Home / Electric boilers

Back to

Published: 02.06.2019

Reading time: 7 minutes

0

1952

A double-circuit electric boiler is a popular type of heating equipment and has a lot of advantages. It is customary to install it in rooms remote from the centralized gas and water supply in order to heat the building and supply hot water. Before purchasing a unit, you must carefully study the principle of its operation and performance characteristics.

- 1 Types of double-circuit boilers

- 2 Design and principle of operation of the electric boiler 2.1 Connection diagram

- 3.1 How to calculate power

What are double-circuit electric boilers

Double-circuit electric boilers are almost always wall-mounted models, which, with the same technical characteristics and previous or slightly large dimensions, combine the functionality of two devices at once - the heating boiler itself and a flow-through (less often storage) water heater. The heating medium from the heating circuit is never mixed with sanitary water in the hot water supply (DHW) circuit.

Double-circuit electrical models are best used in small residential buildings with an area of up to 150-200 m2. And it's not only about high operating costs, but about the length of the pipeline from the boiler to the points of consumption, which should not exceed 8-10 m, otherwise it will be possible to get hot water in more than 20 seconds after opening the tap.

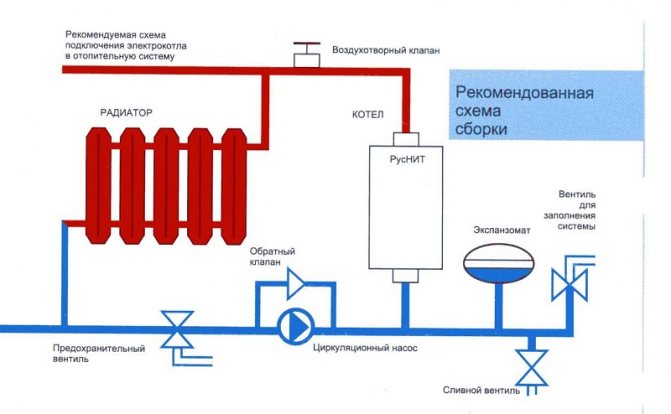

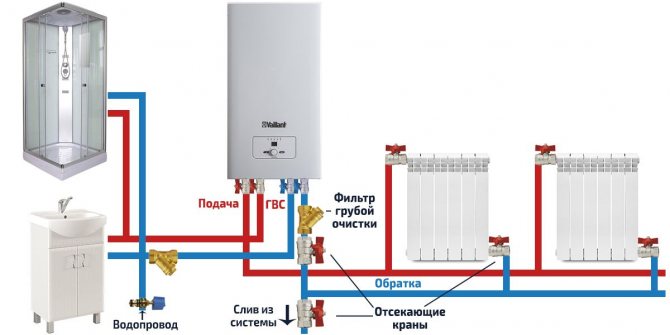

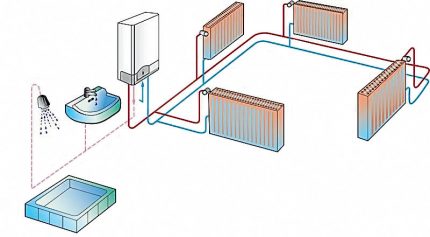

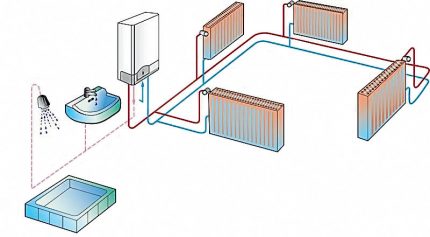

Wiring diagram for a double-circuit electric boiler.

If you do not take into account the high cost of electricity, double-circuit hot water electric boilers are ideal boilers, because, unlike other types, they are easy to install, do not require a chimney and ventilation, are not demanding on the parameters of the room, are reliable and functional. Only models with a capacity of over 10 kW require approval from the Energy Supervision Authorities.

It is also worth considering that models with a power of over 6 kW must be connected to a three-phase (380 V) power grid, a single-phase (220 V) network will not be enough to provide higher power.

How to calculate how much electricity an electric heating boiler consumes

Device and principle of operation

The device of a double-circuit electric boiler using the example of SAVITR Premium.

