Advantages of antifreeze liquid for heating

- The main advantage can be considered the following: when the building will not be used for a long time, and the heating system, of course, is deactivated, then there is a great risk that in winter the frozen water can simply burst pipes. In the case of using antifreeze, this cannot happen. Therefore, such a coolant does not need to be drained.

- Special additives prevent the occurrence of corrosion, various kinds of plaque, and the dissolution of the sealant is excluded.

Disadvantages of antifreeze

- First of all, it is poisonous, so its use in dual-circuit systems is highly undesirable. In addition, antifreeze is highly flammable. Although in recent years, non-toxic propylene-based antifreezes have begun to appear in the country.

- This antifreeze liquid for heating systems has a lower heat capacity (about 1/5 lower than that of water).

- It is more viscous, so it will be more difficult to "move" it through the pipeline.

- Most importantly: antifreeze is completely incompatible with galvanized pipes!

I would also like to give a few words to fans of using antifreeze for cars as a coolant. It is not necessary to do this, since the antifreeze contains substances, the use of which in residential premises is unacceptable.

When should you not use antifreeze?

The subtitle sounds this way because you can familiarize yourself with the positive qualities of an anti-freeze liquid right at the time of purchase. But there are other qualities that manufacturers try not to expand on.

- For antifreeze, a sufficiently powerful circulation pump is needed, since its viscosity is higher.

- It cannot be used with double-circuit boilers (the reasons for this were indicated in the previous chapter).

- For antifreeze, more powerful radiators are also required, since it absorbs heat worse.

- Never use antifreeze in open systems. Then it can simply evaporate.

- Zinc can cause antifreeze to lose most of its properties.

Benefits of plain water

Firstly, water is relatively inexpensive, which is why it is available. Secondly, most boilers and other elements of the heating system assume precisely the use of water as a heat carrier. And, finally, if a leak occurs in the system, then ordinary water will spill into the room, which is absolutely harmless to the human body.

Cons of using water

There are several similar disadvantages at once.

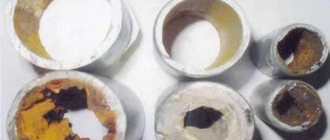

- If the pipeline is made of metal, then sooner or later the water coolant will cause corrosion.

- Sudden frosts when the heating system is not started can cause pipeline rupture, sometimes it happens to the boiler itself. Material damage, you guessed it, will be significant.

- If, instead of good antifreeze, you use water, albeit purified, then soon a plaque will form on the surface of the pipes. It, in turn, leads to unnecessary consumption of the received energy (such a gap can reach thirty percent). And due to the fact that fuel costs a lot today, the cost of heating a house will be significant.

- The heat capacity of water is much higher.

- Overheating of the water in the system will not cause any serious problems, which cannot be said about antifreeze: in this case, it simply decomposes, forming acid.

Outcome

The choice, of course, will always remain with you, that is, with the consumer.Which antifreeze liquid for heating systems is better and which is worse cannot be said with certainty. Most likely, such a choice should be made based on a specific characteristic of the heating system, or even better - after consulting a specialist in advance.

How to choose an antifreeze liquid

Ideally, immediately choose heating elements, taking into account the fact that you will be using antifreeze, and not ordinary water. In this case, you can avoid the nuances associated with damage to equipment.

If the heating installation is already in operation, and you decide to replace the water with a modern "anti-freeze", then when choosing it you must:

- Choose the type of antifreeze, taking into account the installed heating structures (metal from which the elements of the heating system are made, type of heating boiler - if double-circuit, then the use of ethylene glycol antifreeze is prohibited, the power of pumps and radiators);

- Choose the optimal manufacturer for you in terms of price, quality and reliability;

- Get acquainted with the properties of the additives that make up the fluidto anticipate possible effects on the material of construction;

- Carefully study the instructions for use and recommendations by diluting the anti-freeze agent;

- Clarify the terms of operation and features of the goods (usually antifreeze can be used no more than 5 years).

Taking into account all the above points, you will accurately select the best product for you.

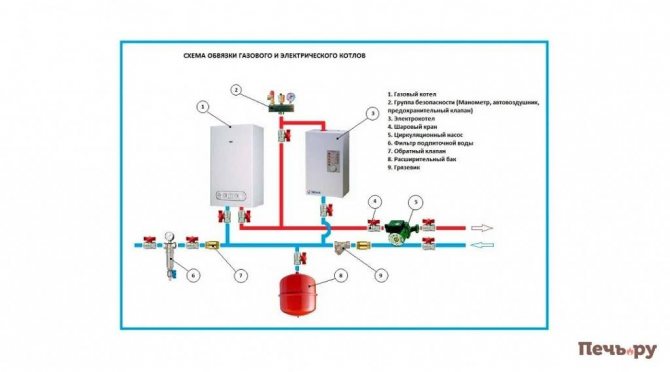

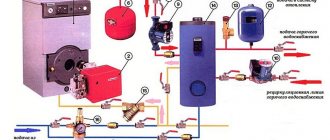

How to pour coolant into the system

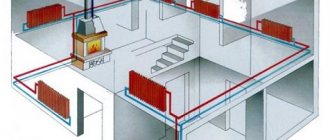

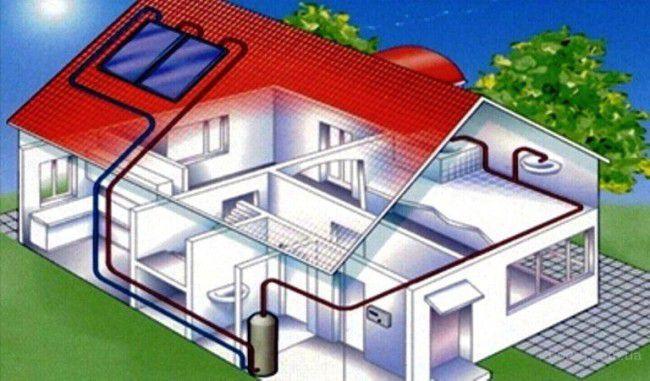

If you have a heating system with natural circulation, then the coolant must be placed in an expansion tank, which is better placed slightly above the highest point of the system and connected with a strong hose.

The main thing to consider here are two points:

- Bleed air (check all installed taps, if you use float valves that release air automatically, then just watch the filling);

- Make sure that the container is not empty, because then an air lock will form in the system and the liquid will have to be drained again.

Thus, if ordinary taps are used, then it is better to carry out the filling together - one person makes sure that the container is filled all the time, and the second checks the taps. If there are automatic taps, you can pour liquid into the structure yourself.

