Types of noise and its diagnostics

House heating system

If water is noisy in the heating pipes during the operation of the heat supply, then there are certain reasons for the occurrence of this effect. First you need to identify them, and then proceed to reduce the noise or completely eliminate it.

Why does the water in the heating pipes make noise and how to correct this deficiency? Let's deal with the main types of extraneous sounds. It is they who indicate the objective factors in the occurrence of the undesirable effect:

- Crackling pipes. Occurs when the heating system is turned on;

- Clicks that appear at regular intervals;

- Constant hum in highways;

- A barely audible knock.

All these side effects - noise in the heating battery or radiators significantly reduce the comfort of living in the house. In addition, they may indicate that the heating supply is not working properly. If you do not take action to remedy the situation in time, some heating element may fail.

If the heating pump or other component of the system is noisy, you should first try to localize the cause of the extraneous sounds. To do this, it is recommended to use the following technique:

- Trace the frequency of occurrence of the effect.

- Try to identify the relationship - an increase in temperature in pipes, pressure surges, etc.

- Make sure that the noise in the heating boiler comes from it, and not from other objects in the boiler room.

If it has been identified that the source is a component of the heating system, certain actions should be taken to eliminate this phenomenon.

Often, noise in the heating riser appears due to faulty elements of the safety group - an air vent and a drain valve. Therefore, it is recommended to first check their functionality.

Noise in heating radiators

Heating radiator repair

To identify why heating radiators make noise, you must first check their condition. Often the reason for this is their breakdown - damage to the case or other obvious design defect. In this case, a battery replacement or restoration work is performed.

If everything is normal with the appearance and integrity, the type of noise is determined. Most often, the effect occurs in the form of clicks or constant hum. This can be explained by several factors:

- The appearance of a small airlock... It only slightly hinders the movement of hot water, but at the same time there is a hum in the system;

- A large number of foreign elements in the heating device... This is a common reason why radiators make noise;

- Malfunctions of the thermostat... The check stem has shifted resulting in unwanted noise defects;

- Incorrect battery installation... Vibration during the flow of the heating medium is transmitted to the mounting units in the wall.

These are the main causes of noise in radiators. After correct diagnosis, you can start to work to reduce the sound effects.

In a centralized heating system, a noisy riser can only be fixed by a management company. To do this, you must draw up a statement and hand it over to representatives.

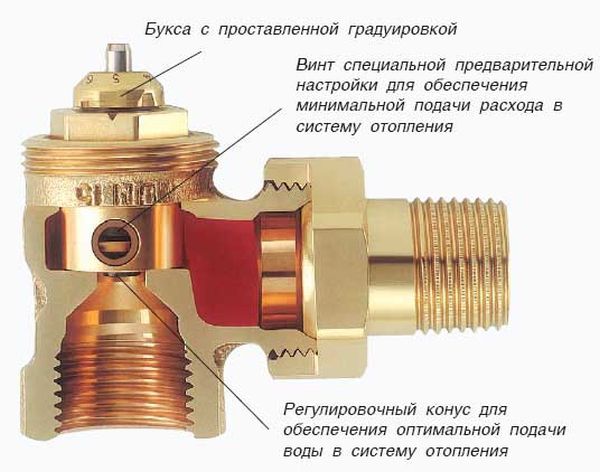

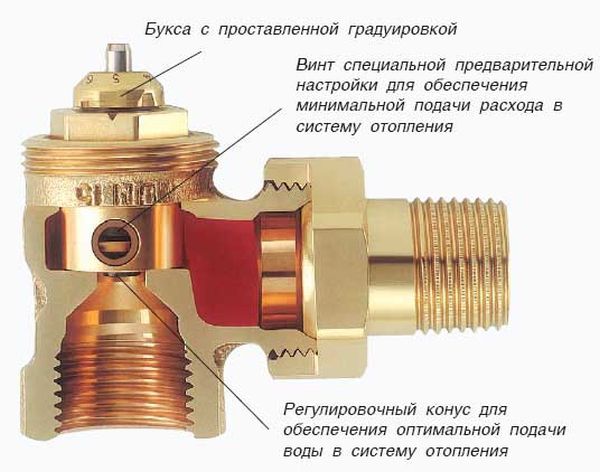

Mayevsky crane design

The elimination of the airlock can be done using the installed Mayevsky crane. It is designed specifically for this purpose.

With the noise of the heating batteries, the autonomous heat supply should be stopped so that the water temperature drops to + 25-30 ° C.Then you should do the following:

- Open Mayevsky's tap.

- Fill the heating system with water gradually.