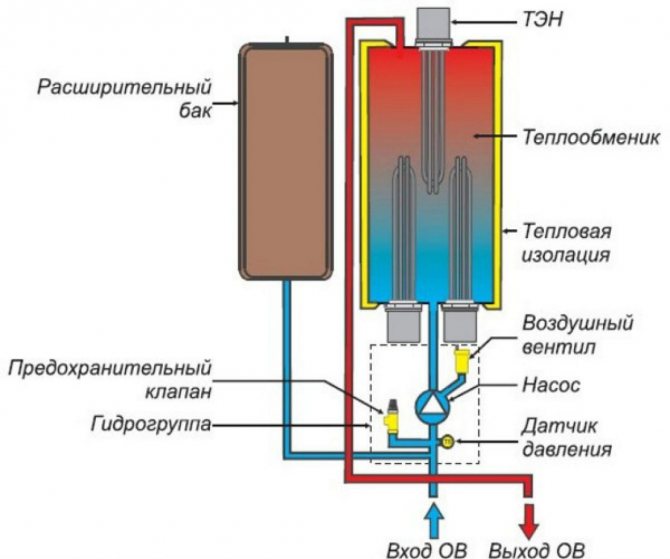

Electric double-circuit boilers differ from single-circuit boilers only by the presence of a heat exchanger in which sanitary hot water is heated, as well as by means of capacity distribution between the circuits. All models have exactly the same basic device: the heating unit of the heating circuit, which contains the heating elements and the DHW heat exchanger, in which the water is heated.

Almost always, the housing already from the factory contains all the necessary elements and assemblies of the heating system: an expansion tank, a circulation pump, an automatic air vent, a safety valve, a pressure gauge, a set of sensors, etc. This means that in order to install and connect the boiler to the system, it is enough to bring the heating supply and return lines, hot water supply and a source of sanitary water (for example, water supply) to it.

To clearly understand the principle of operation of double-circuit boilers, consider how each circuit works separately:

- heating - the primary circuit, the coolant continuously circulates in it, warming up in the heating unit and giving off heat through radiators installed throughout the house;

- water heating - it is activated only when the hot water consumption point is opened, directs the heating agent of the heating circuit to the DHW heat exchanger, through the contact heats it, and therefore the sanitary water inside.

In double-circuit electric boilers, the distribution of power between the circuits is carried out using a three-way valve, therefore not all power is given to heating hot water, which allows maintaining the temperature in the main heating circuit.

For models with a flow-through heating principle, a delivery delay of about 5-15 seconds is characteristic, however, there are models with a built-in boiler with a volume of 50-300 liters, in which the water is constantly heated. This allows not only to minimize the delay in the supply, but also to provide a certain supply of already prepared hot water, leveling the low performance of DHW.

How the device works

The design of a double-circuit boiler provides for the placement in one device of two heating elements for heating water and a heat carrier. The system works due to the conversion of electric current into thermal energy.

Design features of a double-circuit boiler

To heat the room, a closed-type heating circuit is connected to the boiler, along which the coolant moves. The second pipeline is designed to supply hot water, which is heated in a built-in storage tank or on a flow-through basis.

In the warm season, the heating can be turned off and the boiler can only be used as a boiler.

Two circuits of an electric boiler can function both independently of each other and at the same time, heating the house and heating the water

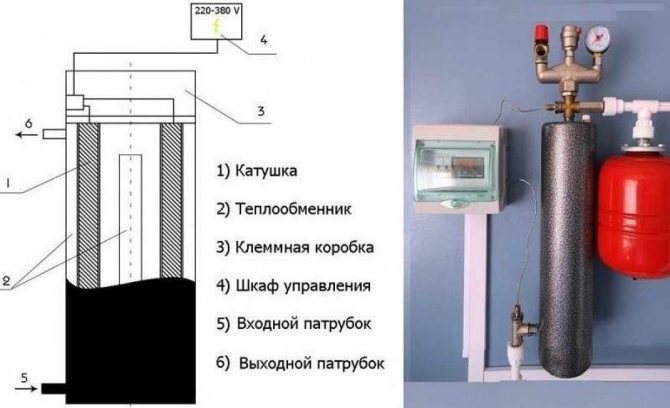

The device consists of the following main elements:

- enclosures with thermal insulation, inlet and outlet fittings;

- a heat exchanger through which the coolant circulates;

- control systems and automation unit, allowing to set temperature parameters and turn off / turn on the device;

- heating device;

- expansion tank for pressure relief;

- safety valve;

- air vent (automated or manual) for removing air locks;

- circular pumps for hot water supply and heating systems;

- safety groups with temperature sensors and relays.

