Today it has become very important to use foam as an external insulation. Indeed, it can be said with great confidence that this is a good way to keep the room warm. Let's look at what the technology of wall insulation with foam plastic is from the outside, as well as its main stages and nuances. Believe me, there really is something to talk about.

Why is it needed, or What will it give?

It is quite a logical question, because hardly anyone wants to spend an impressive amount of money without getting the desired result. The fact is that any technology of wall insulation with foam outside has several undeniable advantages. Firstly, during the heating season, you save a significant amount of fuel, and in the summer, there are less air conditioning costs. Secondly, unlike internal insulation, the area of rooms is not reduced, and this is very important, especially when it comes to a small house or apartment. The so-called "dew point" will be located behind the insulation. This completely solves the problem of wall freezing, and also prevents its early destruction due to moisture. It is worth drawing your attention to the fact that these are far from all the advantages of this method of insulation. We'll look at the rest a little later.

Insulation of the facade of the house outside reviews

Polyfoam is a white cellular material. The structure is 98% air foamed with plastics. The cells are insulated from each other, so the material has good thermal insulation properties.

Polyfoam is used for thermal insulation of buildings for various purposes, for the manufacture of chests, refrigeration units, for frost protection of underground telephone line and power supply cables and for insulation of underground utilities.

- qualitatively protects against cold and freezing;

- does not lose its characteristics when in contact with moisture;

- does not lend itself to the influence of fungi and microorganisms;

- does not react with concrete, cement mortars and finishing materials;

- lightweight: there is no need to additionally strengthen the insulated structures;

- does not absorb odors;

- suitable for insulating roofs, facades, floors and door leaves;

- safe subject to installation rules.

- the material is susceptible to damage by mice: to prevent damage to the material, it is better to take polystyrene for insulating the floor with impregnation;

- it is quite flammable, therefore it is not recommended to lay it in places that heat up, and where there is contact with sparks or open flames;

- burns quickly, emits toxic substances that are dangerous to human life.

Polyfoam is a good insulation. However, before using it, it is worth thinking about what problems exist in your room. It is not recommended, for example, to use Styrofoam in homes where there are problems with rodents, high humidity and insufficient ventilation. If these moments are absent, you can safely insulate the room with polystyrene foam.

This insulation is one of the cheapest, it is lightweight, has excellent insulation, moisture-repellent properties, is easy to use (sheathing walls with foam, even alone, will not be difficult). It is indispensable for wall insulation in city apartments, but for summer cottages it is not the best option.

I used styrofoam as insulation during construction. It so happened that the second floor of the house could not be completed in one season. It was urgent to insulate all the walls and ceiling of the unfinished floor. For this I used 50mm thick foam.Outside, around the perimeter, I screwed vertically 50 x 50 bars, inserted foam sheets between them and covered everything with siding. The gaps were filled with polyurethane foam. Now it's already February, and we can say that the insulation works perfectly.

Wall insulation outside with foam: reviews and recommendations of consumers

Before using this method, you need to make sure that it is effective. The best way to do this is by listening to the comments of other people who have made such insulation. This source is the most informative and at the same time completely free. As practice shows, wall insulation outside with foam, reviews of which are mostly positive, really makes sense. According to consumers, electricity costs are reduced by about 15%, and gas costs by more than 20%. These are very good numbers. In a few years, the purchase of polystyrene will fully pay off. Nevertheless, professionals recommend that you carefully deal with this issue and pay attention to important details. For example, you do not need to buy sheets of the same thickness, since this does not make sense. This is due to the fact that the corners must have a larger layer, like the south wall. In addition, users recommend not purchasing polystyrene brands below C-20 (20kg / m3), since it is easily deformed, and in general there are more problems with it.

Polyurethane foam

A relatively new product on the insulation market, but nevertheless, it is he who receives a lot of positive reviews. Well, what - breathes, does not sag, has outstanding heat-saving abilities (they are even better than that of polystyrene) and is not very afraid of water.

But of course, there are "But" here too.