- Wait until coolant flows from the tap pipe. It should be weaved for 1.5-2 minutes so that the air lock is completely removed.

Then the system is fully started and checked to see if the noise has appeared in the heating radiators again. If the cause has been identified correctly, this effect will no longer occur.

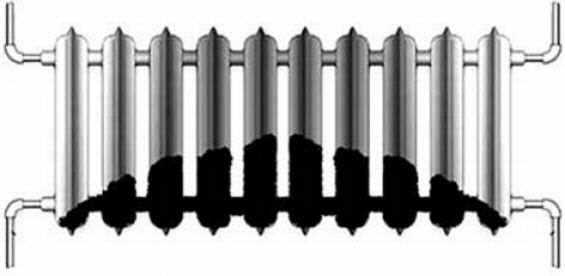

Debris concentration in the radiator

To eliminate noise in the radiator due to a large amount of debris, the condition of the strainer is first checked. The presence of foreign elements in it (the remains of rusting pipes and radiators, limescale) indicates a clogged system.

Having found out the cause of the noise in the radiators, the system should be cleaned. There are several ways to do this:

- Hydrodynamic... Garbage and limescale are removed from the mains and batteries under the action of a strong pressure of water;

- Chemical... Special reagents decompose the clog into small fractions, which are then flushed out of the heating system.

In this way, noise can be eliminated.

Before choosing a cleaning technology, in particular a chemical one, it is necessary to read the instructions for using the composition or method. In some cases, they can adversely affect the integrity of system components.

It is easiest to diagnose the appearance of noise in heating radiators due to improper installation. Its source is fasteners installed in the walls. In this case, it is necessary to replace them and re-install them.

The noise in heating radiators can be caused not only by the problem in them. In some cases, the reason is the malfunctioning of other system components - boilers or pumps. Experts recommend a comprehensive approach to solving the issue of noise in heating radiators. Only a complete diagnosis will help determine the true cause.

Noise in heating pipes

Types of heating pipes

How to determine why heating pipes make noise and what caused this phenomenon? The first step in identifying the causes is to follow the methodology described above. So, a constant hum may indicate incorrect operation of the circulation pump.

The noise of water in heating pipes can be caused by a number of factors. Often they are complex in nature - as if adjusting to each other, they create a complex kind of sound effects. Let's deal with the cause of noise in heating pipes by the nature of the sound:

- Bubbles and clicks indicate a blockage in the pipes.... Reducing the bore diameter creates excessive pressure in a certain section of the system, which is the cause of noise;

- Cracking sound causes air valve breakage... After checking it and detecting a malfunction, replace it;

- Vibration caused by improper installation... Noise in the heating pipe occurs when the coolant passes - the line can hit the wall.

The easiest way to get rid of extraneous sounds is to flush the heating system. To do this, you can use the methods described above. Diagnosis of incorrect attachment is carried out by touching the line. If strong vibration is felt with simultaneous noise of water in the heating pipes, additional fasteners should be installed.

The water in the heating pipes can make noise due to improper operation of the mixing unit - a large temperature difference leads to the expansion of the metal lines and the appearance of extraneous noise.

The use of copper pipes for heating

When deciding which pipes to choose for heating, you can dwell on copper products. It should be remembered that they oxidize in the presence of eddy currents and interaction with aluminum.Eddy currents appear when laying a heating pipe in a wall nearby with electrical wiring.

Copper pipes can be used not only for connecting batteries, but also in underfloor heating systems

Copper pipes do an excellent job with their functions even if there is an unstable (from negative indicators to +500 ° C) temperature of the flowing water.

Note! Due to the presence of smooth and non-corrosive inner walls, the material exhibits good wear resistance (it lasts up to 100 years).

The copper pipe for heating has a high flow rate and thermal conductivity, it is tear resistant, can withstand high pressure and is impervious to oxygen. In addition, the material has a bactericidal effect. The copper system must be installed in one of the following ways:

- low temperature;

- high temperature.

It is better to give preference to the first method, which involves the use of flux. Copper pipes for underfloor heating are ideal for laying laminate flooring. Their cost is slightly higher than that of analogues made from other materials.

Noise in heating pumps

Breakdown of the heating circulation pump

Constant noise in the heating pump may appear due to partial breakdown of its components - the impeller or rotor. At the same time, the functioning of the entire system deteriorates, which leads to a decrease in the efficiency of its work. To eliminate this cause, repair the pump or install a new one.

Also, constant noise in the circulation pump can be caused by its unstable operation. voltage drops lead to a loss of synchronization and, as a result, to an uneven movement of the coolant. This can cause noise in the heating system in other areas - in pipes and radiators. It is possible to check the operation of the pump only after a complete diagnosis. It is impossible to do it at home without special equipment.

