Features of Rehau pipes

The production of pipes using a new technology determines the fundamental features of the products, which consist in the following aspects:

- increased noise insulation. XLPE is capable of absorbing sounds produced by the flow of water;

- installation of Rehau pipes is carried out using a unique method that allows you to create the most durable connection;

- the material from which the pipes are made is versatile. From pipes, you can create systems for hot and cold water supply, heating, and use for arranging a warm floor. The maximum temperature of the liquid in the pipe is 95 ° C;

- pipes are practically not susceptible to cracking and deformation during mechanical damage, so they can be laid under plaster or covered with other structures;

- high degree of thermal insulation, which helps to save natural resources;

- any pipe is able to withstand changes in the temperature regime of the liquid and internal pressure;

- complete safety for humans. The company's products are certified;

- a special coating of the inner walls of the pipes prevents the formation of plaque and a reduction in throughput.

Materials that give Rehau pipes unique qualities

Rehau pipes and various fittings can be used to design pipelines of any complexity and purpose.

The only drawback of Rehau pipes is the high cost of products and fittings.

Varieties of pipes

According to the purpose, the products can be divided into two types: for water supply and heating.

Also separates internal engineering systems and radiant heating and cooling systems. The former can be used for both water supply and heating, the latter only for heating / cooling.

Heat supply systems are placed in a separate category.

Rehau also produces polypropylene domestic sewage pipes.

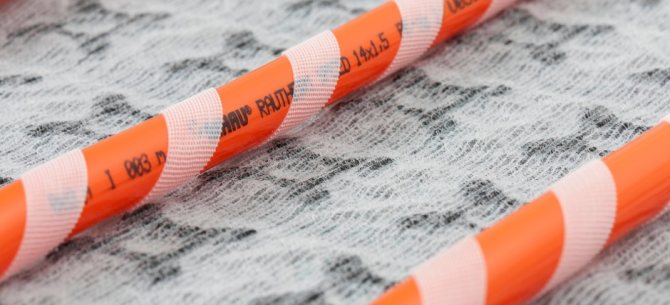

Special pipes RAUTITAN his and RAUTITAN pink are used for internal engineering systems. The former are intended for cold and hot water supply, the latter are used for heating systems.

All Rehau products are manufactured using the RE-Xa method, i.e. the peroxide crosslinking method. The suggested diameters are from 16 to 63 mm.

RAUTITAN stabil can be used as universal pipes, however, their maximum diameter is 40 mm, or RAUTITAN flex with a diameter of up to 63 mm.

A novelty are insulated pipes of these brands, which have a layer of extruded insulation made of foamed polyethylene. They are intended for thermal insulation of the heating system on load-bearing ceilings.

Insulation allows:

- enhance the water-repellent effect;

- increase resistance to aging;

- protect from heat generation, condensation;

- protect against sound transmission through building structures.

For radiant heating and cooling systems (such systems also include underfloor heating) RAUTHERM S and RAUTHERM SPEED are offered. The second feature is the presence of adhesive tape on the surface for attachment to the laying mats.

In addition to floor systems, both wall and ceiling systems can be equipped. At the same time, ceiling tiles are offered in the form of gypsum boards with an already built-in pipe.

RAUVITHERM UNO (with one insulated pipe) and RAUVITHERM DUO (with two) are used as heating systems.

They find applications in the following areas:

- centralized and local water supply;

- drinking and hot water supply;

- pool equipment;

- refrigeration equipment;

- industry and agriculture;

- air-water pump connections;

- heat pumps using the heat of the earth.

The sound-absorbing internal sewerage system is represented by RAUPIANO PLUS. The diameter of these products is from 40 to 200 mm. These are polymer multilayer pipes with reinforcements in the cornering zones. Special clamps are also used to absorb noise. Polypropylene is more expensive than HDPE pipes, but it is lighter, stronger and has a smoother surface, so it is more resistant to dirt.

Pipe installation

To install Rehau pipes with your own hands, you need:

- purchase the necessary tool;

- pre-familiarize yourself with the instructions for assembling the pipeline.