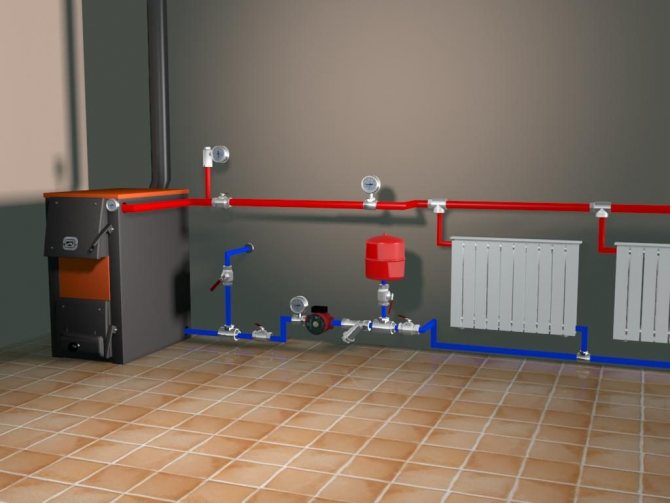

If you operate an installation with forced circulation, then the coolant must be supplied under pressure, using a pump with a bottom water intake. Connect a durable hose to it and fix it well at the joints. Dip it into a container with antifreeze and turn on the pump.

There are also nuances here:

- Since the pump empties the container rather quickly, it is imperative to monitor its filling in order to avoid the formation of an air lock;

- Monitor the pressure in the system (so that it does not rise above 2-3 atmospheres), turn off the pump in time;

Before pumping antifreeze, it is better to fill the installation with water a day in advance to make sure it is tight. Revealing a leak after the "non-freezing" is in the system is undesirable, since it is toxic and can get into the living space. And to drain the liquid for troubleshooting is problematic.

If water was previously used in heating, then you must definitely pay attention to the fact that it has greater expansion properties than antifreezes. And before using them, it is necessary to change all the seals at the joints, in order to avoid leaks.

It is also worth considering that it will not be possible to drain all the water from the system, and then additional dilution of the anti-freeze agent will occur. To avoid loss of density, you need to mix the antifreeze solution with the concentrate approximately 1: 1.

Non-freezing liquids are not used if:

- You have galvanized pipes installed.This will entail chemical reactions as a result of which a lot of salt precipitation is formed, which will block the operation of the heating system;

- They are produced on an ethylene glycol basis, and you have a double-circuit boiler in operation. In this case, the ingress of antifreeze from the heating cycle into the water supply circuit is not excluded, and this is dangerous to human health.

- You have an open heating system, as the non-freezing agent can evaporate and its vapors are toxic.

Why is it better to use antifreeze liquid in the heating system, rather than water?

Non-freezing liquid (or antifreeze) in the heating system greatly simplifies the work with the equipment. If you use ordinary water as a heat carrier, then the heating system has to be equipped with additional devices, for example, a valve for bleeding air from the expansion tank. In addition, in the variant of a country house that is not constantly used, the water will have to be drained or poured into the heating system at each visit, otherwise it will simply freeze in winter.

On the one hand, water has a higher heat capacity and retains heat longer when moving through the pipelines of the heating system. This is what determines the wider use of water as a heat carrier in private country houses.

Influence of the composition on heating

Antifreeze for filling tanks, which is available on the market, is made from one of two substances:

- monoethylene glycol;

- propylene glycol.

Each of the substances differs in characteristics and properties and has its own purpose.

Fill

Monoethylene glycol

This compound is a dihydric alcohol, and is the simplest representative of the polyol group. In its pure form it looks like a transparent, oily liquid. Has no smell. Refers to toxic substances and, if ingested, can lead to severe damage or death.

When using monoethylene glycol for heating, the following features must be taken into account:

- When starting the system using such a composition, it is advisable to start electric boilers with a minimum power level. After that, it is necessary to gradually increase the parameter of the heat received, while it is possible to allow the limit value to be exceeded.

- Monoethylene glycol may only be used in closed circuits with one line. The substance is poorly soluble in water, therefore, if it enters the water supply system, it can lead to poisoning.

Substance based on monoethylene glycol

Propylene glycol

In the functional composition, the differences are minimal. Instead of diatomic, unsaturated ethylene, the more common triatomic propylene is the basis. The main difference that leads to the use of propylene glycol in heating is harmlessness to a living organism. It can be poured into any type of system.

Choosing the right fluid is difficult for many reasons. There are many aspects to consider, including pipe material, aluminum, stainless steel or plastic. Non-freezing coolant requires high costs associated with the purchase and installation of equipment, insofar as it is necessary to install a forced water pump.

It can be difficult to calculate the parameters yourself, so it may be necessary to involve a team of specialists, both for design and for installation of the system. When using antifreeze, you will have to decide how to cool the tank. The boiling point of organic alcohols that are used for this purpose is significantly higher than that of water, which also requires attention during design.

In addition, there are many product options on the market that differ in operational parameters.

https://youtube.com/watch?v=ePyAZ3vEUr0

Propylene glycol

The "Eco" logo is often used on the packaging of liquids of this type, which indicates complete safety of use at normal temperatures. They can be used in double-circuit boilers, since the ingress of a small amount of propylene glycol into the water usually does not cause negative consequences. The level of heat capacity here is higher than that of ethylene glycol. The propylene glycol solution, as it were, lubricates the walls of the pipeline, reducing the overall level of hydraulic resistance. This leads to a decrease in heat loss and increases the efficiency of the heating system.

As for the inadmissibility of contact with galvanized products, propylene glycol antifreeze also has this drawback. The price of this type of heat carrier is an order of magnitude higher than that of ethylene glycol. Antifreeze goes on sale in a ready-to-use form: special additives bring the durability of the fluid to almost 10 years. In general, this substance is an excellent solution to the question of what is the best antifreeze for heating a house.

b356b770e14ddf5cfaba674c591e843e.jpe

Which type to give preference to?

Non-freezing mixtures differ in cost and chemical composition

Therefore, when choosing, you need to pay attention to the properties. There are a large number of products on the market that have suitable parameters from many manufacturers.

The choice of a specific mixture for the needs can be significantly complicated by non-obvious advantages and disadvantages. For a long time, favorites have appeared on the market among liquids.

Warm house

One of the most widespread and popular brands is the "Warm House" article produced in Russia. Due to the absence of transport costs and duties, the cost of the goods is quite stable and affordable.

The advantages of this mixture are high performance properties. Once filling the tank, you can not replace it for the next several seasons. You can not change the liquid for 5-10 years. The feature is indicated on the marking, so it is worth focusing on it as well.

The cost of mixtures varies depending on many factors: volume, ingredients and manufacturer. Therefore, you will have to choose among a large number of options. Domestic and foreign manufacturers are expanding the range of goods. Moreover, the updated versions are distinguished by reduced harm to health in the event of an accident. Raw materials for the production of mixtures due to the use of new cleaning methods are becoming of a higher quality. To improve the characteristics, propylene glycol for the food industry is chosen as the main component.

Recommendations for the selection and operation of heat carriers - which one is better to choose

None of the manufacturers of heat carriers will refute the fact that in the case of stable operation of the heating system in winter, it is water that is the best option, which heat carrier to choose for heating. It is better if it is a special distilled liquid with modifying additives, as mentioned earlier. Homeowners who consider buying store water a waste of money usually do their own preparation, softening it, and fitting the system with the right filters.

If it was decided to use non-freezing coolants, it is important to have information on the conditions that exclude the likelihood of their use:

- If the house has an open system.

- When using natural circulation in the circuits: such a concentrate of the coolant for heating the system simply "will not pull".

