The need for thermal insulation of the pool

One of the ways to prolong the life of the pool is to insulate it. It is of two types: wall insulation and bottom insulation.

The pool is insulated for two reasons:

- The temperature difference between the pool bowl and the ground, the water will quickly cool down;

- The second reason follows from the first. Too high costs for electricity, which is spent on heating the water in the bowl.

It is necessary to insulate the pool with the material, the thermal conductivity coefficient, which is quite high. Because the temperature of the ground is about 5 degrees Celsius, and the temperature of the pool is 25 degrees. The drop is too great.

Insulated room for the pool

Features of warming the room for the pool

To make it pleasant to be in the room where the pool is located, the air temperature should be several degrees higher than the water temperature. On average, the water temperature in the pool is maintained at about 26 degrees, so the air needs to be heated to 28-29 degrees. At the same time, heating requires significant costs, and heaters cannot always provide the desired temperature. The way out of the situation is to make an insulated room for the pool.

Due to the fact that water is regularly evaporated from the pool, the room is always humid. Its level is reduced by organized ventilation, air dehumidifiers, etc., but due to the special microclimate of the pool, it is required to buy moisture-resistant materials, both for decoration and for insulation.

It is necessary to prevent heat loss through the following zones:

Basically, the walls are insulated from the outside. The construction of internal insulation is extremely laborious, it is necessary to take into account the capacity of ventilation, heaters, dehumidifiers, climatic zone, etc. An error in miscalculations or a change in the operation of any device for regulating the microclimate leads to the loss of condensate between the wall and the insulation. As a result - the gradual destruction of walls and a decrease in heat-shielding properties.

Pool types

Pools are of various types, from special sports and health-improving ones to stationary and stationary ones installed in the country.

Stationary

Such a pool is not transferred over the site, a foundation pit is pulled out under it and the formwork for the pool bowl is poured. A place is being arranged for drainage and water intake. But there are times when there is no water on the site, which could constantly fill the bowl. In this case, resort to the following solution. At the request of the owner, a fire engine is brought in, which fills the pool with water. But what about water purification, you ask. That's how. A skimmer cleaning system is installed, which, with proper care and proper use of water in the pool throughout the year, the water can not be changed for several years.

Stationary pool

Mobile

This type of pool costs the owner less than a stationary one and does not require year-round maintenance. Only for the swimming season in summer. In addition, this type of pool can be moved by the owner to different parts of the suburban area. In turn, there are several subspecies of a mobile pool: inflatable and frame. The first is one of the simplest. But it is easy to pierce it with careless handling. The second type is more durable and durable. The water in it can not be changed all season if a good filter is installed. But unfortunately, you have to face the following problem: many insects in search of water find your pool and often drown there. The most unpleasant thing is that wasps can fly in on a hot afternoon, which will interfere with rest.

How to insulate the pool?

The presence of a pool on your own personal plot is no longer a luxury, but still the cost of building it is not cheap. Therefore, each owner wants to extend its service life. This can be done even at the stage of its construction, taking care of good waterproofing, correct installation and selection of quality materials. But so that the operation of the private pool is not accompanied by a number of problems, it is also necessary to insulate it.

The insulated walls of the pool will help to better retain heat.

Thermal insulation of swimming pools is an important attribute in their operation.

Foam insulation is considered the most economical and simplest way.

Thermal insulation is necessary for a number of reasons related to both weather and energy conditions. It is a known fact that the soil, even at the very peak of the heat, warms up to a maximum of 12 ° C, which contributes to high heat losses in the absence of thermal insulation. But what about the winter? Insulation of the pool in winter is simply necessary to avoid cracking the walls of the bowl in extremely low temperatures. And also if thermal insulation has not been made, a large amount of heat loss promises an increase in the cost of electricity used to heat water. To reduce the risk of damage to pools and energy costs, it is necessary to insulate it.

Thermal insulation materials for the pool

It is impossible to insulate the pool with any material you like. It will be money wasted. Because it may not fit and not provide the necessary parameters. Let's figure out which material is best.

Thermal insulation membrane

The advantages of this material are:

- Mechanically strong and flexible;

- Meets all hygiene requirements;

- Very little water rinse;

- Easy to fit and cook by hand welding;

- Welding seams are very strong, have double thickening;

- Environmentally friendly;

- Ease of repair;

- Can be sent for recycling.

Foam concrete

This type of material waterproofs the pool well, as it has:

- low water permeability;

- resists high pressure;

- holds a blow in front of an aggressive aquatic environment;

- is one of the most budgetary waterproofers.