The principle of operation of the electric boiler consists in heat exchange: a circular pump pumps water into the tank, which is heated to a certain temperature by a thermoelement and is output either to the heating circuit or to the DHW system.

In fact, a double-circuit electrical appliance, like its gas counterpart, can perform the function of both a house boiler room and an instantaneous water heater.

Advantages and disadvantages of electrical equipment

Electric heating refers to environmentally friendly methods of heating, because it does not pollute the air with smoke and soot like a solid fuel boiler, carbon monoxide and other harmful "waste" like gas equipment.

In addition, the peculiarity of the operation of heating on an electrician practically excludes emergency force majeure in the event of a water leak - if there is no coolant in the system, the equipment is automatically turned off.

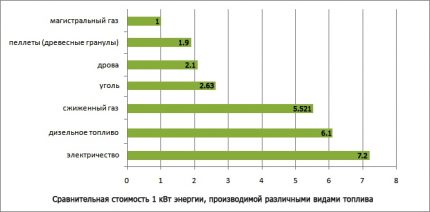

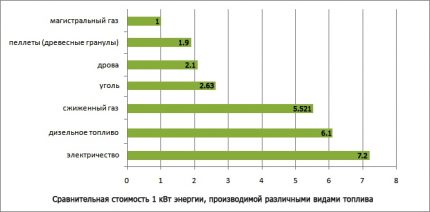

An electric boiler has an excellent efficiency indicator - 95-99%, but even such a high heat transfer does not compensate for the high consumption of electricity, therefore, in comparison with a gas boiler, the electrical appliance loses

Also, the common advantages of electrical equipment include:

- Simple assembly - there is no need to equip a chimney, a forced ventilation system, supply a gas pipeline and issue a bunch of permits, as when installing a gas boiler.

- Safety - the probability of leakage or boiling of an electric boiler is very small, in addition, the design of the device does not provide for the use of an open flame, flammable materials and explosive gas.

- Compact dimensions - an important point for small rooms. In addition, the device can be installed not only in places specially provided for by the project (like gas equipment), but in any convenient place where it is possible to connect to the power grid and heating system.

- Noiselessness - the electric boiler works without vibrations, "exhaust" and other sounds that solid fuel and gas appliances sin.

- Affordable cost both the device itself and its installation, maintenance.

As for the disadvantages, one of the most significant is the cost of the consumed energy. If we are talking about electric heating and hot water supply for a large cottage, the amounts will be impressive.

Therefore, it will not be superfluous to make at least an approximate calculation of consumption before buying by analyzing information about the area, water consumption and power of the device. And then decide whether the "game" is worth the cost.

Installation of special controllers, storage devices and differential meters operating in the "day-night" mode will help to significantly reduce costs

Other cons:

- Energy dependence - in an area with constant power outages, the installation of such a heater makes no sense. However, if outages are accidental, and not the norm, buying a generator that stores energy will help solve the problem.

- Power surges have a detrimental effect on the sensitive automation of the boiler, therefore, before installing the equipment, it is worth purchasing good energy stabilizers.

- Sedimentation. Since running water is used for hot water supply, the heating elements are gradually covered with scale, which must be removed from the equipment. The solution may be to install filters at the cold water inlet and regular servicing.

In addition, before installing an electric boiler, it is worth finding out if your home network is designed for such a load. For example, for an area of 200 squares, at least 16-20 kW will be required.

And this is only for heating, excluding other electrical appliances. And if in new cottage settlements such power is provided for by connecting to a three-phase network, then no more than 10 kW is usually allocated for a summer cottage.

