Any autonomous heating system of a country house must have a chimney, therefore, before erecting a building, many owners are faced with the choice of materials for it. Often the competition is won by asbestos pipes, which are successfully used for the construction of other building elements. For example, ventilation ducts are made of them, or used in the construction of foundations. The solution is quite logical: such an asbestos structure is inexpensive, the material is non-combustible, so it will fit perfectly. However, in any case, the owners have a new concern - the need for thermal insulation work. You need to arm yourself in advance with the knowledge of how and what to insulate an asbestos chimney pipe, or structures made of other materials.

Chimneys and materials for their insulation

Such structures are necessary for any heating device: both solid fuel and gas. Despite the need for a design, not everyone pays due attention to the chimney. And in vain: it requires protection from many influences, just like it needs to be regularly looked after.

All chimneys need protection. The most common structures are made of bricks, metal and asbestos-cement pipes. Any of them is threatened with gradual destruction, as they provoke combustion waste and corrosive moisture that regularly accumulates on the walls of the channel. The question of how to insulate an asbestos chimney pipe, as well as metal or brick structures, requires a correct answer.

The choice of heat-insulating material is limited, since it must meet the requirements for heat resistance and guarantee fire safety. Neither polystyrene, nor its "relative" - expanded polystyrene, nor other analogs are suitable for this purpose. Insulation should:

- have a minimum thermal conductivity;

- be light so as not to create unnecessary load on the roof;

- be plastic, flexible, so as not to complicate the installation of the master;

- not to be afraid of atmospheric precipitation, moisture, any aggressive environment;

- have a sufficiently long service life without loss of qualities.

Various materials are chosen for the role of insulation: for example, mineral wool, glass wool. They are fire-resistant and can easily withstand temperatures above 400 °. Other candidates are fiber insulation or slag concrete slabs. The most convenient are roll materials, the installation of which can be easily handled even alone.

The method of installing insulation for structures is different. A brick, metal and asbestos chimney requires "own" material and specific technology. Naturally, speaking of thermal insulation, they mean the protection of the outer walls.

Asbestos pipes are the most controversial candidate on the list for the title of a smoke exhaust system, so you first need to consider them in detail, assess the advantages, disadvantages and potential threats.

Insulation types

The following requirements are imposed on the insulation for the chimney pipe:

- the material must be available for DIY installation;

- it must be non-flammable;

- it should be suitable for insulating your type of chimney.

We recommend that you familiarize yourself with: How to calculate and mount heating registers yourself

Three types of chimneys are common:

- brick;

- steel;

- asbestos.

Each pipe has its own best type of insulation:

- Refractory mineral wool (basalt insulation). This insulation can be used for any kind.For the installation of the shell of an iron pipe with high-temperature operation, basalt friable non-combustible cotton wool is used, since the metal has the highest thermal conductivity. The shell structure is produced ready-made (sandwich) or can be assembled by hand.

- Plaster. The classic type of insulation for brick chimneys. Suitable for stoves using any fuel.

- Broken brick or slag. The material at hand is poured into the gap between the outer wall of the chimney pipe and the mounted insulating casing. The disadvantage of this design is its heavy weight.

- Extruded polystyrene foam (EPS). A special heat-insulating material that is used to insulate brick chimneys or other structures that have a square, rectangular shape. Not suitable for classic wood-burning or coal stoves, since the heating temperature of the chimney exceeds the performance characteristics of the material, in other words, the expanded polystyrene will melt.

Why and where is insulation needed?

No one doubts the fact that any structure will begin to deteriorate over time. This applies to all structures: chimneys made of bricks, metal or asbestos pipes. In the process of exhausting gases, combustion products accumulate on the pipe walls. Condensation forms in them, which forms at the dew point: where cold masses meet warm streams. High-quality insulation solves several problems at once. It allows you to:

- to strengthen the structure, since the heat-insulating frame is an additional protection against temperature extremes and gusts of wind;

- to reduce the risk of destruction of the walls of the structure due to constant contact with condensing aggressive moisture;

- to make the work of the heat generator more efficient, since thermal insulation implies less fuel consumption;

- prevent problems with a deterioration in traction: high-quality insulation reduces the thermal conductivity of pipes, prevents intensive accumulation of deposits.

The insulated chimney will look better and will last longer, as the wear resistance of the protected materials increases. In addition, the roof adjacent to the structure will also receive additional protection.

Insulation is necessary in the place of the pipe where the warm surface of the chimney "meets" cold air. As a rule, this site is located either in a cold attic, or where the structure is displayed on the roof.

The basis for the insulation of the chimney

In the process of passing the smoke through the chimney, the inevitable cooling of the warm flue gases occurs. As a result, the heat from the flue gases heats up the walls of the tube to remove the smoke into the atmosphere.

The draft in your stove also directly depends on how quickly the walls of the chimney warm up. With a decrease in thrust, the smoke begins to go at the least resistance, and simply begins to move from the stove to the scrap, and this is fraught with carbon monoxide poisoning, especially if in a private house, the stove is located right in a private house, and not in a boiler room allotted for this.

Another important factor in favor of chimney and pipe insulation. There is such a thing as time, during which the moment of condensation manifestation is overcome.

The time spent on warming up the chimney largely depends on what it is made of.

Table for calculating the temperature regime of the structure of the chimney

A brick lined chimney can warm up in 15-30 minutes

Photo of a brick chimney

The chimney made of steel heats up much faster - in 2-5 minutes;

We offer you to familiarize yourself with Rustic-style curtains - 67 photos of ideas and novelties

Steel flue duct

Since the hot stove chimney is constantly in contact with cold atmospheric air, the appearance of condensation in the chimney channel cannot be avoided.Together with the appearance of condensation, due to the mixing of water with carbon dioxide and other combustion products, an acid solution is formed, which, absorbing into the walls of the chimney, gradually destroys it.

If the chimney is made of bricks, then the moisture of the condensate is absorbed into the brick walls, and this most often leads to freezing of the brickwork of the pipe. The chimney that cooled down overnight in the frost heats up again in the morning, it is from such frequent temperature changes that the brickwork of the chimney inevitably collapses.

Brick chimney after regular freezing

So why are chimney ducts insulated? It is due to the fact that the appearance of condensation is practically impossible to avoid, but on the other hand, we can protect the chimney from freezing and destruction, it is imperative to insulate any chimney, the sooner you do this, the longer it will be in operation.

Areas of application of asbestos products

Asbestos pipes, initially considered suitable only for the construction of reclamation systems, are now used much more widely. They began to be used:

- during the construction of a gravity sewage system;

- as casing pipes for wells;

- in sanitary and technical water supply systems;

- when creating drainage systems, storm drains;

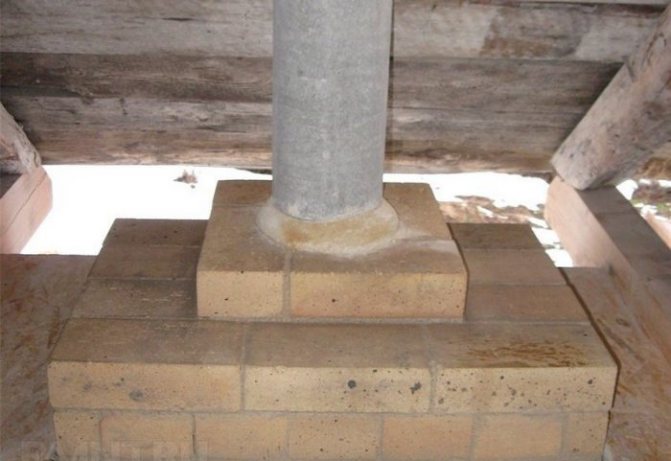

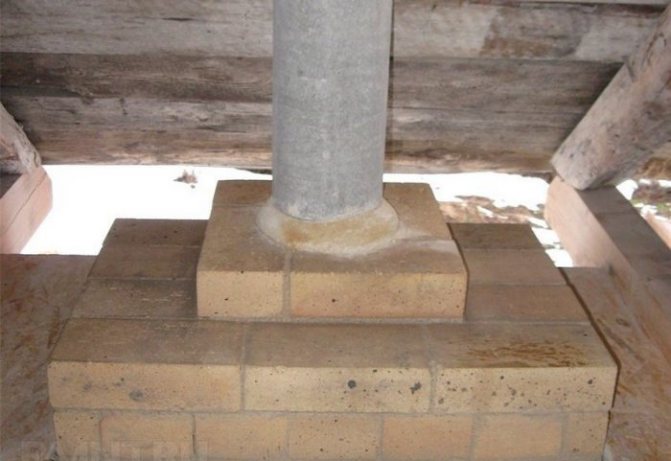

- as a formwork for bored columnar foundations;

- and in the construction of ventilation systems, smoke ducts.

