Underfloor heating is increasingly used for heating residential and industrial premises. This is a whole system consisting of a coolant, a thermostat and heat sensors. The situation when the warm floor does not work gives the owners a lot of unpleasant moments. Knowing the causes of the breakdown, it will not be difficult to eliminate it. Many craftsmen can do it on their own.

Underfloor heating is especially important in a home with small children.

Human striving for comfort is the engine of progress. An increasing number of people use heated floors to create a warm atmosphere to furnish their homes. However, the technique has the ability to break, and sometimes does not heat the warm floor. There are a number of basic faults that should be checked if there is insufficient or no heating at all.

Getting to know the underfloor heating device

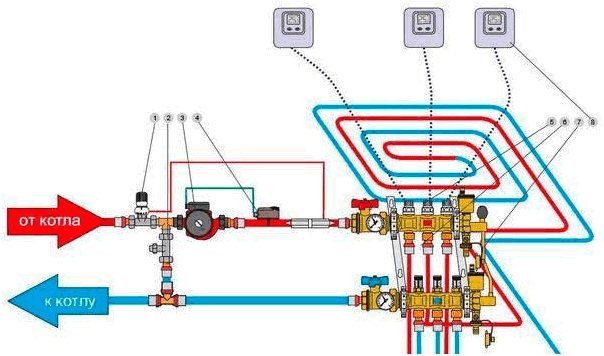

In order to know about the probable reasons due to which your home heating works intermittently or does not function at all, you need to know the principle of operation of the heating system and how the main parts and structural elements function. If your water floor does not heat well, not meeting the specified parameters, the main reasons lie on the surface. It's all about the technical flaws made during the installation of the water floor. Usually these are violations of the installation technology, the wrong consumables and additional equipment were selected.