Foam concrete - material for pool insulation

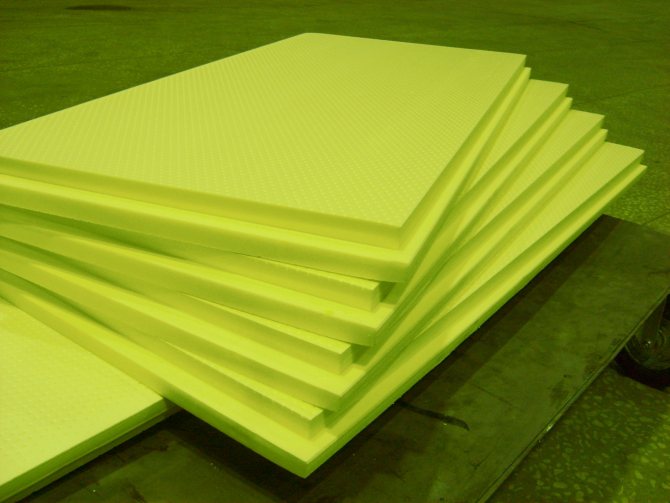

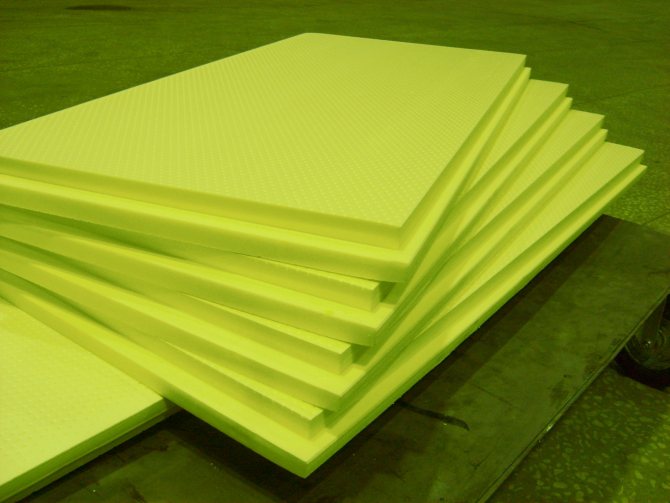

Styrofoam

Polyfoam is one of the most affordable and inexpensive types of pool insulation, which will stop the transfer of heat from water to the ground. Its advantages are:

- availability;

- little weight;

- environmental friendliness;

- low price;

- high thermal insulation and waterproofing properties;

- does not progress corrosion.

In addition, this material is easy to install and does not require special installations and machines.

Material selection

Polypropylene pool layout.

There is a wide selection of materials for pool insulation on the market. The most commonly used are: foam concrete, foam plastic, expanded clay concrete, thermal insulation membranes, expanded clay, and so on. But all of the above materials for thermal insulation have one common drawback - the presence of seams through which large heat losses occur. And then it becomes necessary to seal them, otherwise the thermal insulation will have little efficiency.

Experienced builders consider the most suitable material for thermal insulation of pools of all types of polyurethane foam. This material is easy to use, so insulation of even the most complex structure will not be difficult. The use of polyurethane foam as a heater for swimming pools will save money, since this material does not have a high price.

Pool system using a skimmer.

Polyurethane foam has a number of advantages over other materials:

- Polyurethane foam is at the same time a waterproofing, which will reduce costs for the latter.

- Has a low flammability.

- Resistant to temperatures from -100 to 130 ° C.

- Additionally, it does not load the structure, since it has a small mass.

- Seamless surface of the insulating layer.

- High adhesion to various types of surfaces.

- Wide range of applications.

- Ease of transportation and storage conditions.

- Chemical resistance to industrial hydrocarbons and weakly acidic precipitation.

- Maintainability.

Technological features and advantages of sprayed PU foam

Polyurethane foam is most effective when insulating a house or pool. This is due to its cellular structure. In addition, the cells are filled with carbon dioxide. In addition, the heat transfer coefficient of this material is higher in comparison with other materials. On this point, PPU surpasses even air.

Other advantages of the material:

- spraying does not leave seams through which cold could break through;

- spraying can be carried out on structures of various shapes, of any configuration and complexity;

- simultaneous insulation and waterproofing is provided by PPU spraying;

- fireproof, as it extinguishes when ignited on its own.

Material selection

Polypropylene pool layout.

There is a wide selection of materials for pool insulation on the market. The most commonly used are: foam concrete, foam plastic, expanded clay concrete, thermal insulation membranes, expanded clay, and so on. But all of the above materials for thermal insulation have one common drawback - the presence of seams through which large heat losses occur. And then it becomes necessary to seal them, otherwise the thermal insulation will have little efficiency.

Experienced builders consider the most suitable material for thermal insulation of pools of all types of polyurethane foam. This material is easy to use, so insulation of even the most complex structure will not be difficult. The use of polyurethane foam as a heater for swimming pools will save money, since this material does not have a high price.

Pool system using a skimmer.