The great popularity of the material is explained by its advantages when comparing asbestos products with metal pipes. Asbestos cement is not threatened by corrosive processes. It has a small coefficient of linear expansion, which is acceptable when heated. The cost of asbestos pipes is quite affordable.

These products have no significant drawbacks, but there is a drawback. They can be considered as their inability to withstand strong impacts. If serious damage is not allowed during installation and operation, then the pipeline can serve for 30-40 years.

Asbestos pipes: pros and cons

Chimneys made of asbestos pipes are an option that has become widespread since the days of the Soviet Union. There was a "breakthrough" for a banal reason. It is cheap because of the huge deposits of "inextinguishable" material and rather simple production. Later, after the collapse of the USSR, asbestos-cement pipes also turned into smoke channels, although these materials are considered far from the best of contenders.

Typically, a list of candidates' advantages is given first. The pluses of asbestos products include:

- relatively low price;

- light weight for easy installation;

- lack of seams and resistance to moisture.

But the list of disadvantages is much more.

- Asbestos pipes can withstand a maximum of 300 °, therefore they are completely unsuitable for stoves that run on solid fuels, since in this case the temperature inside is much higher. It is 600-800 °.

- The porous structure of the material facilitates the absorption of condensate trapped on the walls. This inevitably leads to the destruction of pipes. Chimney cracks can start a fire.

- In addition to condensation, soot accumulates in the asbestos smoke channel, which after a certain period of time begins to burn. A possible consequence is the explosion of an asbestos chimney.

- Large amounts of soot lead to a dangerous narrowing of the inner diameter. Due to the reduced clearance in such pipes, the thrust, which is not the best as it is, will only worsen.

- High-quality cleaning of the channel is somewhat difficult, since there is no way to make an inspection hole in it to monitor the technical condition of the chimney sections.

A serious disadvantage of asbestos products is their health risks. This has been recognized by the World Health Organization - WHO.However, the biggest hazard is asbestos dust, not the products themselves. When heated, pipes do not emit harmful substances, so there is no real threat to the owners of such chimneys.

Heaters for chimney insulation

According to the regulations, only non-combustible materials can be used for chimney insulation in order to ensure the fire safety of the structure. Among the popular means of thermal insulation of smoke channels, there are 3 categories - plaster, slag and stone wool.

Plaster

When planning how to insulate a brick or stone chimney on the street, you can use a heat-resistant plaster mortar. To apply the finishing mixture, surface reinforcement with a metal mesh is required.

If a brick channel or an iron chimney is to be insulated, a casing is built from improvised means, and the voids are filled with broken brick or other non-combustible material.

Stone wool

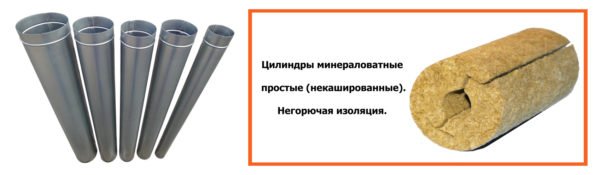

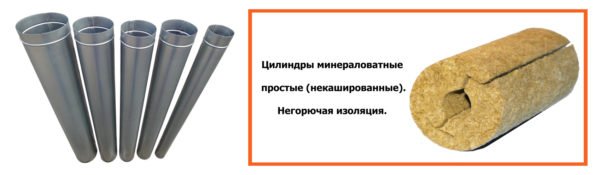

When deciding how you can insulate a metal smoke exhaust pipe with your own hands, basalt wool is most often preferred. Insulation options in the form of cylinders are of interest: the material is presented with different internal sections. You can also use basalt mats. A stone wool heat shield is wrapped around an iron pipe and fixed with clamps or metal wire. Further, the structure is equipped with a sealed steel casing.

Basalt wool

If proper insulation is not performed during the construction of the chimney, such a structure will begin to deteriorate rather quickly.

The following factors have the greatest influence on destructive processes inside the chimney:

- Humidity. Although the chimney is a fairly warm place, the level of humidity inside it is constantly increased, since the air masses rising through it contain water. And as the chimney cools down, a certain amount of moisture settles on its walls in the form of condensate (for more details: “Why does condensate appear in the chimney pipe and how to get rid of it”).

- Exposure to fuel combustion products. Any fuel that burns in the furnace of the stove eventually breaks down into various chemical components, and quite toxic ones. In particular, nitric, carbonic and sulfuric acids, when the chimney is operating, are discharged outside together with warm air. However, in those moments when the chimney does not perform its functions, decay products begin to accumulate on the walls of the pipe, destroying both brick and metal.

Thermal insulation of chimneys minimizes the harmful effects of moisture and fuel combustion products on the walls of the chimney and prolongs its service life.

When choosing insulation for chimneys, it should be borne in mind that when the system is heated, its surface temperature can reach 200-300 ℃. Therefore, the material for the thermal insulation of the chimney must be absolutely non-combustible and resistant to high temperatures.

These materials include slag concrete slabs, mineral or glass wool, and other insulation materials with a fibrous structure. Alternatively, ordinary plaster mortar can serve as thermal insulation for chimneys. If the chimney is made of sandwich pipes, then stainless steel sleeves can serve as a heater.

It is important to remember that the final mass of the chimney, together with the insulating layer, must be such that the roof can withstand such a load. Otherwise, a very heavy pipe will eventually fall inside the house. It is optimal in this case to use lightweight insulation, such as mineral wool, for example.

Asbestos chimney: to be or not to be?

Arrangement of flue ducts for stoves requires a serious approach to the choice of materials. Some characteristics of asbestos pipes cannot be considered suitable for such structures.

- Heat. As already noted, the maximum for asbestos is 300 °. However, the temperature in the chimney is much higher.Another disadvantage is the use of rubber seals during installation. These elements stretch quickly, which means they lose their qualities. The pipe itself will crack sooner or later.

- Accumulation of soot on the walls. Since a large amount of heavy substances is regularly concentrated in the chimney, they invariably remain inside the duct. Due to the high porosity of the material, condensate accumulates on the walls, it mixes with soot. It is simply impossible to deduce them due to the nature of the material.

These criteria are often decisive. Especially if the installation of the chimney is done for a wood or coal stove. A porous surface leads to a rapid accumulation of soot, and in such conditions, its ignition can occur at any time. After a fire, the temperature inside will rise greatly, which means that the risk of a possible explosion will increase. A suitable option for asbestos is one. Rather, two: this is the installation of an intermediate or last section of the chimney duct.

A chimney from asbestos pipes can be justified only on one condition: if the equipment is gas. But in this case, the question of how to insulate the asbestos chimney pipe is considered without fail.

Thermal insulation options

For insulation of the chimney, materials with a low coefficient of thermal conductivity and high temperature resistance are used. The second requirement is not met by the majority of modern insulating materials, which include polystyrene, polystyrene foam, foam rubber, cellulose porous insulation and materials based on polyethylene foam.

The effectiveness of a heat insulator depends on the material from which it is made and its thickness, an important characteristic is the ability to absorb moisture

Fig. 9 Popular heat insulators (glass and basalt wool)

Glass wool

It is a material obtained from thin glass fibers, has high heat resistance and low thermal conductivity, is not afraid of moisture and does not absorb water. The service life of glass wool is quite high, but the material has a low density, which makes it difficult to install. Although glass wool is mainly produced in rolls, it is more convenient to use foil hollow cylinders with a slot for thermal insulation.

