceed 20% of the total, and each battery can be equipped with a separate choke or thermostatic head.

It is also advisable to equip each radiator with a valve with which you can completely disconnect the battery from the general circuit, and a valve that will direct the water flow through the shunt (bypass).

Replacement of radiators is carried out in the absence of water in the heating system. The new batteries are attached to brackets and connected to the common system using ball valves. The joints are sealed with fiber or fum tape. The air from the radiators is vented through the Mayevsky cock. It is necessary to check the tightness of all connections.

Prices for the installation of radiators, convectors, pipes, registers, mud collectors, air collectors and air taps should be found in the collections for the internal devices of heating systems GESN-18, FER-18, TER-18.

SCHEME OF OPERATIONAL CONTROL OF THE INSTALLATION QUALITY OF THE INTERNAL HEATING SYSTEM

Scope of operations and controls

| Stages of work | Controlled operations | Control (method, scope) | Documentation |

| Preparatory work | Check: - availability of documents on the quality of the product; - compliance of the materials used with the project, standards and specifications; - preparation of places for laying pipelines, installing heating devices; - assembly of sections of cast iron radiators | Visual Visual, technical inspection Visual Also | Certificates (passports), work log |

| Installation of pipelines Installation of heating devices | Control: - quality of pipeline connections and their fastening; - slopes of connections to heating devices; - verticality of pipelines; - the distance from the wall surface to the axis of the pipelines, from the riser being laid to the edge of the window opening and the length of the connections to the heating devices; - the number and method of mounting brackets for heating devices; - installation distance of heating devices from the floor, wall, window sill boards, etc. | Technical inspection Measuring Also -«- Visual Measuring | General work log |

| Acceptance of completed works | Check: - compliance of the actual position of the installed pipelines and heating devices with the requirements of the project; - fulfillment of project requirements and regulatory documents for the quality of pipe connections, fasteners of heating devices. | Technical inspection, measuring Technical inspection | Acceptance certificate of work performed |

| Control and measuring tool: vernier caliper, plumb line, metal tape measure, building level. | |||

| Input and operational control is carried out by: foreman (foreman). Acceptance control is carried out by: quality service workers, foreman (foreman), representatives of the customer's technical supervision. | |||

Requirements for the quality of work

a) radiators must be installed strictly vertically, without distortions, at a height from the floor not lower than 40 mm, from the top of the radiator to the window sill - not less than 50 mm. The distance from the device to the surface of the wall plaster must be at least 25 mm;

b) the vertical axis of the heating device, when installed under a window, must coincide with the axis of the window opening with a permissible deviation of not more than 50 mm;

c) devices located in the same room must be installed at the same level;

d) it is not allowed to wedge the radiator brackets in the holes with wooden wedges;

e) radiators should rest on all brackets with their necks, and the section edges should be located vertically;

f) the distance between the walls and the axes should be: 35 mm - with the diameter of the risers 15-32 mm and 50 mm - with the risers with a diameter of 40-50 mm. Deviations of ± 5 mm are allowed;

g) risers must be laid strictly vertically.

Technical requirements

The slopes of the connections to the radiators are from 5 to 10 mm for the length of the connections in the direction of the coolant movement.

With a line length of up to 500 mm, the pipe slope is not performed.

In a one-pipe heating system with one-sided connection of heating devices, an openly laid riser must be located at a distance of 150 ± 50 mm from the edge of the window opening, and the length of the connections must be no more than 400 mm.

Radiators of all types are installed at distances of at least:

- from the floor - 60 mm;

- from the bottom surface of the window sill boards (in the absence of a board - from the bottom of the window opening) - 50 mm;

- from the surface of the wall plaster - 25 mm.

In the premises of medical and prophylactic institutions, radiators are installed at a distance of at least:

- from the floor - 100 mm;

- from the wall surface - 60 mm.

The number of brackets is at least 3 per radiator (except for radiators in two sections).

The brackets should be installed under the radiator necks:

2 - with the number of sections up to 10;

3 - if the number of sections is more than 10.

Work instructions

The connection of steel pipes, as well as parts and assemblies from them, should be carried out by welding, threads, union nuts and flanges (to fittings and equipment).

Galvanized steel pipes, assemblies and parts must be connected, as a rule, on a thread.

With open laying of pipelines, the distance from the surface of the niche to the heating devices should ensure the possibility of laying the connections in a straight line.