In addition, noise effects in the riser or other areas of the heating supply can occur due to a pump malfunction for the following reasons:

- Incorrect installation... The rotor of the device must be strictly horizontal;

- Inconsistency of equipment power with calculated data... This leads to a significant increase in the rate of flow of the coolant through the mains. The only way out is to install a pump of the appropriate power.

In practice, it is extremely difficult to diagnose noise in a heating circulation pump. To do this, it is necessary to dismantle it and disassemble the structure. This can be done only with special skills and diagnostic tools. Therefore, this work is best entrusted to professional repairmen.

For the correct calculation of the pump power, it is recommended to use special software systems.

Selection and recommendations for the use of an inhibitor for the heating system

One or another inhibitor must be selected based on several indicators:

- An open or closed expansion tank is used;

- Type of construction materials used: ferrous metals, alloys based on copper or aluminum;

- PH indicator of water;

- Indicators of "hardness" of water (the amount of dissolved salts in the coolant).

Depending on the hardness and acidity of the coolant, as well as the characteristics of the heating system, it is necessary to choose an inhibitor of a certain composition. The following additive compositions are distinguished:

- Orthophosphate. The reagent forms a protective film, causes the precipitation of salts, in case of their large amounts. It is necessary to add to the coolant based on the proportion of 10 - 20 mg / l. It is used in heating systems where elements are made of ferrous metals with a water Ph level of less than 7.5 units. Chlorine concentration in water of 300 mg / l and more levels the effectiveness of orthophosphate and leads to metal corrosion.Can be used in combination with zinc polyphosphate or phosphanate additive;

- Polyphosphates. They are used to protect pipelines made of ferrous metals with water Ph up to 7.5 units. No water softening is required when using polyphosphate. The amount of chlorine also does not affect the properties of this inhibitor. The effectiveness of the action of polyphosphates is increased with the help of zinc. The optimal amount is 10 - 20 mg / l;

- Phosphonates. It is used only in combination with zinc, orthophosphates or polyphosphates. The composition will be effective at a concentration of 10 - 20 mg / l and at Ph 7 - 9. Protection of ferrous metals is provided by the addition of calcium;

- Molybdate. The reagent protects ferrous and aluminum alloys. It is necessary to add to the coolant at the rate of 75 - 150 mg / l, in order to reduce the amount of the composition without reducing the efficiency, the addition of phosphorus components is required. Recommended water Ph is 5.5 - 8.5. Hard water causes the molybdate to precipitate. Chlorine and sulfur impurities neutralize the use of molybdate, but without the occurrence of pitting corrosion;

- Silicate. It is used for soft water at a concentration of 10 - 20 mg / l. Provides protection for systems made of ferrous metals and copper alloys with water having a Ph 7 and higher. A protective coating forms on surfaces over several weeks;

- Zinc. It is used as an additive to other additives: orthophosphates, polyphosphates, phosphonates, molybdates. And also with combinations of inhibitors that do not contain zinc: orthophosphate / polyphosphate, orthophosphate / molybdate, a mixture of phosphonates in the amount of 0.5 - 2 mg / l. Zinc strengthens the protective film and reduces the amount of the main inhibitor. If the Ph of water exceeds 7.5, it is necessary to use zinc stabilizers;

- Benzotriazole. The required concentration is 1 - 2 mg / l in water with Ph 6 - 9 for the protection of copper alloys;

- Tolitriazole. A benzotriazole analog;

- Calcium orthophosphate. Used to eliminate the adhesion of calcium phosphate deposits. The content of calcium orthophosphate in water should be 10-15 mg / l;

- Polyacrylates, polymaleates, hydrolyzed polyacrylamides and acrylate substances. Used for biological contamination. The optimal concentration is 2-3 mg / l;

- Chlorine and bromine are used to kill microorganisms. A concentration at the level of 0.1 - 0.5 mg / l is sufficient. Chlorine is effective only in water with a Ph below 8. If the pH exceeds this value, bromine is used;

- Zeolites. Used to soften water;

- Nitrite. Used in closed systems, it causes the formation of a stable iron oxide film on the surface. Effective in concentrations of 250-1000 mg / l and increasing Ph up to 9 - 9.5, by adding borax. The amount of nitrite can be reduced to 300 mg / l if the same amount of molybdate is used. Nitrites lend themselves to decomposition by bacteria, therefore, in the complex, it is also necessary to use a non-oxidizing bactericide, copper corrosion inhibitors and a polymer dispersant;

- Alkalis (caustic soda, ash). Used to increase the Ph of water to 9 - 10.5 units.