The first is the cost of both the work and the work product. Whatever numbers the PR people give you, but even according to the most modest calculations it will be twice as expensive as expanded polystyrene, which, which is important, you can insulate yourself without outside help, while you cannot do without special equipment to apply polyurethane.

And the second factor, which we often forget about, is the vapor of hydrocyanic acid (there is such a poison) it is it that is released from the polyurethane foam when it burns.

Do you need a reinforcing mesh?

A very strange question, the answer to which can only be one - of course, yes. This is due to the fact that without such an important element, cracks will soon appear, and it is quite possible that the sheets will float. Fiberglass mesh should be used as the basis for the plaster. The preferred density is at least 150-160 g / m2. It is best to attach it to glue (cement base). The latter is applied in a meter by meter area. Next, we need a wide spatula, with which we will sink the reinforcing mesh into the glue. Many people recommend applying another layer of glue on top for greater security. We periodically check how flat the surface is. It is desirable that the horizontal stripes overlap at least 7-10 cm, and the corners of the facade are reinforced with a perforated corner.

How to insulate a house outside

Building materials used in the construction of external walls of residential buildings can be completely different: brick, concrete, cinder concrete, aerated concrete, wooden logs, and so on. However, the creation of this structure does not solve the problem of thermal insulation of the building, and therefore the question invariably arises - how to insulate a house outside. One of the most effective, reliable and durable insulation methods the house is a thermal insulation system "wet facade».

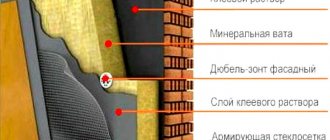

This method involves the use of foam sheets or basalt wool as the main insulation elements, followed by finishing with decorative plaster, clinker tiles, and so on. At the same time, for the facade of the building, be applied many color solutions, and the durability of such insulation will be more than 30 years.

, engaged in repair and construction work in the city of Bryansk and the Bryansk region, is ready to offer its customers prompt and high-quality thermal insulation of facades of residential buildings at mutually beneficial prices. We have a question how to insulate a house outside You will receive an answer in the form of a comfortable warm home. In our work we use certified materialswho passed climatic tests with a reliable manufacturer's warranty. Our specialists have extensive work experience in this field of activity and a high level of qualifications. All this is reliable guarantee the fact that your home will receive high-quality thermal insulation for many years.

How to insulate a house from the outside - the essence of the wet facade system

This thermal insulation technology is not only capable of providing good results, but is also comparatively economical. The main stages of work during the application of the thermal insulation system for houses with a wet facade are as follows.

Insulation elements are mounted on the outer walls of the building from bottom to top - either sheets of expanded polystyrene or mineral wool slabs. If foam sheets are chosen as the main heat-insulating material, then it is imperative to make a heat engineering calculation. Otherwise, if the thickness of the insulation is incorrectly selected, this can lead to the accumulation of moisture in the thickness of the wall, which will invariably lead to the multiplication of pathogenic microorganisms - fungi and mold, as well as insects.

We are the official representatives of specialized materials for facades in the Bryansk region. You can buy products such as "Baumit" from us. You can get acquainted with their products in our product catalog. These are world-renowned manufacturers who have established themselves in the construction industry.

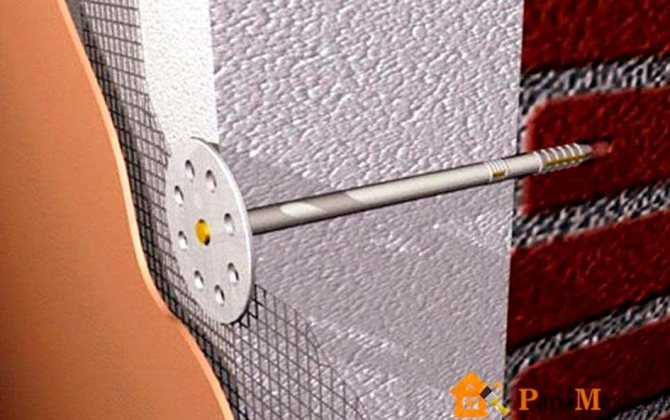

The process of fixing thermal insulation boards consists in fixing them to the base base using special adhesives and special disc dowels. Each insulation element must be fixed with at least 5 dowels: 4 - in the corners, 1 - in the center.