Tools required for installation

Before proceeding with the installation of pipes, you must:

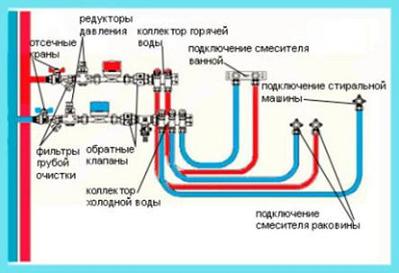

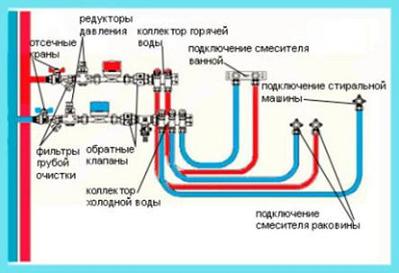

- purchase the required number of pipes, connecting fittings and adapters. To calculate the necessary materials, a water supply diagram is drawn up;

An approximate wiring diagram for hot and cold water pipes in a city apartment

- prepare a tool for installing Rehau pipes:

Expander for pipe mounting

press clamp with additional attachments of different diameters. Since the installation of the type of pipes under consideration is somewhat different from conventional welding, then such a specific tool for installing Rehau pipes is also required for the procedure;

Hand press used for connecting pipes, REHAU RAUTOOL

pipe cutting tool. Standard pipe cutter, used for all types of plastic pipes;

Tool for cutting polymer pipes

tape measure, pipe marker.

Standard measuring tool used in construction

All tools can be purchased individually or as a set. The average cost of a set is 2,500 rubles.

Pipeline assembly process

The installation of Rehau XLPE pipes begins with the preparation of the pipes. Preparation consists of two steps:

- according to the previously prepared drawing, pipes of various sizes are cut;

The process of cutting a pipe to the desired size

- the fittings required for the assembly of a specific section of the pipeline are prepared.

If heating with Rehau pipes is being installed, then it is more expedient to immediately prepare all sections of the system, and then first check the correctness of the sections according to the scheme.

For inspection, all pipes and fittings are placed on the floor in a specific order. This is especially true for heating in city apartments, since it is required to turn off the heating throughout the house.

When cutting pipes, one should be guided by an old Russian proverb - “measure seven times, cut once”. Mistakes in pipe cutting can make it impossible to install the piping system indoors.