Fig. 10 Thermal conductivity of insulators

Mineral wool

Basalt insulation is widely used in the construction industry due to its high insulating qualities and environmental friendliness. Mineral wool is resistant to high temperatures, but is capable of absorbing moisture; for insulation, it is better to use mineral wool in the form of hollow cylinders. Mineral insulation has a high density, so it is convenient to install and process it - the material is the main type of insulation for chimney pipes.

Chimney brick. The industry produces special types of hollow bricks with a hole for the chimney pipeline, the insulation is the air cavities in its walls. Chimney bricks are best used in conjunction with insulation, which prevents the pipeline from contacting the brick walls.

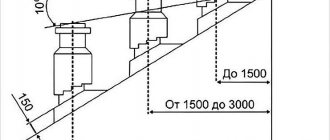

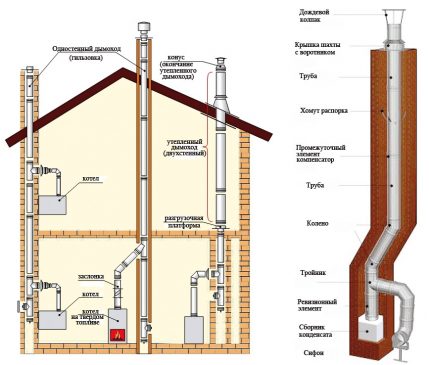

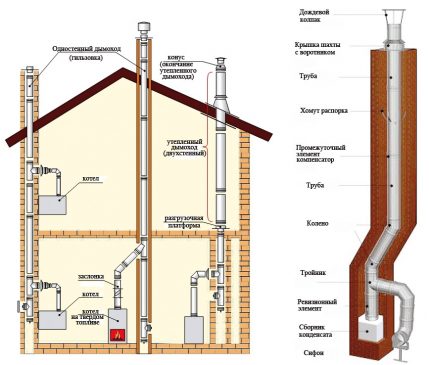

When installing chimney ducts, to ensure their effective operation and fire safety, the requirements specified in the normative documents SNiP 2.04.05-91 and DBN V.2.5-20-2001 should be strictly followed. Their main provisions are the following points:

- The chimney cross-section (pipe diameter) must not be less than the boiler outlet.

- The main pipe should be located vertically without inclined sections (for example, a slope of no more than 30 degrees), there should be no curvatures and narrowed sections in its structure.

- The maximum number of turns in the branch line is no more than three with the length of the branches to the side up to 1 meter.

- The permissible distance between the walls of the chimney and non-combustible surfaces is at least 5 cm, if it passes through combustible walls and the roof, the permissible distance is more than 25 cm.

- The material for the manufacture of the chimney must be resistant to high temperatures and have a structure that prevents the passage of gases.

- All connections must be sealed, insulation must not allow moisture and gases to pass through.

- In the place where the pipe channel passes through the roof, the structure must be solid and without joints.

Fig. 3 Boiler piping diagram

- A condensate collection element is usually located at the bottom of the pipe. Its material must be resistant to moisture and gas combustion products.

- In places where turns are provided, the location of inspection hatches is mandatory to clean the chimney from contamination and condensation.

- The length of the chimney must provide good draft, the height of its outer part must be at least 50 cm above the roof ridge.

- When installing a smoke exhaust duct, it is imperative that there is a protective cover in its upper part to prevent the ingress of dirt and atmospheric precipitation.

Before starting work, you need to decide on the insulation material. You can use almost any, you just have to take into account that the chimney heats up to high temperatures, which means that the insulation must be heat-resistant and non-combustible.

Gone are the days when chimneys were made mainly of bricks. With the advent of gas and solid fuel boilers, they began to be made of metal, and asbestos pipes are also not uncommon. Insulation of different pipes requires an individual approach.

For thermal insulation of pipes of fireplaces and stoves, which are not the main source of heating, but are used periodically, it is enough to plaster the pipe. Most often this method is used for brick pipes, but it is also applicable for metal ones.

A different method is used for the chimneys of stoves and heating boilers. These are the so-called sandwich chimneys. Such designs are commercially available, but they are not cheap. With a limited budget, you can make them yourself.

A sandwich chimney can be bought on the construction market or made by hand

The asbestos pipe is insulated according to the same principle. In addition to mineral wool, you can use bulk insulation.

The best insulation for an asbestos pipe is mineral wool. This material is most often covered with a moisture-proof protective film, which is very important for asbestos due to its ability to absorb moisture. For thermal insulation with bulk material, a protective casing must be mounted around the pipe, into which the insulation should be filled. To prevent moisture from entering from above, the gap between the pipe and the casing is filled with cement mortar.

Brick, like asbestos, is capable of being saturated with moisture, so it is important to think not only about insulation, but also waterproofing. The simplest way is plastering, but it is much safer to do it with mineral and basalt wool.

Brick chimney can be protected and insulated with plastering

Insulation with slag concrete slabs and mortar or panel materials is also suitable.

The method of insulation needs to be thought out even at the stage of construction of the chimney; in some cases, it will be necessary to pre-lay the wire for fasteners in the masonry so as not to spoil the brick.

When passing through the boiler pipe, heated gases lose their temperature, giving off part of their own heat to the walls of the structure. But at the same time, the gas must be discharged outside.

The quality of draft largely depends on the temperature of the walls of the chimney. With insufficient draft, there is a possibility of smoke in the room and even poisoning with waste combustion products.

The efficiency of the removal of combustion products, in other words, the quality of traction, depends on the speed of overcoming the moment of condensation formation.This indicator is largely determined by the material from which the chimney is made.

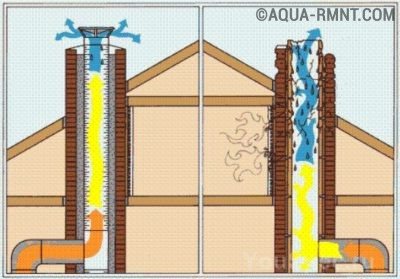

In the insulated chimney, the moment of condensation formation is reduced and the quality of draft improves

If a stainless or galvanized steel pipe is used as a chimney, then the period of condensation formation lasts for 2-3 minutes, but a standard brick chimney needs much more time - about half an hour.

At the moment the condensate appears and until it disappears, water is actively mixed with the combustion products, as a result of the reaction, an acid solution appears. It is this acid that has a negative effect on the pipe, causing its destruction.

If an asbestos pipe or brickwork is used as a chimney, then the residual condensate can be absorbed into their walls. In the absence of high-quality insulation, the accumulated moisture will freeze and destroy the chimney.

If you qualitatively insulate the chimney from a gas boiler, then you can identify a considerable number of advantages. The main ones are:

- Reducing the impact of atmospheric precipitation;

- Reducing heat loss during the heating season;

- Improving traction quality;

- Presentable appearance of the chimney;

- Reducing the volume of condensate that forms on the outside of the chimney.

Taking into account the above advantages, it is obvious that insulating the pipe of a gas boiler is simply necessary. For work, various heaters can be used, each of which differs not only in physical characteristics, but also in the features of the work.

Before proceeding to an overview of heaters and the rules for working with them, you need to understand the requirements that must be met when installing a chimney. This point is very important, since violation of the norms can lead to the inability to operate the equipment.

Compliance with norms and requirements for the construction of gas chimneys ensures their reliable and safe operation.

Chimney ducts must comply with the requirements of DBN V.2.5-20-2001 and SNiP 2.04.05-91. The basic requirements are as follows:

- The inner diameter of the chimney must be larger than the diameter of the outlet of the gas boiler;

- The main pipe cannot have curved or tapering sections, it must be located vertically, a slope of no more than 30 degrees is allowed;

- The branch line can have no more than three turns;

- The distance from the outer surface of the pipe to walls made of combustible materials is 25 cm, to walls made of non-combustible materials - 5 cm;

- Insulation of the joints of the chimney elements must ensure complete tightness of the joint;

- No connections are allowed within the passage of the roof (this part of the chimney must be solid);

- In places of turns, it is necessary to arrange inspection hatches;

- The lower part of the chimney must be equipped with a condensate collection structure;

- The upper part should rise above the ridge of the roof by at least 50 cm, the length of the chimney itself should provide high-quality draft.