When installing a radiator under a window, its edge on the side of the riser should not go beyond the window opening.

The alignment of the vertical axes of symmetry of the radiator and the window opening is not necessary.

Pipe bends should be performed by bending pipes or using seamless welded carbon steel elbows # M12291 1200030177 GOST 17375-2001 # S.

Bending radius of pipes with nominal bore:

- up to 40 mm inclusive, there must be at least 2.5 D (bunk);

- 50 mm and more - not less than 3.5 D (pl.).

Brackets for heating devices should be fixed to concrete walls with dowels, and to brick walls - with dowels or fixing the brackets with cement mortar of at least 100 grade to a depth of at least 100 mm (excluding the thickness of the plaster layer).

Heating and heat supply systems testing

Systems are tested after the completion of installation work. But first, all plumbing pipelines must be flushed.

Before testing, they check the compliance of the system under test with the project, perform an external examination of pipelines, connections, equipment, instruments, fittings.

The systems as a whole and individual types of equipment are subjected to testing, as well as their regulation. Acts are drawn up based on the test results.

Systems are tested by hydrostatic and gauge (pneumatic) methods.

Hydrostatic tests are carried out by filling all elements of the system with water (with complete removal of air), increasing the pressure to the test pressure, holding the system under test pressure for a certain time, reducing the pressure and, if necessary, emptying the system. The hydrostatic test is safe: the system is tested under conditions that are closest to working conditions. However, such a test requires the supply of water to the building to fill the sanitary system, which is unacceptable. If the tightness is violated, the premises may be flooded, the building structures may be soaked; in winter, water in pipes may freeze and “defrost” them.

Therefore, hydrostatic tests of heating systems, heat supply, boilers, water heaters are performed at a positive temperature in the premises of the building. The temperature of the water used to fill the system must be at least 278 ° K (5 ° C).

Hydrostatic tests are carried out before finishing the premises.

Gauge tests are largely devoid of the disadvantages of hydrostatic tests, but they are more dangerous, since in case of accidental destruction of pipelines or system elements under the influence of compressed air, their pieces can get into the people conducting the tests.

Gauge tests are carried out by filling the system with compressed air at a pressure equal to the test one and keeping it under this pressure for a certain period, then the pressure is reduced to atmospheric.

For testing, a TsSTM-10 pneumohydraulic unit is used in the form of a two-axle trailer, on which a 2.5 m tank and all testing equipment are mounted.

Heating systems testing. Acceptance of heating boilers is carried out on the basis of the results of hydrostatic or gauge testing, and of heating systems - on the basis of the results of hydrostatic and thermal tests, as well as an external examination of the mounted devices and equipment. Heating systems are tested for tightness (but not strength) by the manometric method under an excess air pressure of 0.15 MPa to detect installation defects by ear and then with a pressure of 0.1 MPa for 5 minutes (while the pressure should not decrease by more than 0, 01 MPa).

Hydrostatic tests of the hot water heating system are carried out at the end of its installation and inspection. To do this, the system is filled with water and air is completely removed from it by opening all air collectors, taps on risers and at heating devices. The system is filled through the return line, connecting it to a permanent or temporary water supply. After filling the system, all air collectors are closed and a manual or powered hydraulic press is turned on, which creates the required pressure.

Hot water heating systems are tested with a hydrostatic pressure equal to 1.5 working pressure, but not less than 0.2 MPa at the lowest point. During the test, the boilers and the expansion vessel are disconnected from the system. The pressure drop during the test should not exceed 0.02 MPa for 5 minutes. The pressure is monitored with a checked and sealed pressure gauge with graduations on the scale through 0.01 MPa. Minor malfunctions found that do not interfere with the hydrostatic test are marked with chalk and then corrected.

Hydrostatic testing of panel heating systems is carried out (before the installation windows are sealed) with a pressure of 1 MPa for 15 minutes. In this case, the pressure drop should not exceed 0.01 MPa. At negative outside temperatures, a gauge test of these systems is allowed.

After hydrostatic, a thermal test of the system is carried out for 8 hours, checking the uniformity of heating of the heating devices. If the outside air temperature is positive, then the water temperature in the supply lines should be at least 60 ° С, if negative - at least 50 ° С.

Steam heating systems with a working pressure of up to 0.07 MPa are tested by the hydrostatic method at a pressure of 0.25 MPa at the lowest point of the system.After the hydrostatic test, the steam heating system is tested for tightness of the heat pipe connections. For this, steam is introduced into the system at operating pressure. Then check to see if the connections are leaking pairs.