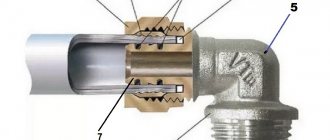

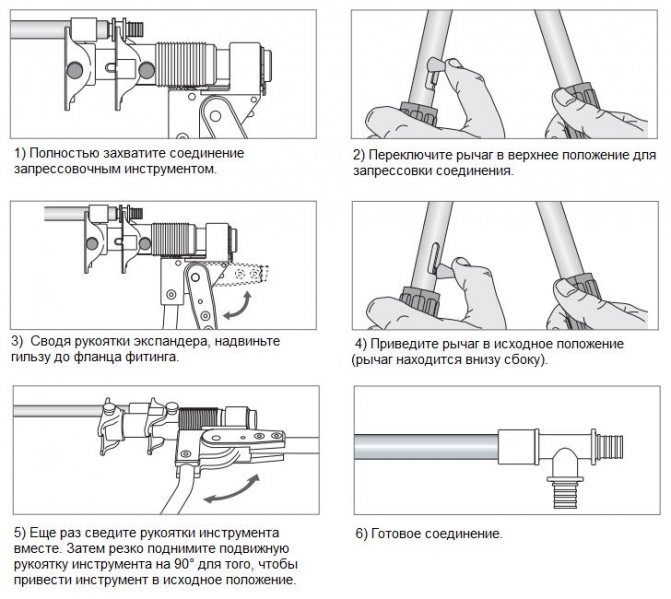

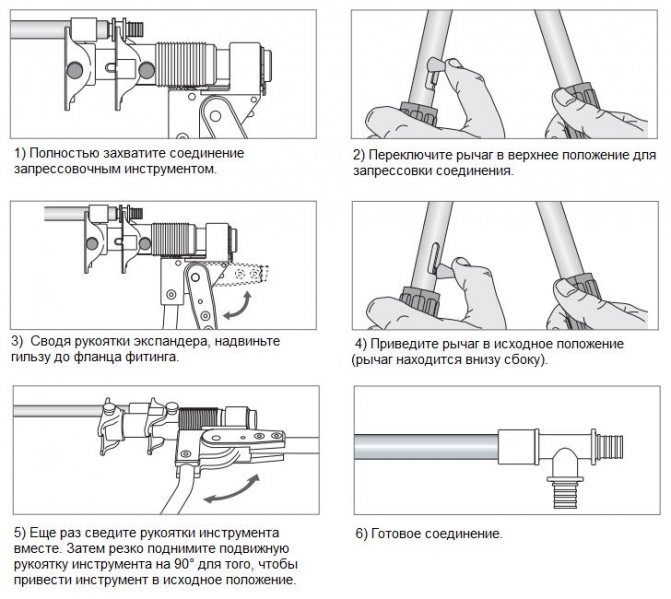

Docking of pipes and fittings to each other is carried out using sleeves, which are fixed as follows:

- a nozzle is selected on the expander, the diameter of which fully corresponds to the diameter of the pipe used. In this case, the tool handle must be completely divorced (the ends of the handle are at right angles to each other);

- the nozzle on the expander should hold firmly and sit on the pin until it stops;

- a sleeve is put on the piece of pipe that needs to be connected to the fitting. The diameter of the sleeve used must also match the diameter of the pipe;

Each sleeve is chamfered. During installation, it should be directed towards the future joint.

- a pipe is put on the other end of the nozzle installed on the expander. When the handle of the expander is brought together, the pipe expands;

Pipe expansion process for further installation

- the expanded end of the pipe is connected to the fitting that must be installed in this place;

Inserting a fitting into a prepared pipe end

- a previously installed sleeve is supplied to the fitting;

- using a press clamp, the sleeve is pushed all the way into the fitting. A strong and secure connection is ready.

Fixing the fitting with a press clamp

When arranging the connection of pipes and fittings, even the slightest distortions must not be allowed. All connecting parts must be located strictly horizontally to each other. Otherwise, the connection will be unreliable.

Step-by-step diagram of work with a press clamp

Installation of Rehau pipes for heating, gas or water supply must be carried out in compliance with all safety standards. First of all, care must be taken to protect the eyes (use of a mask) and hands, which are not recommended to be inserted into moving parts.

The video below for the installation of Rehau pipes will allow you to observe the process from the outside in order to more accurately find out all the most important aspects.

Everyone can install pipes of the German manufacturer Rehau. The main thing is to have the necessary tool and strictly follow the instructions above.

Cost of Rehau pipes and fittings

For XLPE, pipes and fittings, the price of Rehau is quite high. However, the quality of this brand can be called a reference.

The main influence on the cost of the same type of product is the diameter and dimensions. Thus, the larger the size, the higher the cost. In the above list, the boundary parameters of size and cost are indicated, on the basis of which conclusions can be drawn about the approximate cost of products within the range.

Standard products for heating and water supply:

- RAUTITAN his for water supply, diameters from 16 to 63 mm - from 1.76 to 21.79;

- RAUTITAN pink for heating, diameters from 16 to 63 mm - from 1.75 to 18.75.

The cost is indicated in euros for 1 running meter.

Stabil:

- RAUTITAN stabil universal in corrugated pipe, diameter 16.2 or 20 mm - from 3.99 to 5.45;

- RAUTITAN stabil universal without corrugated tube, diameter from 16.2 to 40 mm - from 3.08 to 24.77;

- RAUTITAN stabil PLATINUM universal in corrugated tube, diameter 16.2 or 20 mm - from 3.99 to 5.45;

- RAUTITAN stabil insulated square, diameter from 16.2 to 20 mm - from 6.86 to 11.56;

- RAUTITAN stabil insulated round diameter from 16.2 to 25 mm - from 4.67 to 9.92.