Next, a special glue is applied to the fixed insulation, into which a strong reinforcing fiberglass mesh is laid. Then a primer with quartz filler is applied to the prepared surface for better adhesion with a finishing layer in the form of decorative plaster. It can be cement, acrylic, silicone, silicate, silicate-silicone and mineral mixture. Some types of decorative plasters can be painted. To the question of how to insulate a house from the outside, the answer is very simple - the thermal insulation system is a wet facade.

If you are not familiar with the insulation of houses according to the system "wet facade", Then the experts will tell you in detail about this system. They will select suitable materials for you and make an accurate estimate.

The use of this technology does not imply the appearance of any voids inside this "puff cake", which is a reliable guarantee of thermal insulation for many years. In addition, the wet facade thermal insulation system involves finishing the outer walls with decorative plaster. This means that the outer walls of the building will have a presentable appearance.

We hope that in this article you have fully received the answer to the question - how to insulate a house outside.

A little about finishing

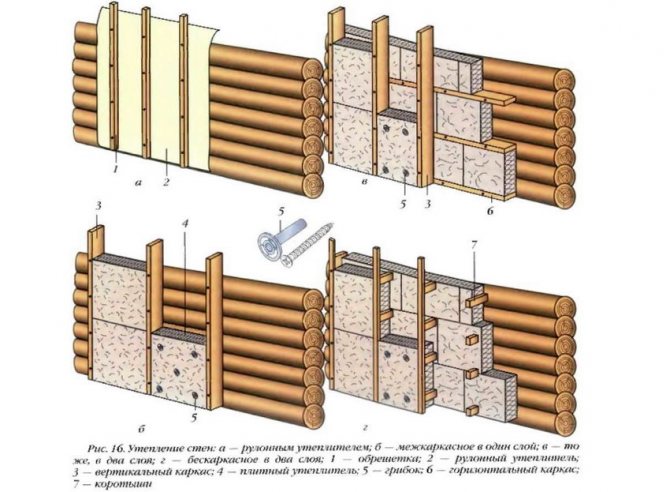

In principle, the technology of wall insulation with foam from the outside is fully considered. All that remains to be done is to take care of the exterior finish. Of course, this is a personal matter for everyone, but a painted facade looks much better than an untreated one. Remember to prime the surface before painting. We can say that the insulation of wooden walls with foam plastic from the outside is carried out in the same way as concrete walls, with several minor differences.First, you need a thin layer of plaster to protect the room from fire. Secondly, you need to provide an air gap, which will exclude the appearance of condensation between the wall and the insulation. Keep in mind that ideally the styrofoam sheet should not be more than 50mm thick.

Mineral wool

Most experts, when asked what is the best way to insulate a house from the outside, would point to mineral wool. This means, of course, basalt products, since everything that is sold in rolls or mats for insulating building envelopes is not suitable.

The thermal insulation properties of this product are within the same limits as that of expanded polystyrene, but at the same time, basalt is not afraid of fire, does not litter when heated with poisons, and easily passes steam through itself. What is not an ideal product?

But mineral wool also has its minus - fear of hydration. Even with a slight moisture, its thermal insulation properties are halved. There is no need to talk about significant wetting.

Engineers, of course, have developed many ideas on how not to let this moisture through to the insulation, but at the same time films and membranes often kill the very vapor permeability of the wall cake, leveling the difference between fibrous insulation and expanded polystyrene.

Instructions

The process of insulating a brick house will depend on what material is used for this.

Foam insulation

The first step is to carefully assess the condition of the brick wall. If there are defects, then they need to be corrected. Then remove various contaminants from the surface. Dry the wall and prime with a primer. This will improve the adhesion of the material to the wood. Install a galvanized corner or profile along the perimeter of the wall. This will be a kind of level for laying insulation, a drain for moisture and a barrier for mice. Then spread the adhesive onto the board and press it firmly against the wall. Tap slightly with a rubber mallet.