Reviews of household double-circuit electric boilers: advantages and disadvantages

| Benefits | disadvantages |

| Favorable price - the initial price of double-circuit models is only 15-20% higher than single-circuit analogs, therefore this is the cheapest way to organize hot water supply in a private house or apartment (in comparison with an indirect heating boiler, a separate water heater, etc.) | High operating costs - heating and hot water preparation using electricity are the most expensive pleasure today |

| Compact dimensions - often the dimensions of double-circuit models are comparable to single-circuit ones, and only with rare exceptions they are 30-100 mm larger in either direction | Volatility - both heating and heating of sanitary water depend on the stability of the power grid, therefore, in case of interruptions, an inverter with a battery, a generator or a UPS is needed |

| Simplicity of installation and connection - in addition to the fact that the installation of an electric boiler is already much easier and faster, the installation of a two-circuit model is even simpler when compared with the need to install a separate boiler requiring a chimney and a device for preparing hot water | Models over 6 kW require a three-phase (380 V) mains connection |

| High efficiency - the efficiency of all modern electric boilers is more than 99% | Extremely limited selection of models on the Russian market |

| Almost completely silent operation | According to the owners' reviews, powerful models create a significant load on the electrical network of the house, so it is desirable to have high-quality and serviceable wiring. |

| Availability of models with built-in storage tank |

Rules for installing and piping an electric heating boiler

Regardless of whether the boiler is an electric double-circuit wall-mounted or a floor-standing unit is installed, there are a number of necessary requirements to fulfill the requirements:

- the room maintains an average level of humidity, with a high level of moisture content, the boiler may fail;

- the room must be equipped with ventilation or well ventilated;

- a base of heat-resistant material is formed for floor models, wall-mounted models are fixed with strong brackets on a solid wall panel or base;

- connection to the network only with cables of the cross-section specified in the product data sheet;

- units with a capacity of 3 kW or more are connected to a separate line;

- all network devices must have a residual current circuit breaker;

- when installing electrical units, you need to take care of the grounding of the devices.

Depending on the type of pipeline, fixation and connection are made with fittings, nozzles, adapters. It is important to ensure the tightness of the joints in order to prevent leakage of the coolant. The expansion tank and the safety group are mounted regardless of the heating scheme, but the circulation pump is required only when the forced water flow is installed.

On a note! After collecting the circuit and installing the electric boiler, it is necessary to carry out a pressure test - fill the circuits with water and run in test mode. If there are no leaks, the equipment is put into continuous operation.

How to choose the right model

Electric boiler type

Combining the functions of heating and hot water preparation is possible only in heating element models of electric boilers, where tubular electric heaters are used as heating elements. We would not focus on this point if it were not for the frequent mistakes of online stores or a play on words by manufacturers who designate electric boilers with nozzles for connecting an indirect heating boiler as double-circuit.

Heating elements are the most common in general among all electric boilers, but they also have a special unpleasant drawback - a tendency to form scale on the heating elements, which over the years leads to a decrease in efficiency by 10, 20 and even 30%, the boiler needs more electricity and time to heat up the same amount of coolant through the scale layer.

A layer of scale on the heating element due to the use of a hard coolant.

Electric boilers can be electrode: simpler and more reliable, not involving the formation of scale, but demanding on pipes, radiators, coolant and high-quality grounding. And also induction: reliable, used mainly in industrial areas, characterized by faster heating, with the possibility of using antifreeze as a coolant. But it is worth remembering that today neither electrode nor induction boilers exist in a double-circuit design: only heating elements.

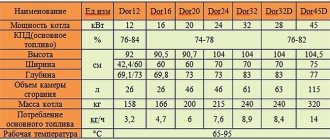

Minimum required power

In a simplified form, the minimum required power of an electric double-circuit boiler for heating and water supply at home is calculated based on the rule of 1 kW for every 10 m2, we also recommend laying 25-30% of the stock. This method is more than enough for an average house (no or weak insulation, 2 bricks laying, ceiling height 2.7 m, climate zone of Moscow region).