The cost is indicated in euros for 1 running meter.

Flex:

- RAUTITAN flex universal in a corrugated tube, diameter 16.2 or 20 mm - from 3.23 to 4.27;

- RAUTITAN flex universal without corrugated tube, diameter from 16.2 to 63 mm - from 2.36 to 23;

- RAUTITAN flex insulated square, diameter from 16.2 to 20 mm - from 5.94 to 9.94;

- RAUTITAN flex insulated round, diameter from 16 to 25 mm - from 3.85 to 8.16.

The cost is indicated in euros for 1 running meter.

Fitting:

- sliding sleeve - from 0.79 to 11.75;

- adjustable tees - from 6.07 to 35.88;

- equal tees - from 6.07 to 78.21;

- tees with reduced side or end passage - from 8 to 119.57;

- connecting couplings - from 4.23 to 57.94;

- adapters - from 9.49 to 133.23;

- corner adapters - from 5.55 to 100.57;

- collectors - from 79.11 to 239.84 (the cost of industrial ones reaches 1,500 euros).

The cost is indicated in euros for 1 piece.

Preparation for installation work

The collector outlets should be the first items requiring increased attention. Only their correct processing will ensure complete tightness in the system.

Before installation, the workplace must be completely free of dust and debris, as well as the equipment. Welding, threading and gluing are the most widespread methods during installation. You only need to purchase the appropriate type of fitting, depending on the method of installation you have chosen.

Watch video: Bir Pex systems

Absolutely all parts that are used during installation must be whole and clean. A visual inspection is required prior to purchase. This will ensure the quality of the finished product. Their transportation deserves special attention.

REHAU HIS pipe

This is a pipe intended only for wiring the water supply system. does not have an oxygen protective layer. It is washed from chemical residues that are formed during the crosslinking of polyethylene by the peroxide method and is certified for use with drinking water. Her color is white. The advantage is a lower cost due to the absence of an oxygen protective layer and therefore cannot be used in heating systems. With large volumes of wiring of water supply systems, the use of this particular pipe is absolutely justified.

Why is unprofessional installation dangerous?

Installation of Rehau pipes in an apartment, which is carried out by non-specialists and without the use of professional equipment, can entail the most disastrous consequences. In the event of a burst of pipes, the flooding of the dwelling and all adjacent areas is ensured.

If a gust has passed on the heating system, then in winter you are in danger of a complete defrosting of the system and the difficulty of restoring it. If you order the installation of the Rehau pipeline in, then you will not face any of the unpleasant consequences.

The work done by professionals has several distinctive characteristics:

- the pipeline layout is the most optimal, does not interfere with other systems and the conduct of normal life processes for the owners of the dwelling;

- each pipe connection is of high quality and has even seams;

- the correct type of pipes was selected for installation, which is compatible in parameters with the installed system;

Preparatory actions

The installation of a piping system using Rehau polyethylene pipes begins with the process of preparing the products.

How it happens in practice:

- First, the pipes are cut according to the pre-made markings;

- Next, fittings begin to be selected to the pipes, which will be needed to design a certain section of the water supply system.

Of particular importance at this stage is the verification of the correct cutting of all elements of the system according to the layout of the water supply system.

The check can be done by arranging all the necessary elements in the required sequence. It is especially important to make sure of the correct fit when installing heating systems, since during operation you will have to turn off the heat throughout the house.

When cutting pipes, it is advisable to check the markings several times before finally cutting anything. Because in the event of an error, repair work can be delayed for an indefinite period of time, which will entail additional waste and inconvenience.

What are the main advantages and features

- Reverse shrinkage. Products are able to resist high levels of pressure, and after prolonged exposure, they return to their original form. Other materials with similar parameters simply stretch after a while and become unusable completely.

- Increased heat resistance. Such pipes work normally at temperatures up to 120 degrees.

- Availability of prices.

- The ability to resist freezing.

- They tolerate high temperatures and pressures.

- Convenient installation.

- Low weight.