We suggest that you familiarize yourself with To what temperature can concrete be poured without additives

Compliance with the norms and requirements for the installation of gas chimneys, not only ensures an increase in the efficiency of equipment operation, prolongs the service life of the chimney, but also guarantees fire safety and eliminates the threat of smoke pollution in the room.

How to use an asbestos chimney pipe?

Is it possible to arrange a smoke channel from asbestos-cement pipes? Yes. But in order to avoid harmful effects, two conditions must be met:

- The installation of such a channel is recommended only in those areas that are significantly removed from the heater. For example, only in the role of the final section.

- When designing, it is necessary to provide for insulation and insulation. Often, brick protection is arranged for such a chimney.The second option is a sandwich with an outer jacket.

These measures will help to avoid possible fires, protect from the consequences associated with unsafe material. Now pipes made of asbestos cement are used much less often if we compare our time and what happened 30-40 years ago. Experts do not recommend making such a chimney: its effective operation is possible only if heating devices are not used constantly, but periodically.

Insulation of steel and brick chimneys

It is worth noting that if you make a chimney from scratch or decide to completely replace the pipes, then it is better to use steel sandwich chimneys with thermal insulation. A sandwich pipe made of stainless steel or galvanized can be purchased at any store. A stainless steel chimney is more expensive, but at the same time durable and beautiful. The sandwich consists of pipes of larger and smaller diameters, between which there is a heater.

When it decreases, acrid smoke will begin to move along the path of less resistance, that is, it will move into the house. This is a very dangerous process, since it greatly increases the likelihood of gas poisoning (except when the stove is located in a special closed boiler room).

As a rule, this parameter depends on the material from which the channel is made. For example, a brick chimney heats up on average about 20-35 minutes. Steel - slightly faster (3 to 5 minutes).

It is no secret that the presence of condensate in the chimney space cannot be avoided. This is due to the fact that the heated chimney is in contact with cooled air from the outside every second. Also, a complex acidic solution can form with condensation. This is due to the reaction of water with combustion products, in particular - carbon dioxide. Drops of acid gradually penetrate through the walls of the chimney and begin to destroy it.

Condensate, when interacting with combustion products, forms acid, which subsequently destroys the walls of the chimney

If the chimney is made of bricks, then condensate moisture can lead to freezing of the pipe masonry, which managed to cool overnight and will be subject to wear and tear from frequent temperature changes. As a result, it will quickly lose its properties.

It is worth noting that nowadays there are cottages in which chimney and stove chimneys go directly to the roof through the loggia. In this case, it would be rational to thoroughly insulate the loggia.

- Various lukewarm (mineral).

- Basalt slabs.

- Glass wool.

- Refractory bricks (rubble or red).

- Galvanized sheet metal.

They are all affordable, easy to work with and fireproof. They also have high indicators of durability and they are absolutely neutral to almost any chemical environment. Due to the fact that all these materials are easy to bend, they can be used to work with objects that have complex geometric configurations.

Of all the materials listed above, mineral wool basalt tiles are the most popular for insulating furnaces fired by gas or coal. It has low thermal conductivity and as a result it is best suited for chimney insulation. Basalt tiles perfectly maintain a minimum temperature in the outer part of the casing. Among the advantages of this tile are the following factors:

- Basalt tiles are absolutely safe and made from exclusively ecological materials.

- To work with this type of insulation, you do not need to use many tools. It is enough to get a hacksaw and a tape measure.

- This material is easy to adapt to even the most complex chimney geometries. Basalt tiles are resistant to fungus and ultraviolet radiation.

- The service life of this insulation is at least 50 years.

Chimneys made of bricks are somewhat more difficult to insulate. There are several ways to isolate:

- The first is the application of insulating plaster. For this method, you need to make a special solution, which must be applied to the pipe with a layer of at least 4 cm. Experts recommend applying 5-7 layers of plaster.

- The second method is insulation using special asbestos-cement, mineral wool or basalt slabs. The thickness of the material must be at least 5-6 cm. The fastening must be made using a facing mixture. A reinforcing net must be laid on top of the insulation. Only then can you start plastering.

In addition to these two methods, there is another one - insulation using wooden shields. This method is considered the simplest. It is performed as follows:

- First of all, a special wooden frame must be built around the entire perimeter of the pipe. It can be made from a bar. You need to leave a small gap between them - about 15-17 cm.

- Further, the entire frame must be sheathed using flat slate.

- Then they begin to fill in the gaps. For this, sand or slag is suitable. When filling the void, remember to tamp the mass from time to time.

- After these works, complete the decorative frame of the wooden frame. To do this, you need to use colored profiled sheets, which are attached with roofing screws.

With this type of insulation, you can save an average of 25% in heat.

In conclusion, it is worth noting that no chimney for a gas boiler can do without insulation. Insulation is necessary to increase the service life of the structure and save heat costs. It can also help you avoid fire or carbon monoxide poisoning.

Insulation of the chimney pipe with various materials

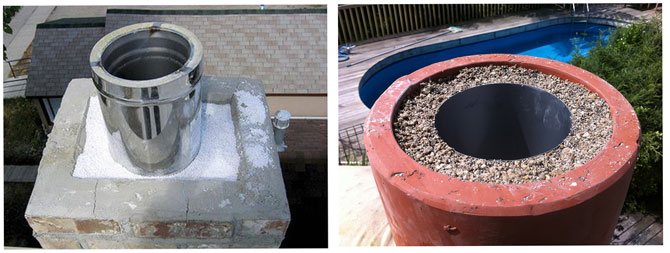

The figure shows an example of thermal insulation of a chimney pipe with mineral wool and galvanized sheet (left), and thermal insulation with mineral wool and decorated cinder concrete (right). This example is considered for a chimney from an asbestos-cement pipe.

A comparative example of the work of thermal insulation is shown in the figure, as they say: "Find 10 differences".

The protective effect of the insulation

A layer of insulation material protects the structure from the formation of condensation inside and from weathering outside.

We suggest that you familiarize yourself with: Heaters for a bath - The choice of insulation for a bath and steam room, an overview of the best heaters for a bath - Foam concentrate for foam concrete

The materials required for insulation are listed in the examples considered.

The tool required to carry out the insulation:

- locksmith tools (hammer, clamps, pliers, screwdrivers, etc.);

- measuring tool (tape measure, ruler, square, level, construction pencil, felt-tip pen);

- assembly knife for cutting insulation;

- riveting set and a set of rivets for connecting the galvanized casing (or self-tapping screws);

- electric drill and portable cable extension 220 V;

- drills with a diameter of 4 mm for making holes for rivets;

- for work on the application of cement mortar, you will need a spatula, a trowel and a container for mixing the mortar;

- you may need a construction syringe with a tube of bitumen mastic to seal small cracks. But also mastic may be needed for additional waterproofing of the plaster.

It should not be forgotten that any of the chimney insulation methods is work at height.

Assess the workplace with all possible risks in mind. Try to minimize them. Prepare the ladder in advance, check its condition, reliability and stability. If you have to move on a roof with a slate flooring, walk on the laid boards, this way the weight is better distributed over the area. The board should be laid across the slate waves.

The insulated chimney is a pipe-in-pipe structure, similar to a sandwich pipe, which is also used for the construction of chimney ducts.Usually, a wooden box lined with asbestos slabs or a large-diameter steel pipe acts as an outer pipe.

Any insulated chimney consists of a smoke exhaust channel, an outer shell and a layer of insulation between them

A non-combustible heat-insulating material is placed between the outer shell and the chimney, mechanically fixed or glued to a heat-resistant glue or sealant. The inside of the insulated chimney is nothing more than a chimney.

The layer of material used as insulation acts as a thermal insulation barrier. On the one hand, it prevents heating elements directly in contact with the chimney. On the other hand, cold air does not cool the chimney and thus does not create a sharp difference between the temperature of the outgoing combustion products and the inner surface of the chimney.

Before purchasing insulation and materials necessary for assembling the frame around the chimney structure, you will need to calculate them. This will save money, especially if specialized expensive products are used for insulation.