Polyurethane foam has a number of advantages over other materials:

- Polyurethane foam is at the same time a waterproofing, which will reduce costs for the latter.

- Has a low flammability.

- Resistant to temperatures from -100 to 130 ° C.

- Additionally, it does not load the structure, since it has a small mass.

- Seamless surface of the insulating layer.

- High adhesion to various types of surfaces.

- Wide range of applications.

- Ease of transportation and storage conditions.

- Chemical resistance to industrial hydrocarbons and weakly acidic precipitation.

- Maintainability.

Insulation methods and materials

There are slight differences in the insulation of pools made of different materials. Let's take a closer look.

Plastic basin

The pool is insulated by spraying polyurethane foam. You can do this yourself by purchasing a special device. Further, the bowl is placed in the ground or belongs to a specially designated room. This type of insulation helps to prevent the pool water from cooling down.

Concrete basin

Warming is carried out by the method of PPU spraying. Here it acts as both a heat insulator and a hydro and steam insulator. However, insulation must be carried out not only outside, but also inside. So that there is no early cooling of the water in the pool bowl. Inside the pool, polyurethane foam is sanded, reinforced, and then cement mortar is applied. Then everything is decorated with mosaics.

PPU spraying - a way to insulate the pool

How to insulate the pool?

The presence of a pool on your own personal plot is no longer a luxury, but still the cost of building it is not cheap. Therefore, each owner wants to extend its service life. This can be done even at the stage of its construction, taking care of good waterproofing, correct installation and selection of quality materials.But so that the operation of the private pool is not accompanied by a number of problems, it is also necessary to insulate it.

The insulated walls of the pool will help to better retain heat.

Thermal insulation of swimming pools is an important attribute in their operation.

Foam insulation is considered the most economical and simplest way.

Thermal insulation is necessary for a number of reasons related to both weather and energy conditions. It is a known fact that the soil, even at the very peak of the heat, warms up to a maximum of 12 ° C, which contributes to high heat losses in the absence of thermal insulation. But what about the winter? Insulation of the pool in winter is simply necessary to avoid cracking the walls of the bowl in extremely low temperatures. And also if thermal insulation has not been made, a large amount of heat loss promises an increase in the cost of electricity used to heat water. To reduce the risk of damage to pools and energy costs, it is necessary to insulate it.

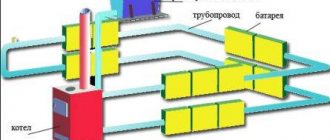

Thermal insulation of the bowl and pipeline

It makes sense to insulate the bowl and the pipeline only in stationary pools. Mobile models simply do not need this. The simplest way to insulate the bowl is to use foam. Insulation sheets are simply laid around the concrete during pouring.

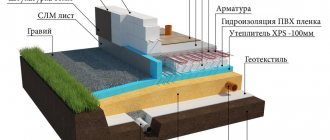

As a rule, the bottom is not insulated. The average depth of the pool is sufficient to keep the water from freezing. Thermal insulation of the pool with foam will also save the structural material from moisture.

Ultimately, this will save the concrete from the freeze-thaw cycle when moisture gets in. Polyfoam performs an additional function of moisture protection. Sometimes, in addition to or instead of polystyrene, expanded clay backfill is used with a layer of 20-30 cm thick.

For thermal insulation of the pipeline, it is better to use foil and basalt mineral wool shells. The shell has already been formed for the size of the pipe, it remains only to insert the pipe into the insulation and glue the joint with foil tape.

It is impossible to immediately fill the insulation with earth, since the matted clods of dirt and stones can damage the insulating layer. Therefore, a sand pillow is always poured under the bottom of the insulation. Ideally, you need to fill the pipes with sand as well until the main part is hidden under its layer.

Pool insulation is an important part of the installation work. Thanks to which you can save money on electricity in the future, as well as the water in the pool bowl will always be at the same set temperature.