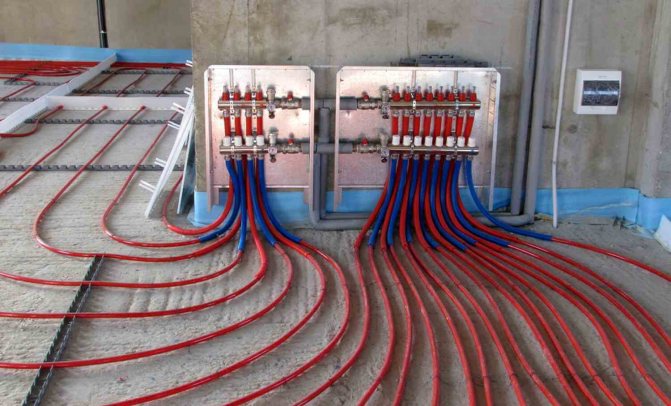

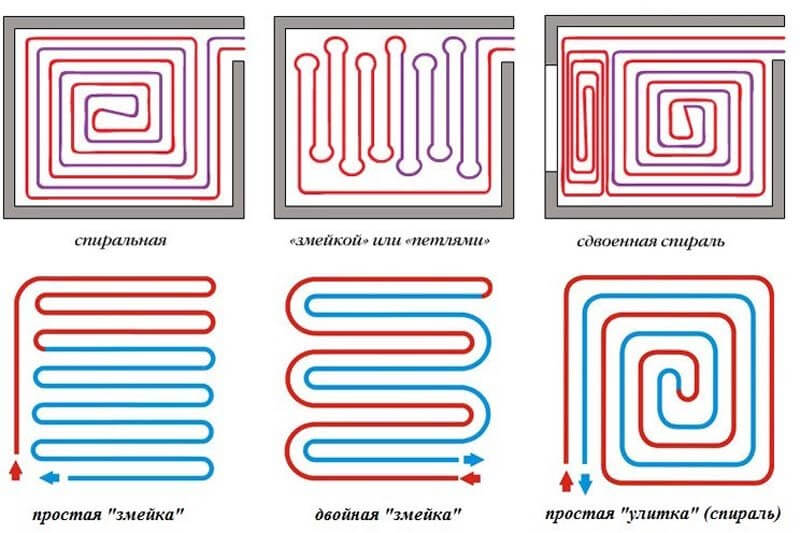

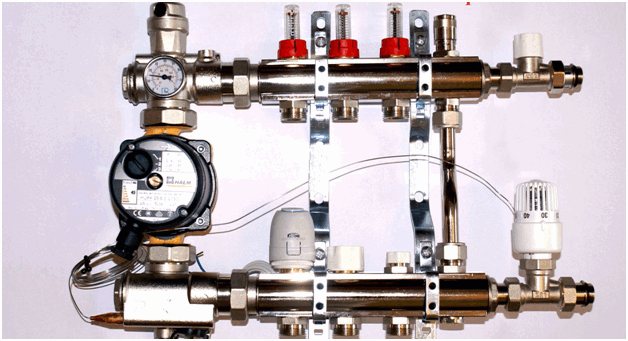

The specificity of the installation of equipment lies in how correctly the water circuit is laid and how the pipeline is correctly connected to the heating system. The lack of correct hydraulic calculations, incorrect adjustment of the mixing unit lead to the fact that the heating floor begins to flow into the pipeline intermittently, or its temperature is significantly lower than required.

When evaluating the entire structure, you can focus on the following structural elements of the heating system. Underfloor heating most often does not heat for the following reasons:

- the thermostat and temperature control sensor are out of order;

- the balancing valve is out of order;

- the circulation pump stopped working;

- the overhead thermostat-fuse has broken;

- the drives of the collector inlet pipes are out of order;

- the integrity of the water circuit has been violated;

- bypass problem.

Each of these elements can fail, making your underfloor heating not functional.

On a note: breakdown of the servo drive, temperature control sensors, there is a high probability of failure of the thermostat. The situation is similar with the balancing valve. A failed valve will not be able to provide a normal admixture of cooled water to the hot coolant. Accordingly, the water temperature in the water circuit will be insufficient for heating.

It is possible to enumerate for a long time the probable breakdowns of individual elements of the heating system. In each individual case, you will have to look for the immediate reason due to which the warm floor does not turn on or works intermittently.

Consider separately, the most common types of floor heating breakdowns.

The floor is "pierced" with electricity

The main reason is poor insulation of the connections of the supply wire and current-carrying strips. Inspection of all terminals and connections is required.

Violation of the insulation of the supply wire - a problem may arise during long-term operation of the warm floor if the connecting wires are improperly installed (especially if they were overlapped).

The room is very humid - for example, there has been a water leak or moisture somehow got under the topcoat on the warm floor. In this case, the joints between the film floor and the supply wire are a "weak" spot, which must be checked first.

The floor is not heating enough. Low coolant temperature

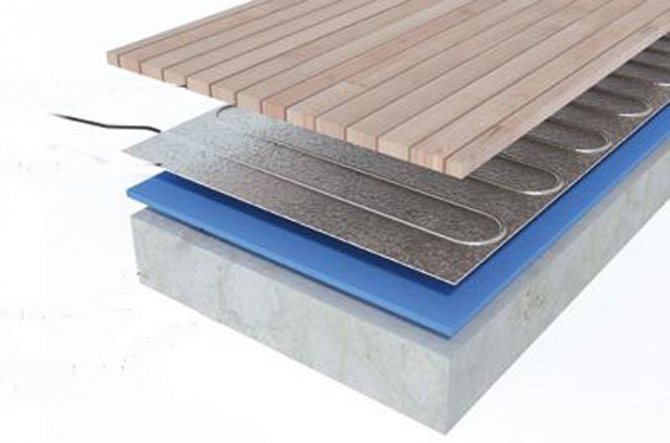

A typical and widespread problem that owners of city apartments and private houses are forced to face, complaining about the unsatisfactory performance of the warm floor, is uneven heating. During normal operation, the water circuit must completely and evenly heat the concrete screed or floor covering, creating the necessary conditions for heating the home.

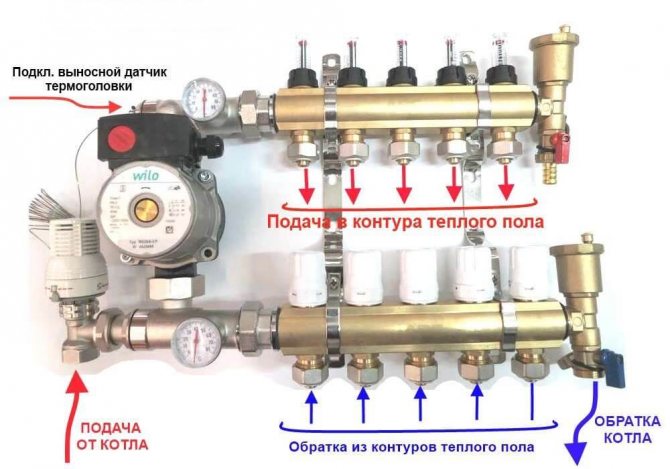

In this case, the problem is the uneven flow rate of the coolant along the water circuit. Due to the fact that the pipelines can have different lengths, due to the same intensity of the coolant supply, the degree of heating of each pipe is different. Usually, before starting in the manifold cabinet, the levels of the electric drives are set to the required position.