Before making calculations, you will need to measure:

- outer section of the chimney;

- length and width (diameter) of the chimney;

- the height of the pipe from the inlet.

The data obtained allow us to calculate the required amount of thermal insulation material and additional accessories. As an example, we will calculate the materials for insulating a steel chimney with a section of 200 mm and a height of 5 m.

For thermal insulation of round chimneys, ready-made cylindrical fragments of insulation are produced

https://www.youtube.com/watch?v=Dr7FZKKhUL4

When using a basalt "shell", you will need products with a total length of 5 running meters with an inner cylinder diameter of 210 mm. The density of the insulation is 120–150 kg / m3. The thickness of the heat insulator is selected taking into account the temperature regime in the region. For operation in Russian winter conditions, cylinders with a thickness of 70–100 mm are sufficient. As an outer pipe, you will need a product made of galvanized steel with a section of 280-310 mm with a total length of 5 m.

For insulation of square chimneys, it is convenient to use basalt wool in slabs

To insulate chimneys with a square or rectangular cross-section, you will need to know their dimensions. For example, a square chimney with a side of 0.3 m will require (0.3 * 5) * 4 = 6 m2 of insulation. The length of the chimney is still considered to be 5 m.

If you buy a high-quality insulation, then usually there is a roll with a total area of 5 m2 in one package. This means that for our example, two packs of basalt wool in rolls are required. Roll parameters - 5000x1000x50 mm. To assemble the frame around a square chimney, a 50 × 50 mm bar can be used. An asbestos board 3000x1500x12 is better suited as an external cladding.

Plastering

How to insulate an asbestos chimney pipe?

An asbestos-cement pipe is able to withstand temperatures up to 300 °, but the material has a high thermal conductivity, therefore it quickly gives off heat to the environment. The heating of the chimney surface is almost the same as the temperature of the smoke. Warming it with a non-combustible heat-insulating material makes it possible to waterproof the pipe, significantly reduce the formation of condensate, and avoid its freezing. Such measures are necessary to increase the service life of the structure.

Simple winding of the pipe in this case will not help to achieve the goal. To ensure good thermal insulation characteristics, the work is carried out in stages. The first one is the choice of thermal insulation material. The best option would be mineral wool, or its basalt variety.

Other types of cotton wool insulation - glass wool or slag wool are also suitable for work. The most ideal insulation is one that has a lower degree of water absorption.The thickness of the material for external insulation is in the range of 70-100 mm. The process of warming itself is unlikely to cause difficulties.

- Fixation of mineral wool. The heat insulator is wound around the pipe, then attached to it using a knitting wire, or with special clamps.

- Insulation protection. Minwata needs protection. A layer of foil-clad insulation must be arranged on top. It makes it possible to protect the material from moisture.

- Manufacturing of a frame for thermal insulation. Metallic is more often used. For example, a steel pipe of a suitable diameter becomes the ideal outer layer of such a sandwich.

Since the thermal insulation material needs to provide reliable protection, the top of the gap is closed with cement mortar. Installing the baffle hood completes this job.

A brief overview of the main materials for thermal insulation of a gas chimney

The process of insulating metal chimney pipes in a private house begins with the selection of the necessary heat-retaining material. The main characteristics that the insulation must meet:

- Resistance to high temperature impact and drops. The material must be both frost-resistant and non-combustible, withstanding up to -35 degrees on the outside (for example, on a frosty night outside) and up to 300 degrees on the inside.

- Relative lightness. As in the case of carbon deposits, the applied insulation should not overload the pipe structure and worsen its stability. Also, you should not allow its weight to strongly "press" on the roof or other roof material.

Mineral wool - a common insulation for chimney pipes

It is equally important to select the material (including its composition, shape and dimensions) in such a way that it matches the design and type of the chimney itself, otherwise it will be fraught with difficulties in its installation (application).

Having specified the quality characteristics of heat-retaining materials we need, we will consider a number of them that can most often be found on sale via the Internet in construction markets or in hypermarkets:

- Construction plaster. A relatively cheap material that allows you to reduce heat loss by about 25-30%. The disadvantages include the weighting of the structure from additional retaining elements.

- Mineral wool. Such insulation is least of all subject to thermal effects and is resistant to toxic smoke fumes generated during operation. Cotton is used to cover both indoor pipe elements and those that go outside. The filler of the coating differs in fiber, fiber length and viscosity (thickness). On sale you can find cotton wool with 4 types of filler: fiberglass, stone chips, basalt and slag. The advantages include its high temperature resistance and environmental friendliness.

- Cylindrical "sandwich" heat insulator. Its undoubted advantage is ease of installation, since it is sold already in "finished form" for different diameters of the outlet pipe. The design includes cylindrical stainless steel rolled metal, in which a light mineral wool filler is laid, for example, basalt, with a longitudinal hole in the center for the pipe diameter.

- Extruded polystyrene foam or EPS. A durable waterproof material that is used for external thermal insulation of stone and brick chimneys. It is sold in the form of plates, subdivided into classes, depending on heat resistance (or flammability). The coefficient is considered from 1 to 4, where the first two are the most heat-resistant and can withstand gas temperatures up to 500 degrees at the exit from the pipe.

- Stainless steel casing. Just like the "sandwich" cylinder, a stainless steel casing is put on the outer elements of the pipe, filling the space between it and the pipe with mineral fiber or asbestos, closing the top with cement mortar from moisture and combustible particles escaping along with the smoke.

- Wood.In order to save money, the material of the "cylinder", or rather, in this case, the outer box, can serve as a tree. It is made of panels knocked together at right angles so that 15-17 cm remain between them and the pipe. This space is then laid and sealed with a suitable heat insulator.

The cylindrical "sandwich" heat insulator is easy to use

You can supplement your furnace unit with pipes made of a material such as stainless steel. First of all, before carrying out subsequent manipulations, you need to make sure that the system fully complies with all the requirements and safety standards.

Requirements for stainless steel chimneys:

- To create a properly working traction mechanism, it is necessary that the height of the pipes, in total, be at least five meters;

- A small gap must be left between the brick, stainless steel pipe and the roof, other non-combustible materials, a free space of at least 30 centimeters;

- Outside, at the very top of the chimney, a spark arrester is installed, which can protect the surface of ondulin, slate, roofing material from accidental ignition.

When passing through ceilings, this surface is sealed and insulated accordingly

Do-it-yourself insulation of a metal two-layer pipe

In the last step, the stainless steel pipes are wrapped on the outside. What for? In order to strengthen, isolate and seal the structure as much as possible. But winding can be done only after you are fully convinced that the structure is working correctly, without interruption.

The winding in this case is made of stainless steel or galvanized steel.

How to properly form a sandwich structure:

- We make a certain number of holes in the roof slab, so that their diameter is 20-30 centimeters larger than the chimney section;

- We carry out the winding with a small overlap. In this case, we use mineral fiber, the thickness of which will be at least 6 centimeters;

- We fix the cotton wool with a wire that turns 2-3 times;

- Next, we put on a previously prepared casing of a larger diameter. If necessary, we perform a screed or fixing with adhesive tape (in the event that the steel is very thin).

The best draft will be from the unit, the chimney of which rises higher than the buildings on the roof or near the house

Chimney insulation scheme in a private house

At the last stage, the pipe must be fixed with the branch pipe of the furnace unit, led through the roof overlap. The space near the riser must be filled with non-combustible materials.

Before proceeding with the installation of thermal insulation, prepare everything you need for work. Clean the pipe from dust, repair cracks and chips. It is important that the surface is dry, otherwise the quality of the thermal insulation will decrease.

Plastering

- The mixture is mixed with water using a construction mixer in the proportions indicated by the manufacturer. It is more correct to first pour water into the container, and then add the dry mixture.

- With a spatula or trowel, the solution is applied with spots over the entire surface of the pipe and leveled. The plaster is leveled over the entire pipe surface

- The pipe is covered with a reinforcing mesh over the mortar spots, which will fix it to the surface. The mesh is necessary to strengthen the plaster layer, it plays the role of a frame.