- Bir Peks, Rehau and other firms have a high rate of sound insulation. Thanks to this, the room itself is protected from extraneous sounds. The pressure surges are completely absorbed by the system itself.

- Long service life combined with high strength. You can forget about rotting and corrosion when working with this material.

- Environmental friendliness. Polyethylene does not emit harmful substances, even when it is very hot.

- Elasticity.

REHAU FLEX pipes

Universal pipe. Those. it can be used both in water supply systems and in heating systems. Certified and protected against oxygen. It differs from REHAU PINK only in color, it is also washed from chemistry. They are identical in form factor and specifications. Loved by installers because can be used both there and there. When performing installation in small rooms, you should focus on purchasing this particular pipe because almost all of the leftovers will be used up. And you will never be able to calculate everything down to the millimeter.

Installation process

Installation technology includes several steps.

- We screw the nozzle with the required diameter onto the expander.

- After that, we put on the crimp rings on the pipes themselves. And we do this so that the place of the pipe expansion is not occupied.

- An expander must be inserted into the pipe. It expands when the installer pushes the special handle. The next step is to turn the pipe itself or the expander by 30 degrees. And then they press the handle again.You can repeat the operation to consolidate the result. After that, proceed to using the fitting.

- The shutter is retracted from the press with your own hands. Next, pull out the pins used for fastening. The next step is threading the nozzles that are fixed with pins. The shutter clicks.

- The connection takes on a finished form. The product must be pulled out of the press.

Using

Rehau pipes are often used for heating systems, underfloor heating, water supply, sewerage systems and a central vacuum cleaner.

It should be noted that the use of products in each area implies a different type of material and production technology.

Moreover, the company has developed a special program - RaubasicPress, according to which two system options can be offered:

- With PE-Xa product and movable sleeve.

- With product PE-Xb.

Rehau polyethylene pipes can be used for hot or cold water supply due to the fact that their operating characteristics are not worse than metal-plastic ones. This is due to the high level of sewing performance.

As for Rehau pipes for sewerage, they can be used for indoor and outdoor systems. Installation is carried out using fittings and fittings. Therefore, the process does not take much time.

Rehau plastic products can be used for underfloor heating. Thanks to the use of stitched material and the minimum number of components, installation time and costs are reduced by a third.

Installation of a cross-linked polyethylene pipe

Materials (edit)

Before starting work, prepare the necessary tools and consumables. You will need:

- Vise.

- Fittings: couplings, adapters, elbows, tees, sliding sleeves (when installing a sliding sleeve, you do not need to use rubber gaskets, which increases the reliability of the structure).

- Expansion device.

- Roulette.

- Pipe cutting tool.

Rehau pipe - construction

Cross-linked polyethylene Rehau price per meter

Consider some prices for cross-linked polyethylene Rehau.

- Rehau rautitan flex pipe 16 x 2.2 mm.

Price: 132 rub. for 1 m.

- Specifications:

- material - made of cross-linked polyethylene, PE-Xa with an oxygen protective layer;

- outer diameter - 16.0 mm;

- wall thickness - 2.2 mm;

- working temperature - 95 ° C;

- working pressure - 8 bar;

- color - silver RAL 9006 (white aluminum);

- length of the bay - 100 running meters

- Rehau rautitan pink pipe 16x2.2 mm

Price: RUB 97.50 for 1 m.

- Specifications:

- material - made of cross-linked polyethylene, PE-Xa with an oxygen protective layer;

- outer diameter - 16.0 mm;

- wall thickness - 2.2 mm;

- working temperature - 90 ° C;

- working pressure - 10 bar;

- color - RAL 95090, lilac;

- length of the bay 120 rm.

- Rehau rautitan stabil pipe 20x2.9 mm

Price: 246 rub.

- Specifications

- material - made of cross-linked polyethylene, PE-Xa with an oxygen protective layer;

- outer diameter - 20.0 mm;

- Wall thickness - 2.9 mm;

- Working temperature - 95 ° C;

- Working pressure - 10 bar;

- Color - silver RAL 9006 (white aluminum);

- The length of the bay is 100 rm.