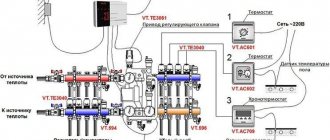

For reference: The electric drives are connected to a distribution block, which in turn is connected to an external thermostat. The signal from the thermostat arriving at the electric drives activates the rods, thanks to which the intensity of the coolant flow in each pipe is regulated.

Before starting the system, the optimal parameters are initially set, calculated for each circuit. By measuring the temperature of the coolant in each water circuit, the electric actuators are set to the appropriate position. Consequently, the heating temperature of the coolant in the system changes, and the degree of heating of the water circuit also changes.

The way out in this situation is as follows. We are looking for a water circuit in which the coolant does not heat the water floor in accordance with the set temperature, then manually increase the flow of boiler water.

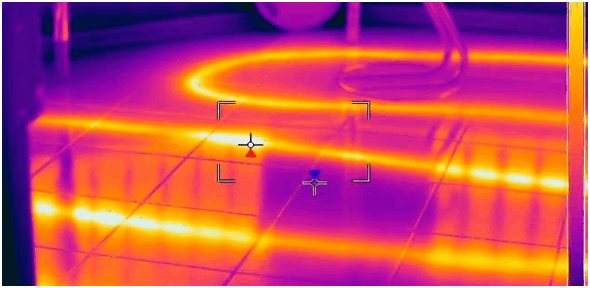

Damage to the water circuit

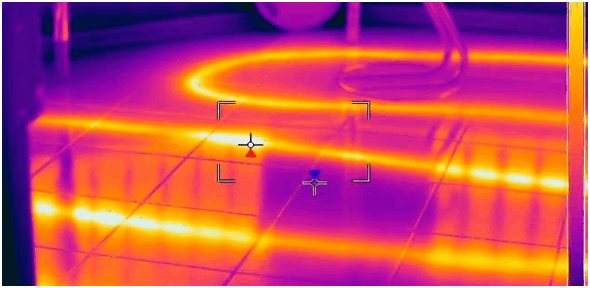

Pressure drops in the system can rupture the piping. A leak in this case is the most unpleasant factor, which will have to be eliminated urgently. A slight depressurization of the water wire causes a weakening of the intensity of the coolant flow. Accordingly, the floor warms up unevenly enough. The screed may collapse soon. There are several ways to determine the location of the leak. There is a mass of information material about the simplest options, using available means. The quickest and easiest way in this case is to use a thermal imager. This device will pinpoint the location of damage to the water pipe with high accuracy.

On a note: your floor is not working, then there is not enough coolant in the water circuit. To begin to eliminate the leak, it is necessary to turn off the supply of coolant through the manifold. Through the return pipe, water is drained from the water circuit.

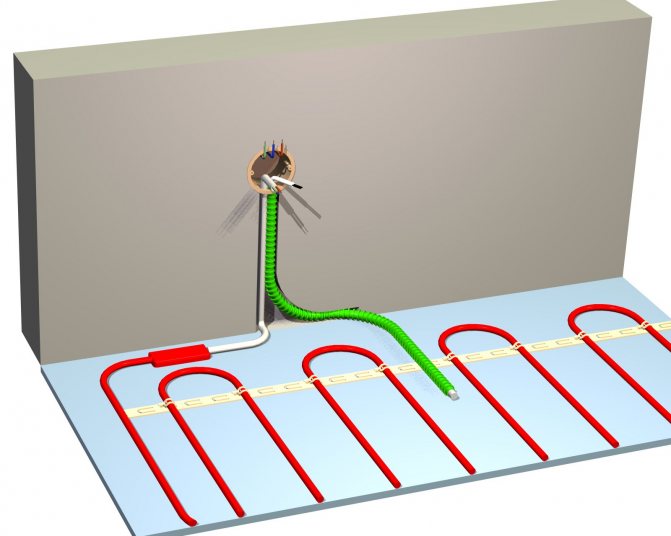

Leakage technology depends on the pipes used.