- The presence of pipes or other elements in contact with the coolant with a galvanized surface is unacceptable.

- All connecting assemblies equipped with seals made of tow or oil paint must be repacked, since glycolic substances will destroy them very quickly. As a result, antifreeze will start to leak, creating a real threat to people in the room.The old tow can be used as a new sealing material by treating it with a special sealing paste "Unipak"

- It is forbidden to use non-freezing liquids in those systems that are not equipped with devices for accurately maintaining the temperature of the coolant. The heating level dangerous for glycol antifreezes starts already from + 70-75 degrees: these processes are irreversible and fraught with the most unpleasant consequences.

- Usually, after pouring antifreeze into the system, it is required to increase the power of the pumping equipment, install a larger expansion tank, and increase the number of battery sections. Sometimes it is necessary to change pipes to wider ones.

- Incorrect operation of automatic air vents after pouring antifreeze was noticed: they are recommended to be replaced with Mayevsky taps.

- Before pouring antifreeze, the system must be thoroughly cleaned and rinsed. This is done using special formulations.

- To change the concentration level of antifreeze, use only distilled water. In this case, it is better to resist even from the use of purified and softened water.

- The correct concentration of antifreeze coolant for heating systems is of utmost importance. It is better not to expect that the winter will not be very harsh by overly diluting antifreeze. It is recommended to adhere to a threshold of -30 degrees, even in traditionally warm regions. In addition to protection against abnormal frosts, this will create optimal conditions for inhibitors and surfactants, the effectiveness of which is noticeably reduced with an excessive water content.

- After filling with new coolant, it is forbidden to immediately turn on the maximum mode of the system. It is best to build up power smoothly so that the antifreeze has time to adapt to new conditions and circuit elements.

- Studies show that at present the most reliable antifreeze coolant is a propylene glycol composition. Ethylene glycol is too dangerous, and glycerin is so controversial that it is rarely used. So it's better to overpay, but sleep well at night.

Non-freezing coolants - antifreeze

Strengths and weaknesses of anti-freezing liquids

After purification and enrichment with useful components, water turns into a good heat carrier. However, its main drawback is freezing, which cannot be overcome in this way. Therefore, systems with unstable operation in winter are recommended to be filled with special fluids with a lower freezing level. They are called antifreezes: they are well known to motorists, as they are used in engine cooling systems and glass cleaning.

Advantages of antifreeze:

Low freezing point

At the same time, which is very important, even their crystallization does not provoke hardening and volume expansion. Although the fluidity level of the gel-like substance does not allow the heating to function normally, this completely eliminates the risk of damage to pipes, radiators and heat exchangers.

After normalizing the temperature, the non-freezing coolant completely restores its fluidity, which does not affect its performance in any way.

Possibility of adding water. The freezing level in normal concentration is about -65 degrees. Such an ultra-low temperature regime is rare in nature, which makes it possible to dilute antifreeze with distilled water. As practice shows, the lower limit of -35 degrees will suit all regions of the country.

Chemical stability. It is typical for most modern antifreezes. Although the range of operating temperature differences is very significant, the service life of a high-quality coolant without replacement can reach 5 years.

Considering antifreezes in a qualitatively potential use as a coolant, it is important to know the negative aspects:

- High viscosity level. It is an order of magnitude higher than that of water, therefore, good circulation of non-freezing liquids along the circuit is possible only with powerful pumps. If the house is equipped with a natural circulation heating system, the use of antifreeze as a heat carrier is completely excluded.

- Low heat capacity. Even the most effective non-freezing heat carrier for heating in this regard is usually inferior to water by at least 15%. It seems that the figure is not large, but on the scale of the heating system of an entire building, the consequences of such a difference are very significant, and are expressed in a decrease in efficiency, an increase in the cost of maintaining the desired temperature, and the need for a larger number of powerful radiators.

- High level of penetration through gaskets. Despite the higher viscosity of antifreeze, even those seals that remained dry on the water do not hold it. Therefore, if the coolant is replaced, it is imperative to repackage all fittings and threaded connections. In this case, the aggressiveness of anti-freezing liquids should be taken into account, which implies the use of only chemically resistant seals.

- Toxicity. Most antifreezes contain chemical compounds harmful to humans that can cause severe poisoning, damage to the skin and mucous membranes. Therefore, the systems where they are used must be as tight as possible in order to exclude the slightest chance of leakage or evaporation of liquid. In any case, antifreeze cannot be used in double-circuit boilers, where there is a real risk of the coolant entering the hot water pipes.

- High level of thermal expansion. This indicator for antifreeze is an order of magnitude higher than that of ordinary water. Because of this, larger diaphragm expansion tanks have to be used. The use of cheap open-type expanders in this case is completely excluded, since this threatens not only with the evaporation of an expensive heat carrier, but also with the ingress of toxins into the indoor air. Currently, three types of antifreeze coolants are widely used - based on ethylene glycol, propylene glycol and glycerin.

Varieties of antifreeze and their properties

Antifreeze, or antifreeze liquid, is a mixture of several substances. The composition includes distilled water, propylene glycol or monoethylene glycol and inhibitor additives.

Typically, two types of non-freezing liquids are used for heating systems in a home and industrial ventilation systems:

- with ethylene glycol. This antifreeze contains the following percentage of the components: 63%, 31%, 6% (ethylene glycol, water, additives);

- with propylene glycol. This antifreeze has a lower concentration of the main active ingredient: 46%, 50%, 4% (propylene glycol, water, additives).

If you have never dealt with non-freezing before, then please note that this liquid differs from ordinary water in several ways at once:

- by viscosity;

- by fluidity;

- by thermal conductivity.

This means that antifreeze requires special operating conditions. How it works? Antifreeze imparts a higher resistance (in terms of hydraulics) to the piping networks and ducts in the batteries. This means that it will be necessary to pump the anti-freeze through the pipes with greater intensity - that is, the system with antifreeze requires more pump pressure for correct operation. But the heat transfer of antifreeze is 2 times higher than that of water - accordingly, it will take 2 times less heat energy to heat the anti-freeze.

Important: Please note that ethylene glycol is toxic and gives off harmful fumes. However, as can be seen from the composition of non-freezing, almost half of it consists of purified water. In addition, before pouring antifreeze into the system, it must still be diluted with water.This suggests that the harmful properties of ethylene glycol are leveled.

Blitz Tips

- "Non-freezing" is ideal for heating houses. which are rarely visited in winter and the system is turned off most of the time;

- Choose special equipment for using antifreeze;

- It is better to purchase radiators with a power 30-40% higher than that of conventional ones;

- Due to the increased viscosity of anti-freeze agents, it is advisable to use pumps with reinforced hydraulics;

- If necessary, prepare a solution from the concentrate. then use only distilled water for this;

- Do not mix different types of antifreeze, it is better to use one. But if there is no other way out, then first mix them in a container and observe whether a precipitate falls out;

- The use of automotive antifreeze in heating structures is unacceptable. since it contains components, the use of which is unacceptable in residential buildings;

- It is better not to use a concentrate with a freezing threshold of -65 degrees Celsius in its pure form. this will lead to overheating of the heat exchanger and decomposition of the additives;

- But if a solution with a freezing temperature of no more than -25 degrees is used in the system, and the temperature has dropped below (which is unlikely), then you should not worry. The heating installation will not be damaged at all. Antifreeze will thicken, and when the temperature rises, it will return to its original state, without loss of properties.