- The first layer of plaster is applied over the reinforcing mesh. It is important that it covers the entire surface without gaps. In order for the layer of plaster to stay on the surface of the chimney, use a reinforcing mesh

- The plaster is leveled and left to dry.

- After that, several more layers are applied, each of which needs to be dried. For good thermal insulation, 3-5 layers are required.

- After drying the last layer, the pipe is painted in the color of the roof for aesthetics.

We offer you to familiarize yourself with How to insulate a bathhouse on screw piles

The quality of draft largely depends on the temperature of the walls of the chimney. With insufficient draft, there is a possibility of smoke in the room and even poisoning with waste combustion products.

The efficiency of the removal of combustion products, in other words, the quality of traction, depends on the speed of overcoming the moment of condensation formation. This indicator is largely determined by the material from which the chimney is made.

In the insulated chimney, the moment of condensation formation is reduced and the quality of draft improves

If a stainless or galvanized steel pipe is used as a chimney, then the period of condensation formation lasts for 2-3 minutes, but a standard brick chimney needs much more time - about half an hour.

At the moment the condensate appears and until it disappears, water is actively mixed with the combustion products, as a result of the reaction, an acid solution appears. It is this acid that has a negative effect on the pipe, causing its destruction.

If an asbestos pipe or brickwork is used as a chimney, then the residual condensate can be absorbed into their walls. In the absence of high-quality insulation, the accumulated moisture will freeze and destroy the chimney.

If you qualitatively insulate the chimney from a gas boiler, then you can identify a considerable number of advantages. The main ones are:

- Reducing the impact of atmospheric precipitation;

- Reducing heat loss during the heating season;

- Improving traction quality;

- Presentable appearance of the chimney;

- Reducing the volume of condensate that forms on the outside of the chimney.

Taking into account the above advantages, it is obvious that insulating the pipe of a gas boiler is simply necessary. For work, various heaters can be used, each of which differs not only in physical characteristics, but also in the features of the work.

The choice of the method of insulation is determined by the material from which the gas chimney is made. Insulation of the chimney from a gas boiler depends not only on its design, but also on the material chosen.

It is possible to insulate an asbestos-cement pipe in three fundamentally different ways. Mineral wool, brickwork or plaster are suitable for their implementation.

Mineral wool

Steel chimneys are a separate topic for reflection. A special type of stainless steel is used as a material for modern chimneys. The functionality of the stainless steel is very high. First, the pipe warms up quickly. Secondly, it does not rust from moisture.

The so-called sandwich chimneys have become common. These are structures that consist of two pipes of different diameters. Insulation is laid between them. However, such chimneys have a number of disadvantages, including their price and operating period. The advantage is that the sandwich chimneys are already insulated by themselves. You just need to install them correctly. The quality of the chimney insulation is guaranteed by the manufacturer.

How and with what to insulate other structures?

The most difficult work lies ahead for the owners of a brick chimney; the metal may not require additional manipulations at all. But in any case, the main requirement for insulation is its incombustibility.

Thermal insulation for brick construction

There are two options. It is possible to insulate with mineral wool (or cotton varieties) or plaster, but in the latter case, the work will take more time and will require efforts from the master.

Use of cotton wool

The easiest option is to fix mineral wool (glass wool, basalt) with tape. After wrapping, the insulation is “hidden” under cinder-concrete or asbestos-cement slabs. Or left open at all.This is not the best option, even for an attic.

Application of plaster

The whole work consists of several stages, very extended in time.

- First, a reinforcing mesh is fixed on the walls of the chimney with dowels, then a solution consisting of fine slag, cement and lime is thrown onto it. The maximum layer thickness is 30 mm. Cover all surfaces at once.

- Mineral wool is attached to the slightly dried solution, then the solution is again thrown in, which is pressed in with a fiberglass reinforcing mesh. Then they wait for the plaster layer to dry completely.

- After the mortar has set, the surfaces are leveled, this time the mortar layer is made thinner. The dried walls are treated with a primer: at least twice with a break for drying the composition.

The last stage is painting the chimney. Often, facing brick, stone, artificial or natural, decorative plaster or porcelain stoneware tiles are used to decorate chimneys.

Thermal insulation of metal pipes

Many iron structures do not need additional manipulations, because there are products on sale that can be called semi-finished products. They consist of two pipes, insulating material has already been laid between them.

If there is no such design, then such a product is not too difficult to create on your own. To implement the plan, they buy a pipe that is 60-80 mm larger than the diameter of the chimney. It is put on the channel, then fixed on the base. The space between the elements is filled with light free-flowing or fibrous insulation.

An alternative is to use the same mineral wool as a sandwich filling. If the roofing system is reliable enough to withstand the additional load, then heavy "stuffing" can be used as a heat insulator: for example, sifted slag or broken brick.

Chimney installation rules

For insulation of the chimney, materials with a low coefficient of thermal conductivity and high temperature resistance are used. The second requirement is not met by the majority of modern insulating materials, which include polystyrene, polystyrene foam, foam rubber, cellulose porous insulation and materials based on polyethylene foam.

The effectiveness of a heat insulator depends on the material from which it is made and its thickness, an important characteristic is the ability to absorb moisture

Fig. 9 Popular heat insulators (glass and basalt wool)

Glass wool

It is a material obtained from thin glass fibers, has high heat resistance and low thermal conductivity, is not afraid of moisture and does not absorb water. The service life of glass wool is quite high, but the material has a low density, which makes it difficult to install. Although glass wool is mainly produced in rolls, it is more convenient to use foil hollow cylinders with a slot for thermal insulation.

Fig. 10 Thermal conductivity of insulators

Mineral wool

Basalt insulation is widely used in the construction industry due to its high insulating qualities and environmental friendliness. Mineral wool is resistant to high temperatures, but is capable of absorbing moisture; for insulation, it is better to use mineral wool in the form of hollow cylinders. Mineral insulation has a high density, so it is convenient to install and process it - the material is the main type of insulation for chimney pipes.

Chimney brick. The industry produces special types of hollow bricks with a hole for the chimney pipeline, the insulation is the air cavities in its walls. Chimney bricks are best used in conjunction with insulation, which prevents the pipeline from contacting the brick walls.

When installing chimney ducts, to ensure their effective operation and fire safety, the requirements specified in the normative documents SNiP 2.04.05-91 and DBN V.2.5-20-2001 should be strictly followed.Their main provisions are the following points:

- The chimney cross-section (pipe diameter) must not be less than the boiler outlet.

- The main pipe should be located vertically without inclined sections (for example, a slope of no more than 30 degrees), there should be no curvatures and narrowed sections in its structure.

- The maximum number of turns in the branch line is no more than three with the length of the branches to the side up to 1 meter.

- The permissible distance between the walls of the chimney and non-combustible surfaces is at least 5 cm, if it passes through combustible walls and the roof, the permissible distance is more than 25 cm.

- The material for the manufacture of the chimney must be resistant to high temperatures and have a structure that prevents the passage of gases.

- All connections must be sealed, insulation must not allow moisture and gases to pass through.

- In the place where the pipe channel passes through the roof, the structure must be solid and without joints.

Fig. 3 Boiler piping diagram

- A condensate collection element is usually located at the bottom of the pipe. Its material must be resistant to moisture and gas combustion products.

- In places where turns are provided, the location of inspection hatches is mandatory to clean the chimney from contamination and condensation.

- The length of the chimney must provide good draft, the height of its outer part must be at least 50 cm above the roof ridge.

- When installing a smoke exhaust duct, it is imperative that there is a protective cover in its upper part to prevent the ingress of dirt and atmospheric precipitation.

You can make the chimney insulated using different materials. Their cost does not really matter, since the insulation itself will require a little

But the owner should pay special attention to the insulation technology itself. Usually the chimney is insulated from the outside.

To provide decent insulation, it is better to opt for fiber insulation. These include mineral and glass wool. It will be possible to increase thermal insulation with the help of cinder concrete, broken bricks and similar materials. The most important thing is that the insulation used is distinguished by high fire safety, because the heating temperature of the pipe can be very significant.

It is better for the owner of the house to dwell on such heat-insulating materials that can be installed on their own. Before performing any procedures, you should read the manufacturer's instructions.