For example, for the above-described average house with an area of 150 m2, the minimum required power of a double-circuit electric boiler is 150/10 * 1.3 (30% of the stock) = 19.5, that is, 20 kW.

In other cases, with high ceilings or a large glazing area, southern or northern climatic zone, individual correction factors are taken into account, which change the result by 5-30% up or down. You can accurately calculate the minimum required power using the calculator below.

Calculator for accurate calculations

The power of the electric boiler must provide the total heat output of all radiators, the power of which is calculated for each room separately (based on heat loss). Therefore, to obtain accurate data, use a calculator to calculate the minimum required power for each heated room separately and add up all the values obtained to get the result for the whole house.

Automation functionality

The most energy-saving models are characterized by the presence of a programmer. It allows you to set a boiler operation pattern for a day or a week, for example, setting the temperature to 15 ° C for working hours when no one is at home or 19 ° C during sleep, which will significantly reduce energy consumption, up to 30-40%. If there is no built-in programmer, the same functionality can be provided with a room thermostat.

How to choose an external thermostat for an electric boiler and save up to 30% on heating costs every month

It is also worth paying attention to the number of heating elements and the smoothness of temperature control, models with at least 6 heating elements and temperature control by degrees will be more comfortable and economical.

Many boilers are equipped only with overheating protection, but it is good if, among such a small selection, you can find a model with frost protection and pump blocking. Otherwise, the choice is small and it makes no sense to highlight more criteria.

Types of boilers

Basically, a double-circuit boiler powered by electricity is divided into two groups:

- Wall.

- Floor.

It all depends on the required power for heating a private house.

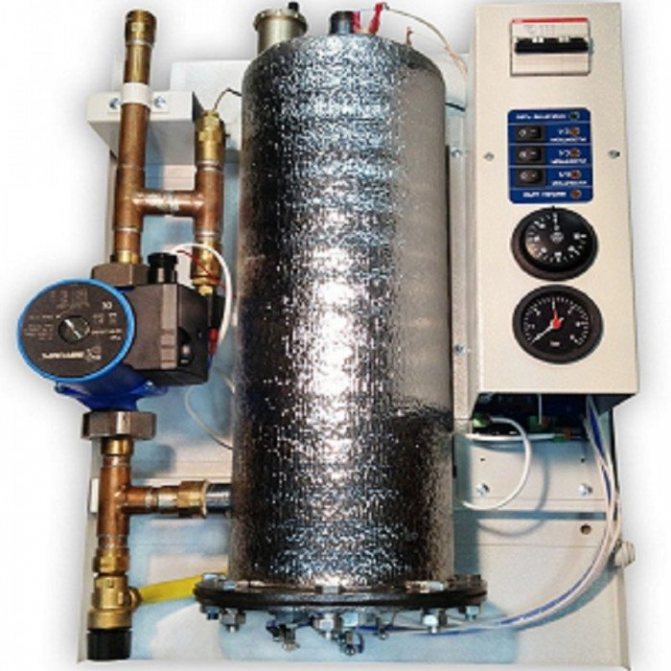

Floor standing

These are powerful boilers that can heat houses with an area of more than 500 sq. They are superior in weight and size to the wall-mounted version. Usually they come with a fairly large set of additional equipment. There is a circulation pump, a boiler, an expansion tank, and a separate automation in the form of a shield.

For such large boilers, a special room is allocated, which is used as a boiler room. It will be equipped according to all the rules. By the way, the installation of floor models is performed only by specialists.

The best known manufacturers and models: characteristics and prices

SAVITR Premium 15 Plus

One of the most common models of domestic production among double-circuit electric boilers. Differs in the presence of a programmer, as well as a complete room thermostat and a remote sensor for outdoor temperature. It should be noted that the layout and build quality are good for Russian production, the heating unit is wrapped with a layer of thermal insulation, which is clearly a plus. In practice, the boiler fulfills its tasks without any problems; there are practically no serious service complaints for almost 10 years of operation.

The only drawbacks are loud clicks of the switching relay, not the most compact dimensions, controversial design and a rather high price. Available in 9, 12, 15, 18, 21, 22 and 25 kW versions.