For example: the installation of a water circuit from cross-linked polyethylene pipes is the most common and affordable option for laying a water floor. However, sometimes you have to pay for the cheapness of consumables during operation. At the slightest mechanical damage, the pipe loses its integrity. You can solve the problem by installing a fitting. The installation location of the fitting must be marked on the schematic diagram or at the installation location of the manifold cabinet.

After fitting the fitting, the edges are crimped. If you turn on the coolant supply after repair work, you should wait two or three days to make sure the connection is reliable. Only after that the integrity of the screed and type-setting floor structure is restored.

The option using PVC pipes looks preferable.Such consumables have the required strength. However, improper handling of construction tools during construction and repair work can easily damage the water circuit. Accident elimination is carried out according to a similar scenario. First, dismantle the old screed. Next, the damaged area is replaced with a whole piece of pipe. The work is carried out using a soldering iron and a repair sleeve.

Re-pouring the concrete screed is carried out only after checking the connection for leaks.

Electric floor malfunctions

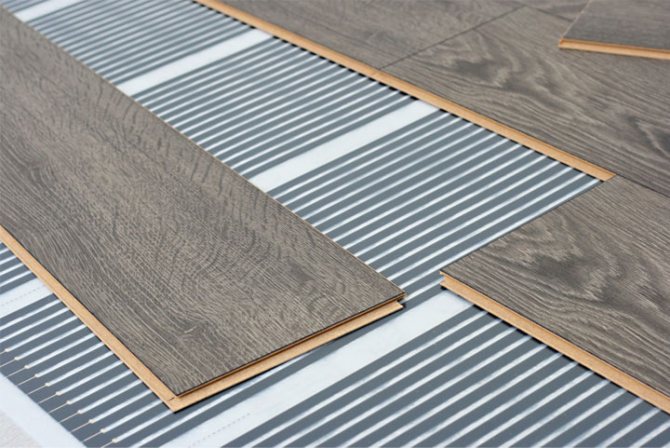

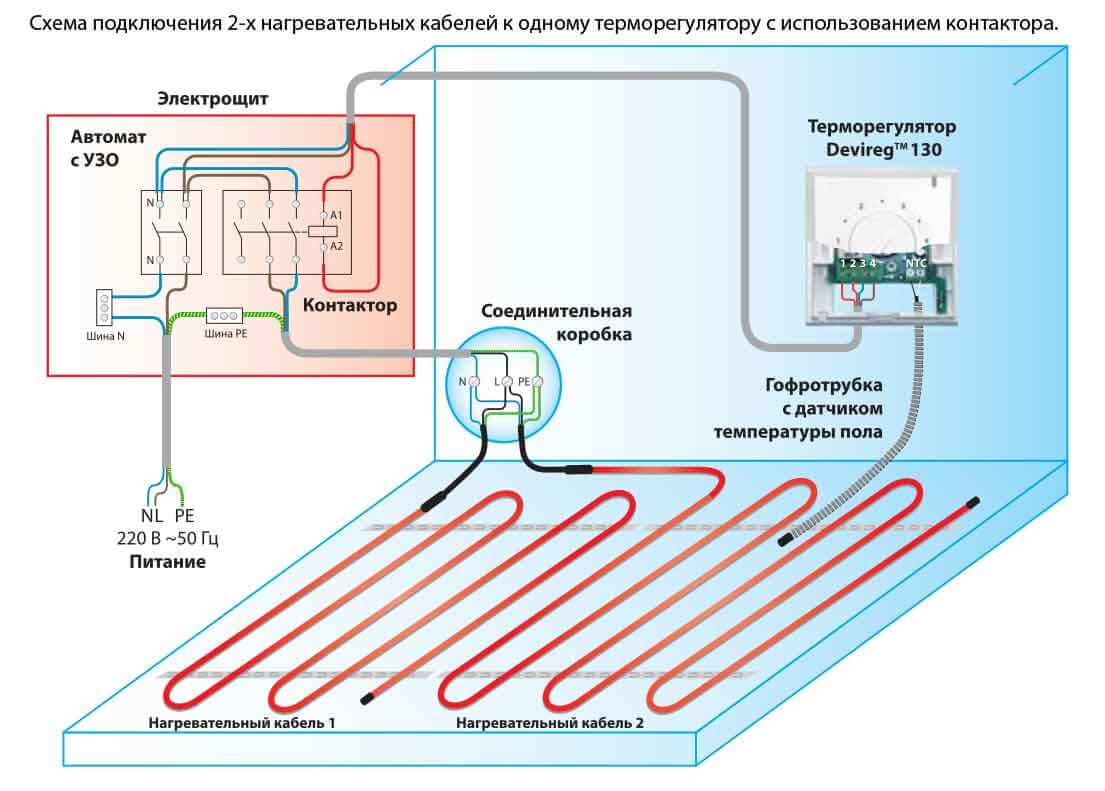

Having figured out why the warm floor does not work from water heating, we turn to electrical systems. They are all based on the classical principle. Under the influence of current, the heating element begins to generate heat, supplying it to the screed or directly to the coating. If the electric underfloor heating does not work, the reason may be:

- thermostat;

- damage to the cable or film;

- temperature sensor.

Thermostat and sensor

In most cases, an electric underfloor heating does not heat well due to a faulty thermostat. This device is responsible for the correct temperature, turning the system on and off. As soon as the heating power reaches the set value, it is automatically switched off. To make sure that the underfloor heating thermostat is malfunctioning, it must be disconnected from the network and dismantled. You will need a multimeter to check.

Quite often, the problem is associated with poor fixation of the terminals connecting the cable, power cord and temperature sensor. If the warm floor stopped working for this reason, just tighten the contacts. When the regulator is on, the voltage at the outputs and in the supply must be identical. If the resistance measurement shows sufficiently serious deviations from the indicators indicated by the manufacturer, the device must be replaced. Only a specialist can eliminate malfunctions that "amaze" a thermostat for a warm floor, and that is not always the case.

It is also important to make sure that the temperature sensor is working properly. The reason why the electric underfloor heating does not heat may be due to the proximity of the device to the heating elements. The sensor records the desired temperature too quickly and turns off, while the system has not yet reached the desired level. In this situation, the warm floor simply does not work. What to do if the equipment runs non-stop is the second problem associated with a damaged sensor. It can simply not shut down, "waiting" for the required temperature, causing large unjustified costs.