- Automotive sealant can be used to prevent leaks at the seals.

Determination of the required amount of antifreeze

The calculation of the volume of antifreeze liquid that is supposed to be poured into the heating system is based on the following:

- What heating structure is used;

- What material is it from;

- Its internal volume;

- The area of the heated room.

Some parameters of the equipment can be determined visually; you can find more detailed nuances in the operating instructions. If exact numbers are not found in the technical documentation (for example, the use of antifreeze is not recommended by the manufacturer), then more complex calculations and, possibly, a professional approach will be required.

In this case, for the calculation, you can:

- Use specialized literature;

- Calculate the volume depending on the number of batteries and sections in them. Taking into account the volume of liquid filling one section;

- Follow the most rational path - contact a specialist, who will carry out all the necessary calculations in the shortest possible time and with a professional approach.

Pouring liquid into the heating system

Characteristics of antifreeze heating fluids

The way a low-freezing liquid for heating systems behaves in the circuit is primarily influenced by the quality of the additive package and, of course, the operating conditions. Regardless of which main active element is added to the glycol base, all formulations have anti-corrosion and anti-foaming properties.

Without these additives, the heating fluid is very corrosive. All non-freezing liquids foam, but especially glycerin anti-freezing liquids for heating systems of houses. Foam is an air-containing substance, and air leads to impaired circulation, the formation of air pockets, as well as water hammer in the heating system.

The additive package has its own time resource. After a certain time, the additives disintegrate at the molecular level.

This will form a precipitate and release acid. It turns out that nothing already smoothes the aggressiveness of the coolant for heating the house, moreover, everything is aggravated by the release of acid. Service life of antifreeze liquid:

- based on ethylene glycol - five years;

- based on propylene glycol - five years;

- glycerin-based - up to ten years.

This is the service life of the compound under favorable operating conditions. The main requirement is, of course, temperature.When the temperature of the coolant rises to 90 degrees, the non-freezing liquid begins to disintegrate and loses its properties. This only happens if the boiler starts up incorrectly after a long period of inactivity, or errors during installation.

Direct contact of the heat exchanger with the flame is undesirable if antifreeze is poured into the circuit

For example, when a heat exchanger is built into a conventional oven. Some people install it so that it is in contact with an open flame. If you plan to use antifreeze for stove heating, then this should not be done. It is necessary that there is a layer of brick between the heat exchanger and the flame. He and the coolant will protect from too hot tongues of flame, and distribute the heat evenly. In this case, the non-freezing liquid for stove heating will not overheat.

Characteristics influenced by the quality of the additive package:

- thermal conductivity;

- density;

- viscosity;

- fluidity;

- thermal expansion.

The higher the quality of the additives, the higher the characteristics will be. That is, as close as possible to the characteristics of water. In the case of the coefficient of thermal expansion, then it should be as small as possible.

Considering the fact that the volumetric expansion of the anti-freeze is greater than that of water, it is necessary to provide for an expansomat of 40% more volume.

The thermal conductivity of antifreeze is lower than that of water. The lowest thermal conductivity of glycerin antifreeze liquids. In relation to water, it is only 85%; in other non-freezing systems, the indicator can reach 90%. As you can see, the difference is not that great.

Non-freezing liquids are half as dense and viscous as water. These qualities impede circulation. In order to pump the coolant along the circuit, a pump of greater power will be required; it would also be nice to assemble a heating circuit from pipes with a cross section larger by one step. For example, when it comes to polypropylene pipes. then instead of 25 in diameter, it is better to take 32.

Despite the fact that the non-freezing liquid is denser and more viscous, it has a lower coefficient of surface tension, that is, it is more fluid. Do you know that you can draw water into a glass "with a slide"? The slide, of course, will be small, but even visually it is visible that the liquid rises above the edge of the vessel. With anti-freeze, this will not work. Due to this high fluidity, it flows out where water does not penetrate due to surface tension. In other words, if there are microcracks and even very small holes, then the non-freezing liquid will find a way out there.

Therefore, often, after there was water in the circuit and it was decided to pour an anti-freeze into it, leaks appear. Major leak points:

- pipe joints;

- connections between radiator sections;

- places for connecting additional elements;

- in the boiler itself.

Water has another useful property, thanks to which a minor leak can disappear by itself. Metal particles settle at the edges of the cracks and seal them. Of course, this is just scale, which, in the case of flushing and further pressure testing of the system, will be removed and flow will resume.

Is it possible to pour anti-freeze into aluminum heating radiators

Each owner who has installed aluminum radiators in a house or apartment is concerned about extending their "life", the efficiency and safety of their work. Often the answers to it lie in the quality of a coolant.

In apartment buildings connected to a centralized heating system, there is no need to talk about the composition and level of Ph water, since after it runs under pressure through the numerous pipes of the heating main, it constantly contains suspensions and dirt, which affect it.

Another thing is when it comes to an autonomous heating system, which gives a person the right to choose what to use, water or special antifreeze for aluminum radiators.

Consumers are so accustomed to the fact that water is used as a heat carrier that they do not even suspect that there are liquids better than it in terms of quality. The biggest advantage of water is its cost and non-toxicity, but otherwise it can be an enemy for the heating system. Her ability to cause corrosion in metals "ruined" more than one generation of radiators.

In addition, in the event of an accident on the heating main in the winter, when the heating is forced to not work, it can freeze in the pipes even at zero temperature. Its ability to expand, both during freezing and heating, causes them to rupture.

Antifreeze, enriched with special additives for use in heating systems, has some advantages next to water, but it also has negative qualities:

- This coolant freezes at -70 degrees.

- It does not harm aluminum, which is very important for such a "sensitive" metal.

- It has a good level of thermal conductivity, although it takes a little longer to heat up than water.

These were the positive qualities of antifreeze. Among its cons:

- It has a higher viscosity, so a fairly powerful boiler is needed to move it through the heating system.

- The fluidity of antifreeze is a threat if the integrity of the joints or elements of the heating network is violated.

- Antifreeze is toxic, so precautions should be taken when using it.

Many consumers are wondering, knowing these disadvantages, whether antifreeze can be used in aluminum radiators. In this case, it is even preferable when it comes to an autonomous heating system. The durability of this coolant is enough to heat the house for 10 winters, which in itself pleases. During this period, aluminum batteries do not change at all under its influence, which also has a positive effect on their service life.

Depending on what substance is added to the distilled water, the technical characteristics of the antifreeze change.

- Glycerin as an additive shows itself perfectly, it is non-toxic and highly soluble, which allows it to be used for a long time in the system without fear of precipitation.

- Ethylene glycol antifreeze is the cheapest and most toxic. The second indicator concerns its ingestion, when it can lead a person to death. If you handle it carefully and check the system for integrity, then it will not cause harm and will serve for a long time inside aluminum radiators.