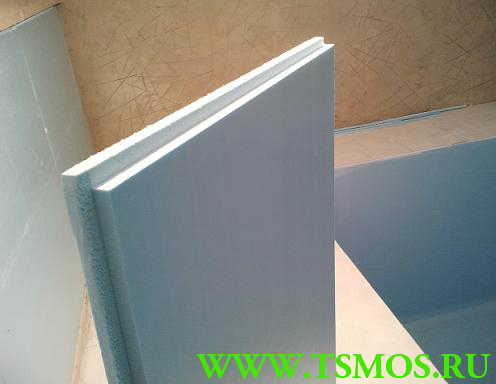

Pool insulation

Insulation for a pool, where moisture is constantly present, must first of all be moisture-proof. Such material with high thermal insulation properties is extruded polystyrene foam of Styrofoam 300-A or URSA XPS N-III brand. After the pool bowl has been installed and the internal walls have been erected, it is necessary to proceed with insulation. With the help of extruded boards, installation will be simple and reliable. Unlike mineral wool, XPS expanded polystyrene will not absorb moisture, which will ensure its thermophysical properties for the entire life of the pool. Extruded Styrofoam boards are an environmentally friendly product. The production of the material takes place using CO2, and it differs from other similar products. The most modern equipment makes it possible to achieve the production of highly efficient materials that have no analogues in the domestic market. Insulation for the pool Styrofoam 300-A has geometric dimensions of 1250 * 600 mm. The minimum thickness of the slabs is 30 mm with the selected quarter. The so-called step allows the installation of plates without gaps and crevices, which is extremely important for insulation. Plates are mounted in a groove in a groove. This avoids cold bridges. The Styrofom pool insulation is fixed with plastic dowels and INSTA-STIK adhesive.If you choose the method of fastening with glue, then the maximum consumption of Inta-Stick 1 cylinder = 750 ml will be 6.75 m2 or 9 plates with a size of 1250 * 600 mm. You can also choose a more economical application, because the adhesive quickly sets and has a high degree of adhesion. Styrofoam 300-A is ideal for insulating foundations, basins and pool walls. CFC-free technology for the production of the material provides the release of modern heat-insulating materials, making in favor of quality and comfort inside the premises. Thermal insulation boards can be sheathed with plastic panels or other finishing products. At the moment, Styrofoam products are not produced in Russia! A similar insulation URSA XPS!

Video: Heater for the pool

Buy insulation for the pool

+7,

It might be interesting:

| |

| |

| |

| |

|

LLC GK "TEPLOSILA" - together with you since 2005!

Varieties of insulation

The choice of materials and methods for insulating the pool is a lot - from economical to highly costly. The most popular are:

- expanded clay concrete,

- polystyrene or penoplex,

- foam concrete,

- expanded clay,

- foamed polyethylene.

These materials are time-tested and confirmed their quality:

- reliability,

- strength,

- high thermal insulation,

- unaffected by outside influence,

- hydro resistance,

- environmental friendliness,

- a light weight,

- ease of installation.

Table of thermal insulation properties of materials:

| Material | Density in kg / m3 | Minimum layer, cm | Thermal conductivity | Hygroscopicity | |

| Bulk | Slag | 1000 | 30 | BUT | B |

| Expanded clay | 500 | 20 | B | D | |

| Perlite, vermiculite | 40-100 | 10 | D | BUT | |

| Basalt fiber | 130 | 15 | D | B | |

| Roll | Glass wool | 75-175 | 10-15 | D | B |

| Minvata | 35-125 | 10-15 | D | B | |

| Stitching mats | 75-150 | 10-15 | D | B | |

| Plastiff | 50-60 | 2 | D | D | |

| Isover, URSA | 35-125 | 10-15 | D | B | |

| Penofol | 60-70 | 5 | D | IN | |

| Expanded polystyrene | 30-40 | 10 | D | IN | |

| Polyurethane foam | 30-60 | 10 | D | IN | |

| Plate-sheet | Styrofoam | 35-50 | 10 | d | IN |

| Mipora | 25-40 | 10 | D | IN | |

| Mineral and glass wool | 75-250 | 10-15 | D | B | |

| Wood fiber | 250 | 1.5-3 | B | BUT | |

| Foam blocks | Expanded clay concrete | 1000 | 40 | BUT | IN |

| Foam concrete | 600 | 25 | B | B | |

| Aerated concrete | 400-800 | 20-40 | B | B | |

| Aerated concrete | 400-800 | 20-40 | B | B | |

| Gas silicate blocks | 400-800 | 20-40 | B | B |

Legend:

A - Very high

B. - High

B. - Average

G. - Low

D. - Very low

Polycarbonate, or "pavilion"

The polycarbonate cover is an arched aluminum structure with polycarbonate walls. Such a covering can be applied to any pool - in terms of size, shape and volume, you can even choose the desired color. The finished structure can be moved on specially built-in rails that are placed along the pool. Also, this "pavilion" has built-in doors that can be locked. This cover has a lot of advantages - for example, it is possible, regardless of the weather, if you install additional water heating, and swim in the cold season. Also, this design will protect the pool not only from debris, dirt and dust, but also from the penetration of various animals and even strangers.

The main disadvantage of a polycarbonate covering is considered to be its cumbersomeness and the need for the presence, and that is, the preparation of a special surface on which the rails will need to be placed. The cost of such a pavilion is quite high.

If you are choosing a pool cover for yourself, you need to decide for which functions you need it. In principle, any of its varieties will be able to protect the water structure from dust and dirt and warm up the water a little. For example, using a pavilion, you create a greenhouse effect. The modern variety of shapes, colors and types of protective coating allows you to choose exactly the option that harmoniously suits the design of the pool.

Click Media LLC, UNP 192220456

Author: Vitalina ASTROVA