When the underfloor heating does not heat up, and the reason is the temperature sensor, it must be replaced. It is installed in a corrugated tube, from where it can be easily removed. This part of the system is not located in the floor, so there is no need to disassemble the floor covering. The only thing that may need a small cosmetic repair of the section of the wall where the corrugation was hidden.

Damage to heating elements

If you cannot determine in any way what is the reason for the fact that the warm floor has stopped heating, it makes sense to check the condition of the cable or film. First you need to measure the resistance and insulation level. If the discrepancies are more than 5% of the norm specified in the data sheet, then there is a break somewhere. When one contour of the warm floor does not heat, the search field is significantly narrowed. Cable models are found much more often, so we will mainly talk about them.

First of all, disconnect the system from the mains, and the wire from the thermostat. A high-voltage generator will help you understand why the electric underfloor heating does not heat. It will mark the place of the accident with a small discharge. If you do not have such a device, use an audio detector.He will indicate the reason why the warm floor does not heat well with a sound signal. Another effective option is a voltage tester. He, too, will accurately determine the location of the gap.

After it became clear why the warm floor does not work, the causes of the malfunction must be eliminated. First you need to carefully remove the top coat on the damaged area. If it was installed on a screed, it will also need to be dismantled. It is necessary to act as carefully as possible, otherwise the problem called "why does the electric floor heating poorly heats" can be significantly aggravated.

When purchasing a ready-made cable system kit, the client usually receives a repair kit. It includes sleeves and shrink sleeves. If such equipment is not available, it will have to be purchased separately. To eliminate the reason for the weak heating of the warm floor, you need to clean the ends at the breakage point, and then connect them using sleeves and couplings for this. The next step is to test the patched system. If it shows that everything is normal, you can re-fill the screed and lay the cover.

Malfunctions of electrical equipment

The last important point that should be taken into account in case of malfunctions with a warm floor is the failure of electrical equipment. This includes all devices and units that are electrically powered. The main element in this group is the circulation pump, the thermostat, which is on the equipment of the mixing unit. Devices can fail due to lack of voltage in the electrical network.

Determine a serviceable pump or not, you can use the characteristic sound of operation, which is emitted by a running unit. You can identify problems with the thermostat as follows:

- with proper operation of the device, the moment of stem rotation is clearly visible. In the event of a breakdown, this process does not occur;

- there is no need to repair the thermostat. It is better to buy a new device that will ensure reliable operation of the entire heating system in the future.