Water heaters are tested for density by hydrostatic pressure 1.25 times the operating pressure plus 0.3 MPa for the steam part and 0.4 MPa for the water part.

Pumping units are tested first at idle and then under load. Before testing, the installation is carefully inspected, the reliability of the fastening is checked, the absence of any objects (gaskets, parts) inside. To do this, the pump shaft is turned by hand and turned on for 3 ... 5 minutes. When extraneous noises and knocks appear, the pump is turned off and disassembled. During normal operation, the pump is run in for 12 ... 15 minutes, after which the rubbing parts are checked, the absence of heating and other malfunctions. The reasons for heating can be inaccurate fit, distortions, tight tightening, contamination of rubbing parts or lubricating oil. Then the pump is run in for 1 hour, then 6 hours, monitoring its condition. If no defects are found, the pump is turned on for trial operation and put under load.

The test results are documented by the act of acceptance of the heating system and heating boilers.

Testing of heating networks. Heat pipelines of heating networks are subjected, in accordance with SNiP, to a hydrostatic pressure test equal to the working pressure with a coefficient of 1.25, but not less than 1.6 MPa.

The hydrostatic test is carried out observing the following requirements: the valves in the test area must be completely open, the glands are sealed; to disconnect the tested section of the heat pipe from the operating networks, smooth flanges or plugs must be installed.

The hydrostatic test is performed in the following order: after filling the line with water at a temperature of at least 5 ° C, a pressure equal to the operating pressure is set in the heating lines and held for 10 minutes. If no defects or leaks are found at the working pressure, it is brought up to the test pressure and kept for the time necessary to inspect the route, but not less than 10 minutes.

The results of testing heat pipelines are considered satisfactory if, during their testing, the pressure did not drop, and no signs of rupture, leakage or fogging were found in the welded seams of pipes and valve bodies.

When performing installation work, in some cases (for example, in winter conditions), the hydrostatic test of heating networks is replaced by a manometric test (usually in separate sections of a heat pipe with a length of no more than 200 m).

Replacing the heating riser

When replacing heating pipes, you should also choose the right building materials, that is, pipes.

If you bet on the choice of pipes made of metal-plastic or reinforced polypropylene, you can get:

- ease of assembly and installation;

- light weight of products;

- the ability to bend well, which is very useful when assembling on site.

But, at the same time, plastics wear out easily and may not withstand pressure surges up to 20 atm., Which occur during a water hammer.

Therefore, many builders now prefer the installation of galvanized steel pipes when installing risers and connections to radiator valves.

First, water is drained from the system, and this must be done by a locksmith from the housing department. If work on replacing risers is carried out in emergency mode, then everything is done completely free of charge.

Only after a complete descent can you begin to dismantle the old risers with the help of a grinder. Then threading is done to screw on the new riser, or it is welded by welding. After that, the new pipes are connected to the threads on the riser using couplings and sealed with silicone sealant or sanitary flax.

In the next step, tees are installed on the threads, and valves are attached to them, and the shut-off valves are attached to branch pipes with a thread that is long at one end and short at the other.Jumpers are mounted, and the last is the connection of the radiator itself.

At the end, the air is vented and a test run of the riser is performed.

All prices for the replacement of heating pipelines made of galvanized steel pipes for pipelines made of multilayer metal polymers, with a riser heating system, can be found in the collections GESNr-65-15- (05-07), FERr-65-15- (05-07), TERr -65-15- (05-07).

And the replacement for similar pipelines, but already made of galvanized steel, should be better noted at the prices of GESNr-65-15- (01-04), FERr-65-15- (01-04), TERr-65-15- (01-04 ). But some estimators recommend using the prices for laying pipelines of galvanized pipes with a diameter of 15 to 150 mm according to the collections of prices GESN -16-02-002- (01-12), FER -16-02-002- (01-12), TER -16 -02-002- (01-12).

Output

As you can see, in fact, there is nothing complicated in the correct calculation and increasing the efficiency of the system of negotiated systems. The main thing is not to forget that in some cases the high heat transfer of heating pipes can lead to high annual costs, so you should not get carried away with this process either (see also the article “The need for an additional pipeline: how to install a pipe tie”).

In the video presented in this article, you will find additional information on this topic.

Did you like the article? Subscribe to our channel Yandex.Zen