Cost: RUB 47,200-53,000

Kiturami KIB-12

Korean, slightly cheaper option with much more compact dimensions. The internal layout is pretty good, the heating unit is thermally insulated, there is even a water filter, which is clearly a plus in the case of heating elements. Due to the absence of mechanical switches, the operation of the boiler is practically silent.However, the build quality is controversial, many nodes and connections are plastic, which in the long run inspires less confidence than in the case of the previous SAVITR Premium with threaded connections.

The disadvantage is also the extremely low performance of hot water supply, for the model under consideration with a capacity of 12 kW - 4.2 l / min, which is enough for the full operation of just one point of hot water consumption (with a weak opening of the tap, a maximum of two points).

Cost: RUB 43,600-52,000

ACV E-Tech S 160

The Belgian technological model is probably one of the best double-circuit electric boilers for a private house. It differs in floor-standing design and the presence of a built-in storage tank (from 99 liters in the younger version and up to 263 liters in the older one), while the dimensions are small, typical of most floor-standing boilers. The DHW performance (not counting the tank volume) is also high, more than 10 l / min for the 14 kW model. Boilers of the ACV brand are known in the market as extremely durable and trouble-free.

The only significant drawbacks are the huge price and small, minimum required functionality. Nevertheless, this can be solved by installing a climate controller in the boiler panel (optional) or by connecting a good programmable room thermostat, the possibility of connecting an external control in the boiler is provided.

Cost: 239,000-249,000 rubles.

The cost of electric boilers from well-known manufacturers

Heating system models can have different costs, which, first of all, depends on the capabilities of the boiler described above and, most importantly, on its power. The equipment and the manufacturer matter.

So, for example, a double-circuit electric boiler, the price of which is high, is most likely of foreign production, since domestic models cannot yet compete with them. How boilers are classified by cost:

- Economy The price varies from 7 thousand rubles. There may be models that cost 2 thousand rubles, but they are not suitable for all the needs of a country house.

- Standard. The cost starts from 16 thousand rubles.

- Suite. Designed for heating and generating hot water in large volumes - from 35 thousand rubles.

Any model is equipped with an automation system that reacts to an abnormal situation and turns off the unit in time.

P.S. (post scriptum)

The purchase of a double-circuit electric boiler for heating an apartment in the future does not bring any benefits to its potential owner. If you buy heaters for the heating system and hot water supply separately, it will be much cheaper and more convenient. It is generally better to forget about water heated floors powered by an electric boiler. There is an alternative - electric underfloor heating, of which there are several types. The likelihood of a coolant leakage is excluded, and even if a breakdown occurs, only some part of the warm floor will cease to function. The newest infrared mats are not afraid of damage at all.

Equipment selection criteria

In the process of choosing a double-circuit electric boiler of floor-standing or wall-mounted type, first of all you need to pay attention to power indicators, on which the heated area of the room, electricity consumption and the price of the unit depend. It is not advisable to purchase a device that is much more powerful than what you need.

When purchasing an electric heating device, it is important to pay attention to the level of noise it produces. Qualitative a double-circuit electric boiler is practically silentexcept for the sound emitted by the circulation pump.

The consumer market of heating systems is full of various models of electric boilers, both wall-mounted and floor-mounted, produced both abroad and in our country. Their assortment is huge and it is not always possible to choose a suitable device on your own. In such situation you can contact the specialists in this matter, which will help you choose the best option for price and quality.

Fundamental features of the electric boiler

A double-circuit electric heating device, both wall-mounted and floor-mounted, works on the principle of converting electricity into heat. This is achieved by means of heating elements, which are responsible for heating the coolant in the heating system and water in the boiler.

The movement of the coolant through the pipeline and radiators is provided by a circulation pump or, according to the laws of physics, in a natural way, under the control of the automation unit. The heating system is equipped with a regulator that sets the temperature mode, upon reaching which the sensor sends a corresponding command to the electric boiler:

- when the set temperature is reached, the heating element is turned off;

- when the temperature indicators drop to the lower response threshold, the boiler turns on again.

Modern programmers allow you to control not only the internal system of the boiler, but the temperature in a particular room. Thanks to such devices, an electric double-circuit boiler will work fully automatically without human intervention.