- Propylene glycol is the best addition to distilled water for antifreeze production. It is non-toxic, does not give precipitation and its only drawback is the rather high price.

Since ethylene glycol-based antifreezes are very popular due to their cost, before buying such a tool, it is necessary to check it for compatibility with the heating network. Such a carrier is used exclusively in autonomous systems with a single-circuit boiler, since if it gets into the water, it can cause serious poisoning or even death.

Ethylene glycol antifreeze must not be used in open heating systems. In the case of fumes, the harm can be just as irreparable.

On the other hand, heat transfer fluids that include propylene glycol or glycerin are completely safe and can be used in all types of individual heating systems.

In order for the coolant to be really effective, you should know which antifreeze for aluminum radiators is optimal.

- Any type of antifreeze has a heat capacity lower than water, so more radiator sections will be required.

- The size of the battery must also be different.Since when heated, this coolant expands strongly, then the container for it is needed 50% more than for water.

- Make sure that the boiler in the heating system is suitable for operation with antifreeze.

- All joints must be checked and made sure that they have not broken the seal. In the event that linen fiber is used as additional gaskets in the heating network, it will have to be replaced with rubber counterparts.

- Antifreeze is not “friendly” with zinc, so all fittings and pipes should be checked so that there are no products made of this metal among them.

Non-freezing coolant does not need to be purchased from a store. It is easy enough to make it with your own hands from distilled water and 40% alcohol.

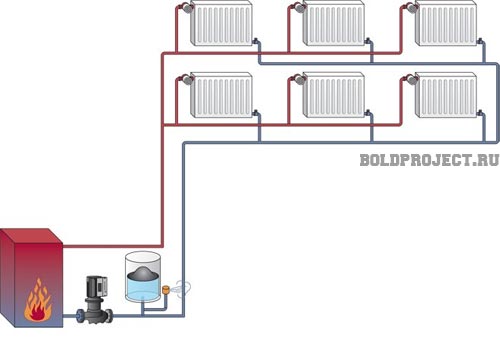

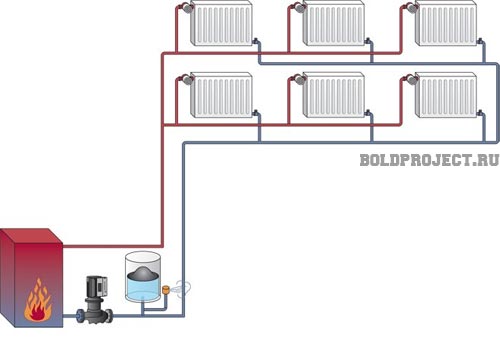

As professionals advise, an antifreeze heating system should be planned prior to installation. It should take into account such nuances as the power of the boiler, the material of pipes and shut-off devices, the presence of an expansion tank through which the coolant is supplied to the system.

In the event that the agent is introduced into a system that previously worked on water, then a lot of work will have to be done to recalculate the power and size of its radiators, thoroughly rinse or replace the pipes.

If it is necessary to add coolant to the heating system, then you can use only the same brand as when pouring for the first time. Different types of antifreezes enter into a chemical reaction, causing the formation of sludge, and the additional additives present in them will be neutralized.

Summing up, we can say that antifreeze coolant has a number of advantages that attract many consumers. Thanks to antifreeze, aluminum radiators last much longer. It is important to follow the safety rules and not to use the product without protective gloves, and in the case of an ethylene glycol-based carrier, also a mask.

When installing a heating system at home, you should not only choose the right pipes and radiators, but also pay attention to the coolant. Let's find out which coolant to choose for aluminum radiators, what conditions for the use of such fluids exist.

If the space of the room is more than 20 square meters, then an additional radiator must be installed.

Installation of aluminum radiators.

The most common heat carrier for a heating system is water, but it sometimes leads to numerous difficulties. This is not only corrosion, but also the formation of scale, the need for more frequent cleaning of the system. In addition, water freezes even at temperatures close to zero degrees, pipes and individual circuit elements can simply burst during thermal expansion. Therefore, it is important not only to choose the right batteries, but also to use an anti-freeze coolant. Of the advantages, it should be noted complete safety for humans. If the system leaks, there will be no harm to health, while antifreeze is poisonous.

As a coolant, you can use not only ordinary water, but also a specially produced antifreeze. Such mixtures do not freeze even at low temperatures, without changing their qualities at all. Each variety is designed for its own limits, this must be taken into account when choosing.

Antifreeze contains special additives that inhibit corrosion and various mineral deposits.

Installation diagram of an aluminum radiator.

But when buying, you should choose exactly those compositions that are suitable specifically for aluminum heating radiators. But such coolants also have their drawbacks:

- heat capacity is fifteen percent lower than that of water;

- high viscosity, that is, a pump is needed to ensure circulation in the system;

- strong expansion is observed when heated;

- fluidity is 50 percent higher than that of water, that is, high demands are placed on sealed joints;

- ethylene glycol antifreezes are poisonous, they can only be used for single-circuit boilers.

You can make your own radiator mix. To do this, you need: distilled water and 40% ethyl alcohol.

To use antifreeze in the heating system, it is not always possible to fill in ready-made purchased mixtures. In this case, you can use a coolant that is easy to prepare with your own hands. How is this possible, you ask? Everything is very simple, such a coolant is an antifreeze mixture of distilled water and forty percent ethyl alcohol. A similar antifreeze, prepared by hand for a heating system, has the following characteristics:

- the viscosity of the liquid is slightly higher than that of water, but much lower than that of purchased antifreezes;

- fluidity is less than antifreeze, which makes it possible to somewhat reduce the requirements for the tightness of the circuit connections. Rubber seals are not damaged when using just such a liquid;

- Alcohol-based blends have another advantage, making them an excellent choice for metal radiators. The fact is that alcohol prevents the development of corrosion, and this is important for systems, the destruction of which can lead to a variety of troubles;

- in this case, it is recommended to use hard water for the heating system, which, together with alcohol, prevents the formation of scale on the inner surfaces. The precipitate is formed in a solid form, with preventive flushing it is very easily removed from the system;

- when the alcohol content in the mixture is from 30 percent, it does not evaporate separately;

- the boiling point of the alcohol heat carrier is approximately equal to the value for ordinary water. That is, when the temperature rises to 85 degrees Celsius, it does not boil with the formation of large masses of steam;

- alcohol in the coolant reduces thermal expansion, that is, heating pipes and other elements are not damaged during freezing.

If you have to choose between water and an alcohol mixture, then many experts recommend giving preference to the second option (if the boiler design allows it). The proportions of such a composition are calculated based on what temperature values are planned:

If for some reason the boiler is turned off, it is imperative to drain the hot water from the radiator, otherwise the pipes may rupture.

- when the temperature drops to minus 10.6 degrees, the alcohol content should be 20.3 percent;

- with a decrease to a value of minus 23.6 degrees, the alcohol content is 33.8 percent;

- when freezing to minus 28.7 degrees - the alcohol content should be 39 percent;

- with a decrease to minus 33.9 percent, the alcohol content is 46.3 percent.