Secure each plate with umbrellas. Wait 1 day for the glue to dry thoroughly. Then you can attach the plastic mesh. A thin layer of cement mixture is laid on top of it, thanks to which reliable protection from the sun and precipitation is created. By clicking on the link, you can find out more about how the technology of facade insulation with foam is happening.

On the video insulation of a brick wall with foam:

Mineral wool insulation

First you need to build a frame. For these purposes, wooden blocks are used. Before installation, they must be treated with an antiseptic and fire retardant. This is necessary in order to create protection against the influence of mold and rodents.

The bars are fastened at a distance that is less than the width of the heat insulator. The thickness of the bars can be different and depends on the size of the slab. Fastening is carried out using dowels.

It is necessary to lay mineral wool between the boards. The material in question has the ability to absorb water. To neutralize this problem, it is necessary to lay a protective film over the mineral wool. Its fastening is carried out using a stapler. On top of the boards, mount another layer of slats, on which the siding will be fastened. Such material can be insulated, including plastic windows, and all the work can be done by hand.

On the video insulation of a brick wall with mineral wool:

Warming with plaster

This material is today considered one of the easiest to insulate a brick house. The main advantage is that you only need one layer of plaster. Thus, it is possible to simplify the entire process of insulation. Plaster also acts as a heat-insulating layer and a decorative element, with which you can give the house an attractive appearance.

The process of applying warm plaster is carried out using standard technologies. If necessary, you can install beacons.To prepare the solution, you must use the instructions that are on the packaging with the product.

After applying a layer of plaster, it is necessary to give it a special texture. For these purposes, you will need to use a structural roller. They walk on the not yet solidified surface, which is distinguished by high plasticity. The result is a pattern. This material, among other things, can be used to insulate a log house from the outside.

In the video, the use of plaster to insulate a brick wall:

Is there any point in insulating housing from the inside

In response to this, the following facts are cited. Firstly, insulation of a home from the inside is 15-25% cheaper than thermal insulation of a facade. Secondly, for houses built of silicate bricks and foam blocks, only internal thermal insulation is possible. This solution is explained simply - the connection of two materials leads to the formation of gaps through which air enters the apartments. If you insulate the building from the outside, then there will be no positive effect. Heat will not retain in the room. The last argument in favor of internal thermal insulation is that the room is insulated in a comprehensive manner. With the thermal insulation of the facade, the border of the insulation will be the zone of neighbors, through which the cold will still make its way to the living space.

Insulation of housing from the inside, like many construction work, depends on the correct choice of material. Requirements for the heat-insulating material: low thermal conductivity, long service life, environmental friendliness, resistance to fire, water and other manifestations of mother nature. Experts also note such a criterion as the possibility of finishing with the most affordable decorative materials.

Usually, home insulation from the inside is performed using one of the following materials - fibrous, expanded polystyrene and polyurethane foam plates, cork material. Fibrous materials include mineral wool, glass wool and ecowool. This type of insulation is characterized by good heat and sound insulation. If we consider the material from the point of view of durability, then ecowool is the best insulation of housing from the inside with the use of mineral wool. The disadvantages are the time spent on assembling the frame, a special passion to absorb moisture and the difficulty of finishing with drywall.

Expanded polystyrene is excellent for insulating housing from the inside. Only its price can be embarrassing. The rest is moisture-resistant and easy-to-mount material. The property of expanded polystyrene, like flammability, spoils the picture. As the best way to insulate housing from the inside, thermal insulation with polyurethane foam is sounded. Except that complications are possible in the form of installing the frame. A plus is the possibility of quick decorative finishing, which is performed using plaster.

Cork materials when insulating a home from the inside is an original move for those who want to add zest to the interior of the room. With the material, you will not have to spend money on additional decorative finishes. In addition, it is environmentally friendly and safe for the health of living beings. They are rarely used for insulating housing from the inside due to the high cost.