Particular attention must be paid to working with glass wool, as it releases dangerous chips. You cannot do without protective equipment while working with it.

The technology of pipe insulation is also determined by what material this element is made of. Most often, brick, steel and asbestos cement are used to create a chimney. Each of these cases has its own characteristics of thermal insulation work.

The chimney made of asbestos cement must be insulated with mineral wool. Any dust and debris must be removed from this element before basic work. The insulation will be placed in a special casing made of galvanized iron. The diameter of the casing is selected so that it is 6 cm larger than the diameter of the chimney.

The length of such a construction for insulation may be different. But it is made up of parts that are inserted into each other. Each element has a maximum length of 1.5 meters. When the casing is put on, a heater is laid between it and the pipe. After tamping it tightly, you can put on the next element, thus building up the pipe.

The remaining voids are filled with cement mortar. The last element of the cover must be inclined. Sometimes the owners manage to do without a metal casing. If this option is chosen, then the mineral wool must be wrapped with clamps.But it is better to use several slabs of mineral wool in this case.

To increase the operational life of such a heat-insulating structure, it is necessary to additionally carry out steam and waterproofing. Otherwise, the mineral wool will deteriorate.

Finding a steel chimney in a hardware store, which has an additional thermal insulation layer, is not difficult today. This design is carried out using two pipes with different diameters. In the space between these elements, there is a fire-resistant thermal insulation material. But you can perform such insulation yourself.

For this, two pipes are taken, differing in diameter. The smaller pipe is placed in the larger one, and the free space is filled with a fibrous heat insulator. At the same time, you do not even need to prepare any complex tools. A tape measure, fasteners, a screwdriver, a stationery knife and a grinder are enough to cut the material. Scotch tape is also useful, with which you can fasten individual pieces of insulation.

The most difficult thing for the owner is if he is faced with the task of thermal insulation of a brick pipe. Two options are possible here, each of which is worth dwelling on in detail.

1. Warming with plaster

The outer side of the brick chimney is covered with a reinforced mesh. A plaster mortar is applied to it so that its thickness is about 3 cm. You need to prepare the plaster from slag and lime, adding a little cement. Usually 2 coats are applied, the first of which is liquid. When it dries, you can cover the work surface with a thick solution. After leveling the plaster, you need to wipe it well. Then the chimney is covered with lime to make it look better.

2. Insulation with asbestos cement and mineral wool

The brick chimney is first covered with mineral wool, after which an asbestos cement cladding is formed. In this case, asbestos-cement slabs are used. They can be plaster later.

The most correct decision of the owner of the house would be to insulate the chimney immediately after the construction of the building is completed. If you miss such a moment, the chimney can no longer be saved, since it will begin to collapse. As a result, it will become necessary to replace or repair the chimney completely.

To exclude conditions for the formation of condensation on the walls of the chimney. This is due to the fact that flue gases, contacting the cold walls of the pipe, deposit a wet film on it, which, interacting with soot (not burnt waste), forms harmful chemical compounds that destroy the walls and have an unpleasant odor.

We offer you to familiarize yourself with Foil insulation for the ceiling in the house

The phenomenon of condensation in nature manifests itself when the moisture content in the air is oversaturated as a result of its cooling, it is compressed, its density increases and, having reached the "dew point", moisture falls out in the form of precipitation (small droplets, fog).

Smoke vapors also have a "dew point"; this point can be located and change its position along the entire length of the pipe. So, for example, when the furnace is fired up, it can be located directly in the firebox and as the pipe channel warms up, it rise higher and higher until it "flies into the pipe".

By the way, this expression tells us that the stove must be heated correctly so as not to consume extra firewood: the most optimal option is that the temperature at the beginning of the pipe channel should be in the range of 250-300 ° C, and at the outlet from 100 ° C to 150 ° FROM.

It is necessary to strive to reduce the time of condensation formation, and this can be achieved by rapid heating of the inner surface of the pipe. That is why it is necessary to insulate chimneys. In houses with year-round residence - this must be done in order to minimize the amount of condensate formed, since its chemical composition contains dissolved harmful substances, including sulfuric acid, which destroys the pipe channel.

If the chimney passes from the outside of the building, then it must be insulated along its entire length. Brick pipes can be insulated by plastering using fiberglass mesh and basalt wool insulation. This method has become widespread in the overhaul of "Khrushchev" and received the name - thermal fur coat. Materials for a thermal fur coat can be purchased at any construction market. The fur coat includes:

- fasteners (dowel and nail with a pressure washer);

- plaster mesh (durable glass fabric, woven in a special way - best known as SSSH - 160)

- insulation (plates, mineral wool or expanded polystyrene mats)

- polymer laminated glue (SARMALEP)

- plaster (special finishing compound - SARMALIT)

- paint (special paint for plaster - SOFRAMAL)

Frame - a universal option

There is another answer to the question of how and with what to insulate an asbestos chimney pipe, or a metal structure. This method is good in that it does not matter at all what is the cross section of the chimney. It is suitable for round, square or rectangular ducts. In this case, a convenient frame box is used. The works are performed in the following sequence:

- They retreat from the perimeter of the chimney by 100 mm, draw a rectangle or square. Then, a low frame is assembled from a metal profile or a bar using self-tapping screws (nails).

- It is sheathed with any available material. The space between the chimney and the frame is filled with expanded clay, sand or roll insulation. Outside, the structure is covered with asbestos panels. Their thickness is 10-12 mm.

The last stage is to ensure tightness: this is the treatment of all joints and the top of the box with heat-resistant plaster insulation. An alternative is brick cladding.

Phased insulation technology

Due to the fact that chimneys are of different types and designs, we will describe how to properly insulate a chimney made of brick, asbestos cement and steel.

Asbestos cement pipe

First, you need to thoroughly clean the place of work from dust and dirt; The next step is to make a special folding casing for insulation (made of galvanized iron)

When determining its parameters, it should be borne in mind that at least 6 cm for insulation should remain between the pipe and the iron; Pay attention to the fact that a casing assembled from several parts is put on the asbestos pipe, and each of them should not exceed 1.5 m; First of all, you should fix the lower part of the casing and carefully fill it with a seal. Then, the second part is put on and the procedure is repeated

This structure should run along the entire length of the asbestos pipe.

Thermal insulation scheme from a home craftsman

This is what an asbestos chimney with a casing looks like

Often, many of the owners of cottages do without a casing. The pipe is simply wrapped with a roll of mineral wool and held together with staples. In order for this method of insulation to become truly reliable, several layers should be wound.

Steel chimneys

So, we sort of figured out with asbestos pipes, now let's see how to insulate a metal chimney pipe. In general, many manufacturers of building materials produce ready-made chimneys made of stainless steel. The design is quite simple and consists of only two pipes of different diameters.

How to insulate a metal chimney? To do this, we take a pipe of a smaller diameter and insert it into a pipe of a larger diameter. Then, the remaining space between the pipes is filled with any of the above types of insulation. If you are interested in modern materials, then you can recommend basalt insulation for the chimney, which in its structure resembles mineral wool, but much more practical and durable.

Thermal insulation of a steel chimney

In principle, it is much easier to insulate an iron pipe than the same asbestos one, so there should be no problems here.

Brick chimney

Brick chimney

Plastering method. To do this, you will need to attach a reinforced mesh to the chimney. Then prepare a solution of lime, slag and a small portion of cement. Pour the resulting solution over the entire surface of the chimney and level it (all work is done in one layer, which should be at least 3 cm).

When the solution dries up, it will be possible to add a few more layers, and immediately cover up the resulting cracks. To give an attractive appearance, the pipe can be whitewashed or painted in the future.

Thermal insulation diagram of a brick chimney

Mineral wool insulation. To do this, you need to take a roll of basalt wool and cut into pieces that correspond to the size of the chimney area. Then, the insulation is glued to the pipe with tape. The last step of the work is to lay the insulation (for example, Rocklight) with a second layer of bricks or asbestos-cement slabs.

Chimney thermal insulation process with mineral wool

Good luck!