When preparing a coolant for aluminum radiators, the volume must be calculated based on the fact that one liter of 96% ethyl alcohol contains 960 ml of anhydrous alcohol. To get a 33% alcohol solution, you need to divide 96 by 33, which will give a volume equal to 2.9 liters. When water is added to one liter of alcohol in an amount of 2.9 liters, we get a 33% alcohol solution, which is an excellent coolant poured into an aluminum radiator for a heating system. The resulting solution will not freeze even at temperatures down to minus 22.5 degrees.

When should antifreeze not be used? But it is not always possible to use such a convenient and effective coolant as antifreeze for a heating system. If you are still choosing which one to use, consider the following factors:

Calculation of the required power of the radiator.

- it is categorically impossible to take antifreeze if ion (electrolysis) boilers are used. In them, heating is carried out by passing current through the entire volume of the boiler tank, and this is unacceptable for antifreeze.When designing a home heating system, make sure that it can be used with a certain type of heat carrier;

- antifreeze must not be used in an open system. But in this case, such a prohibition applies only to those mixtures that are produced on the basis of poisonous ethylene glycol, the rest can be used in open circuits, if there is a manufacturer's indication for this;

- the temperature must not be reduced more than to minus 20 degrees. This can seriously reduce the characteristics of the additives included in the composition, that is, corrosion foci will appear inside the system, scale will appear;

- when making sealed joints, it is not recommended to use linen roll, which is covered with ordinary oil paint on top. When using antifreeze in heating aluminum radiators, it is allowed to use linen winding only with sealants, since oil paint is easily corroded by antifreeze, and this leads to a complete loss of tightness;

- antifreeze must not be used when galvanized fittings and pipes are used for the heating circuit;

- when the boiler heats the coolant to a temperature above 70 degrees Celsius, it is no longer possible to use antifreeze. This value is the limit for most of these mixtures, which have the highest thermal expansion at higher heating.

When choosing antifreeze for aluminum radiators, you must remember about some conditions for working with it. These rules are mandatory to use, they will make the work of the circuit not only more efficient, but also safe:

- the heating system must be equipped with a more powerful pump for circulation than is required for conventional water heating. If the length of the circuit is quite large, then it is necessary to install an external installation of the circulation pump;

- requires the installation of a special expansion tank, that is, a capacious expansomat, whose volume will be approximately twice that required for a traditional water circuit;

- it is recommended to use large-volume aluminum radiators, as well as heating pipes;

- automatic air vents cannot be installed; when using antifreeze, only manual taps, for example, Mayevsky, can be installed in the system;

- when making detachable joints, you can use only gaskets made of paronite, chemically resistant rubber, Teflon. Many experts advise using a linen roll, which is sealed with a sealant resistant to ethylene glycol (if a heat carrier based on it is used);

- it is not recommended to dilute antifreeze with water, but if it is allowed by its composition, then only purified, distilled water can be used. Melt, rainwater is absolutely not suitable for this;

- before pouring antifreeze for aluminum radiators, it is necessary to carry out preparatory work. The entire circuit, including the boiler, must be flushed with water. The replacement times are regulated by the antifreeze manufacturers, but experts recommend doing this once every two to three years, you cannot leave the coolant in the system for a longer time;

- after antifreeze is poured into the system, you should not immediately put a very heavy load on the boiler, that is, put it at a high temperature. In this case, it is recommended to increase gradually so that the coolant has time to warm up smoothly. Such a liquid has a lower heat capacity than water, so this condition must be strictly observed.

Separately, it should be said about the water coolant. If in cold weather, for various reasons, the boiler is shut down for a long period, then it is necessary to drain all the hot water that may be there from the heating system in order to prevent pipe rupture.

Heating a house: how to choose a heating medium for a radiator? When choosing antifreeze or any other coolant for a heating system, numerous factors must be considered. This should be done even at the design stage of the entire heating system, since the water system is not suitable for the use of antifreeze.

If the temperature in the cold season in the general circuit does not fall below five degrees Celsius, then it is best to prefer such a type of coolant as water, but it is necessary to remove all salt compounds from its composition to the maximum. When the temperature in the house is expected to drop to minus values, only antifreeze can be used, since the water will simply freeze under such conditions. To avoid freezing, you can completely drain all the water from the heating system, but there is one serious disadvantage here. The fact is that the radiators will fill with air, and this will lead to corrosion in the presence of high humidity.

There is another way to avoid freezing when using water as a coolant, but for this it is necessary to build in special electric heaters, which will be controlled using temperature sensors or an installed remote control. This option allows you to maintain the temperature level in the system above 5 degrees Celsius, but the cost of the heating circuit increases many times, that is, it is cheaper to immediately install a system designed for antifreeze. When choosing the required antifreeze for the circuit, you should pay attention to the following characteristics:

- extremely low temperature that can be maintained by the coolant;

- the composition of the liquid, its purpose, that is, for which particular system it is intended;

- the purpose of antifreeze. Is the coolant designed to work in aluminum radiators, how does it interact with plastic pipes, rubber, steel elements, etc.

- the length of time for the use of antifreeze;

- the safety of the coolant. Attention should be paid to how safe the liquid is for humans if it is necessary to drain it after the service life is over).

But the color of antifreeze for radiators does not matter, it just shows which brand the liquid belongs to.

The choice of a coolant when installing a heating system is a rather important part of the operation of the entire circuit. The efficiency of home heating, its safety, and service life depend on the right purchase. Today, for aluminum radiators, which are becoming increasingly popular, several types of coolants can be used. This is ordinary water, antifreeze based on various components and a special mixture of water and ethyl alcohol. The choice of coolant largely depends on what conditions of use of the system are observed, since it is not always possible to fill it with it.

Using antifreeze for heating systems

Antifreeze or antifreeze liquids are known to almost everyone. They are widely used in vehicle cooling systems in winter. In a car engine, antifreeze transfers excess heat from the engine, cooling it down. Moreover, even in the most severe frosts, it does not freeze. It is these properties - the ability to transfer heat even at the lowest temperatures and have led to the use of antifreeze for the construction of heating systems. It is especially important to use such a coolant in a system, part of the pipeline of which runs through an open area.

A good feature of "non-freezing" is that it provokes less corrosion on the inner surface of pipeline systems than ordinary water. Another undoubted advantage is the absence of suspended limestone solutions in non-freezing liquids - so you don't have to worry about possible scale formation.

There are several modifications of antifreeze fluids that can be used in heating systems. The choice of a specific type is made taking into account the climatic conditions and the configuration of the heating system of your home.

Heating system flushing fluid

In addition to the heat carrier itself, when operating the heating system, you will also have to purchase a liquid intended for flushing with a pipeline and heating radiators.

Of course, as a last resort, you can rinse the inner surface of the pipes with ordinary tap water, but it is better to do this all the same with the help of special fluids, in which special chemical additives are introduced.

An alternative flushing option can be the use of water with a caustic soda solution added to it. Such a mixture is poured into the heating system and remains inside it for about an hour. The soda solution comes into contact with scale on the inner surface of the system and dissolves it. In addition, the baking soda solution will dissolve the corroded areas.