The safety of modern electric space heating is ensured by a safety system, the price of which does not affect the cost of the boiler, since it is an integral part of it. In the event of overheating of the water, the pressure in the system increases significantly, which leads to the actuation of the valve, which drains the excess coolant into the expansion tank.

How to calculate the required power of a heating boiler

The heat demand of the building and, accordingly, the boiler output depends on the heat loss of the building through the enclosing structures and the climatic conditions of the region. For example, in the central regions of Russia, for heating 10 m2 of space in an average private residential building, about 1 kW of thermal energy will have to be supplied. Since the efficiency of all types of electric heaters is close to 100%, the demand for thermal energy at home is practically equal to the power of the boiler. Depending on the mode of using hot water, another 5-25% should be added. The better the house is insulated, the less energy needs to be spent on heating it. And vice versa. It should also be taken into account that when the voltage drops, the power of the electric boiler will decrease, therefore it is recommended to provide a certain margin of performance.

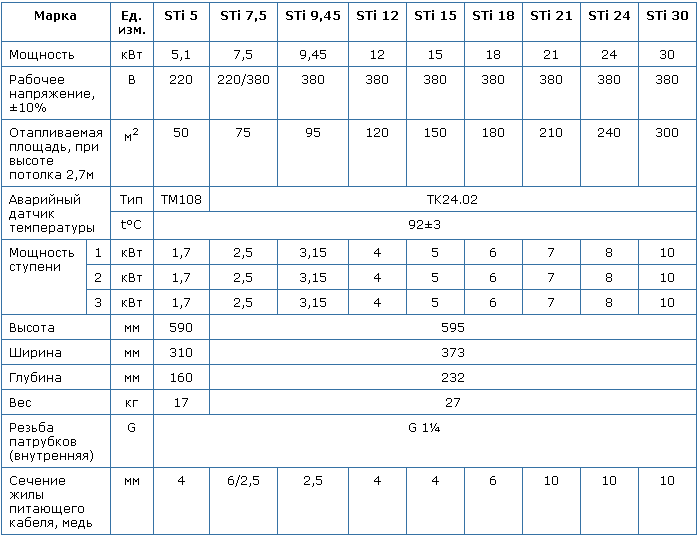

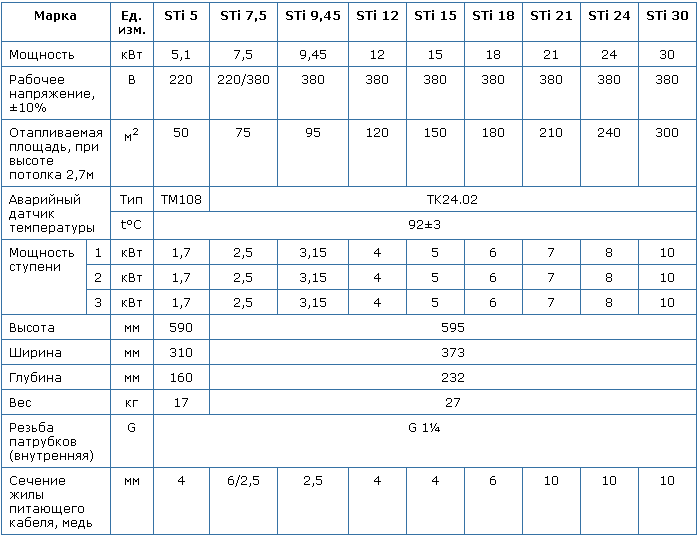

In this table, the manufacturer indicates the heated area for each boiler model, we can correlate these data with the nominal power. It is indicative that a 5.1 kW heat generator can be connected to a regular network, while other boilers will require a three-phase power supply (7 kW is universal in connection)

In boilers for indirect heating, there can be several heating elements, then the maximum power of the unit is the sum of the capacities of all heating elements. Often the performance of heating elements is different, therefore, when each of them is turned on separately (or all at the same time), a stepwise power control is implemented. The power of the electrode boiler is regulated by changing the working surface area of the electrodes; for this, movable fluoroplastic plates are used.