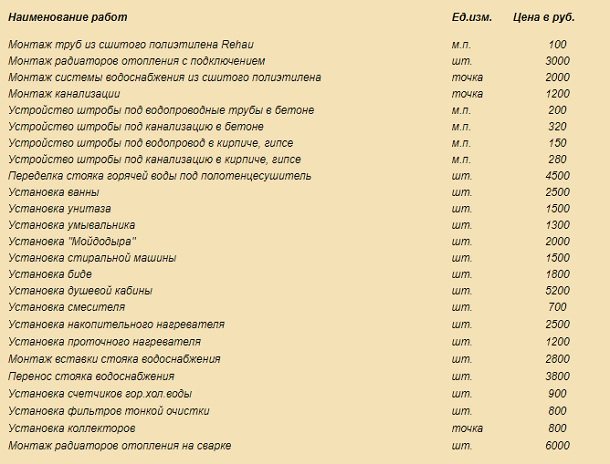

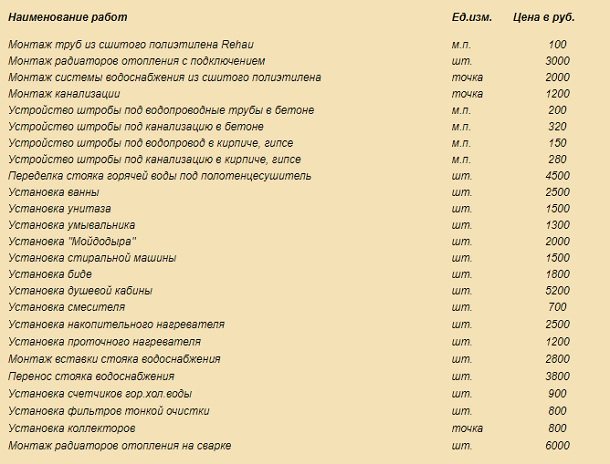

Sewn propylene Rehau installation price

Installation of pipes made of cross-linked polyethylene (REHAU) is a more expensive option for installing a water supply system compared to metal-plastic polypropylene. Cross-linked polyethylene is very convenient for installation, easily bends and is not afraid of kinks, does not corrode, has a very low roughness coefficient, has a low thermal conductivity, which leads to almost no heat loss.

The service life of the REHAU pipe with correct installation is more than 50 years. XLPE material is also used when installing heating systems.

Installation of REHAU pipes made of cross-linked polyethylene allows you to create reliable and durable plumbing and heating systems.

REHAU pipes made of cross-linked polyethylene are used for the installation of pipelines in external and internal engineering systems for hot and cold water supply, rehau1.png for heating and heating mains, for gas supply and sewerage, for pneumatic networks and networks in the industrial sector.

REHAU XLPE pipes can be used for laying pipelines in screed and under plaster. For the connection, special REHAU fittings are used, which are made of modified brass.

Installation of REHAU pipes is carried out using a sliding sleeve, without the use of O-rings; after connection, the system can be immediately loaded with pressure and temperature. It is recommended to install REHAU pipes only with REHAU special tools.

XLPE and its benefits

In production, the company uses high quality polyethylene, in which a linear bond is crosslinked with peroxide inside its structure. This material is marked with PE-Xa, thanks to which the products have high strength and heat resistance. Polyethylene is able to repair damaged areas due to the fact that the bond between molecules is not broken. The video shows the technology for the production of polyethylene products.

Important! The high cost of products is due to the company's use of high-quality and environmentally friendly raw materials.

The main advantages of the material:

- all products are certified and tested;

- has a high resistance to corrosion processes, the pipe walls do not crack, break or chise;

- the material does not allow dirt to accumulate inside the pipes, which excludes the formation of build-ups;

- the pipeline works without noise;

- has great resistance to high temperatures inside the system, the structure is able to withstand 100 degrees, and with a slight heating of water and 200 degrees;

- retains its shape at low temperature conditions, is shock-resistant;

- high resistance to chemicals;

- environmentally friendly material that is not capable of harming human life and health;

- the service life is more than 50 years;

- installation does not cause any problems, you can do it yourself.