How to choose a liquid for a heating system

First of all, it is necessary to determine the operating parameters of the system. Here two extreme values will be important to you - the maximum temperature of the coolant when heating in the boiler and the minimum temperature of the ambient air. Next, you need to carefully study the technical characteristics of your heating system.

Actually, the main attention should be paid to the characteristics of the heat exchanger in the boiler. Some manufacturers may not allow the use of anti-freeze fluids. And, finally, after determining the permissibility of using an anti-freezing liquid and its possible temperature parameters, proceed directly to the choice of the brand of liquid, focusing on its lowest toxicity

All the same, the heating system will be located in a residential area, and possible fluid leaks should not lead to poisoning.

Using alcohol as a heat carrier

No matter how blasphemous it may sound for a man's ear, it is allowed to use alcohol as a heat carrier. The alcohol does not freeze and can be used over a wide temperature range. Naturally, industrial alcohol is used in this capacity, which is a deadly poison for humans. However, many manufacturers of boilers and heat exchangers are critical of the use of fluids such as bischofite or ethylene glycol as a heat carrier.

The disadvantage of using pure alcohol as a heat carrier is its high volatility - about five liters per year will evaporate through microscopic pores in the system.

Calculation of the volume of the coolant

Before purchasing the required amount of liquid, it is necessary to know the internal working volume of the heating system. This information is available from the installers of the equipment, or the data is obtained independently:

- Measure the length of all pipes, including the length of radiators or batteries, group products by diameter;

- Calculate the flow area of each group and multiply by the length of all heating pipes;

- Add to this result the volume of the coolant for each radiator (it depends on the number of sections and the design of the heater). Thus, you will receive the total volume of the working fluid in the circuit;

- The ratio of water and antifreeze when diluted before pouring into the heating pipeline is indicated on the package.

Antifreeze or other non-freezing liquids in home heating is the safety of the operation of heating devices and equipment. But before pouring anti-freeze into the boiler, it is recommended to study the advantages and disadvantages of these liquids.

Types of antifreeze

The market for this particular product is very extensive. Recently, due to the increased demand for anti-freeze products, manufacturers have greatly expanded their assortment.

Non-freezing liquids are made on the basis of various chemical compounds:

- Glycerin;

- Ethylene glycol;

- Propylene glycol;

- Bischofite brine;

- Saline solution.

The most common household "non-freezing" products are made on the basis of aqueous solutions of ethylene glycol, glycerin and propylene glycol. Since these substances are highly aggressive, special components are added to them - additives.

The purpose of which is to prevent damage, corrosion, scale and foaming.

- Ethylene glycol is the most popular among our consumers. Their main advantage is their low price. But at the same time it is the most toxic non-freezing liquid, the use of which in double-circuit boilers is prohibited, due to the high probability of entering the water supply system, which is dangerous to human health. It should be borne in mind that when the boiling point rises above 110 degrees, ethylene glycol gives a precipitate that can damage some elements of the system.

- Propylene glycols are similar in properties to the first type, but at the same time they are harmless and safe. Most of the manufacturers recommend them.

- Glycerin is absolutely non-toxic and environmentally friendly, providing maximum protection against corrosion. It does not increase in volume when it goes into a solid state, and it is enough to simply heat it up to start the system.

- Antifreezes based on a natural bischofite solution have unique physical and chemical properties. Low freezing point and high boiling point, as well as greater heat capacity and heat transfer than water, which is not typical for most of these products.

- Salt coolants are produced on the basis of solutions of mineral salts (magnesium, calcium, sodium and their compounds). A significant disadvantage of these fluids is their high corrosiveness to equipment.

Antifreezes are sold either already diluted and ready for use (experts recommend using a coolant with a freezing temperature of -20 to -25 degrees), or in the form of concentrates, and then the solution must be prepared independently.

An example of diluting ethylene glycol fluids. They are of two types:

- With a freezing threshold not higher than -30 degrees (then, to come to a freezing point of -25, the mixture must be diluted with distilled water in a ratio of 9: 1);

- With a freezing threshold not higher than -65 degrees (to get a freezing threshold of -25, antifreeze is mixed with water in proportions of 6: 4).

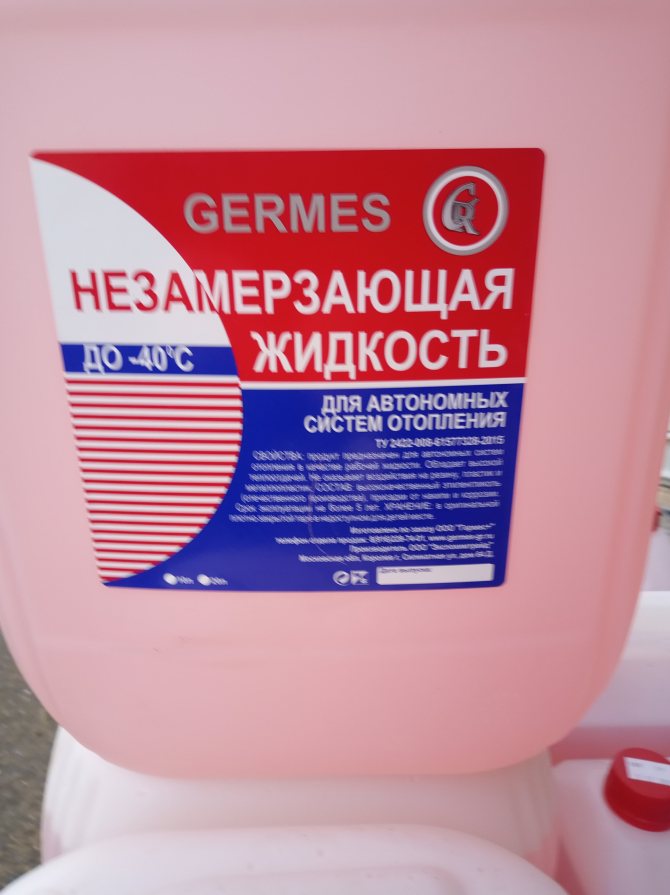

Non-freezing for the heating system of a private house

Before us is a concentrated water antifreeze based on monoethylene glycol. The manufacturer did not forget to add unique additives with which the antifreeze acquired thermal stabilizing, antifoam, antioxidant properties and the ability to protect the system from corrosion.

In addition, the inertness of the liquid to sealing materials has increased significantly. The composition is completely ready to use and does not require dilution with water. However, the manufacturer permits two uses: without dilution and in diluted form.

Among the clear advantages of non-freezing over competitors, I will note a long service life - the liquid can work up to 10 years (!). The product is characterized by high frost resistance, works to remove deposits on the inner surfaces of pipes. Antifreeze does not cause degradation of paronite, rubber, Teflon seals.

The operating temperature range of the non-freezing liquid is simply gorgeous - from -65 to 95 degrees. Crystallization will begin at -66 degrees, boiling - from 111 degrees. Volume - 20 l canister. This anti-freeze for the heating system of a private house has a price of 1.8 tr.

Pros:

- fireproof;

- effective additive package;

- wide range of operating temperatures;

- long service life - 10 years.