Warming errors

The most common reasons for the ineffectiveness of protection are incorrect calculation of the thickness of the insulation, its insufficient sealing. The first sign of poorly performed work is the appearance of condensation inside the chimney. In this case, it is better to "redo what has been done" right away. But already try to provide all the conditions: both the required thickness of the heat insulator and the tightness of the structure itself.

The question of how to insulate an asbestos chimney pipe can be answered as briefly as possible: with something that has a suitable weight and does not burn. For metal channels, it is better to prudently buy ready-made elements that only need to be installed. You will have to spend quite a lot of time on brick walls.

Those who are interested in this topic will find this informative video useful:

How to insulate a metal pipe with your own hands

One of the most important stages in the construction of a bath is the installation of a chimney. And its insulation is a mandatory process during construction, which has two goals: fire safety and corrosion protection.

If you do not make thermal insulation, then under the influence of temperature differences, condensation will form, gradually flowing inward and contributing to the destruction of the structure itself.

The insulated smoke exhaust ducts warm up faster, which makes the stove in the bathhouse work much more efficiently.

Depending on what the chimney of the bath is made of, various materials are used for its thermal insulation.

There are several types of already insulated chimneys for a sauna stove, the most common of which are stainless steel sandwich pipes. A good option is ceramic sections, which are already installed in expanded clay concrete modules.

During the operation of a sauna stove, its chimney gets hot, and the inevitable proximity to combustible materials can lead to a fire.

If the chimney is made of bricks, it heats up less, and if the chimney is made of metal, then much more.

Metal pipes are heated above 600 ° C, and their proximity to the wooden sheathing of the steam room is very dangerous, especially if the bath is close to residential buildings.

The second, no less important problem is the appearance of condensation in the chimney. Condensate is the main enemy of all flue gas systems.

It is not easy moisture that forms on the walls of the chimney, but an aqueous solution of sulfuric acid, which is capable of destroying almost any material. It appears as a result of the passage of heated air through the still cold chimney.

As a result of the effect of condensate on an uninsulated brick chimney, the masonry collapses, since it has the properties to penetrate into microcracks in the brick, and when freezing, it expands. Metal chimneys are also very susceptible to condensation.

Metal of ordinary grades is not resistant to acids, therefore, from the effect of condensate on it, it very quickly deteriorates.

The only way to combat the appearance of condensation is to isolate the smoke exhaust paths, in which the pipe will cool less, and the sauna stove will quickly enter the operating mode of combustion.

Chimneys can be insulated using various methods, using non-combustible materials.

The most common are:

- Chimney thermal insulation with basalt wool and glass wool. Insulation materials used both for large surfaces of brick chimneys and pipes of relatively small diameter. Available as filler, in rolls or in the form of mats. For its use, it is recommended to manufacture an additional casing.

- The method of filling the space around the chimney with heat-insulating material: expanded clay, slag, bricks, special heat-insulating granules. This method involves the manufacture of an additional chimney casing.

- Plastering. This is the most common, until recently, method of insulating brick chimneys. For this, a slag-lime mortar was used, applied with a layer of 5-7 cm on a reinforcing mesh. After drying, a sand-cement mortar of the same thickness was applied to it. But when the smoke exhaust system was heated and cooled, such insulation cracked and required annual repair, therefore this method is considered unjustified in terms of labor costs and efficiency.

- Chimney insulation with modern polyethylene foam materials. "Teploizol" or "Folgoizol" is produced in rolls, has a low weight and good elasticity, it is well cut, which makes it accessible to work with even non-professionals. This is the simplest and most inexpensive way to insulate chimneys, which is widely used today.

The choice of insulation

The choice of insulation, for the insulation of the chimney, must be approached carefully and seriously. You should not buy the cheapest one, because it should have good thermal insulation properties, be comfortable to work with, not require additional reinforcement of the supporting structures of the roof and ceilings, be non-toxic and non-combustible.

Stone or basalt wool is a wonderful thermal insulation made from basalt rock.

This insulation can withstand prolonged exposure to sufficiently high temperatures and does not burn, even in contact with an open fire. When heated, it does not emit any toxic or unpleasant odors. Such insulation can be safely called an environmentally friendly material.

Glass wool is a type of mineral wool insulation made on the basis of waste from the glass industry. There are a lot of voids between its fibers, so it retains heat well.

Glass wool does not burn and does not absorb moisture, is not subject to decay and rodents. It is inexpensive and easy to use. Most often it is produced in slabs and rolls.

Teploizol or foiloizol are multifunctional types of insulation made of foamed polyethylene and covered with a sheet of aluminum foil. It is produced in rolls and has a thickness of 2 to 10 mm. They can remarkably insulate the chimney of a bath, since these heaters can withstand heating up to 150C ° -170C °.

Chimney insulation with mineral, basalt or glass wool can be done in two ways: insulation under a casing or insulation of a chimney without a casing.

In order to insulate the chimney with mineral wool mats, you need to cut out several pieces of the slab from them, which will correspond to the sides of the pipe from the outside.

Then, using wire stitching, fix them on the chimney.

After fixing the insulation on the chimney, it is recommended to make a casing to protect the insulation from atmospheric agents or to perform the process of lining the chimney with bricks, asbestos-cement slabs.

To insulate a metal pipe, you need to wrap it with basalt wool and secure it with wire around the entire perimeter. After that, put a second pipe of a larger diameter on the chimney to make a kind of sandwich.

This method of thermal insulation of chimneys is the most effective and simple, but it allows to reduce the loss of heat by more than half, as well as significantly reduce the fire hazard and the formation of condensate in smoke exhaust systems and protect them from destruction.

Thus, thermal insulation contributes to an increase in thermal efficiency and a safer use of the ovens. At the same time, it gives the building and the structure itself a more aesthetic look.

We offer you to familiarize yourself with the Brick bath (77 photos): the pros and cons of brick construction, do-it-yourself stoves

The operation of the bath must be absolutely safe for humans. To prevent fires in contact with a hot stove or chimney, thoroughly insulate walls and ceilings, as well as hot surfaces. How to insulate the chimney pipe in a sauna will be described in detail in this article.

The favorite material for a bath in Russia is wood. However, it tends to be very flammable. To avoid this, people have long learned how to insulate the chimney in the bath, as well as the stove and all surfaces - walls, ceiling. For these purposes, we used any available means - clay, asbestos or any other non-combustible materials with a low degree of thermal conductivity.

Another argument in favor of thermal insulation of the chimney is that in this case, the pipe will cool down much more slowly, and condensate will not accumulate in it.

It is a mistake to believe that a good solution with regard to how to insulate a pipe in a bath will be to mount sheet metal on the ceiling. Metal is capable of heating up very quickly, which in no way interferes with fire, so it is not suitable for thermal insulation.

Let's consider each of them in more detail.

Folgoizol

It is a two-layer material consisting of an insulating component and a foil. Thanks to the reflective layer, the room does not cool down so quickly, because up to 90% of the heat is retained inside the bath, so this is a very high-quality insulator.

Folgoizol is highly environmentally friendly, because food thick foil is used as a raw material. Such material is not afraid of ultraviolet light and strong temperature drops - the operating range is from -65 ºС to 175 ºС. Therefore, it will be quite a worthy choice for winding a pipe in a bath.

Note that often foil-insol is mounted not only around the chimney, but also on the walls and on the ceiling of the steam room. It serves for high-quality steam and waterproofing, and also insulates the bathhouse well.

Teploizol

One of the options than to wrap the pipe in the bath is thermal insulation. For the production of thermal insulation, foamed polyethylene is used, hidden between two layers of foil, and the upper layer of foil in the material is designed to protect the chimney from overheating.

Thermal insulation has appeared on the building materials market relatively recently. The thickness of such material ranges from 2-10 mm.

Recently, various manufacturers have begun to produce new safe sandwich pipes for baths and saunas. With such a design, there is no longer any need to worry about how to secure the pipe in the bath (for more details: “Advantages of a pipe for a sandwich bath in the construction of a chimney”). The design of such pipes assumes a quick and convenient assembly of sections that are inserted into each other. Moreover, it is optimal to use such pipes with an iron stove.