There are no downsides.

It is a safe antifreeze based on propylene glycol, which favorably distinguishes it from traditional analogues based on ethylene glycol in terms of toxicological properties.The composition is intended for use as a working fluid in heat exchange systems in industry and residential buildings. It successfully eliminates "defrosting" when exposed to negative temperatures.

A complex of additives protects equipment from the development of microorganisms, the formation of corrosion. The fluid is compatible with metal-plastic, plastic pipes and seals, works in double-circuit boilers, in open systems, and allows commissioning at low temperatures. Crystallization starts at -31 degrees, freezing at -40 degrees.

Due to the fact that the antifreeze is based on food-grade propylene glycol, it can be safely used even in food processing systems, not to mention residential buildings. The drug provides excellent frost resistance and prevents the destruction of elements of heat exchange systems during freezing, corrosion of cast iron, steel, brass, aluminum and solder. Plus, it prevents the accumulation of scale and, in principle, prevents its formation. Volume - 20 kg canister. Price - from 1.9 tr.

Pros:

- eliminates the destruction of the system;

- fireproof;

- favorable cost;

- 100% final quality control;

- full set of additives.

Minuses:

- not suitable for the harsh Yakut winters.

Thermotrust antifreeze is used in the form of aqueous solutions or in its original form. It can be safely launched into autonomous heating systems of residential buildings to prevent defrosting against a background of low temperatures. The additive package is optimally balanced and provides protection against microorganisms, corrosion, scale.

The composition is inert to sealing materials, contains heat stabilizing, antioxidant, antifoam components. Does not destroy cast iron, steel, copper, aluminum, brass and solder, compatible with metal-plastic and plastic pipes.

We suggest that you familiarize yourself with Bad smell in the washing machine how to get rid

The basis of the liquid is monoethylene glycol, it is homogeneous, red in color, does not contain mechanical impurities. In regions with a temperate climate, it can be diluted with water, in the regions of the Far North it is used in its pure form. The crystallization temperature is -66 degrees, the boiling point is 111 degrees. The price of a 20 l canister is from 1.8 tr.

Pros:

- high frost resistance;

- blocks the degradation of elements of heat exchange systems during freezing;

- works in the range -65 - 90 degrees;

- diluted with plain tap water;

- made on the basis of quality raw materials;

- service life is 5 years.

Minuses:

- does not work with galvanized systems and electrode-type boilers.

Antifreeze is environmentally friendly and ready to use. The base is propylene glycol (green). The composition can be diluted with plain tap water up to -20 degrees. If you have a double-circuit or heating boiler, dilution is a must.

It is better to use non-freezing liquid on propylene glycol where there are increased requirements for environmental safety (heat pumps, double-circuit boilers), but it is excellent friends with any heating systems.

The liquid is characterized by a good temperature range from -30 to 104 degrees. The composition includes a special set of additives. This gives protection against corrosion, foaming, scale. Antifreeze is not aggressive to metal-plastic and plastic, paronite, rubber, flax. With such characteristics, the possibility of leaks is excluded. The price of a canister for 20 liters is from 1.6 tr.

Pros:

- environmental friendliness;

- explosion and fire safety;

- works in any systems;

- excellent set of additives;

Minuses:

- does not work with galvanized systems.

This is another safe antifreeze in our rating. The composition is based on high quality propylene glycol, corrosion inhibitors, demineralized water, dyes. It successfully works in heating and air conditioning systems for residential buildings.

It is a homogeneous chemical liquid without mechanical impurities of green color.Crystallization begins at a temperature of minus 31 degrees, the boiling point is plus 107 degrees.

Thanks to the latest formula, the composition prevents corrosion of copper, cast iron, brass, steel and solder. There is no aggressiveness in relation to seals, plastic and metal-plastic pipes.

In addition, anti-freeze is recommended for use by the All-Russian Research Institute of Corrosion. Inhibitors and antibacterial additives work for an extended period. Antifreeze is completely ready for use.

Pros:

- environmentally friendly;

- good working range;

- excellent corrosion protection;

- does not affect sanitary rubber, gaskets, plastic and metal pipes.

Minuses:

- does not work with galvanized surfaces;

- not suitable for the regions of the Far North.

Influence of the composition of liquids on heating

The anti-freezing fluids for heating systems currently on the market are made on the basis of two substances.

Monoethylene glycol

This component has the following features:

- if such an anti-freeze is used in the heating system, then when the system starts up, its operation should start with the minimum power. Then this parameter can be gradually increased to the required values, temporarily exceeding the level of the required power;

- antifreeze, the main component of which is monoethylene glycol, is a fairly toxic product. Therefore, it should be used in single circuit systems.

Propylene glycol

If you compare it in terms of workflow, then there are no differences. However, there is one positive point. It lies in the safety of this non-freezing liquid. Its use in the heating system of a private house does not cause any harm to human health.

Which non-freezing liquid to choose, everyone decides for himself. However, it should be noted that it is impossible to unequivocally answer which coolant is the most suitable for the system of a private house - water or antifreeze. If the price of antifreeze liquid is too high for you, then in this case water is the right choice.

In order not to be mistaken with the choice of the coolant, attention should be paid to a number of parameters. It will not be superfluous to consult a specialist

Following his recommendations, your choice of coolant will be successful.

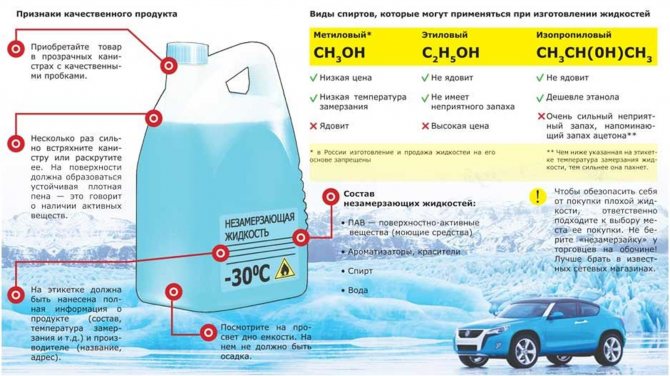

How to choose a good antifreeze for your heating system

When a decision is made to pour a freeze-resistant liquid into the system, it is important to approach it responsibly.

This product is available from many manufacturers. But from all the variety, several leaders stand out who produce really high-quality antifreeze that meets the declared parameters.

When choosing an antifreeze liquid for heating systems, the following characteristics should be observed:

- the period during which it can be used without a complete replacement;

- toxicity level;

- compatibility with heating equipment at home;

- the presence of additives to improve the performance of heating devices.

A good antifreeze can be used for 5 to 10 winter seasons. This period indicates the high quality of the product.

The product is considered safe if propylene glycol is used in the base.

Domestic manufacturers are constantly improving their products and offer universal solutions. So, for example, high-quality products contain additives that protect metal from corrosion.

Important! It is strictly forbidden to use automobile antifreeze instead of a coolant. The additives that are present in its composition are not intended for use in enclosed spaces where people live. Automotive antifreeze and heating fluid with the same properties have a different composition.